A new type of cable bridge

A cable bridge, a new type of technology, applied in the direction of electrical components, etc., can solve the problems of large traction force, large friction force, and cable winding, etc., to achieve the effect of reducing traction force, small friction force, and avoiding fuzzing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

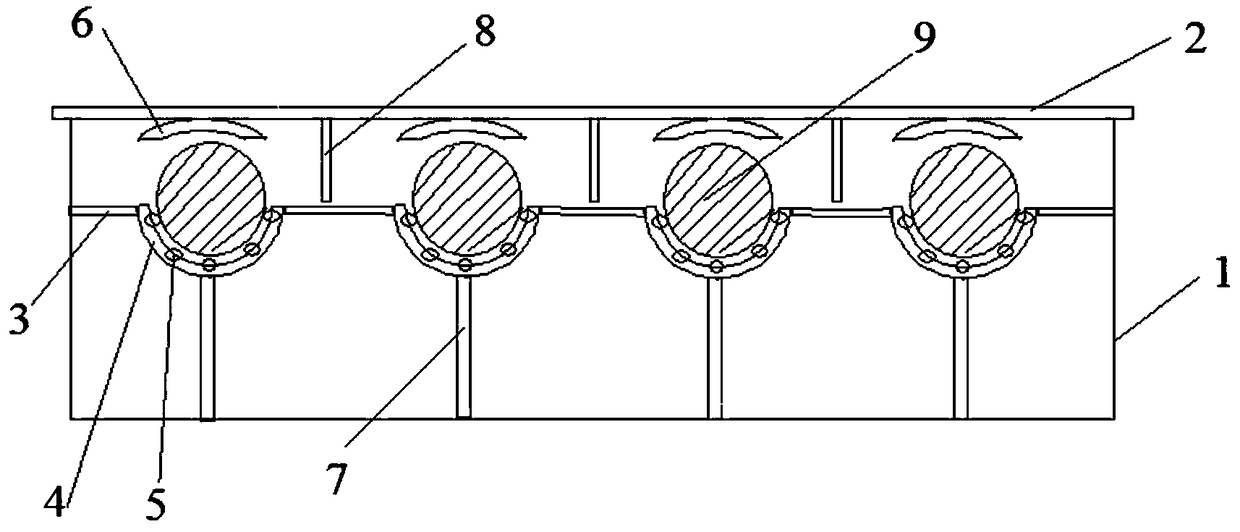

[0014] like figure 1 As shown, a new type of cable tray includes a main body 1 and a cover plate 2. The inner walls on both sides of the main body 1 are connected with load-bearing plates 3. The load-bearing plate 3 is provided with several concave plates 4 along the width direction of the bridge. Inside the concave plates 4 Inlaid with balls 5, the lower end of the concave plate 4 is connected to the upper end of the support rod 7, the lower end of the support rod 7 is arranged on the bottom plate of the main body part 1, the concave plate 4 is used to accommodate the lower part of the cable 9, and the lower surface of the cover plate 2 is connected. There is a buckle part 6, and the buckle par...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap