A kind of membrane yarn for warp knitted fabric

A warp knitted fabric and sheet yarn technology is applied in the field of weaving warp knitted textiles for clothing, and can solve the problems of decreased yarn stability, decreased crystallinity of base materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

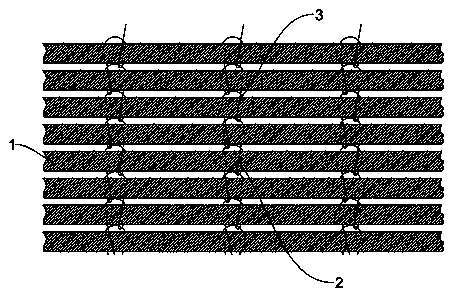

[0021] Such as figure 1 As shown, the membranous yarn 1 is arranged in the weft direction in the fabric in the weft insertion manner, the ground yarn extension thread 2 binds the membranous yarn 1, and the ground yarn loop arc 3 forms a ground yarn chain on the reverse side of the fabric. The needle trajectory of the ground yarn comb is not limited to the straight knitting chain (0-1 / 1-0 / / or 1-0 / 0-1 / / ), various hexagonal meshes, Powernet meshes, circular meshes, etc.; The bar or jacquard bar is configured according to the mesh requirements; the needle movement and configuration of spandex are configured according to the process requirements, and elastic fabrics with spandex and non-elastic fabrics without spandex can be selected.

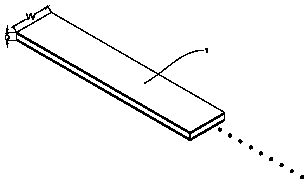

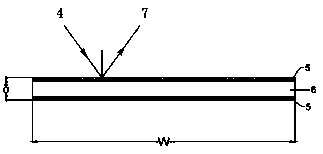

[0022] The appearance of membrane yarn 1 before weaving is as follows figure 2 As shown, the total fineness of the ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com