A magneto-rheological clutch with small size and large controllable range

A magneto-rheological and small-sized technology, applied in the field of clutches, can solve the problems of inability to achieve passive torque, difficulty in achieving large output torque, and inability to coordinate the relationship between external dimensions and required output torque, so as to improve the effective utilization rate , The torque is continuously adjustable, and the effect of reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

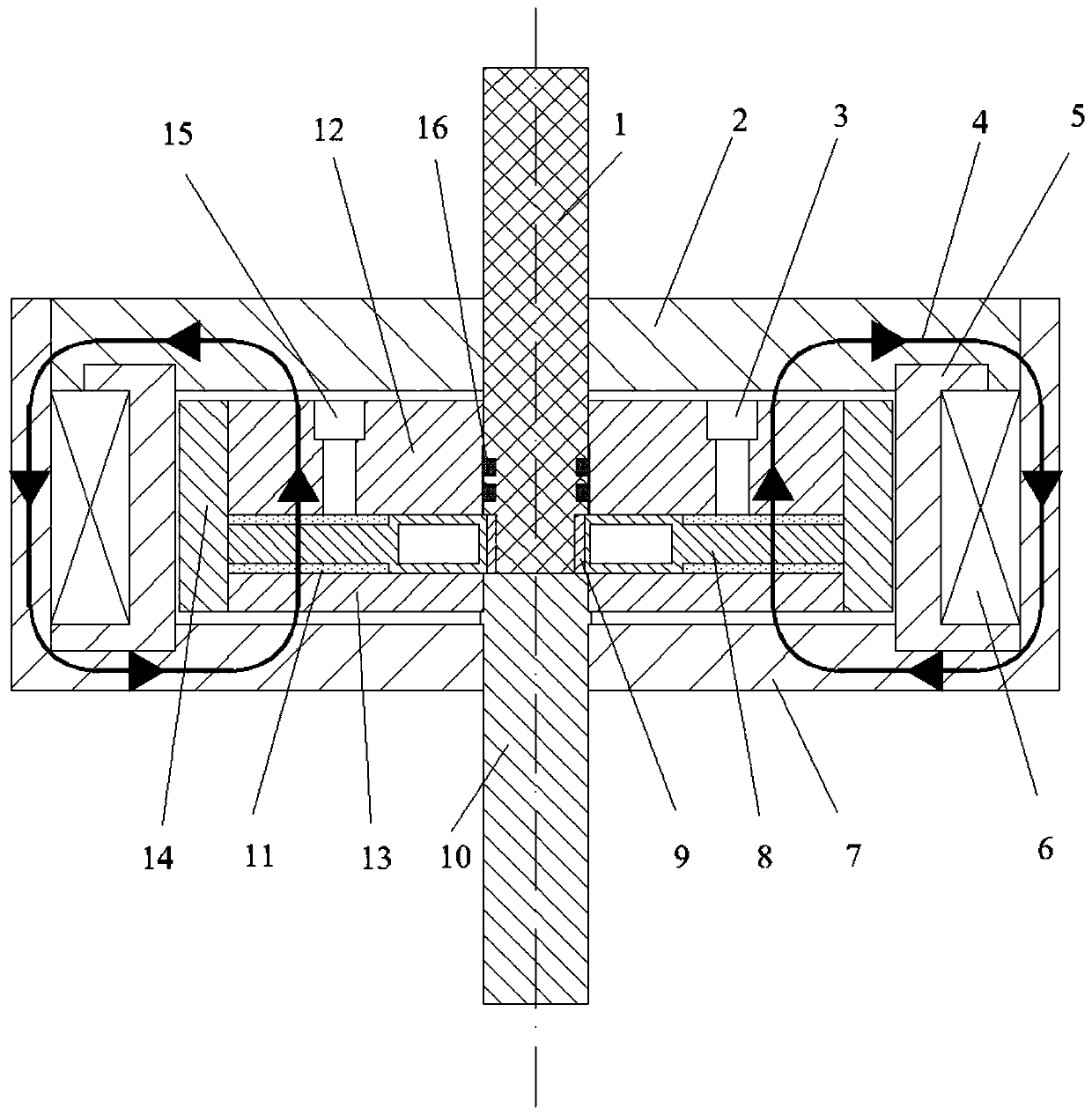

[0033] see Figure 1 to Figure 5 , the present embodiment discloses a magneto-rheological clutch with small size and large controllable range, which includes an outer casing, a driving mechanism and a driven mechanism arranged in the outer casing. The outer casing includes an outer cylinder body 7 and an end cover 2 , the top end of the outer cylinder body 7 is open, and the end cover 2 is threadedly connected with the top end of the outer cylinder body 7 .

