Pouring die storing device for steel manufacturing

A technology for pouring molds and steel, applied in the field of steel manufacturing, can solve the problems of molten steel splashing out, molten steel falling down, hurting workers, etc., and achieve the effects of preventing dumping, increasing blocking area, and blocking sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

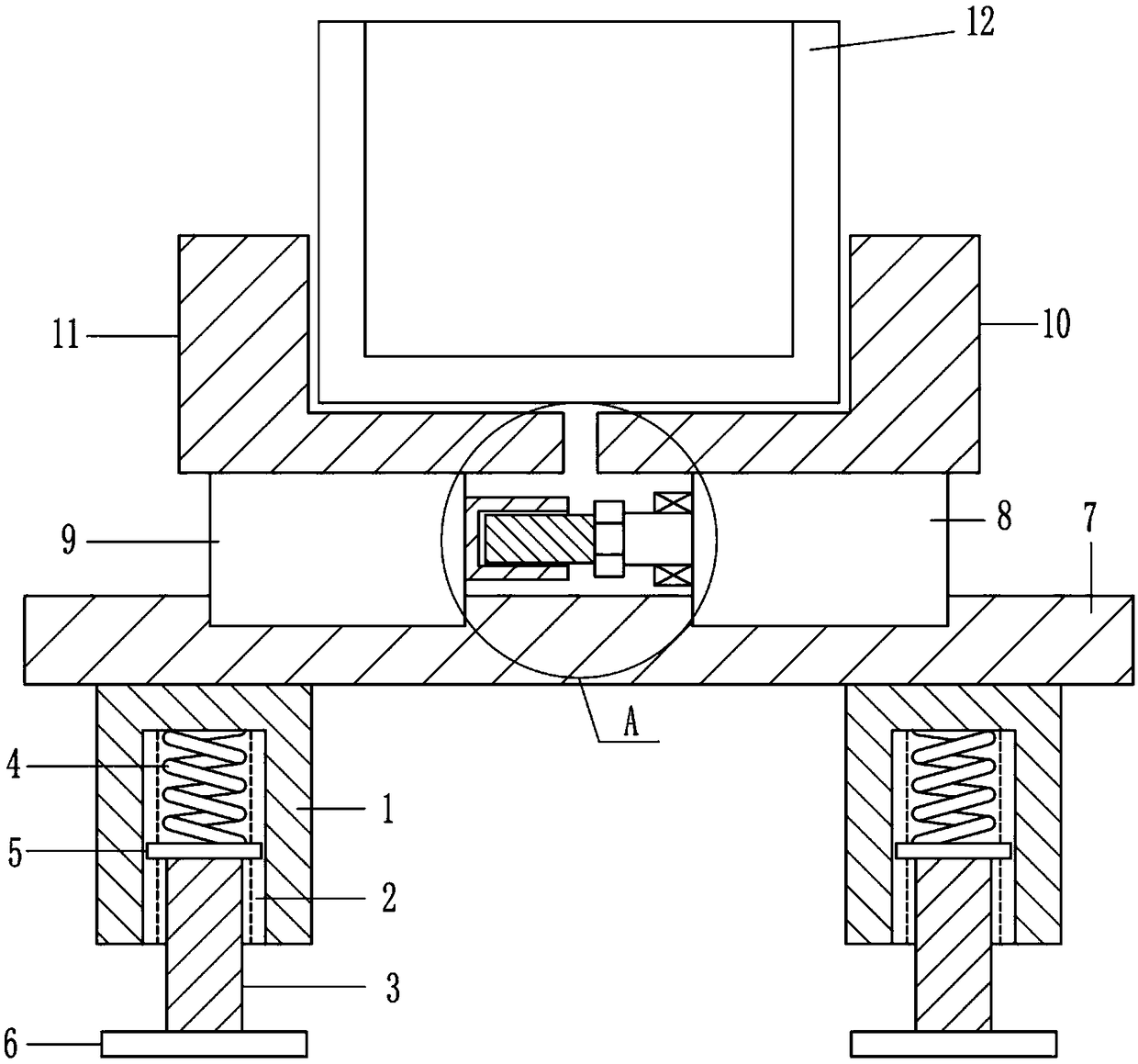

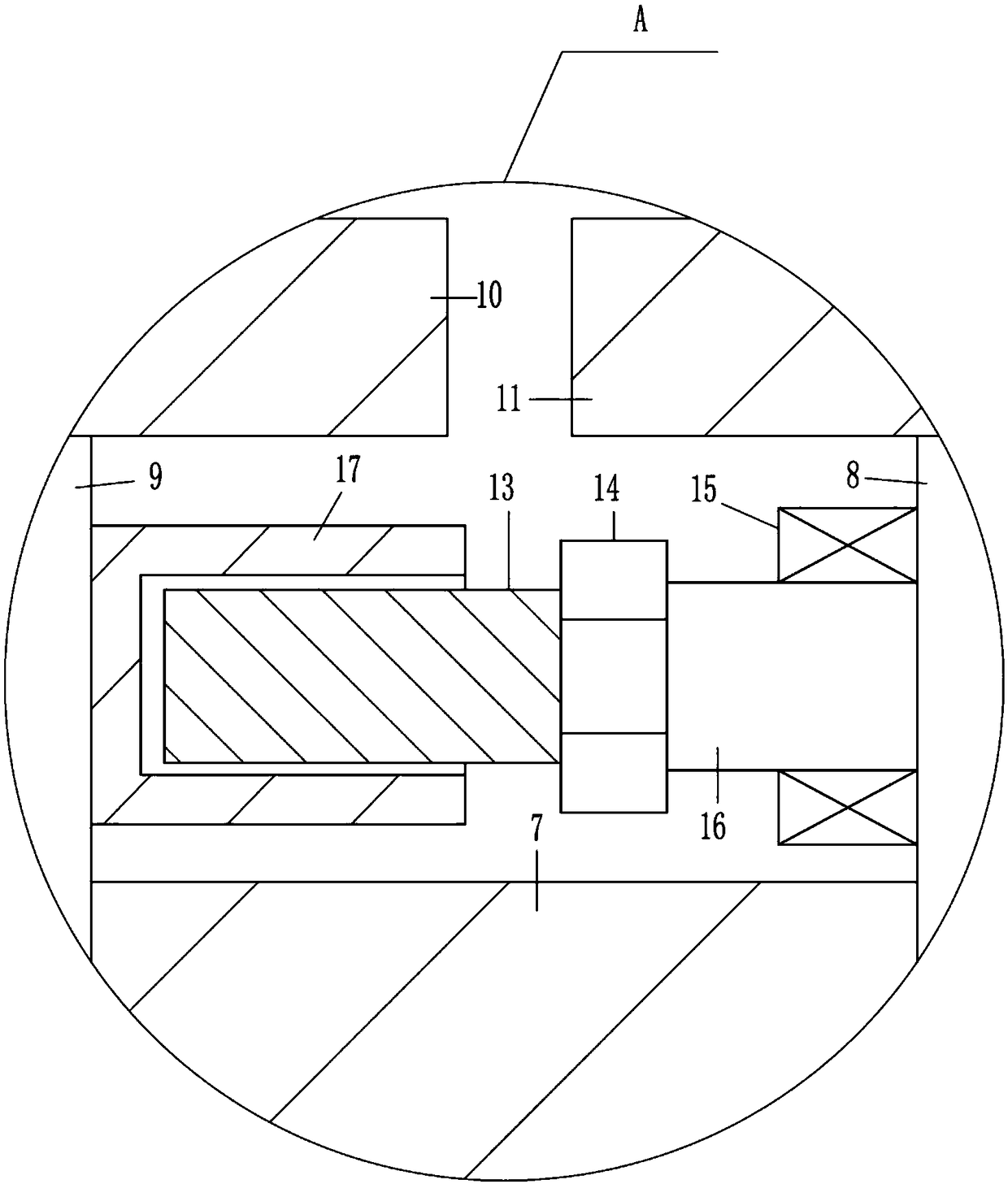

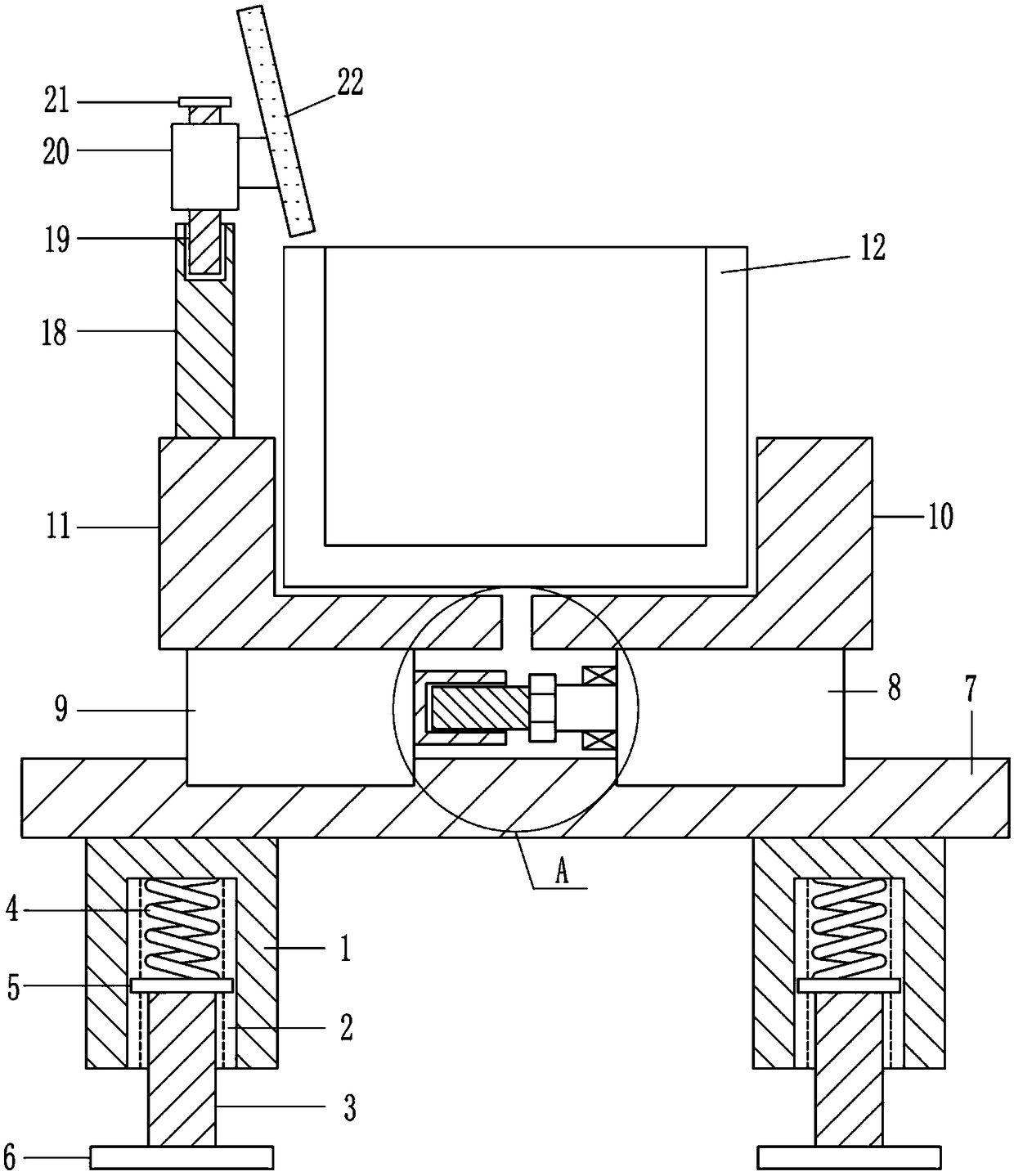

[0023] A pouring mold placement device for iron and steel fabrication, such as Figure 1-7 As shown, it includes a support tank 1, a telescopic rod 3, an elastic member 4, a first slider 5, a support plate 6, a slide rail 7, a second slider 8, a third slider 9, and a first L-shaped shelf 10. The second L-shaped placing frame 11, pouring container 12, screw rod 13, roller 14, bearing seat 15, rotating shaft 16 and threaded groove body 17; two supporting groove bodies 1 are fixedly connected to the bottom surface of slide rail 7 in turn, and the supporting groove body 1 is provided with a chute 2; the telescopic rod 3 is inserted into the support tank 1, and is slidably connected to the chute 2 through the first slider 5; the first slider 5 is connected to the inner top of the support tank 1 through the elastic member 4; The support plate 6 is fixed on the bottom of the telescopic rod 3; the first L-shaped shelf 10 is slidably connected to the slide rail 7 through the second sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com