Patents

Literature

34results about How to "Increase blocking area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

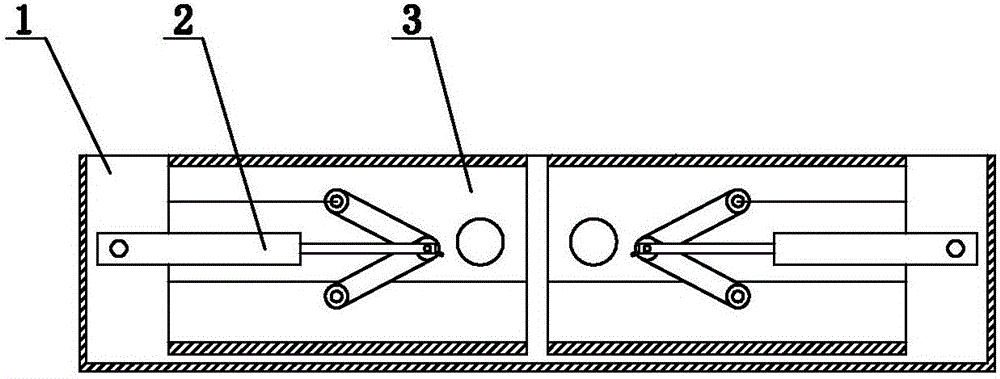

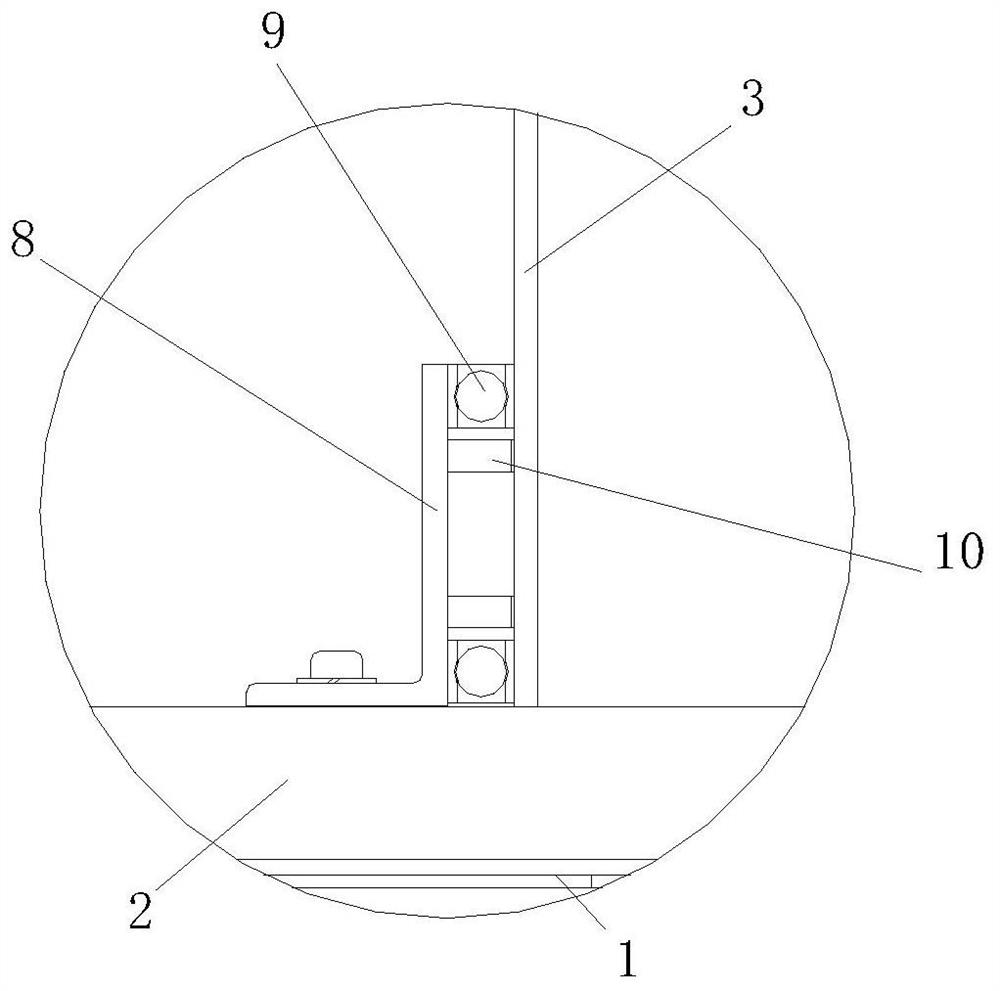

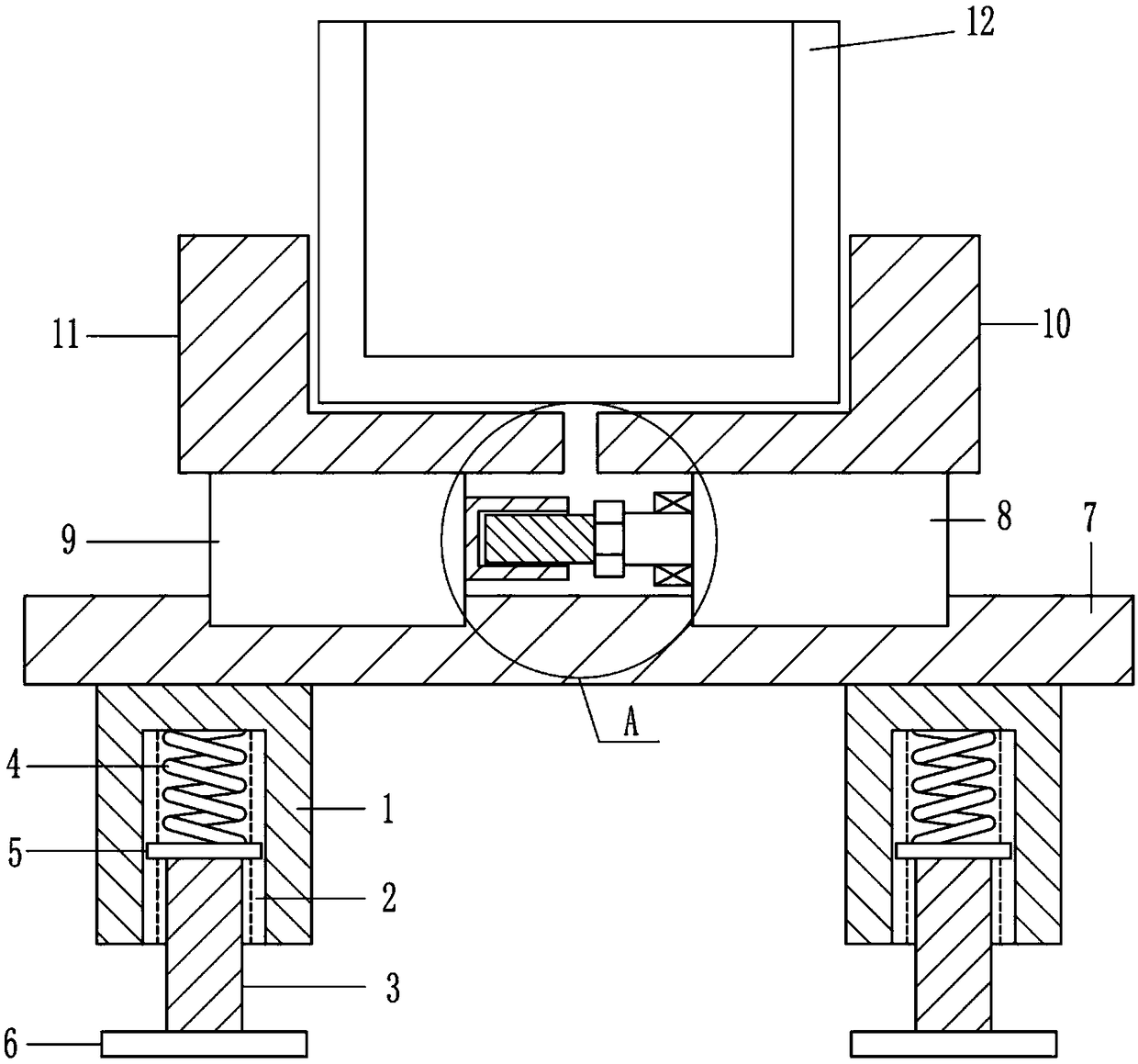

