Filter with automatic dredging function

A filter, automatic technology, applied in the direction of fixed filter element filter, filter separation, machine/engine, etc., can solve the problem that the filter is lifted to the liquid level for cleaning, separated from the filter screen and returned to the liquid storage tank, and the pump cannot suck. problems such as the upper medium, to achieve the effect of good economy, low price and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

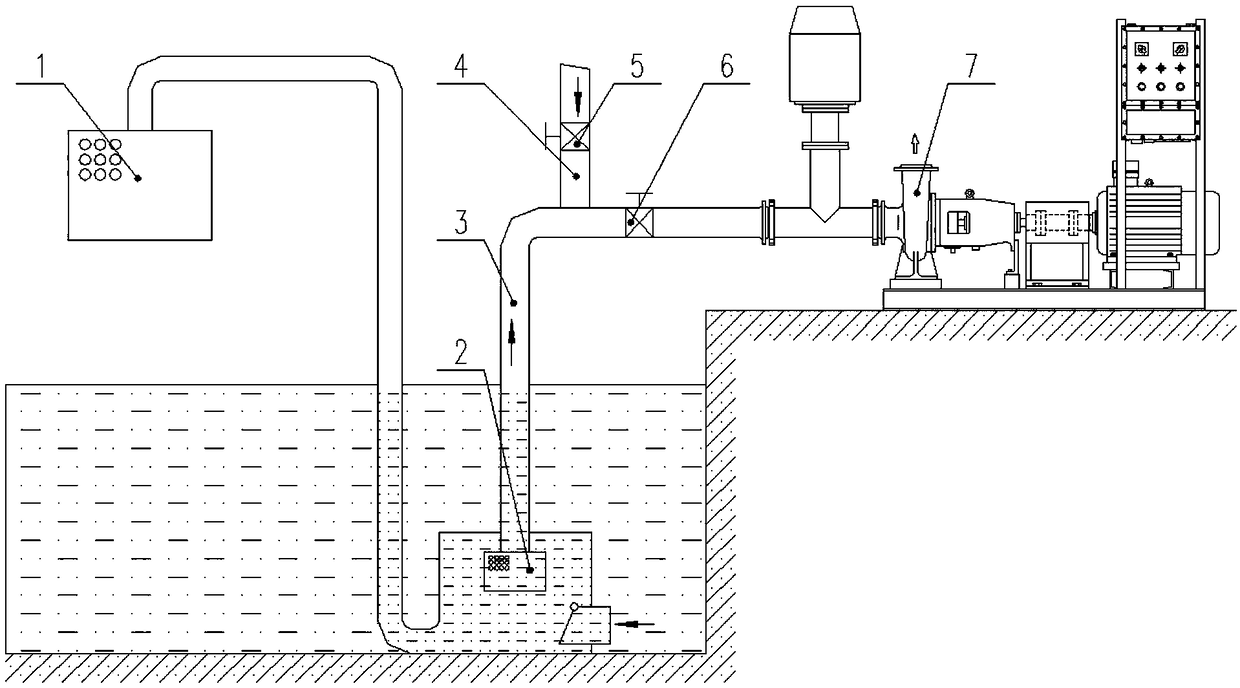

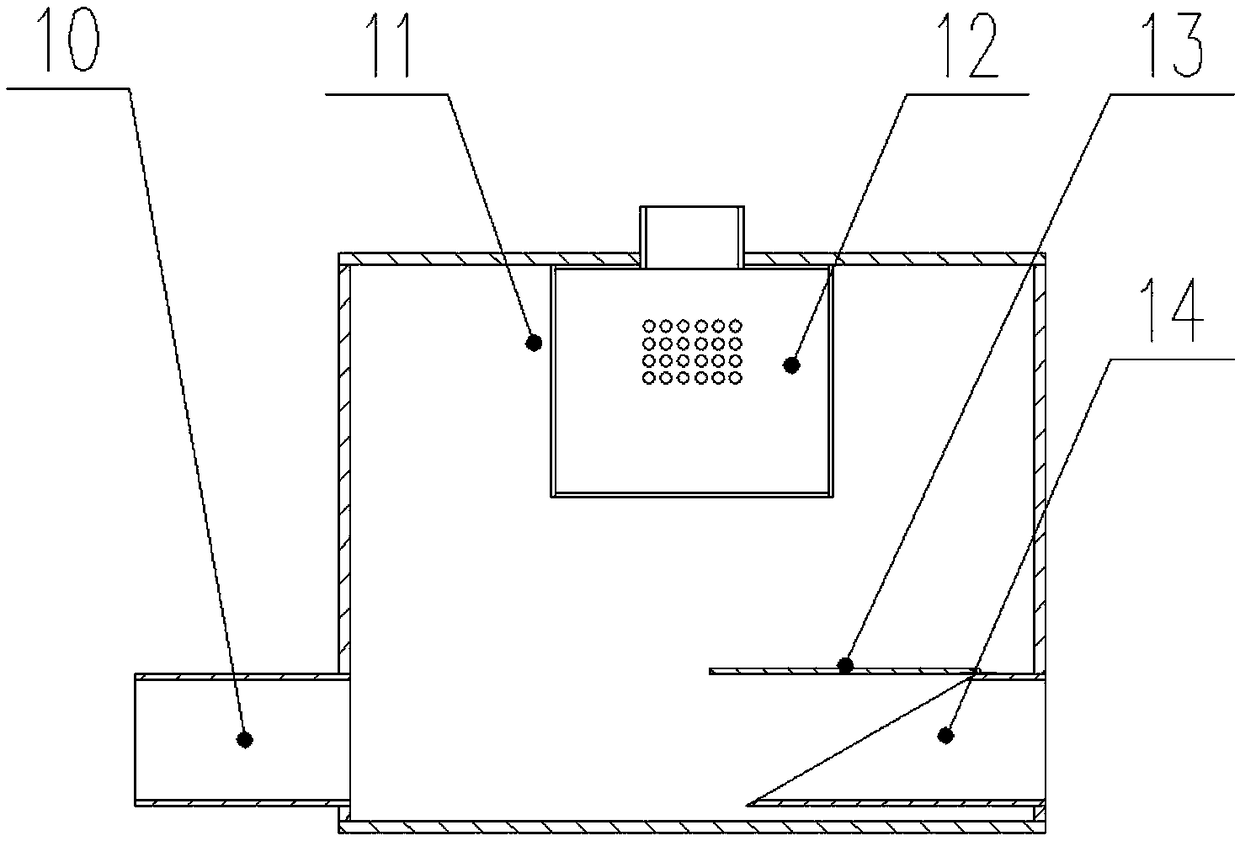

[0029] Such as figure 1 and figure 2 As shown, an automatic dredging filter 2, the automatic dredging filter 2 includes an impurity collection box 11, the impurity collection box 11 is provided with a suction line filter 12, a one-way valve 13 and a liquid inlet pipe 14, and the suction line filters The net 12 is connected to the inlet of the suction pipeline 3, and is used to intercept impurities to prevent them from entering the suction pipeline 3. The liquid inlet pipe 14 is connected to the tank, and is used to introduce the medium and impurities in the tank into the impurity collection box 11, and the one-way valve 13 is set The mouth of the liquid inlet pipe 14 is used to prevent the impurities entering the impurity collection box 11 from returning to the tank. , the slag discharge pipe 10 is connected with the filtrate net 1, the filtrate net 1 is provided with holes for discharging the medium, the automatic dredging filter 2 is installed under the liquid surface, and...

