Channel type heavy vehicle lifting machine

A technology for heavy-duty vehicles and lifts, which is applied in lifting frames and lifting devices, etc. It can solve problems such as troublesome, high economic cost, time-consuming and laborious, etc., and achieve the effects of improving efficiency, reliable pipeline installation, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

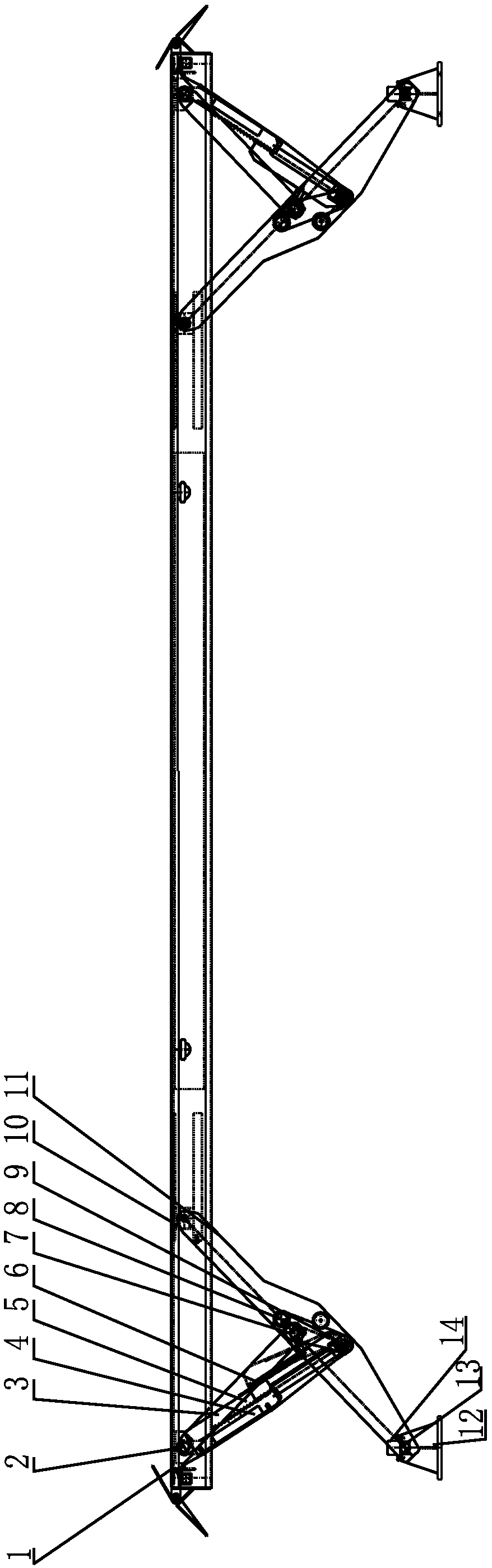

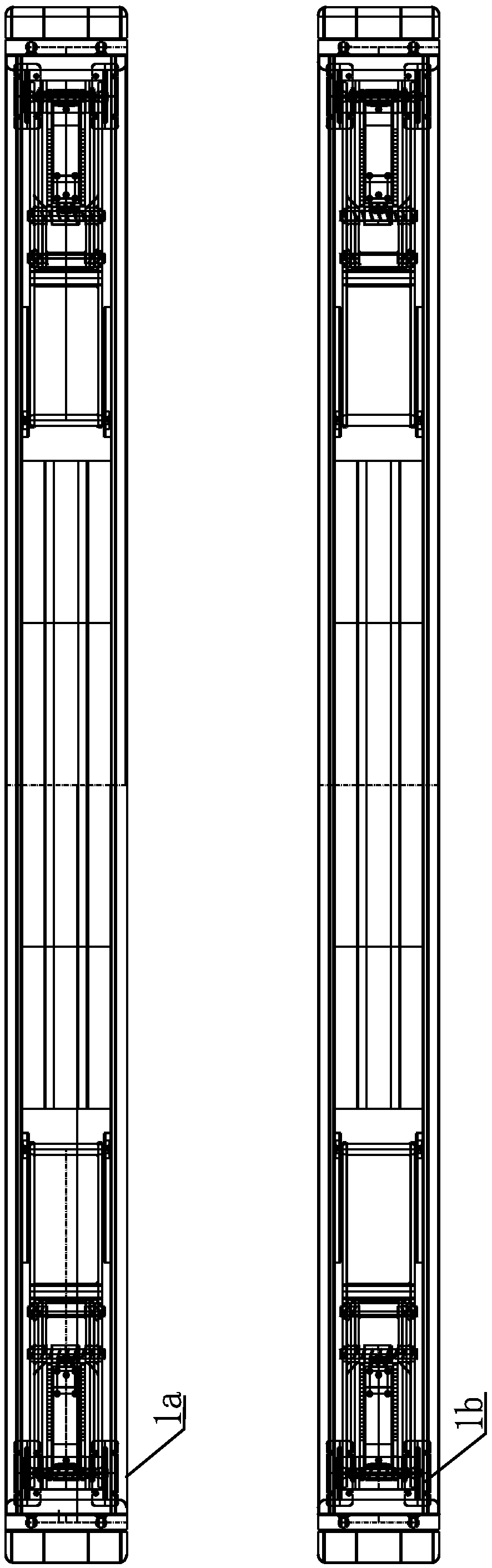

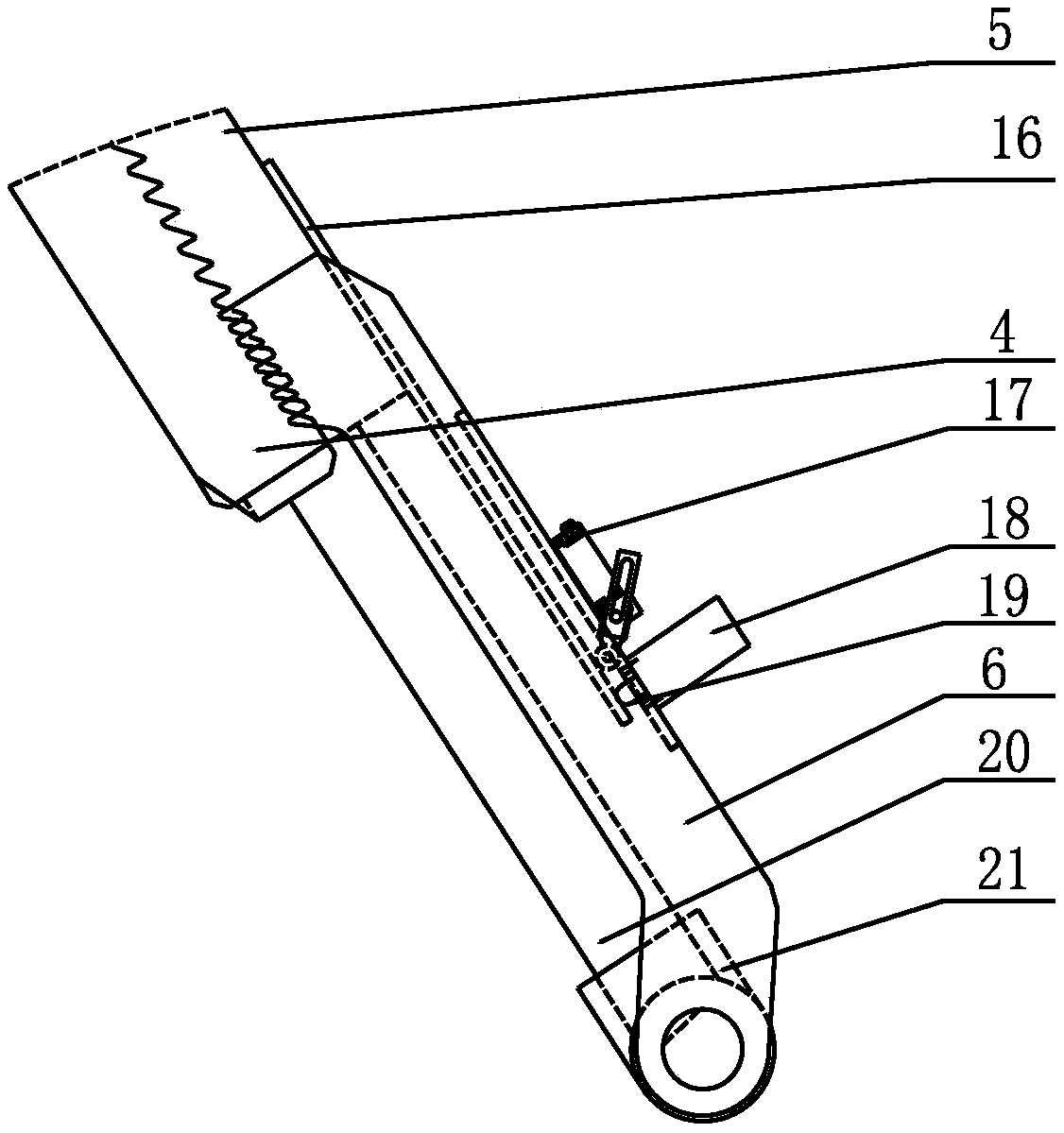

[0024] Such as figure 1 , figure 2 As shown, a channel-type heavy-duty vehicle lift includes two platforms 1 arranged horizontally in parallel, such as figure 1 Shown platform 1a, platform 1b, a main leg 11 is all installed below the two ends of each platform 1, and the all lower end of each main leg 11 is hinged on a base 12 that is set correspondingly with this main leg 11, each main The upper ends of the legs 11 are hinged with a slide block 10, and the two ends of each platform 1 are provided with slide rails corresponding to each slide block 10 and parallel to the platform 1, and each slide block 10 is slidably mounted on the corresponding In the slide rail, a connecting rod 3 is also hinged at both ends of each platform 1, and the other end of each connecting rod 3 is hinged with the middle part of the main leg 11 on the corresponding side, and the upper end of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com