Manufacturing method of segmental steel pipe recycled mixed component and positioner used therefor

A technology of mixed components and manufacturing methods, applied in the field of positioners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

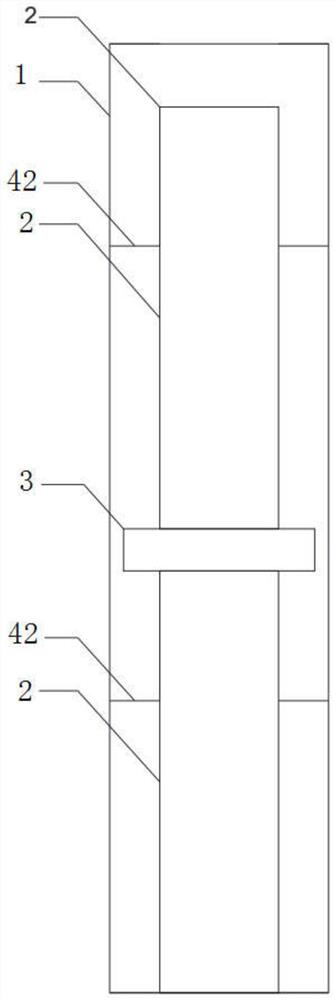

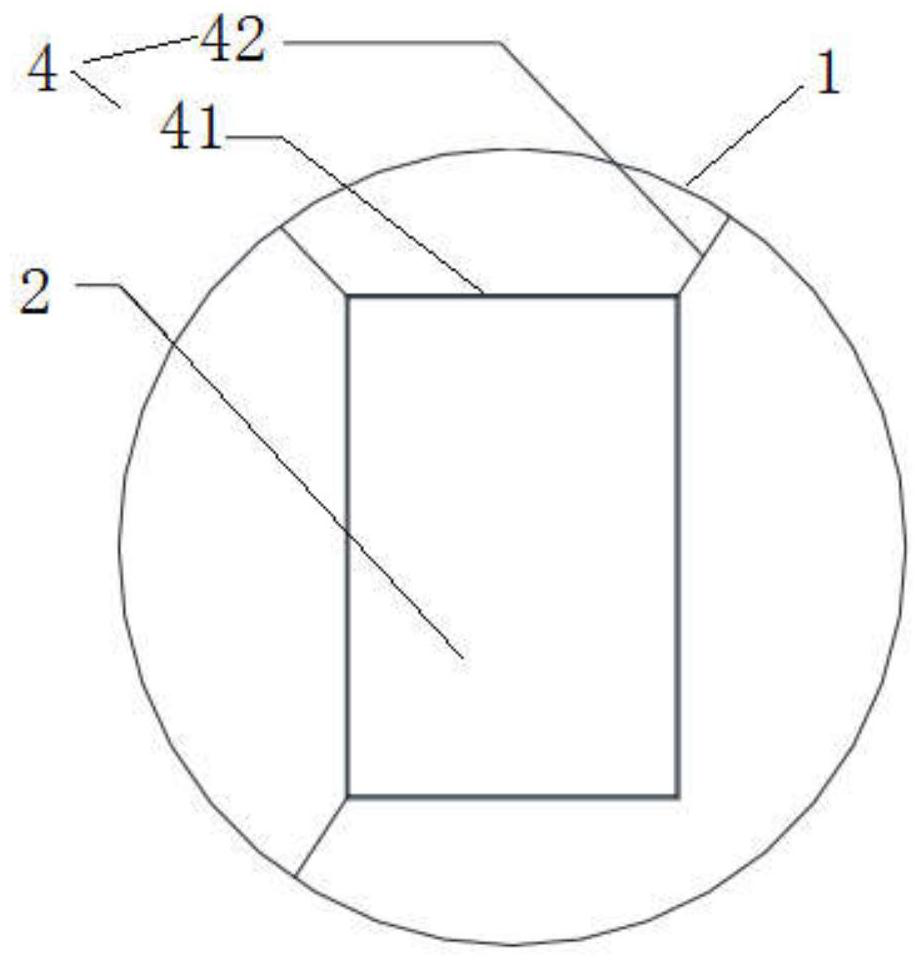

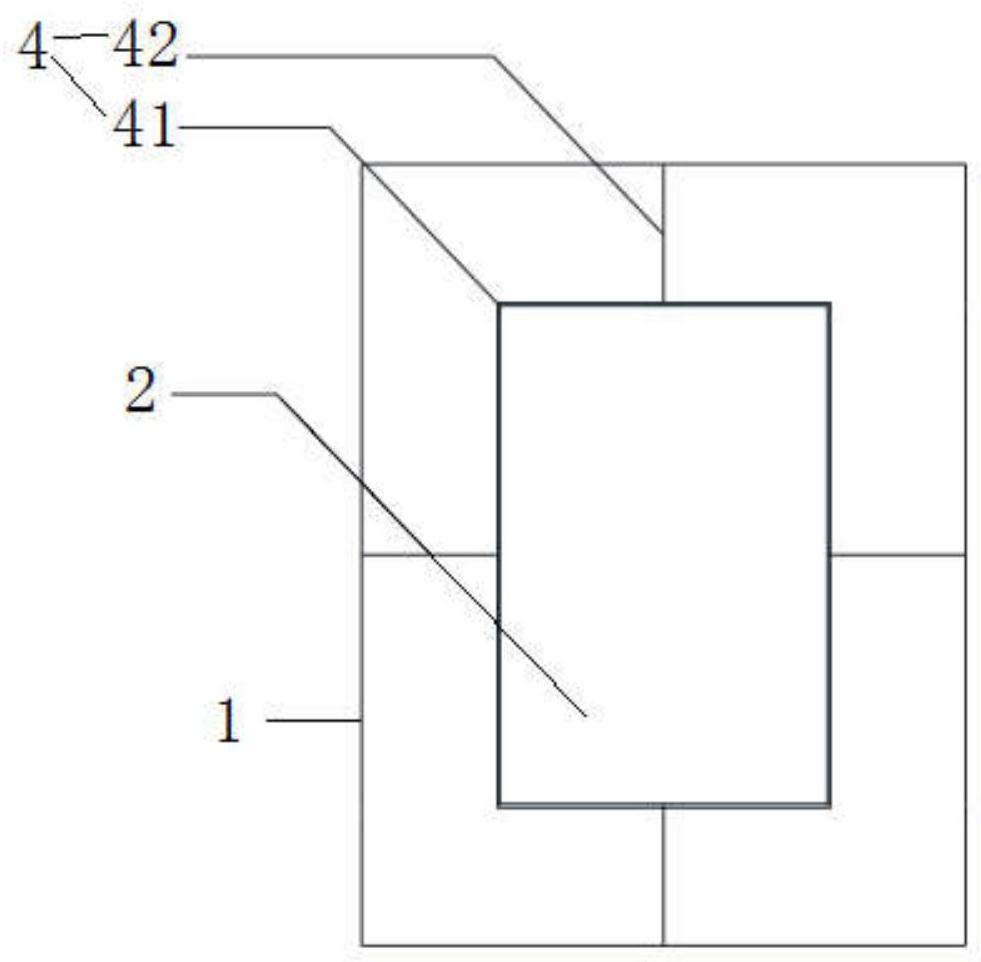

[0042] The invention discloses a manufacturing method of a segmented steel pipe recycled mixing component, such as Figure 1-Figure 5 shown, including the following steps:

[0043] 1) Making the old concrete segment 2: After the abandoned old concrete beams and columns 5 (including concrete beams and concrete columns) are horizontally clamped on the rotatable positioner 8, the surface concrete protective layer and internal steel bars are removed , to obtain the old concrete segment 2 retaining the core of the old concrete beam column 5;

[0044] 2) making the steel hoop 4 used to confine the old concrete segment 2 to the center of the steel pipe 1;

[0045] 3) set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com