Sewage efficient flocculation clarification device

A clarification device and flocculation technology, applied in water/sewage treatment, water/sewage treatment equipment, multi-stage water/sewage treatment, etc., can solve the problem of difficulty in ensuring the stability of effluent water flow, affecting effluent water quality conditions, reducing equipment operating efficiency, etc. Problems, to achieve the effect of improving the purification degree of the effluent water quality and the stability of the effluent water flow after the electrocoagulation reaction to remove impurities, improving the purification operation efficiency and service life of the equipment, and improving the operation efficiency of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

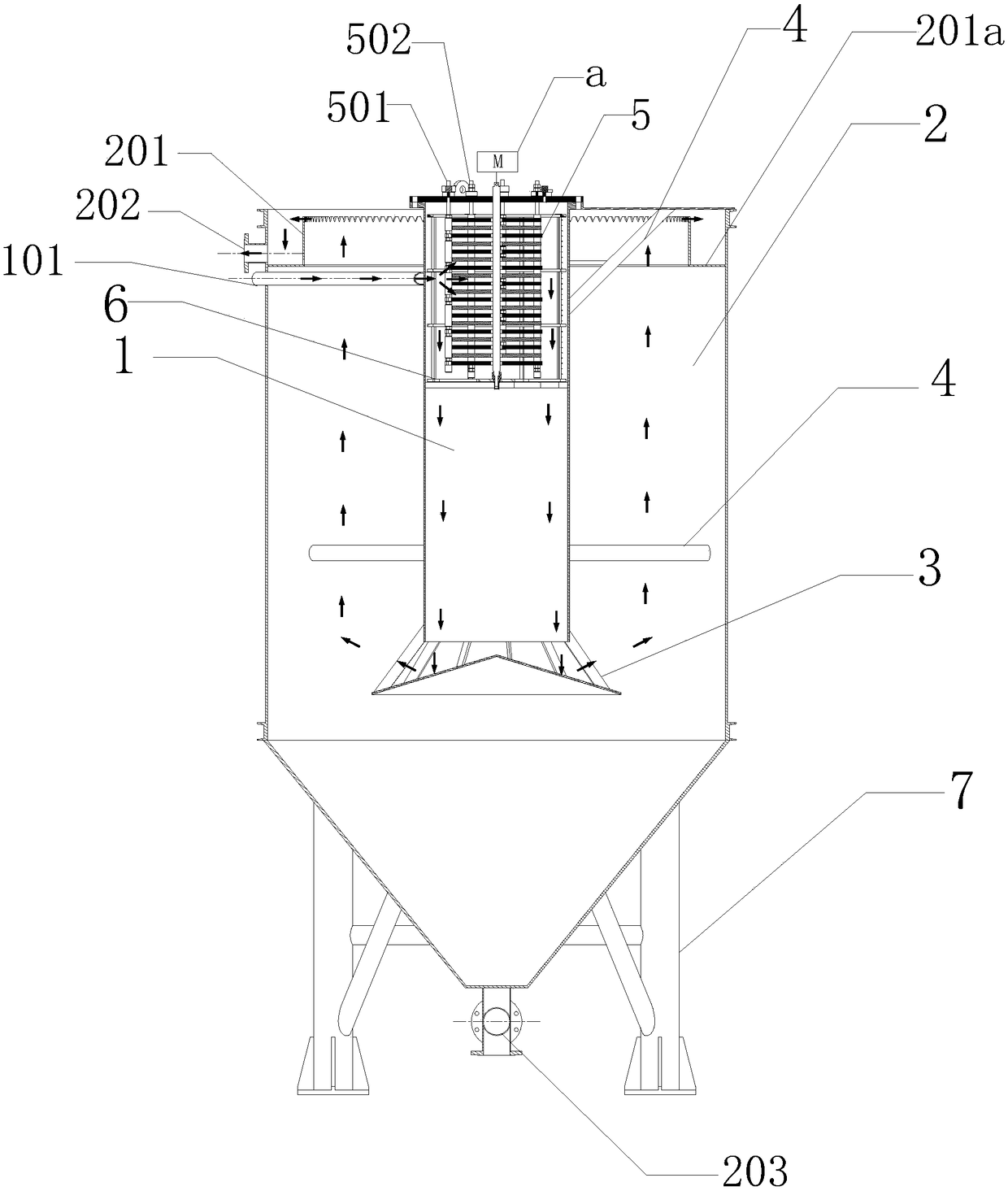

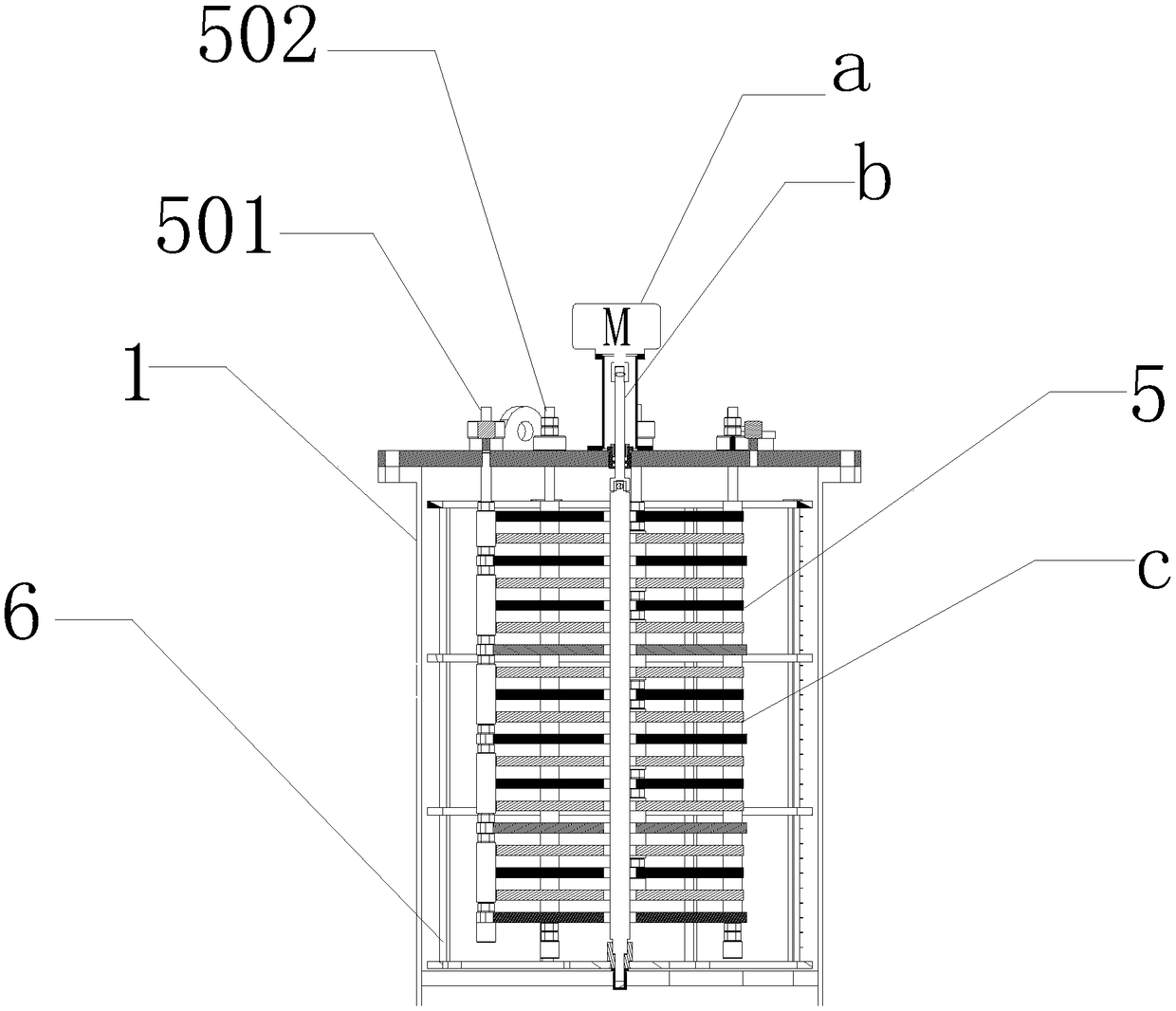

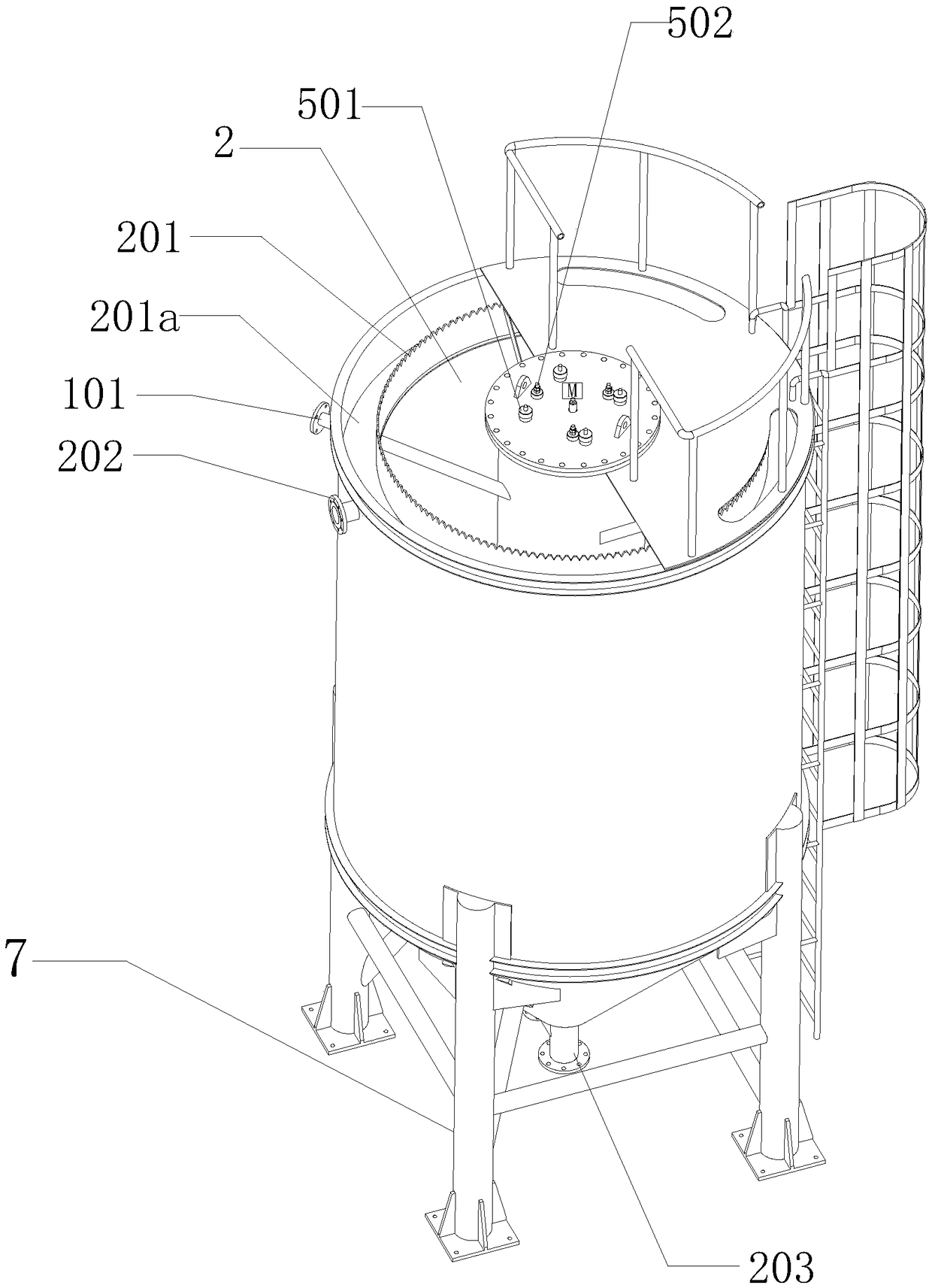

[0039] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present embodiment cites a high-efficiency flocculation and clarification device for sewage, which includes an electrocoagulation reaction chamber 1 with an open bottom, and a clarification and separation chamber 2 with an opening at the top is also provided on the periphery of the electrocoagulation reaction chamber 1; wherein,

[0040] The clarification reaction chamber 2 is specifically preferably a cylindrical or cylindrical or rectangular chamber with an open top. This embodiment is preferably a cylindrical chamber, and a conical or funnel-shaped chamber is connected to the bottom of the cylinder. The bottom of the cylinder is provided with a sewage outlet 203; the bottom of the clarification reaction chamber is also provided with a number of legs 7 for supporting and fixing the entire device.

[0041] The electrocoagulation reaction chamber 2 is fixed on the inner central axis of the clari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com