An upper winding device with high adaptability for a cable crossover

An adaptable, cable fork technology, applied in the field of cable production auxiliary equipment, can solve problems such as outstanding safety problems, increased labor intensity of workers, and low efficiency of manual loading, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

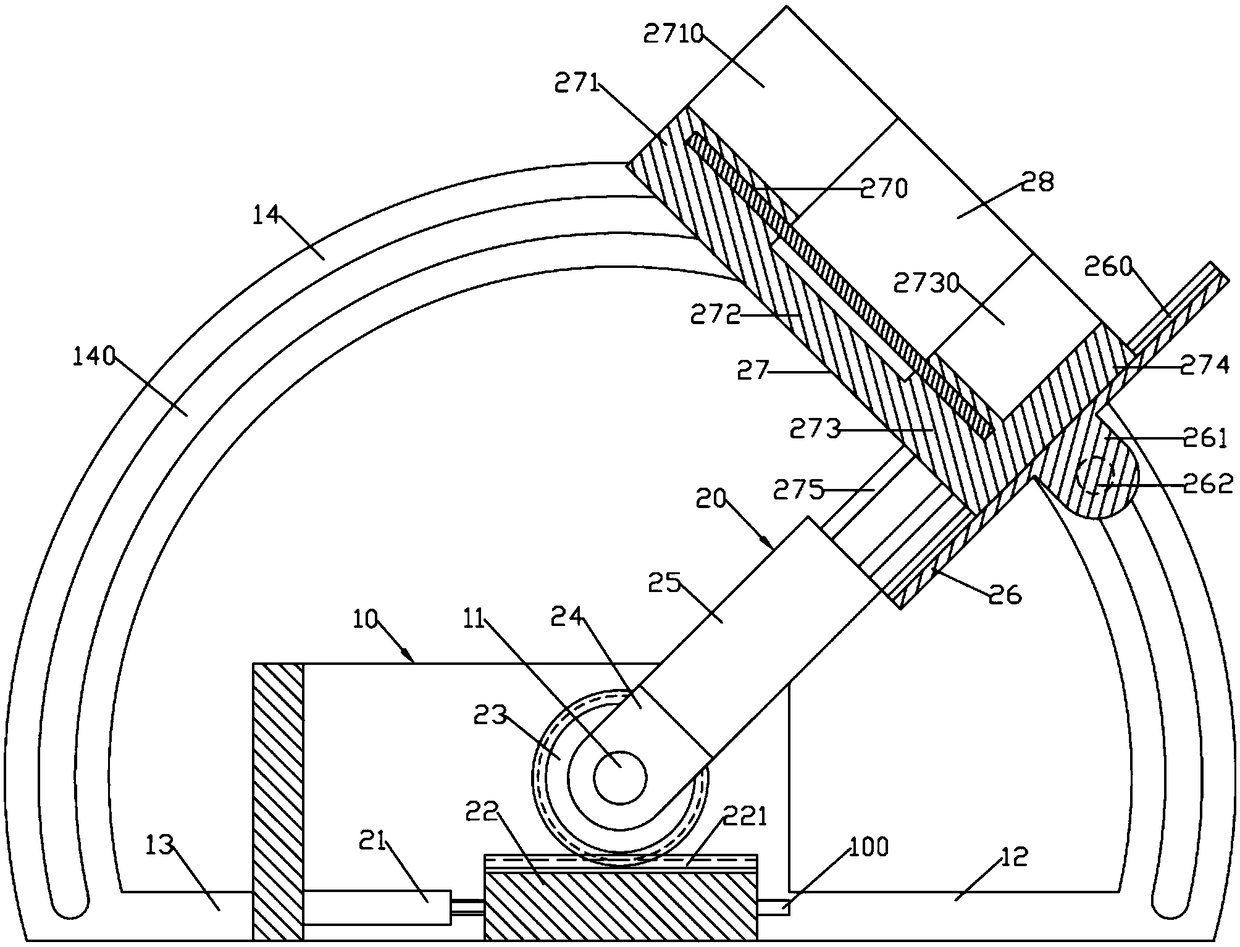

[0012] like figure 1 As shown, a high-adaptability upper plate device for a cable fork winch includes a frame 10 and a swing upper plate device 20; The fork 24 that is arranged symmetrically; A pair of fork 24 is respectively hinged on a pair of lateral parts of frame 10; A height adjustment cylinder 25 is arranged between a pair of fork 24; The length direction is equal; the piston rod of the height adjustment cylinder 25 is fixed with a wire reel limiter 27; the wire reel limiter 27 includes an upper end support plate 271 and a lower end support plate 273; the upper end support plate 271 and the lower end support plate 273 are connected The rods 272 are connected together and the upper end support plate 271 is located directly above the lower end support plate 273; the upper end support plate 271 is formed with a semi-cylindrical groove-shaped upper limit groove 2710 that penetrates up and down on the end surface away from the height adjustment cylinder 25; the lower end sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com