A method of man-made water-resisting formation using strip and solid filling coal mining technology

A solid filling and strip technology, applied in the fields of fillings, mining equipment, earthwork drilling, etc., can solve the problems such as the inability to form water storage space, the inability to recover coal resources, and the lack of effective aquifers, and achieve good promotion and application prospects. The effect of improving the resource recovery rate and protecting the environment of the mining area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

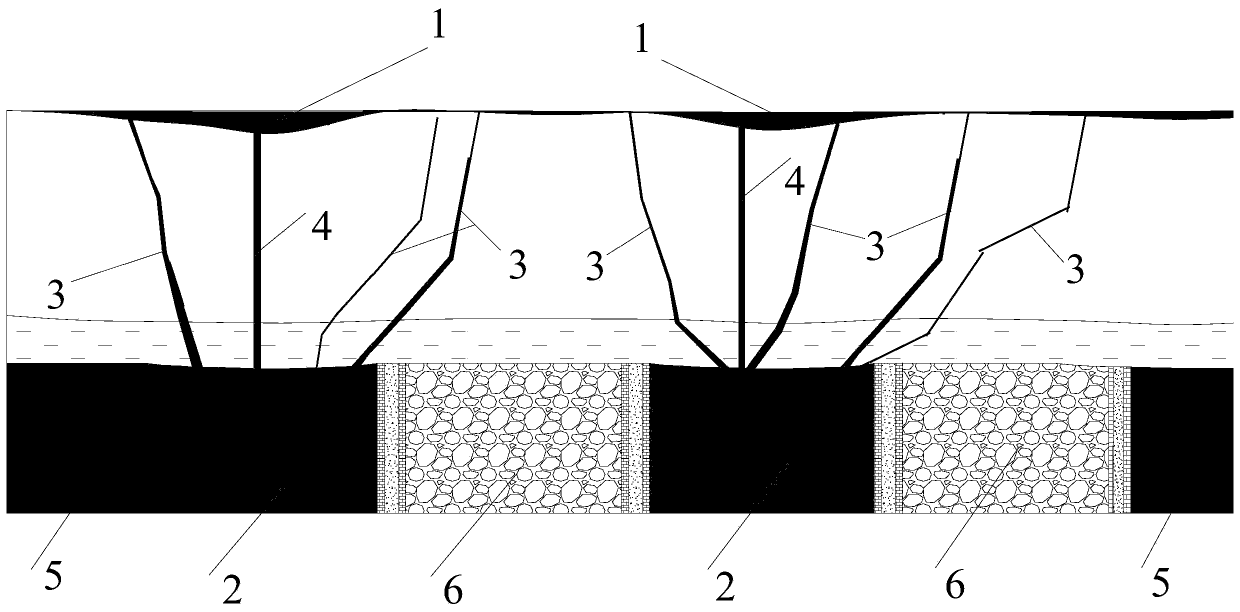

[0022] In a certain mine, strip fully mechanized mining and strip solid filling coal mining face are arranged in the mine protection coal pillar and the surrounding area, which can not only recycle coal pillar resources, but also build artificial water storage strata to store surface precipitation resources for the mining area, thus solving the problem of mining area Serious water shortage problem, but also reasonable disposal of solid waste in mining areas.

[0023] The mining area is a rectangular area with a length of 1000m and a width of 490m. The buried depth of the coal seam is 600m, and the set mining height is 3.2m.

[0024] A method for man-made water-resisting stratum with strip and solid filling coal mining technology, comprising the following steps:

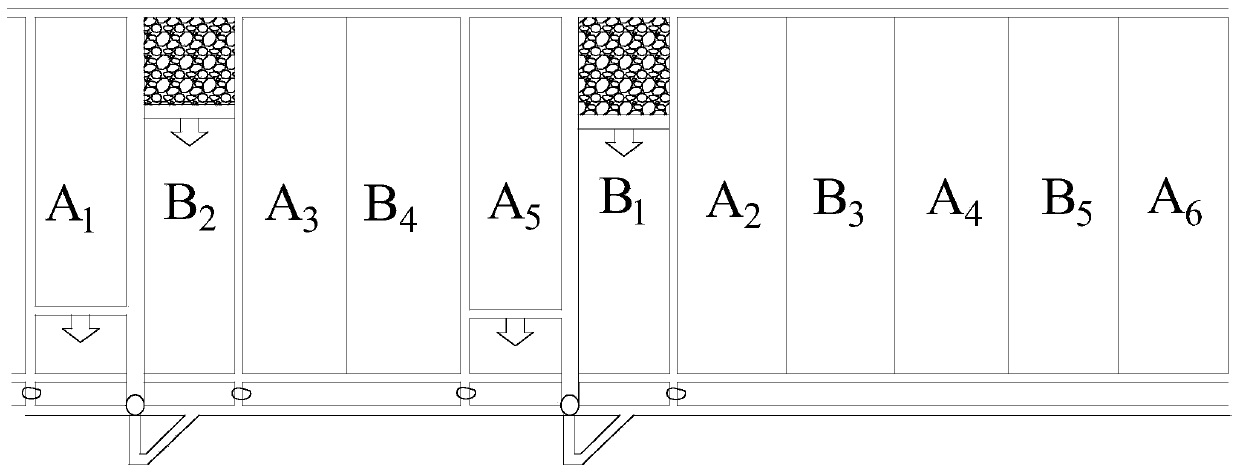

[0025] a. Alternately arrange strip fully mechanized mining face and strip sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com