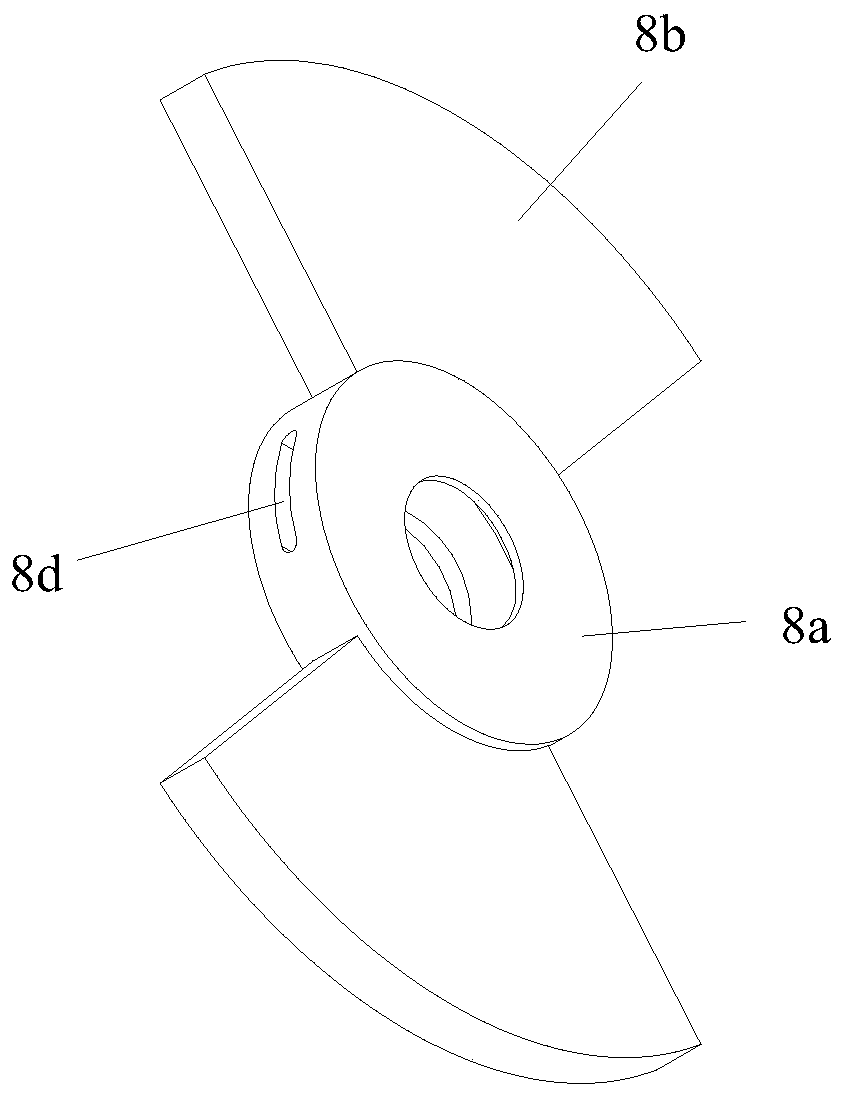

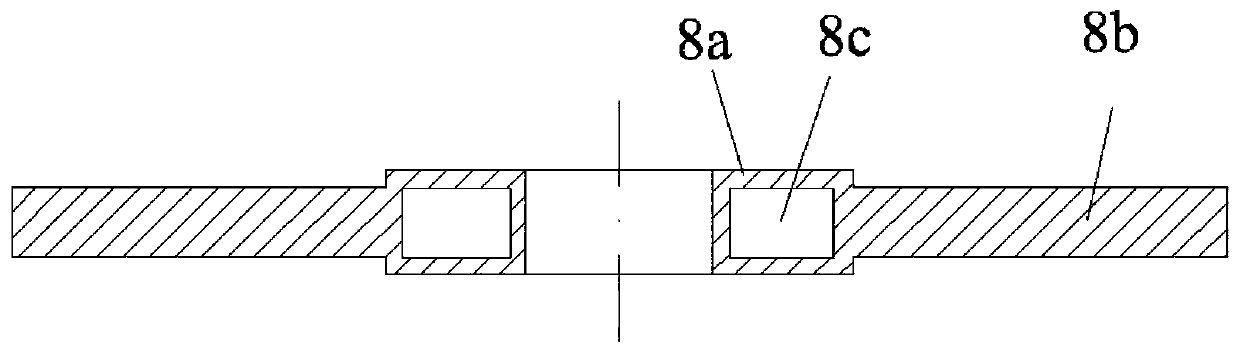

[0034] The active mechanism includes an input shaft 1, an input disc 8 and a permanent magnet 9. The bottom end of the input shaft 1 extends into the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com