Bending following material support device

A follow-up and material-supporting technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of no control system, unsatisfactory use, and unguaranteed safety and stability, so as to reduce the cost of upgrading, Good prospects for use and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

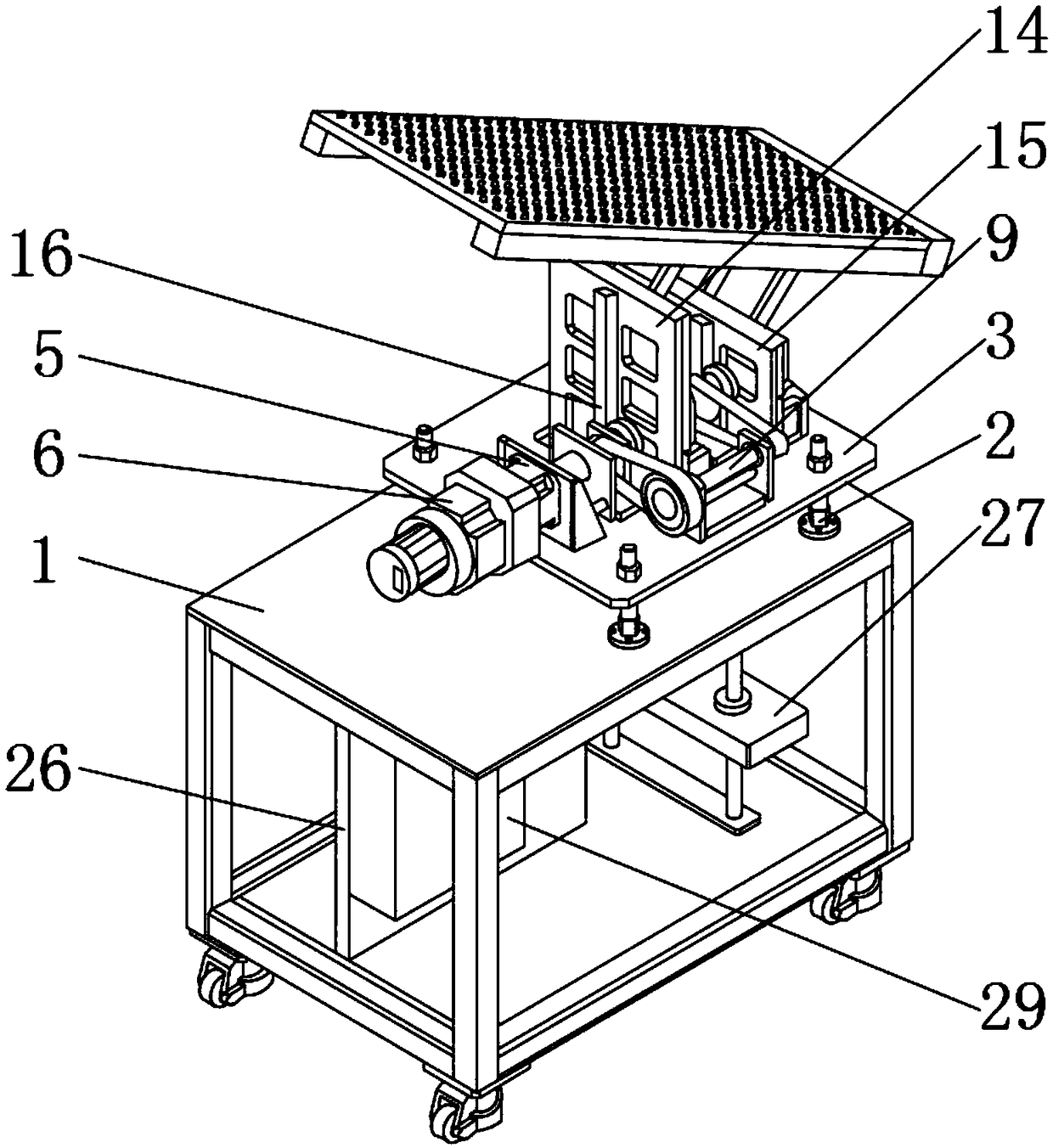

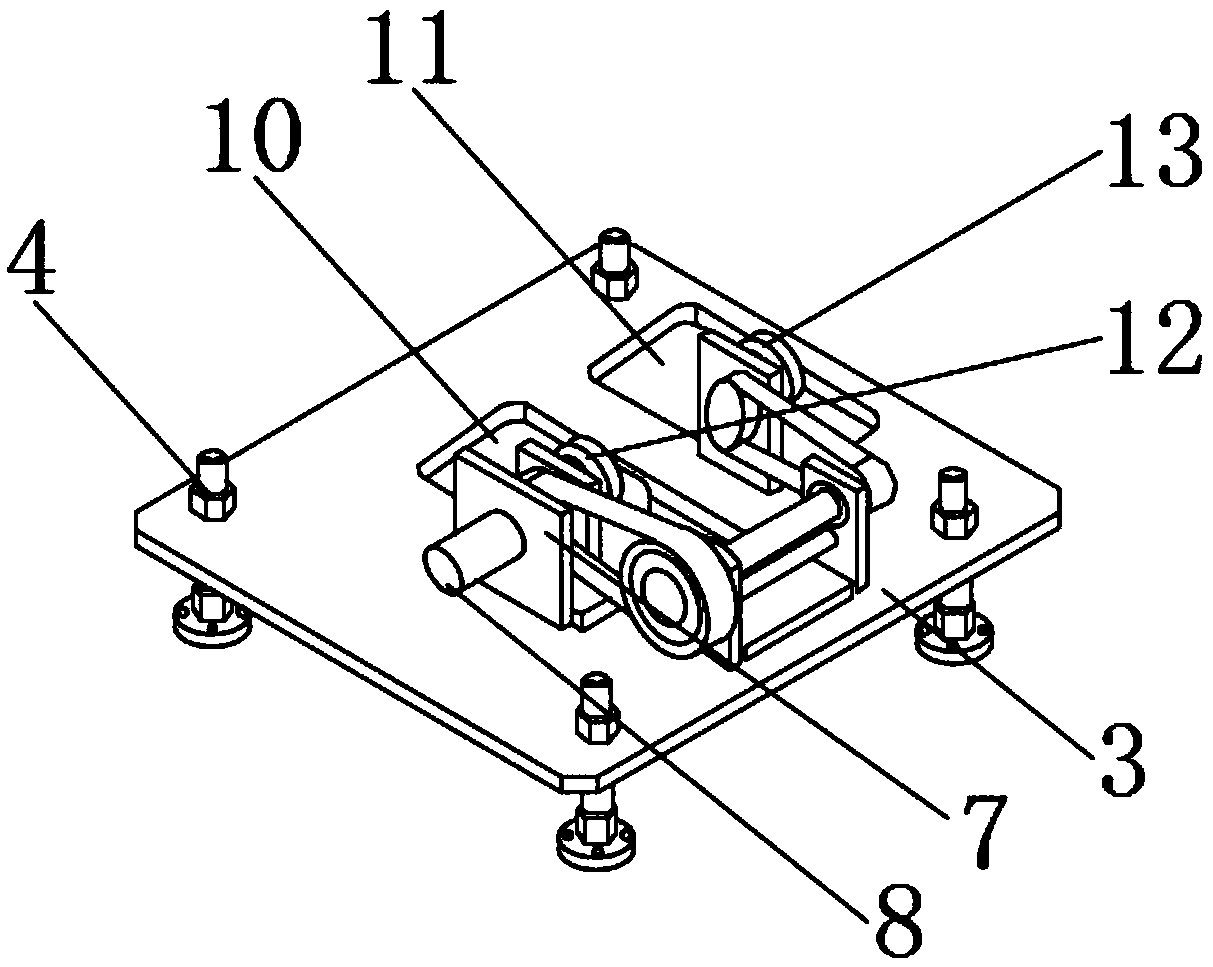

[0028] Such as Figure 1-5 As shown, a bending follow-up supporting device includes a frame 1, four sets of screws 2 are fixedly installed on the outer surface of the upper end of the frame 1, and the upper ends of the four sets of screws 2 are provided with a main mounting plate 3. The upper end of the plate 3 is fixedly installed with four sets of nuts 4, and the four sets of screws 2 correspond to the four sets of nuts 4 one-to-one. The upper side of the main mounting plate 3 is fixedly installed with a motor mount 5, and the upper end of the motor mount 5 is fixedly installed There is a motor 6, the rear end of the motor mounting seat 5 is fixedly installed with a support frame 7, one side of the motor 6 is provided with a rotating shaft 8, and the rotating shaft 8 penetrates the inner center of the support frame 7, and one side of the support frame 7 is provided with a synchronization With a deceleration structure 9, the main mounting plate 3 is provided with a main liftin...

