Method for preparing low-density polyurethane continuous board in all-water

A polyurethane board and polyurethane technology, applied in the field of polyurethane boards, can solve the problems of high viscosity of composite materials, poor dimensional stability, and slow product molding, and achieve good dimensional stability, fast prototyping performance, and uniform foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

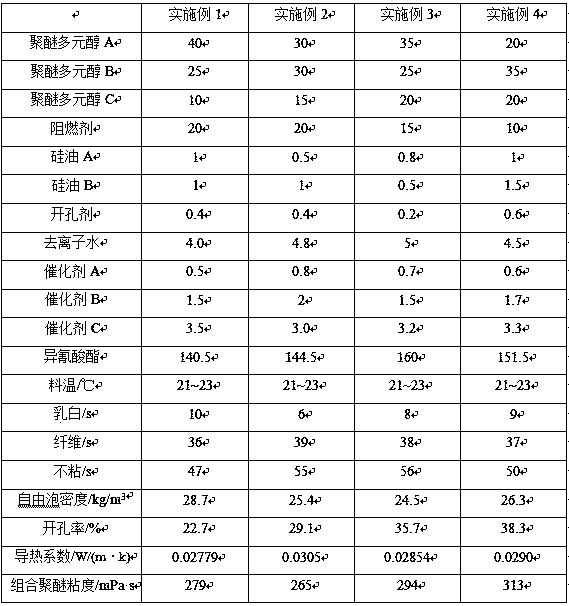

[0016] Implementation examples 1~4

[0017] Polyether polyol A is MH185, Hongbaoli Group Co., Ltd.; polyether polyol B is MH506, Hongbaoli Group Co., Ltd.; polyether polyol C is MH082, Hongbaoli Group Co., Ltd.; flame retardant The foam stabilizer is TCPP; the foam stabilizer A is silicone surfactant B8532, Evonik Specialty Chemical Co., Ltd.; the foam stabilizer B is the silicone surfactant AK8840, Jiangsu Meiside Chemical Co., Ltd.; the cell opener is 0- 501, Jiangsu Meister Chemical Co., Ltd.; Catalyst A is PC-211, Air Products Company; Catalyst B is K15, Air Products Company; Catalyst C is DMP-30, Air Products Company; Isocyanate is M20s, BASF (BASF) company.

[0018] Table 1 shows the formula of all-water combined polyether. First, polyether polyol, flame retardant, foam stabilizer, cell opener, catalyst, and water are added to the reactor according to the formula ratio, and the mixture is heated and stirred evenly to obtain a uniform combination. Polyether

[0019] The obtai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap