Heat exchange pipe of heat exchanger and heat exchanger adopting heat exchange pipe

A technology of heat exchange tubes and heat exchangers, which is applied in the field of reactor engineering, can solve problems such as inapplicability, and achieve the effects of improving service life, reducing the number of occurrences, and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

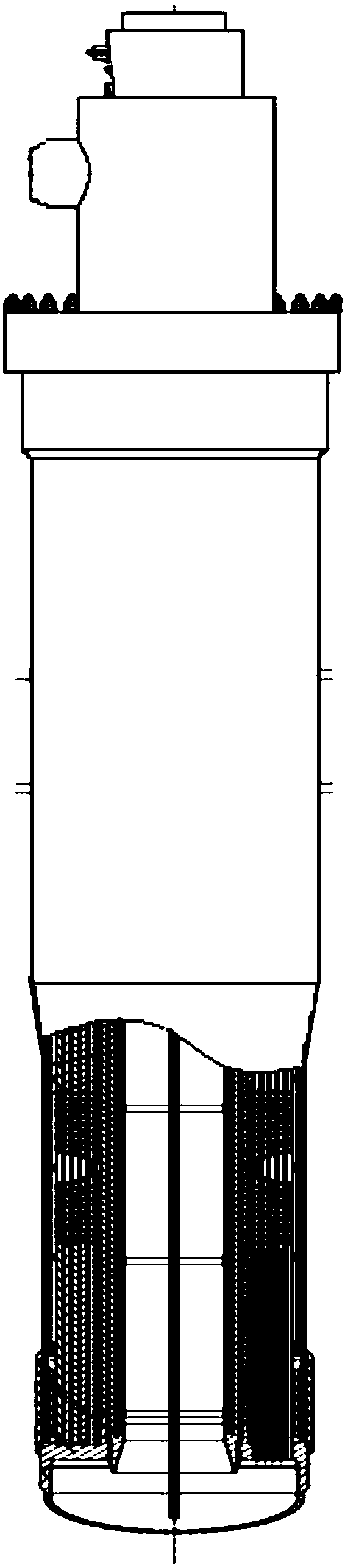

[0033] The working condition of the heat exchanger is that the inlet and outlet temperatures of the primary side are 516°C and 353°C. The inlet and outlet temperatures of the secondary side are 310°C and 495°C;