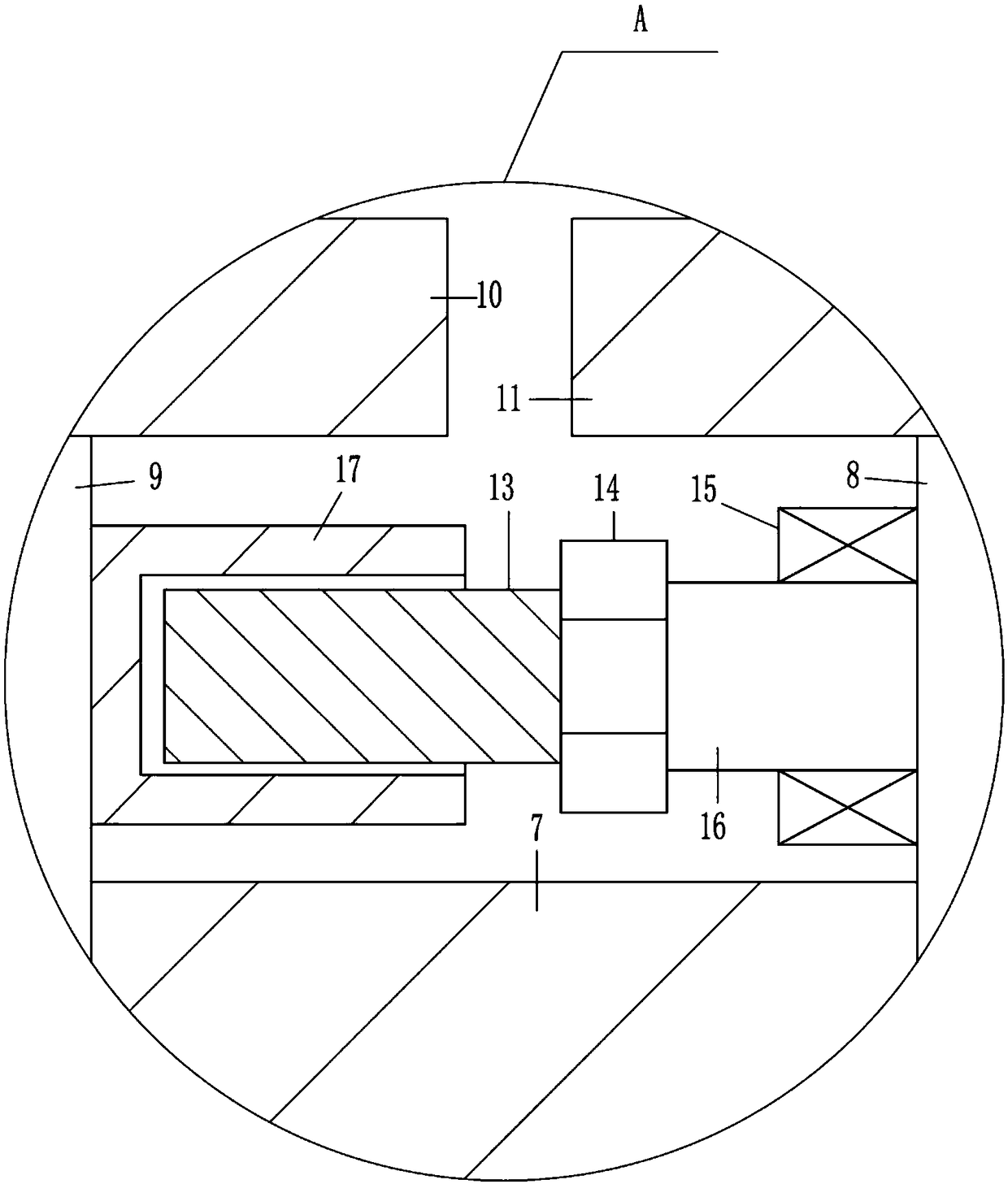

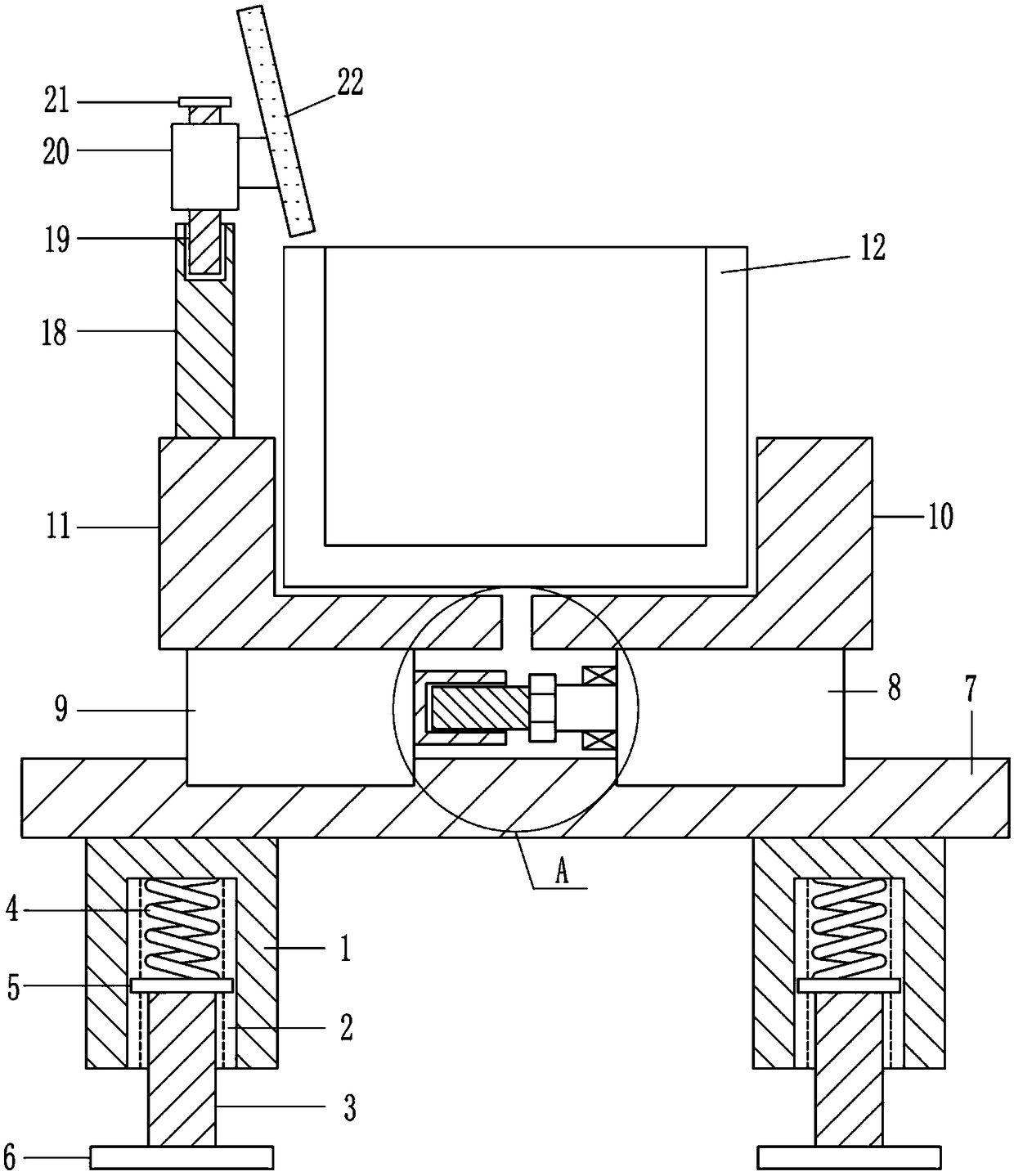

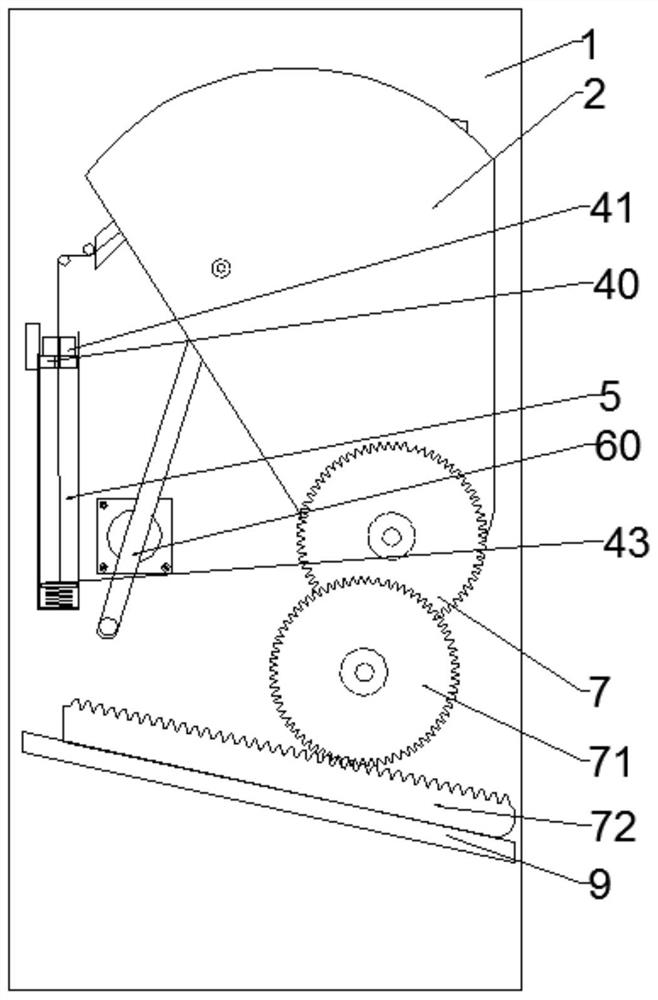

Management device for preventing random occupation of charging space and management method thereof

InactiveCN106355655AOccupation PreventionAvoid leavingTicket-issuing apparatusApparatus for hiring articlesObject detectionPower management

