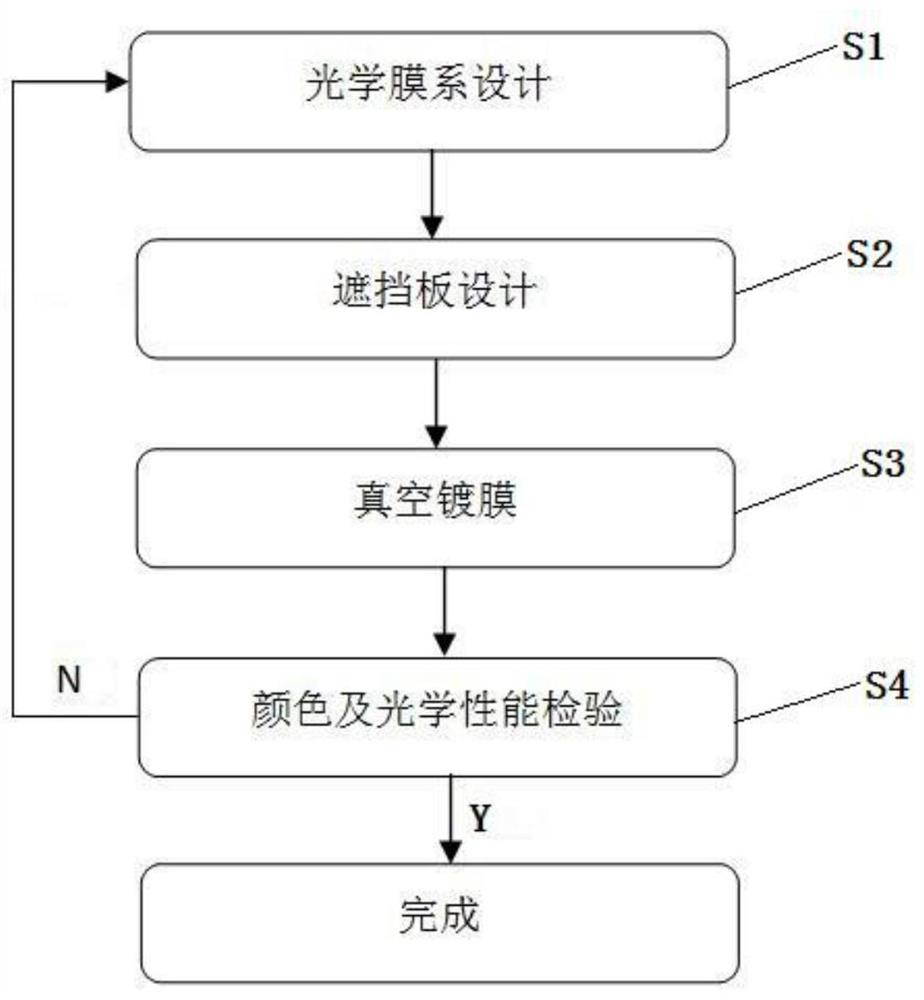

A method for preparing gradient color film by magnetron sputtering machine

A sputtering machine and color technology, used in sputtering coating, metal material coating process, vacuum evaporation coating and other directions, can solve the problems of less gradient color forms, inconvenient production, etc., to achieve a stable refractive index and meet the needs of the market Variety of effects with stable optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

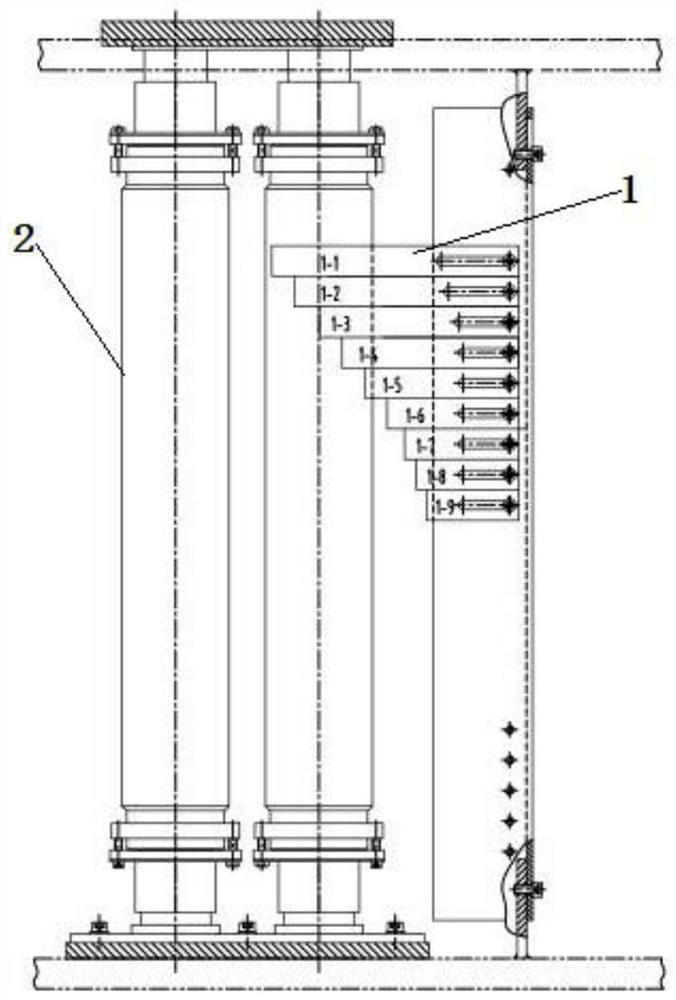

[0108] The sputtering machine used in this embodiment is a SWOS-2000H large magnetron sputtering machine.

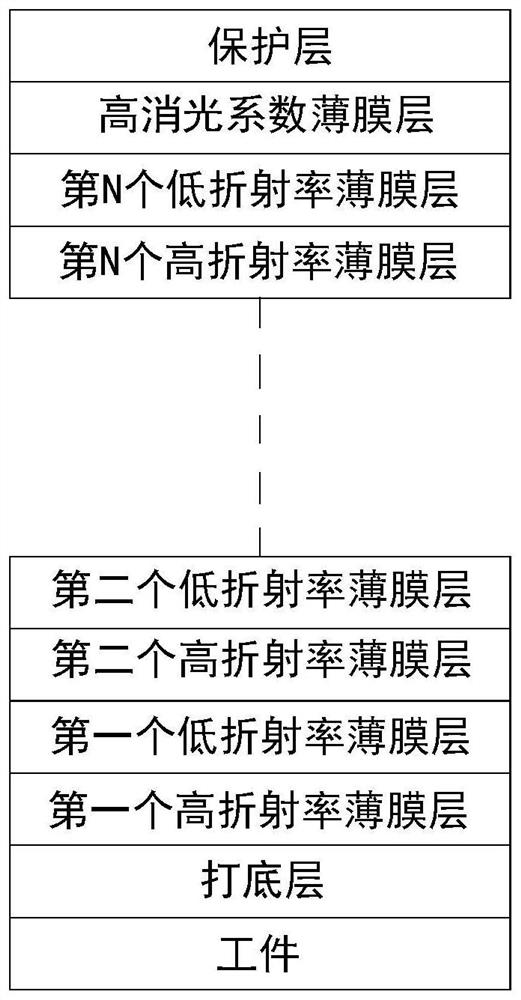

[0109] First, place the cleaned glass cover plate, that is, the workpiece 3, on the workpiece frame 4 of the sputtering machine, wherein the placement schematic diagram of the high refractive index target, the low refractive index target, the workpiece 3, and the shielding plate 1 is as follows Figure 3-5 As shown, the distance between the shielding plate 1 and the high-refractive index target and the low-refractive index target is 2 cm, and the distance between the shielding plate 1 and the workpiece 3 is 13 cm. The shapes of the 2 groups of baffles 1 are all adopted Figure 7 The shapes shown are respectively placed between the high-refractive-index target and the low-refractive-index target and the workpiece 3 . Close the door and pump to 5.0×10 -3 Pa, the workpiece 3 is ion-cleaned for 10 minutes with an anode layer ion source before coating.

[0110] After the i...

Embodiment 2

[0117] First, the cleaned glass cover plate, that is, the workpiece 3, is placed on the workpiece frame 4 of the sputtering machine, wherein the high extinction coefficient target and the glass substrate are placed such as Figure 7 For the baffle 1 shown, the distance between the baffle 1 and the high extinction coefficient target is 4cm, the distance between the baffle 1 and the workpiece 3 is 11cm, and there is no baffle 1 between the other targets 2 and the workpiece 3 . The shape of the baffle plate 1 adopts Figure 7 Shape shown, pumped with door closed to 5.0 x 10 -3 Pa, the workpiece 3 is ion-cleaned for 10 minutes with an anode layer ion source before coating.

[0118] After the ion cleaning of the anode layer is completed, the film coating is started. First, the base layer is plated on the workpiece 3, followed by the first high refractive index film layer, then the first low refractive index film layer, and then the second high refractive index film layer. The fi...

Embodiment 3

[0122] Firstly, the cleaned glass cover plate, i.e. the workpiece 3, is placed on the workpiece frame 4 of the sputtering machine, wherein the low refractive index target and the workpiece 3 are placed between the Figure 8 For the baffle 1 shown, the distance between the baffle 1 and the low-refractive index target is 5 cm, the distance between the baffle 1 and the workpiece 3 is 10 cm, and no baffle is set between the other targets 2 and the workpiece 3 1. The shape of the baffle plate 1 adopts Figure 8 Shape shown, pumped with door closed to 5.0 x 10 -3 Pa, the workpiece 3 is ion-cleaned for 10 minutes with an anode layer ion source before coating.

[0123] After the ion cleaning of the anode layer is completed, the film coating is started. First, the base layer is plated on the workpiece 3, followed by the first high refractive index film layer, then the first low refractive index film layer, and then the second high refractive index film layer. film layer, and finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com