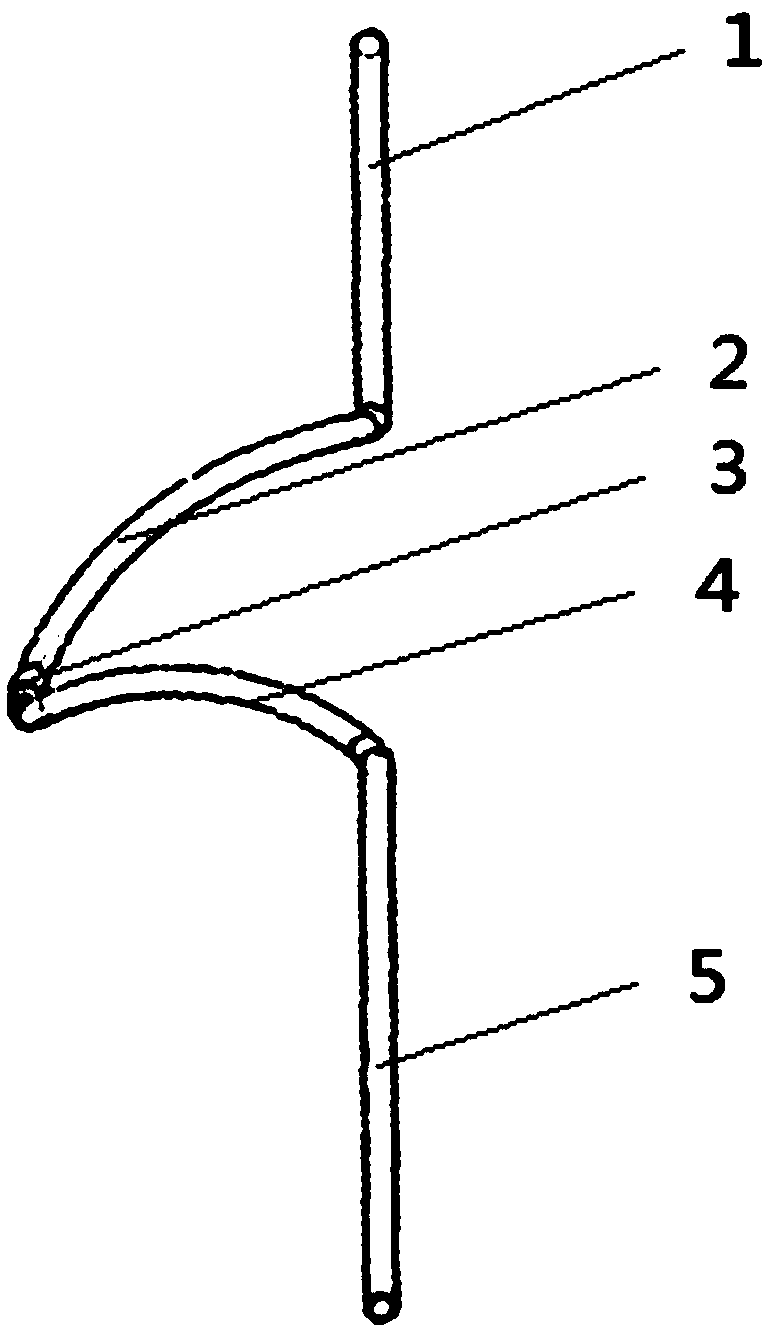

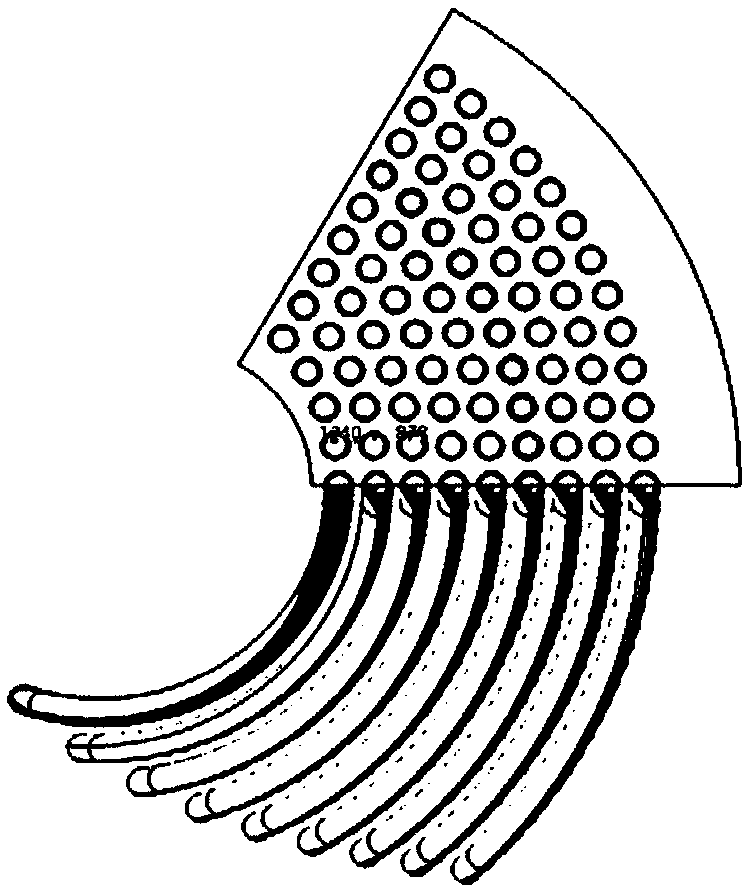

[0034] The heat exchanger adopts the heat exchange tube with the above structure. The material of the heat exchange tube is 304 stainless steel. The specification of the heat exchange tube is φ16×1.4. The length of the first straight pipe section is 1300mm, the length of the second straight pipe section is 1900mm, and the length of the middle straight pipe section is 100mm. The bending radius of the joint of the corresponding space spiral elbow section is 100mm, and the center distance of the heat exchange tubes is arranged equally from the innermost layer of 133.5mm to the outermost layer of 305.5mm; the first and second space spiral elbow sections of the nine-layer heat exchange tube The central angles from inside to outside are: 90°, 78°, 68.5°, 61°, 55°, 50°, 46°...

Embodiment 2

[0038] Present embodiment adopts the same device of embodiment 1, and its difference is:

[0039] The working condition of the heat exchanger is that the inlet and outlet temperatures of the primary side are 516°C and 353°C. The inlet and outlet temperatures of the secondary side are 310°C and 495°C;

[0040] The heat exchanger adopts the heat exchange tube with the above structure. The material of the heat exchange tube is 304h stainless steel. The specification of the heat exchange tube is φ14×1.2. The length of the first straight pipe section is 1700mm, the length of the second straight pipe section is 3000mm, and the length of the middle straight pipe section is 80mm. The bending radius of the joint of the spiral elbow section in the corresponding space is 90mm, and the center distance of the heat exchange tubes is arranged equally from the innermost layer of 300mm to the outermost layer of 500mm; the centers of the first and second space spiral elbow sections of the nine...

Embodiment 3

[0044] Present embodiment adopts the same device of embodiment 1, and its difference is:

[0045] The working condition of the heat exchanger is that the inlet and outlet temperatures of the primary side are 516°C and 353°C. The inlet and outlet temperatures of the secondary side are 310°C and 495°C;

[0046]The heat exchanger adopts the heat exchange tube with the above structure. The material of the heat exchange tube is 316 stainless steel. The specification of the heat exchange tube is φ16×1.2. The length of the first straight pipe section is 2100mm, the length of the second straight pipe section is 1700mm, and the length of the middle straight pipe section is 70mm. The bending radius of the joint of the spiral elbow section in the corresponding space is 130mm, and the center distance of the heat exchange tubes is arranged equally from the innermost layer of 500mm to the outermost layer of 700mm; the centers of the first and second space spiral elbow sections of the nine-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com