A LED light line splitting connection mount assembly

A technology of LED lighting and split-line connection, which is applied in the direction of line/collector parts, connection, conductive connection, etc., can solve the problems that affect the overall line layout aesthetics and conductive effect, low connection strength, time-consuming and labor-intensive, etc. Achieve the effect of improving the appearance quality of the wiring, improving the conductive effect, and reducing the electrical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

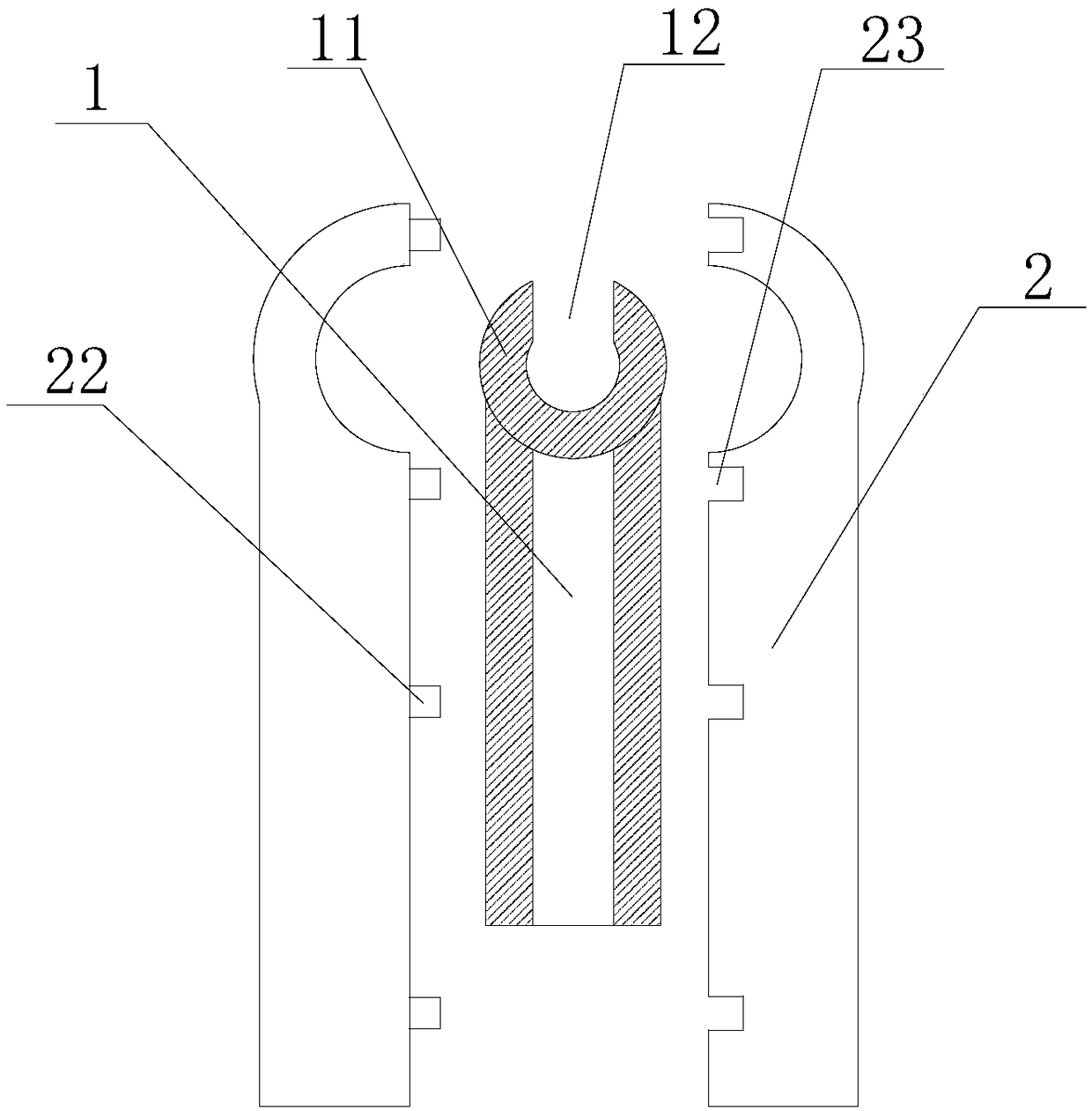

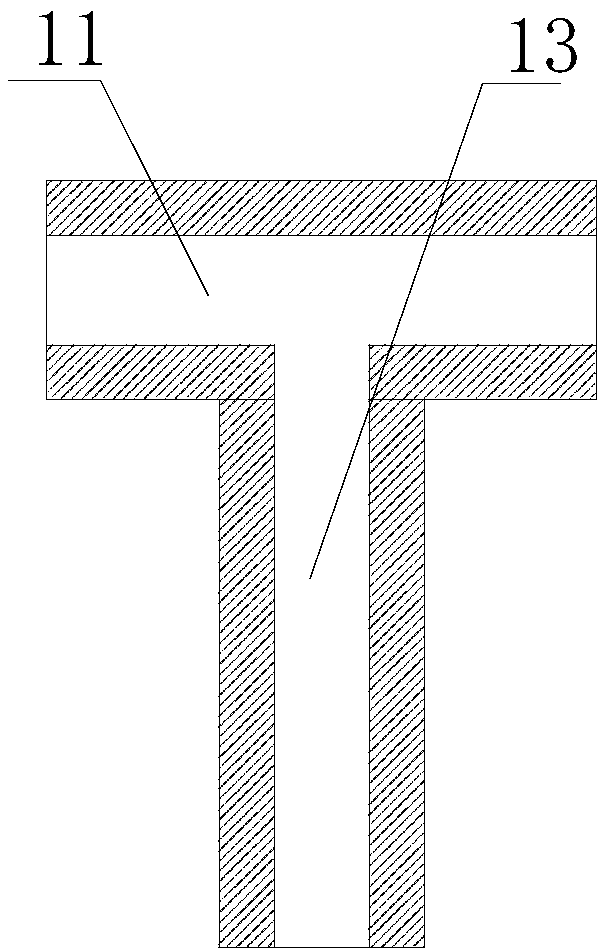

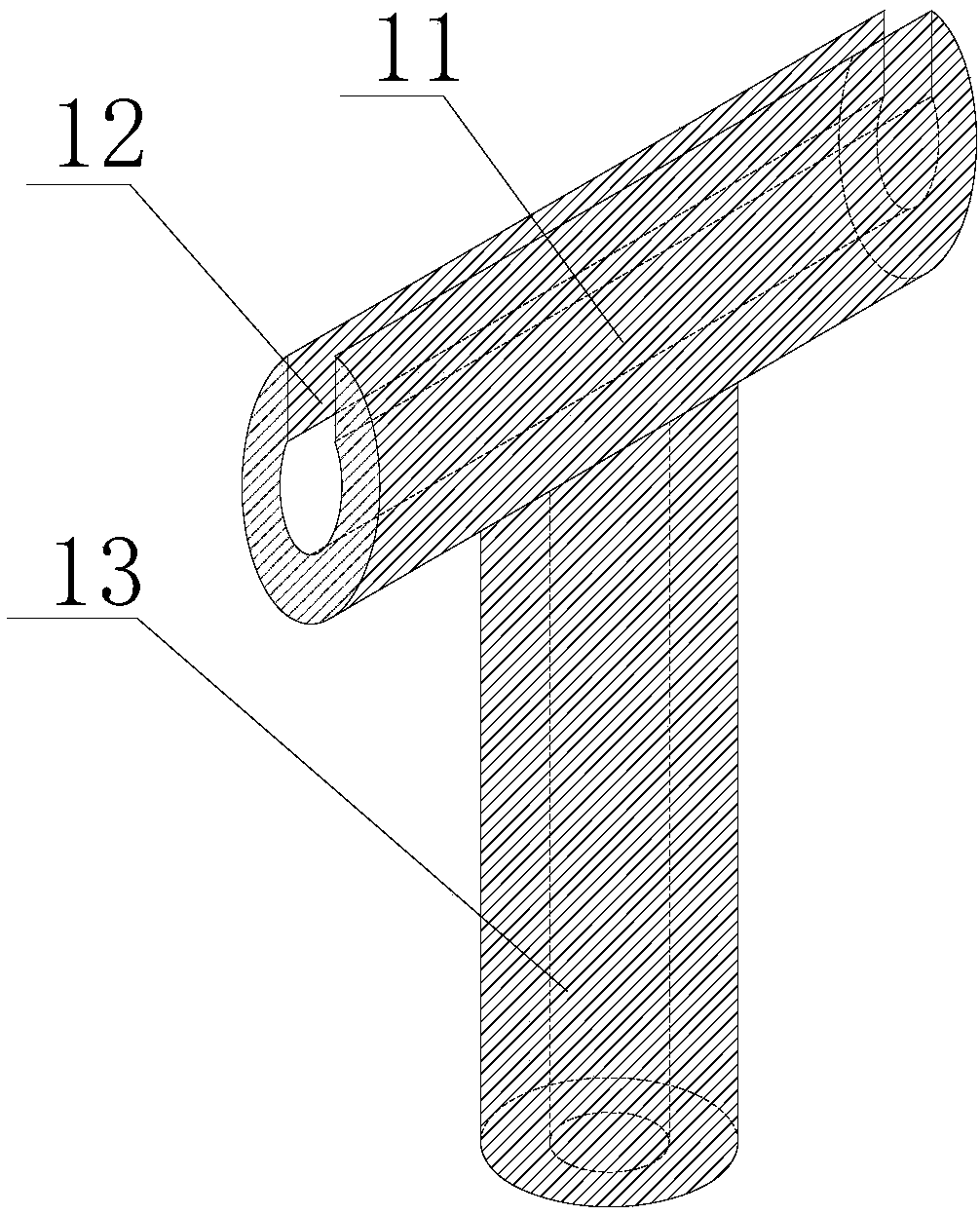

[0023] Such as Figure 1-8 As shown, a LED lighting line branching connection installation assembly includes a branching connection terminal and wiring pliers; the branching connection terminal includes a conductive connecting tube 1 and an insulating protective sleeve, and the conductive connecting tube 1 is a T-shaped tee Pipe structure, the upper wall of the horizontal pipe 11 of the conductive connecting pipe 1 has a radial opening 12 along the center of the pipe wall, and the width of the opening 12 is slightly smaller than the inner diameter of the horizontal pipe 11; T-shaped insulating sheet 2, the length of the T-shaped insulating sheet 2 is slightly longer than the length of the conductive connecting pipe 1, grooves 21 are symmetrically opened on the inner side walls of the two insulating sheets 2, and the grooves 21 and the The outer wall of the conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com