shuttle embroidery machine

An embroidery machine and shuttle technology, applied in the field of shuttle embroidery machines, can solve problems such as harmfulness and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in detail below in conjunction with the accompanying drawings.

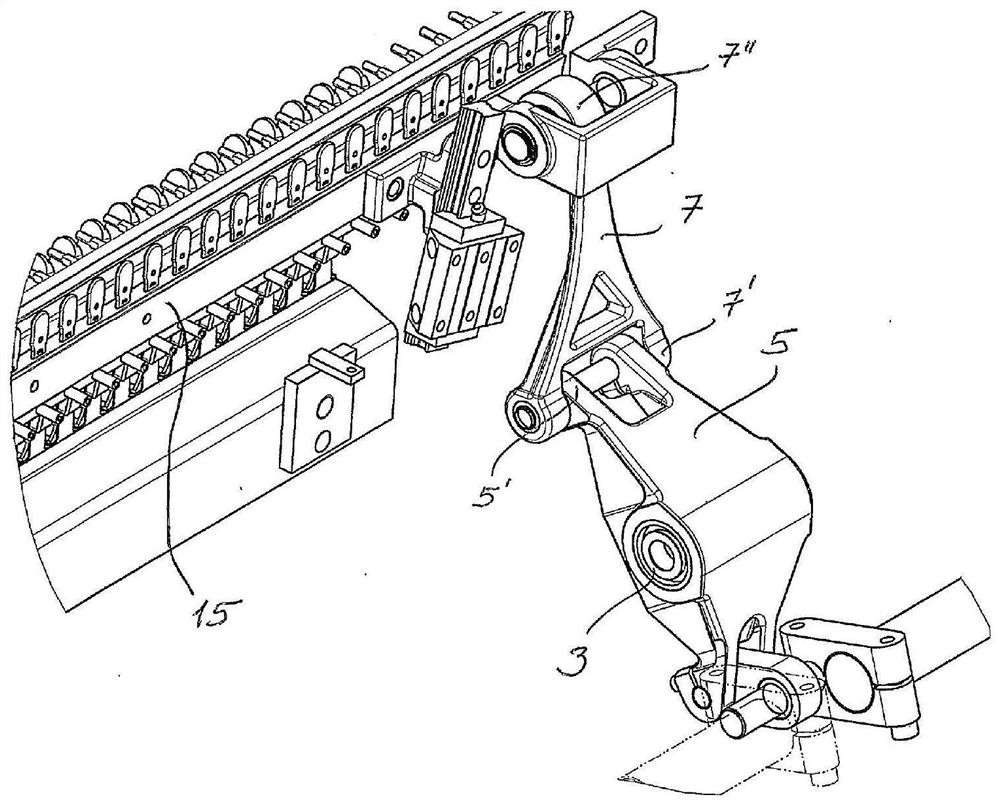

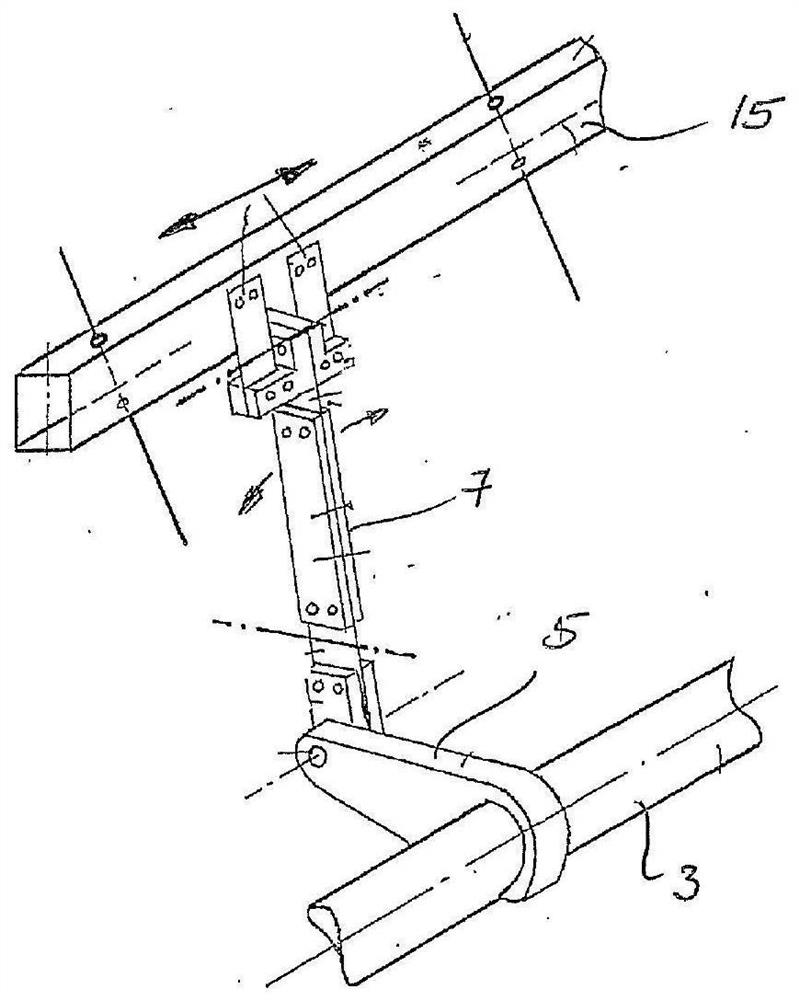

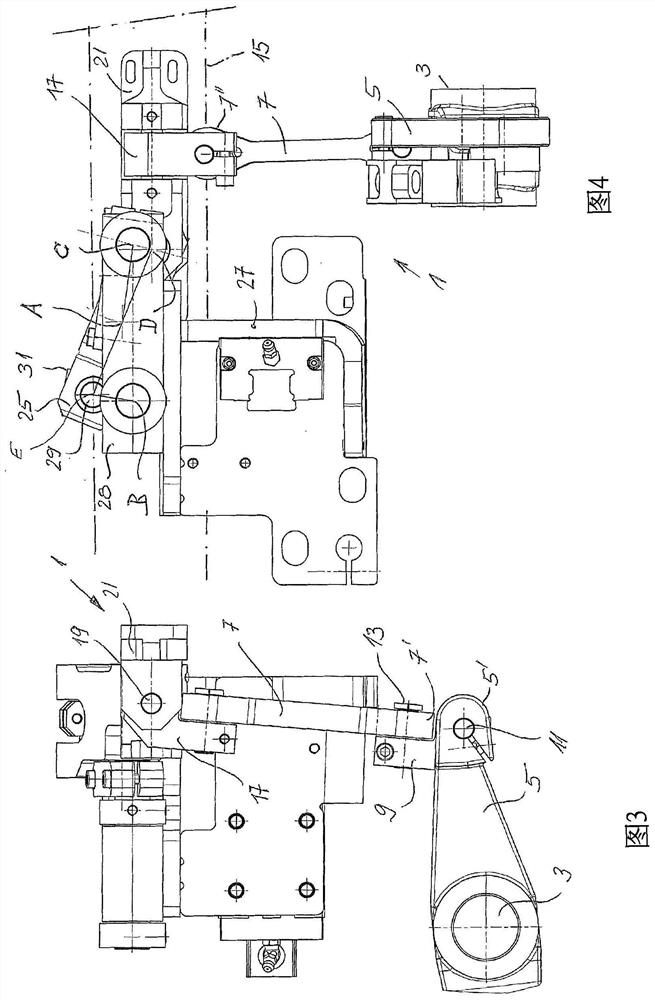

[0074] figure 1 The prior art shown is EP 1 595 990, in EP 1 595 990 Figure 4 Its components and working principles are described in detail in the relevant description of the . According to such an embodiment of the transmission device for the drive beam, the drive beam is supported on several guide rods in a displaceable manner on guides inclined to the vertical. The inclination angle relative to the vertical line is preferably 15°. The hoisting drive for driving the beam and having a crank linkage consisting of a crank and a connecting rod moves precisely vertically. In order to compensate for the lateral movement of the drive beam during its movement, a horizontal shaft is arranged on the drive beam, and the transmission rod / link is supported on the shaft in a manner that can move transversely to the transmission direction, so that the drive beam Lateral move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com