Electrical connector assembly

An electrical connector, plug connector technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problem of heat dissipation of the unsolved power connector, and cannot guarantee the stable contact between the first terminal and the second terminal. , affecting the function of the connector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

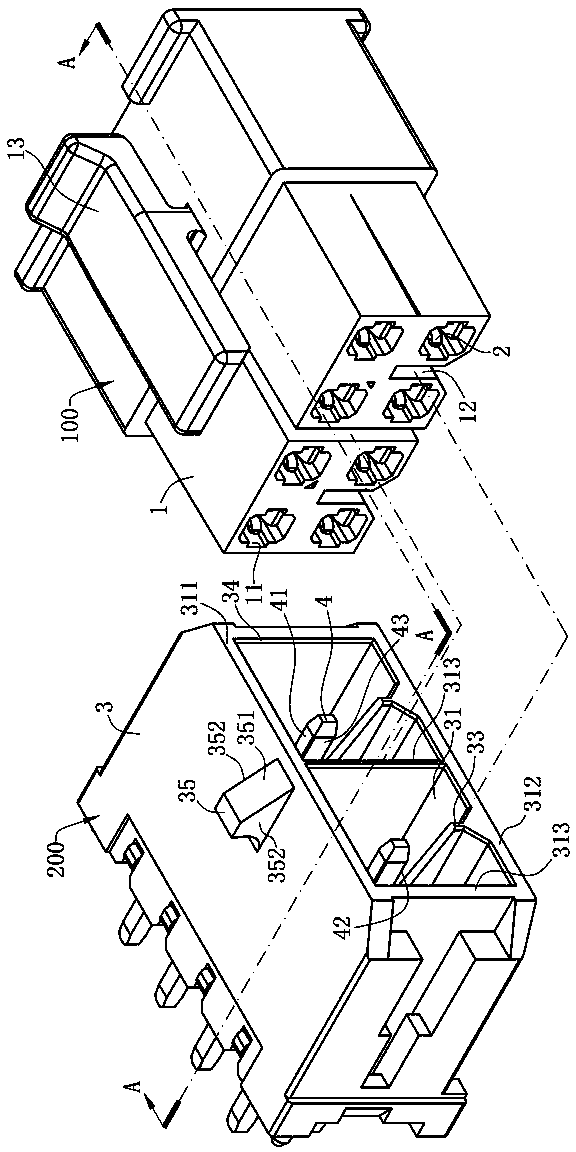

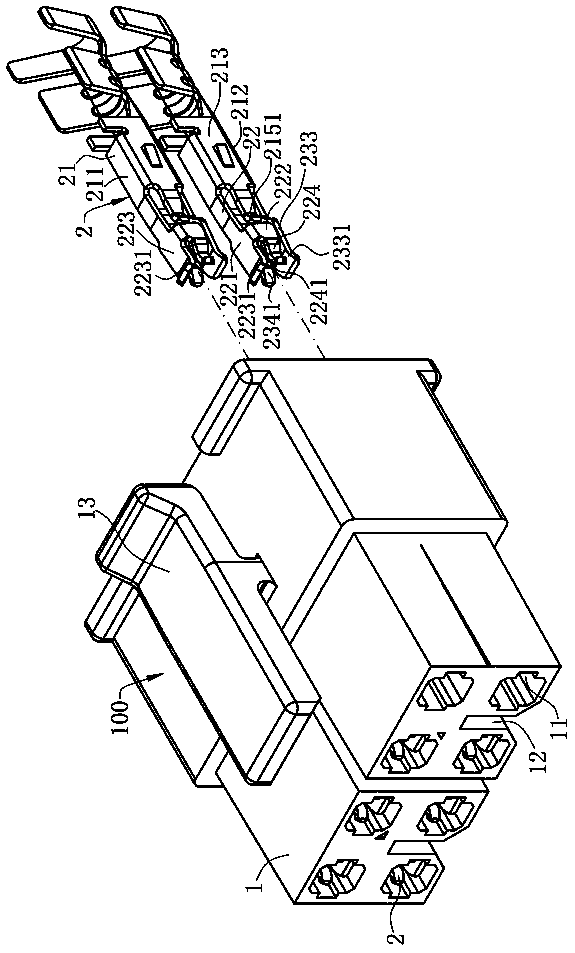

[0045] Please refer to Figure 1 to Figure 9 , is a main embodiment of an electrical connector combination of the present invention, which includes a plug connector 100 and a socket connector 200 .

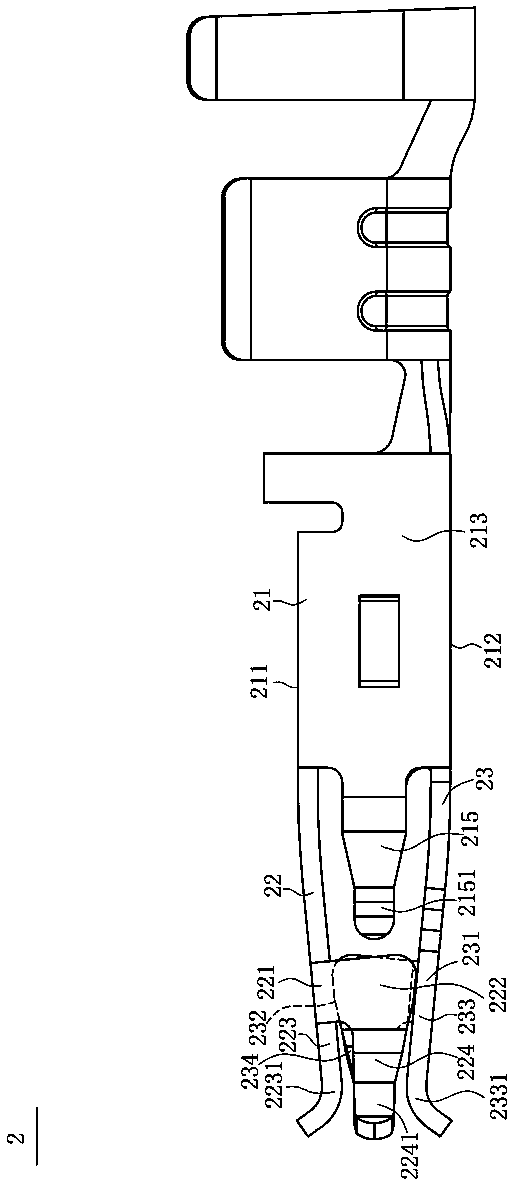

[0046] Please refer to Figure 1 to Figure 9 , the plug connector 100 includes a first body 1 and a plurality of first terminals 2 . The first body 1 has four receiving holes 11 divided into upper and lower rows, each row has two receiving holes 11, and a slot 12 is arranged between the two receiving holes 11 in the lower row. The first body 1 is provided with a locking arm 13 on a side away from the hole 12 outside the receiving hole 11 , and the locking arm 13 is perpendicular to the hole 12 . A plurality of first terminals 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com