Doped fuel-clad combination for transmutation

A fuel and cladding technology, applied in the field of nuclear engineering, can solve the problems of long half-life and inability to fully utilize fissile resources, etc., and achieve the effects of offsetting negative reactivity, reducing cost and difficulty, and increasing life span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

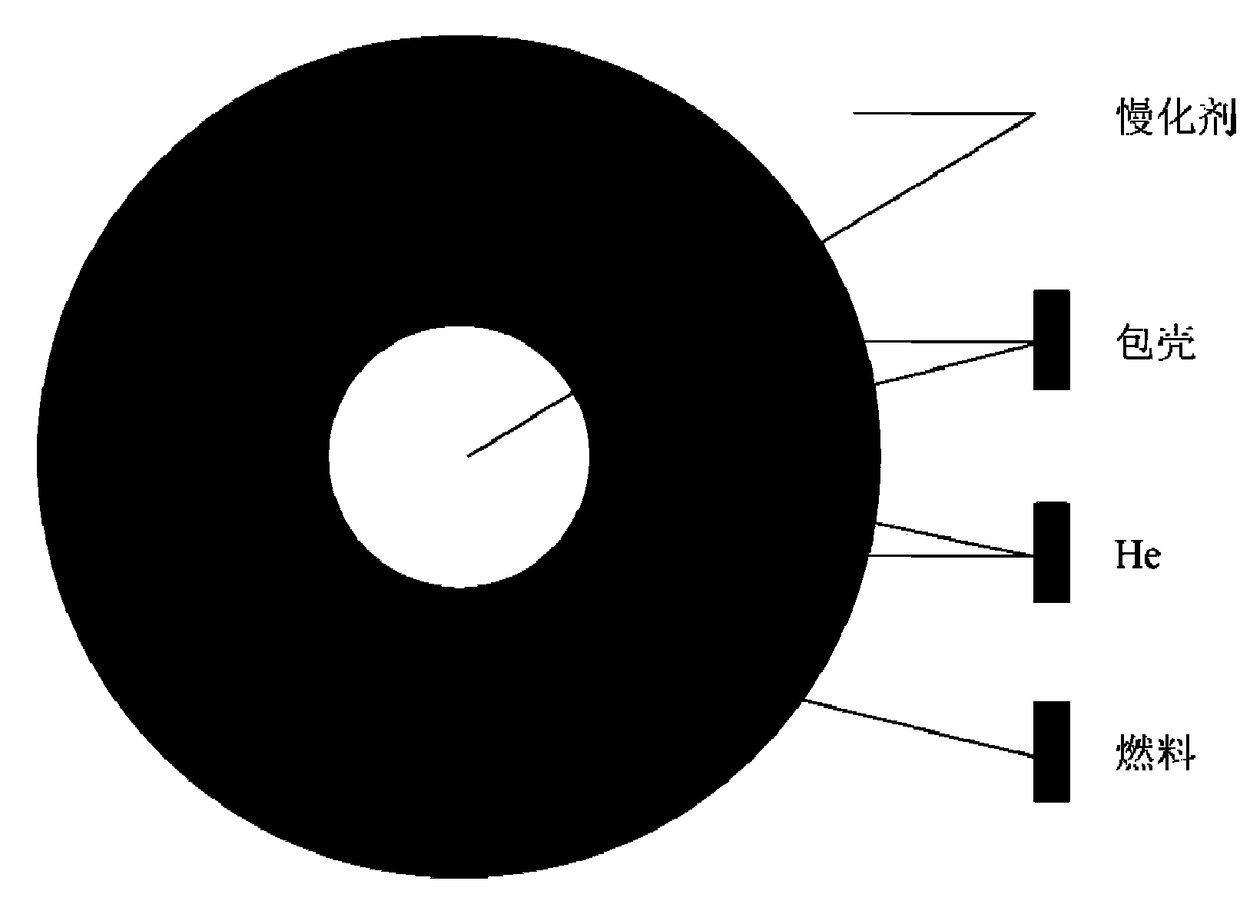

Method used

Image

Examples

Embodiment 1

[0031] The fuel rod of this embodiment is made of cylindrical U doped with long-lived minor actinides 3 Si 2 fuel and FeCrAl cladding, where U 3 Si 2 in fuel 235 The proportion of U is 4.9%, and the doped long-lived minor actinides are 237 Np, its mass percentage is 0.31%.

Embodiment 2

[0033] The fuel rod of this embodiment is made of cylindrical U doped with long-lived minor actinides 3 Si 2 fuel and FeCrAl cladding, where U 3 Si 2 in fuel 235 The proportion of U is 4.9%, and the doped long-lived minor actinides are 237 Np, 241 Am, 243 Am, 244 Cm and 245 Cm, the mass percentage of the sum of the five is 0.31%, and the mass ratio between the five is m ( 237 Np): m( 241 Am): m( 243 Cm): m( 244 Cm): m( 245 Cm) = 42:47:9:2:0.1.

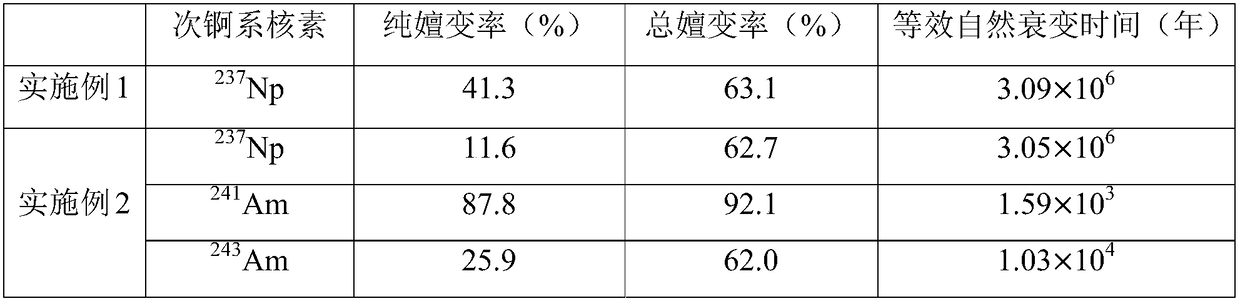

[0034] The transmutation rate of embodiment 1 and 2 is calculated, and calculation result is listed in the following table 1:

[0035] The transmutation rate calculation result of table 1 embodiment 1 and 2

[0036]

[0037] Calculations show that the loaded long-lived minor actinides can be reduced by transmutation while maintaining the same lifetime length as the existing fuel-cladding combination. The transmutation rates of non-transmutation reactors are all less than 0, so it can be seen that the doped accident-to...

Embodiment 3

[0039] The fuel rod of this embodiment is made of cylindrical U doped with long-lived minor actinides 3 Si 2 Fuel and SiC cladding constitute, where U 3 Si 2 in fuel 235 The proportion of U is 4.9%, and the doped long-lived minor actinides are 237 Np, its mass percentage is 0.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com