Material level detecting device for pulverized coal bunker of power system

A technology of material level detection and power system, which is applied in the direction of measuring devices, lubrication indicating devices, engine lubrication, etc., can solve problems such as coal leakage, waste of resources, environmental pollution, etc., and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be further elaborated in conjunction with specific embodiments.

[0019] This case will be fully understood by the description of the following embodiments, so that those familiar with the art can complete it, but the embodiments of this case cannot be limited to its implementation form by the following.

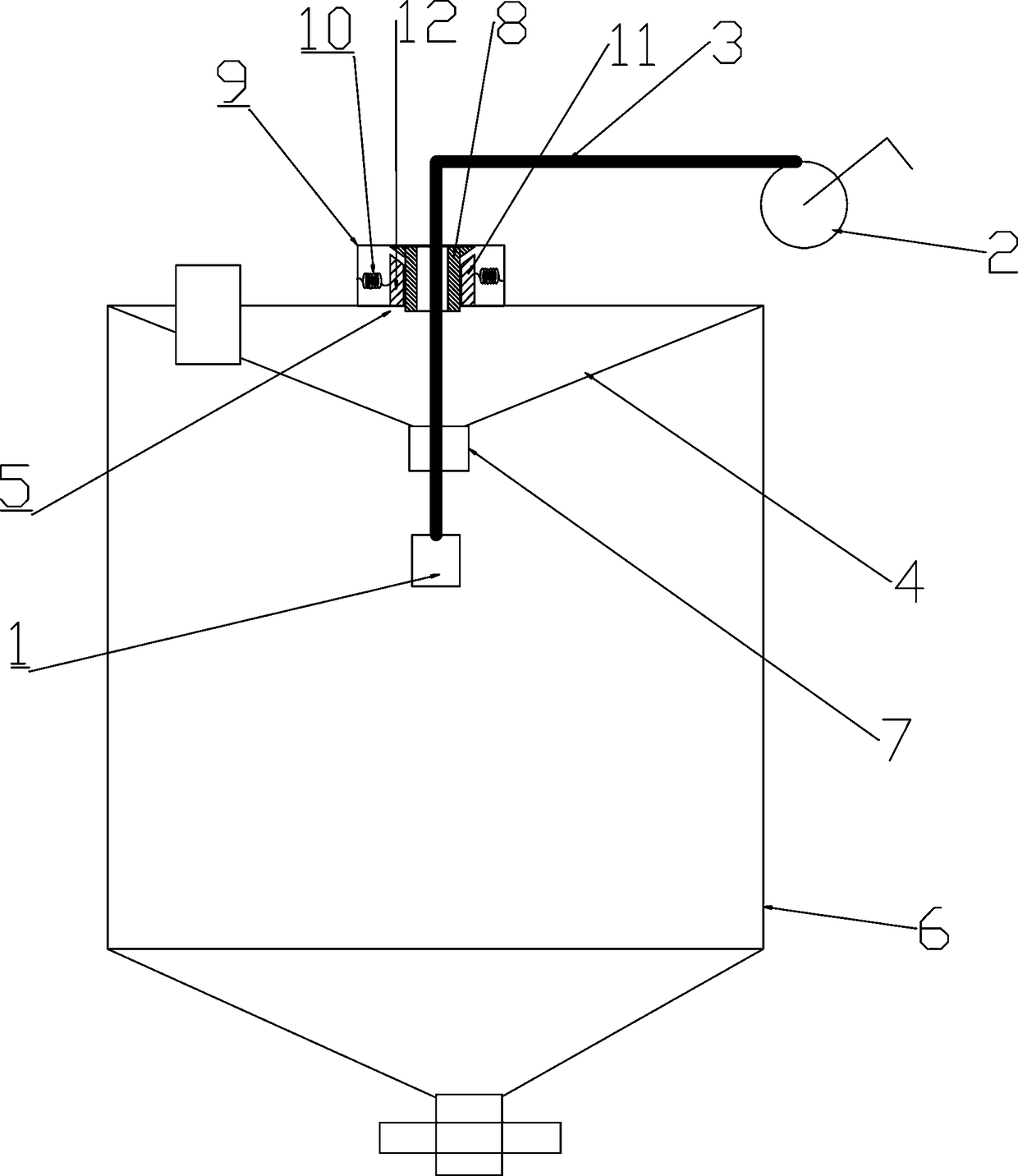

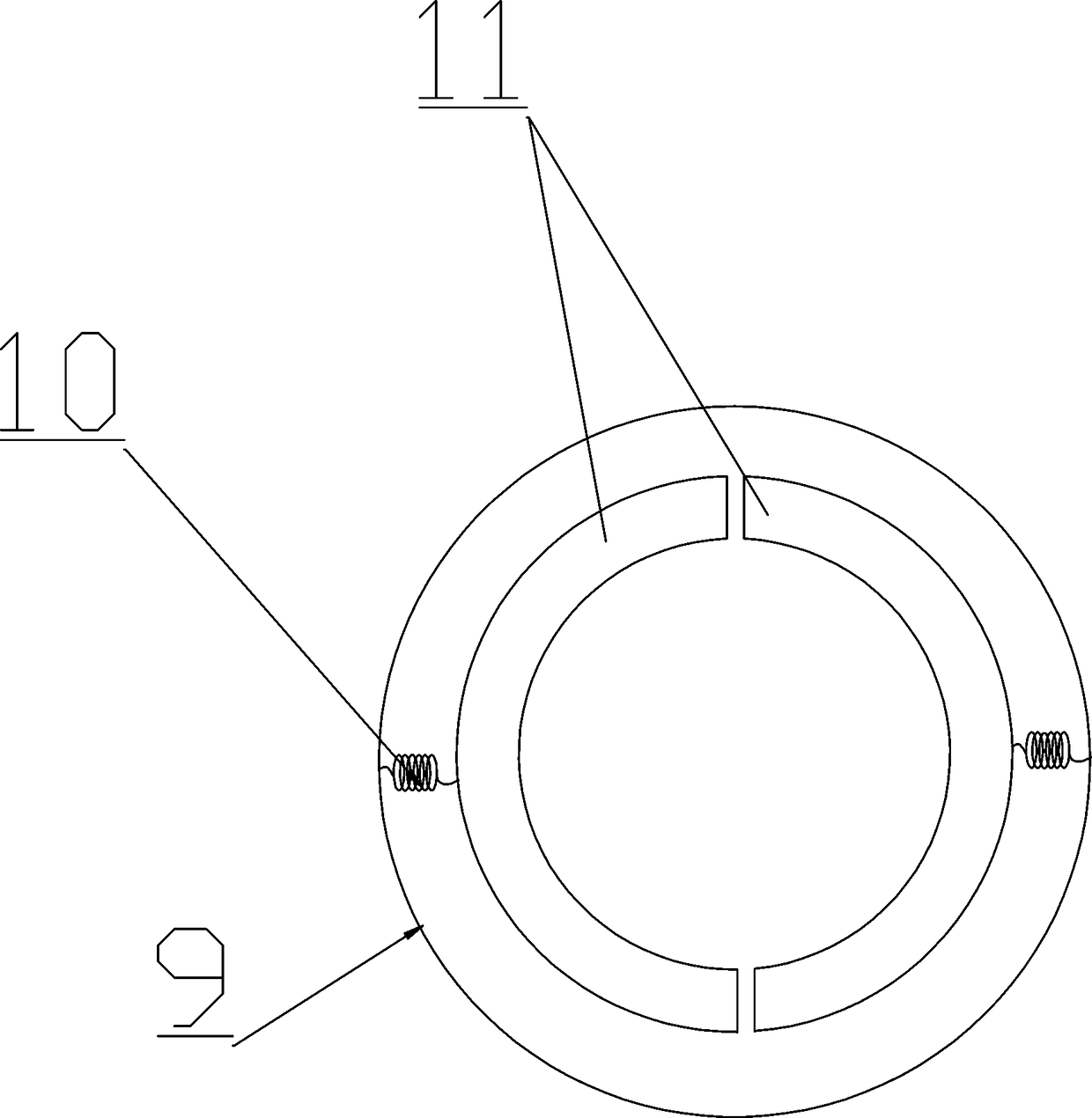

[0020] A material level detection device for a pulverized coal bin 6 in a power system, comprising a weight 1, a winding roller 2, a pull rope 3, a dustproof cover and a dustproof cavity 4 set on the pull rope 3, connected to a weight The stay rope 3 of the hammer 1 passes through the dust jacket and the dustproof chamber 4 that are sheathed on the stay rope 3, so as to ensure that the pulverized coal will not leak from the pulverized coal bin 6 during the material level measurement process.

[0021] The dust-proof cavity 4 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com