Embodiment 2

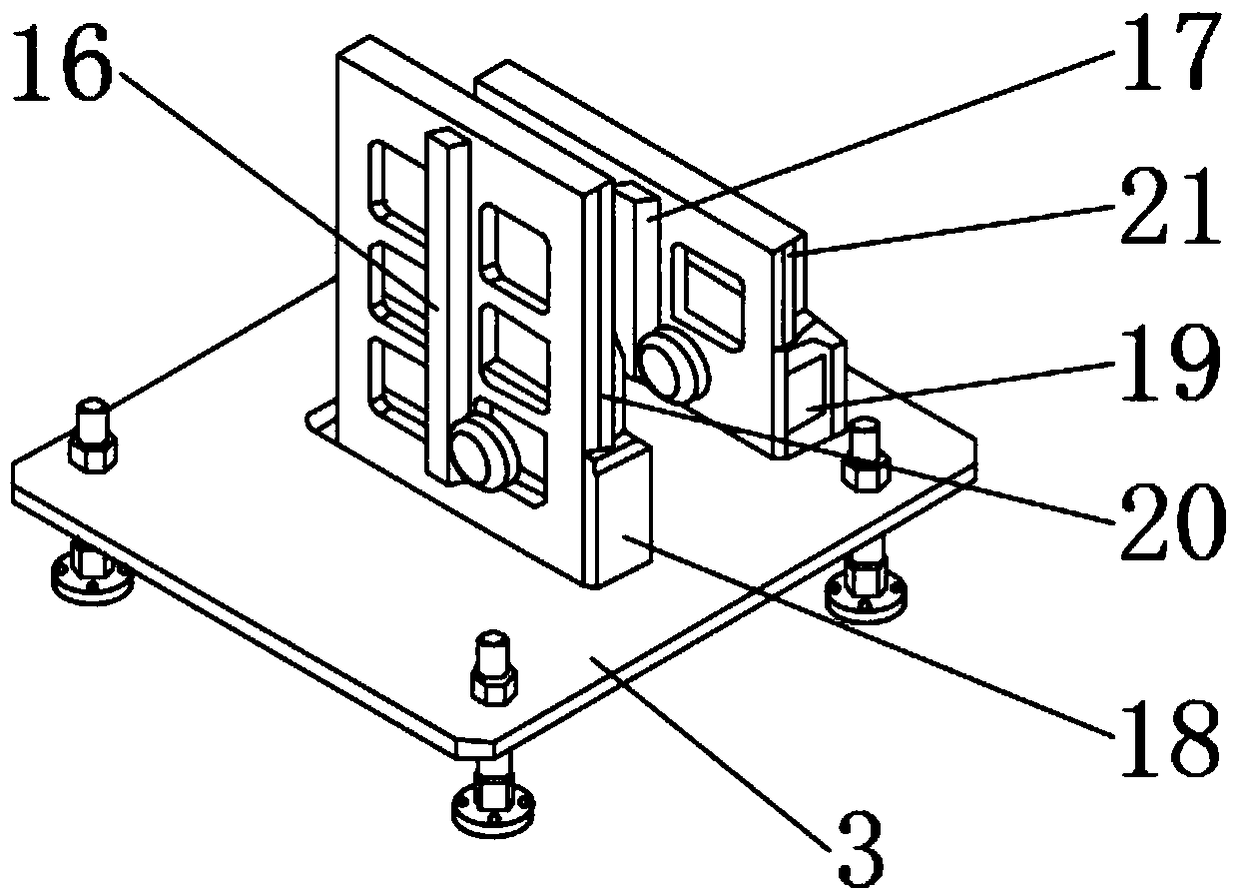

[0030] Such as Figure 1-5 As shown, the No. 1 guide rail 20 is movably connected with the No. 1 slide block 18, the No. 2 guide rail 21 is movably connected with the No. 2 slide block 19, and the No. 1 guide rail 20 is movably connected with the No. 1 slide block 18, and the No. 2 guide rail 21 and the No. 2 slide block are movably connected. 19 all constitute a sliding rail pair, the first gear 12 is movably connected with the first rack 16, the second gear 13 is movably connected with the second rack 17, and the first gear 12 is movably connected with the first rack 16 and the second gear 13 The second rack 17 constitutes a rack and pinion pair. The synchronous belt reduction structure 9 is composed of a bracket, a transmission shaft, a main transmission belt and a secondary transmission belt. The first gear 12 is movably connected with the transmission shaft through the main transmission belt, and the second gear 13 is connected to the transmission shaft. The main lifting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com