Method and device for producing organic calcium potassium liquid fertilizer

A liquid fertilizer and organic calcium technology, applied in the field of liquid fertilizer, can solve the problems of poor solubility and stability, and achieve the effects of maintaining stability, improving utilization rate and application value, and improving land conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

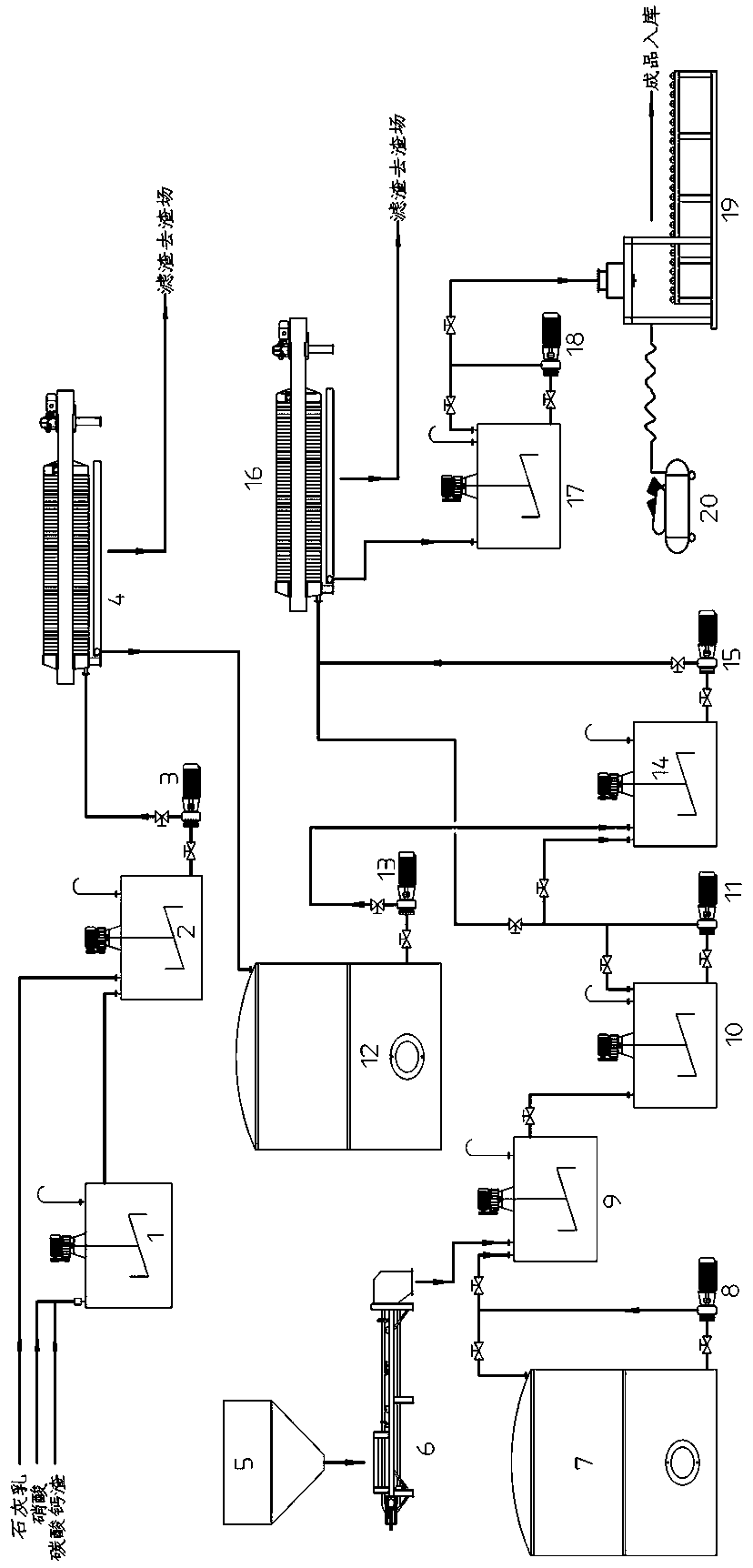

Image

Examples

Embodiment 1

[0033] A method for producing organic potassium calcium liquid fertilizer, which is to dissolve and react calcium nitrate mother liquor with 58% nitric acid, which is the waste of nitrophosphate fertilizer production, to generate calcium nitrate mother liquor, and adjust the pH value of the supernatant of calcium nitrate mother liquor to 8 with milk of lime Finally, pressurize again to 0.65MPa to filter out acid insoluble matter, obtain 50% calcium nitrate clear liquid main material; stir and dissolve the process condensate evaporated by potassium fulvic acid, potassium nitrate, amino acid and calcium ammonium nitrate, and Adjust the pH value to 6.5, ferment and dissolve at 45°C for 40 minutes to obtain auxiliary materials; mix the main materials and auxiliary materials, and adjust the pH value to 5 to obtain a crude liquid, pressurize the crude liquid to 0.6 MPa and then press Filtration, the finished clear liquid of the organic potassium calcium liquid fertilizer obtained by ...

Embodiment 2

[0041] A kind of method of producing organic potassium calcium liquid fertilizer, is to produce calcium nitrate mother liquor by dissolving and reacting calcium carbonate slag, the waste of nitrophosphate fertilizer production, with 60% nitric acid; Then pressurize to 0.6MPa to filter out the acid insoluble matter to obtain 55% calcium nitrate clear liquid main material; stir the process condensate evaporated from biochemical potassium fulvate, calcium nitrate, potassium nitrate, magnesium nitrate and calcium ammonium nitrate Dissolve, adjust the pH value to 6.2, ferment and dissolve at 35°C for 40 minutes to obtain auxiliary materials; mix the main material and auxiliary materials, adjust the pH value to 6.5 to obtain a crude liquid, and pressurize the crude liquid to 0.55MPa Afterwards, pressure filtration is carried out, and the finished clear liquid obtained by pressure filtration to obtain the organic potassium calcium liquid fertilizer is tanked and stored.

[0042] Wher...

Embodiment 3

[0045] A method for producing organic potassium-calcium liquid fertilizer, comprising dissolving and reacting calcium carbonate slag, waste from nitrophosphate fertilizer production, with nitric acid to generate calcium nitrate mother liquor, and adjusting the pH value of the supernatant of calcium nitrate mother liquor to 7.8 with milk of lime, and then adding Press to 0.7MPa to filter out acid-insoluble matter to obtain 45% calcium nitrate clear liquid main material; stir and dissolve biochemical potassium fulvate, calcium nitrate, potassium nitrate, magnesium nitrate, etc. and process condensate evaporated from calcium ammonium nitrate , adjust the pH value to 5.8, ferment and dissolve at 42°C for 40 minutes to obtain auxiliary materials; mix the main material and auxiliary materials, and adjust the pH value to 10 to obtain a crude liquid, pressurize the crude liquid to 0.65MPa Press filtration is carried out, and the finished product clear liquid of the organic potassium ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com