Assembling and positioning structure of main combustion hole bush on flame tube

A technology of positioning structure and main combustion hole, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of large assembly error of part slot position, large deviation of bush slot position, and slot axial direction. Poor consistency and other problems, to achieve the effect of reducing the workload of correction, no rework and repair, and stable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

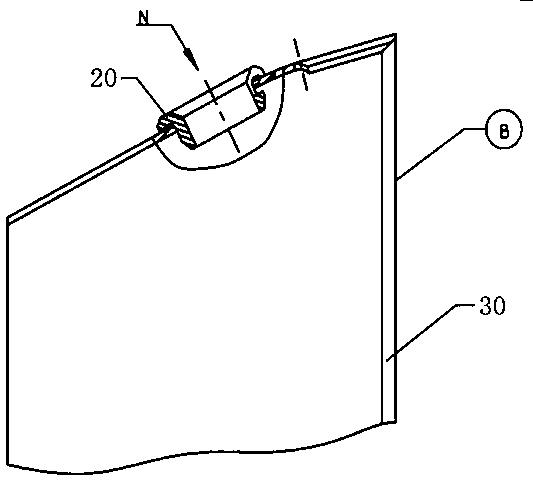

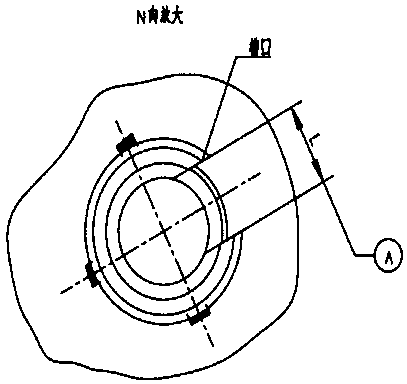

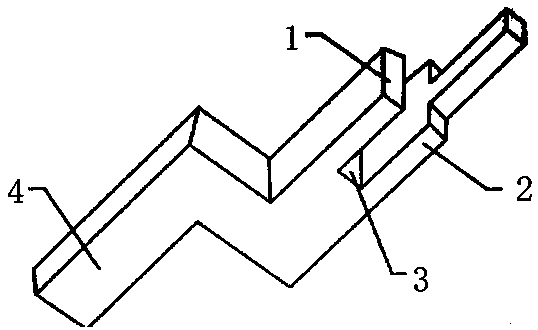

[0021] As shown in the figure, there is a circle of holes on the wall of the flame cylinder 30, and a main combustion hole bushing 20 needs to be installed in each hole. The main combustion hole bushing 20 is C-shaped, and the direction of the notch needs to be consistent. A positioning fixture 10 is designed to control the notch direction of the main combustion hole liner 20. The positioning fixture 10 is in a Z-shape as a whole, with one end being the handle part 4 and the other end being a clamping part. The outer splint 2, the positioning pin 5 extends from the outer splint 2, the width of the positioning pin 5 is the same as the width of the C-shaped notch of the main combustion hole liner 20, and the center line of the positioning pin 5 is on the same plane as the axis of the flame tube 30 . When the positioning fixture 10 is manufactured, ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com