Embodiment 2

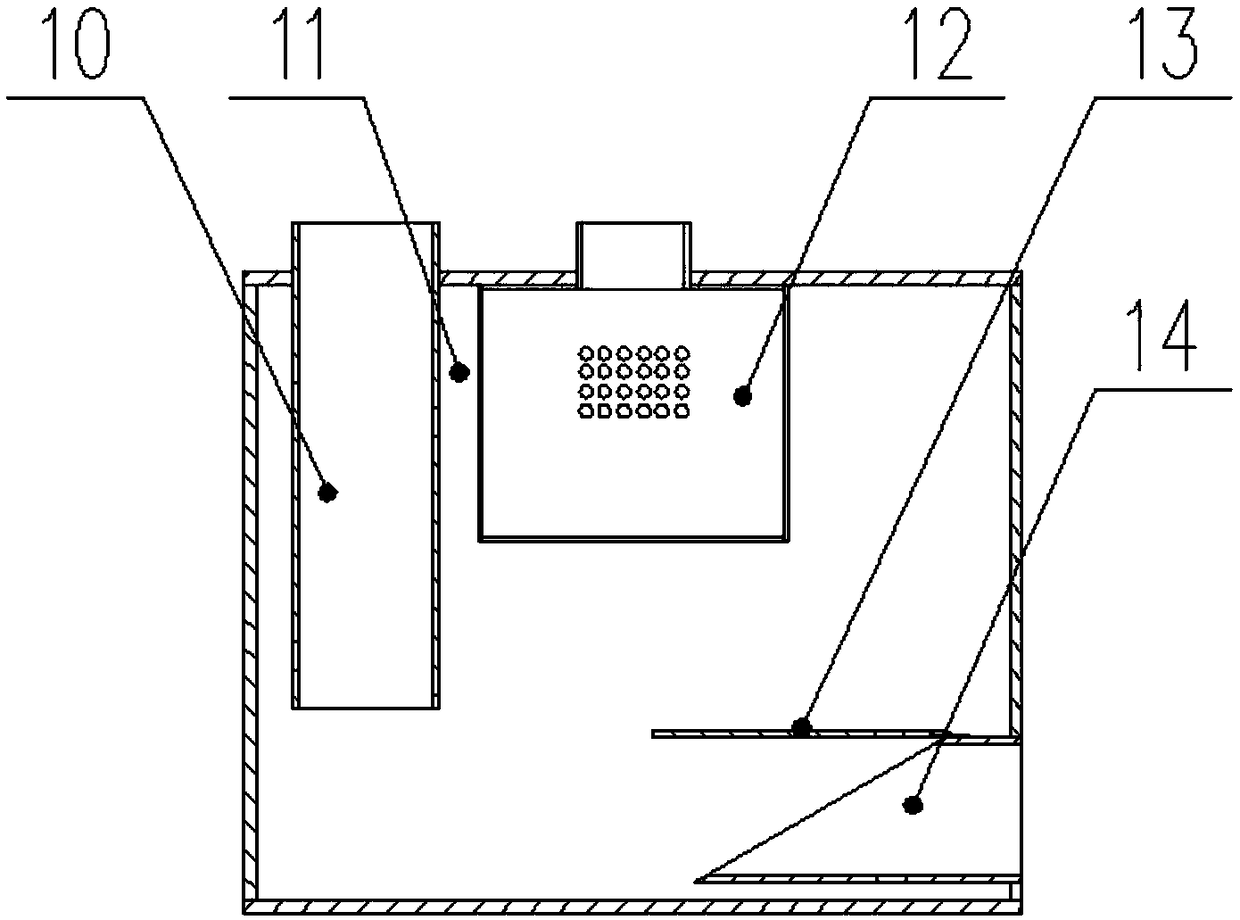

[0034] Such as image 3 As shown, an automatic dredging filter 2, the automatic dredging filter 2 includes an impurity collection box 11, the impurity collection box 11 is provided with a suction line filter 12, a one-way valve 13 and a liquid inlet pipe 14, and the suction line filters The net 12 is connected to the inlet of the suction pipeline 3, and is used to intercept impurities to prevent them from entering the suction pipeline 3. The liquid inlet pipe 14 is connected to the tank, and is used to introduce the medium and impurities in the tank into the impurity collection box 11, and the one-way valve 13 is set The mouth of the liquid inlet pipe 14 is used to prevent the impurities entering the impurity collection box 11 from returning to the tank. , The slag discharge pipe 10 is connected to the filtrate net 1, and the filtrate net 1 is provided with holes for discharging the medium. The automatic dredging filter 2 is installed under the liquid surface, the slag discha...

Embodiment 3

[0037] Such as Figure 4 and Figure 5 As shown, an automatic dredging filter 2, the automatic dredging filter 2 includes an impurity collection box 11, the impurity collection box 11 is provided with a suction line filter 12, a one-way valve 13 and a liquid inlet pipe 14, and the suction line filters The net 12 is connected to the inlet of the suction pipeline 3, and is used to intercept impurities to prevent them from entering the suction pipeline 3. The liquid inlet pipe 14 is connected to the tank, and is used to introduce the medium and impurities in the tank into the impurity collection box 11, and the one-way valve 13 is set The mouth of the liquid inlet pipe 14 is used to prevent the impurities entering the impurity collection box 11 from returning to the tank. , the slag discharge pipe 10 is connected with the filtrate net 1, the filtrate net 1 is provided with holes for discharging the medium, the automatic dredging filter 2 is installed on the ground, the slag disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com