Liquid lens capable of realizing electronic control focusing

A liquid lens, focusing technology, used in lenses, optics, instruments, etc., can solve problems such as increasing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to illustrate the specific flow of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

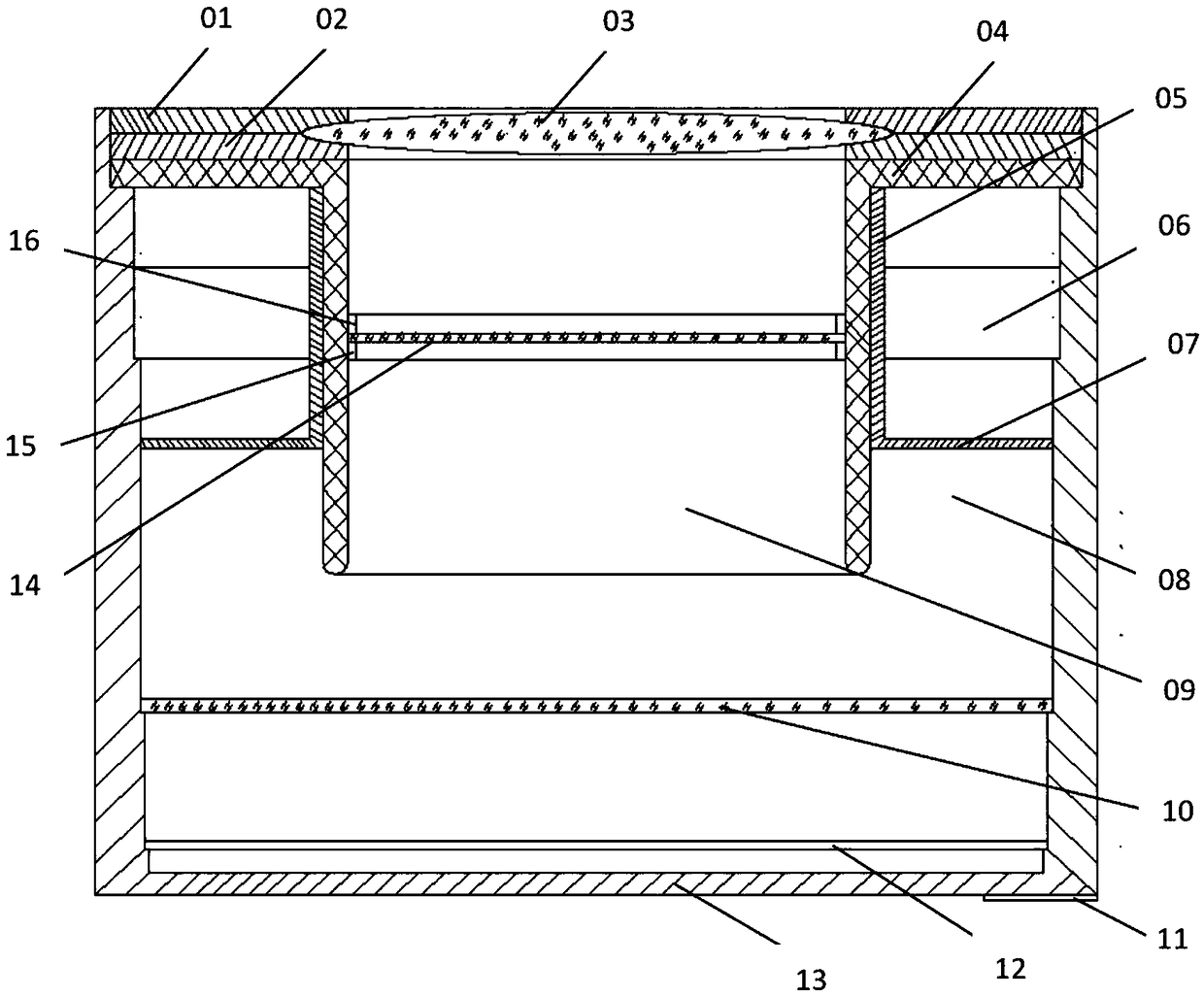

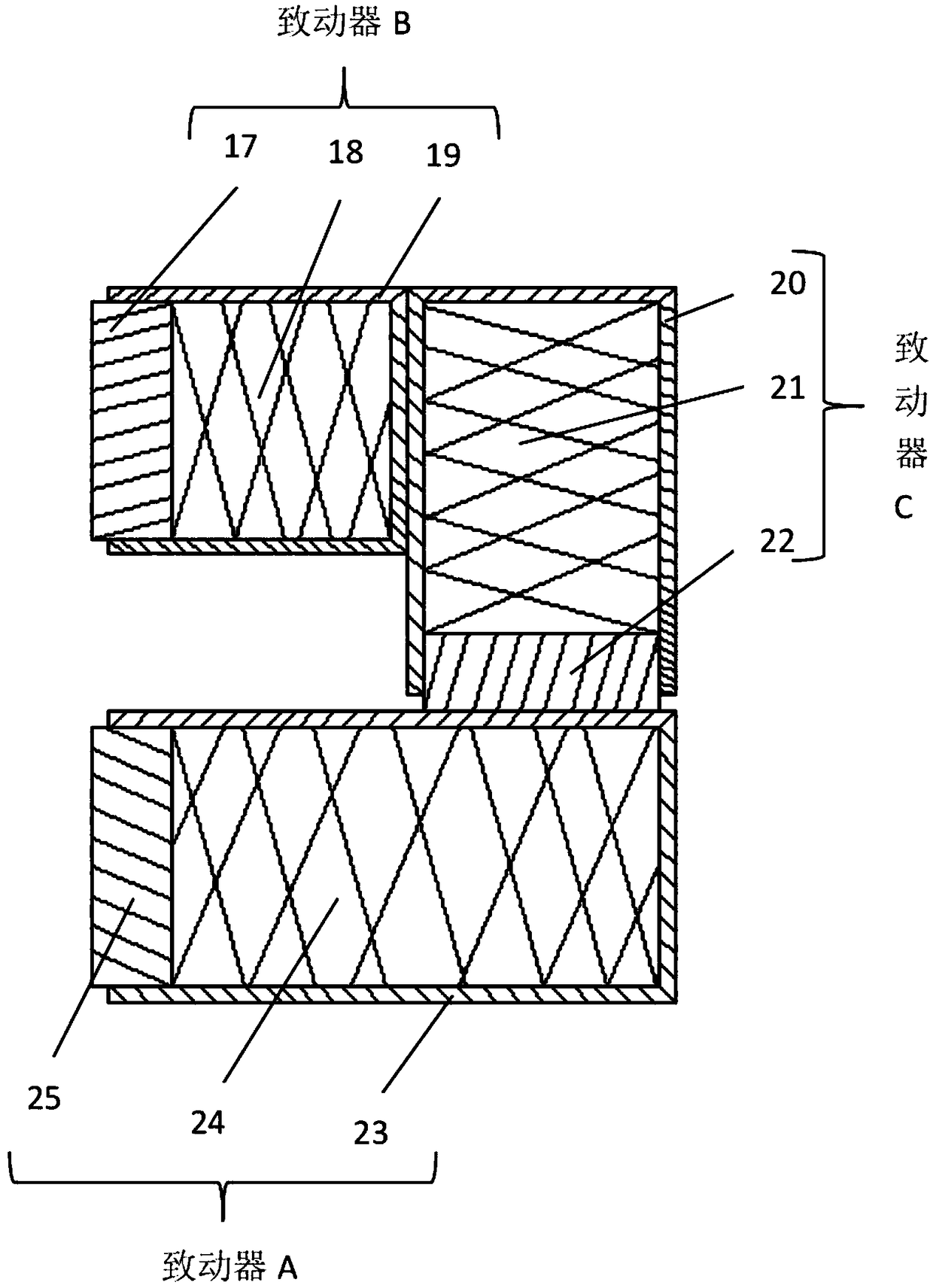

[0039] refer to figure 1 , an electronically controlled focusing liquid lens. The electronically controlled focusing liquid lens in the present invention includes: 01 lens fixing ring 1, 02 lens fixing ring 2, 03 lens window 1, 04 piezoelectric ceramic tube, 05 linear guide rail, 06 piezoelectric actuator, 07 pushing pressure film, 08 actuating cavity, 09 liquid cavity, 10 lens window 2, 11 lens external interface, 12 vision sensor, 13 lens housing, 14 sealing lens, 15 sealing ring 1, 16 sealing ring 2, 17 driving foot B, 18 pressure Electric ceramic stack B, 19 Actuator B shell, 20 Actuator C shell, 21 Piezoelectric ceramic stack C, 22 Drive foot C, 23 Actuator A shell, 24 Piezoelectric ceramic stack A, 25 Driver Foot A.

[0040] The lens fixing ring 1 (01) and the lens fixing ring 2 (02) are connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com