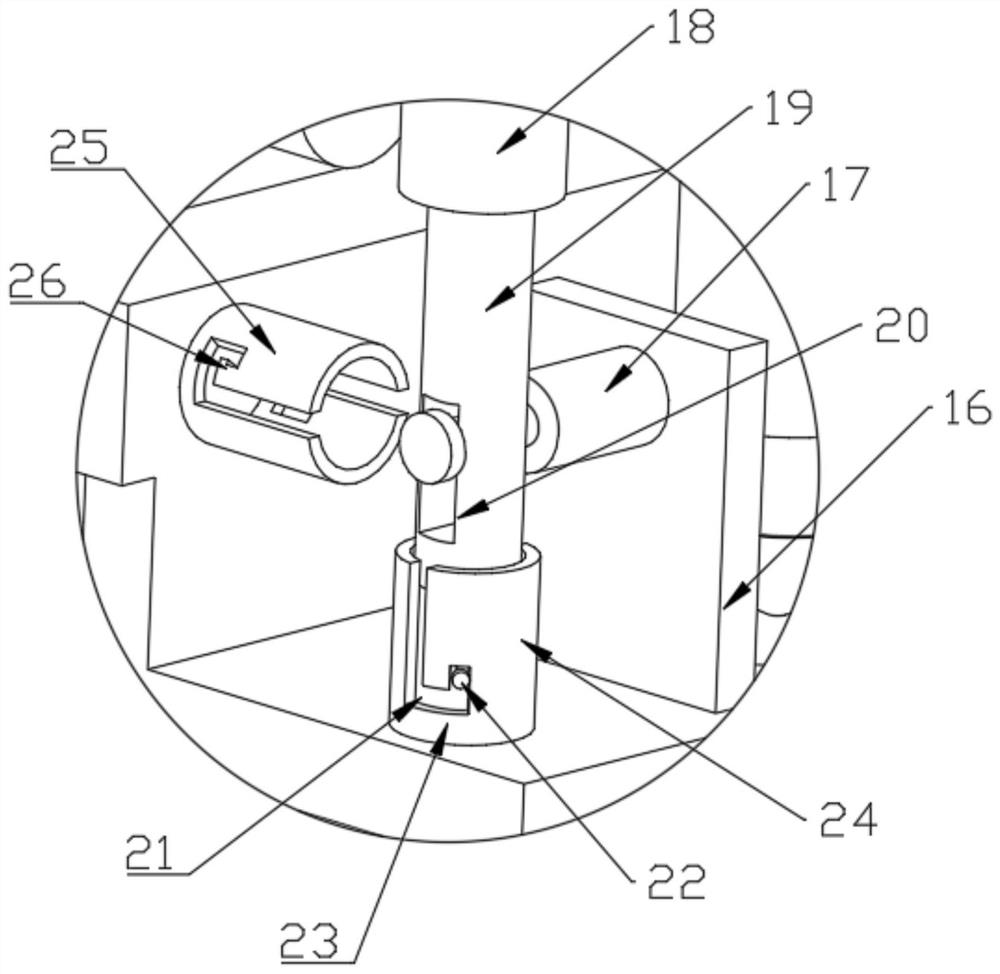

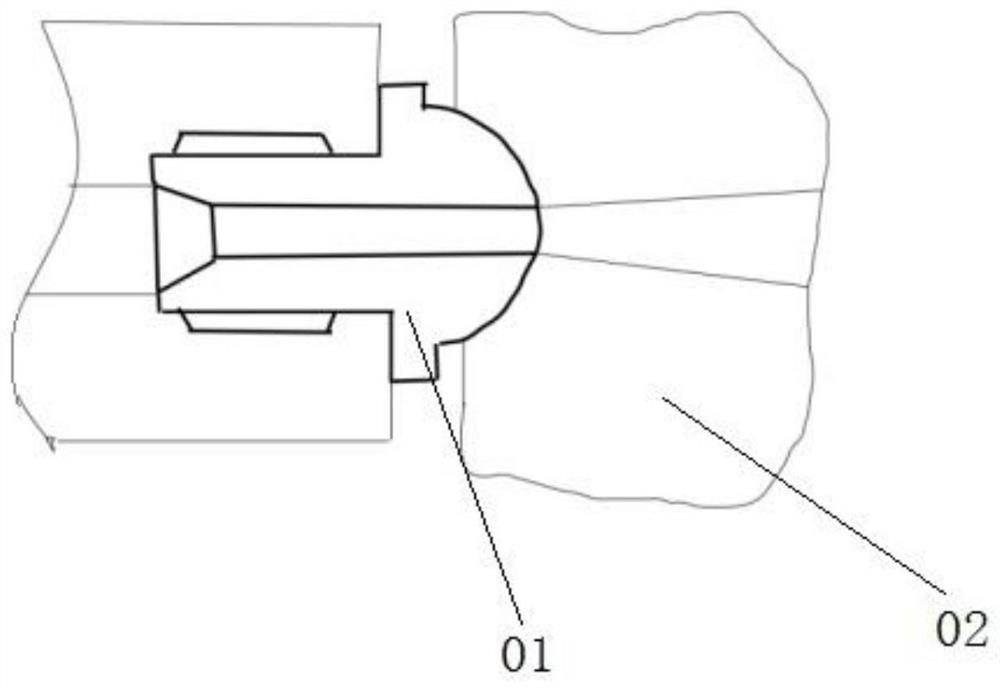

The invention relates to a management device for preventing random occupation of charging space and the management method thereof, which belongs to the field of charging space occupation prevention. The device comprise a charging pile, in which a charging management device is provided. A vehicle blocking device is set around the charging space on one side of the charging pile and ascending and descending of the vehicle blocking device is realized via an actuating unit. The control end of the servo electric cylinder is connected with the charging management device and the charging management device is connected with an object identification device that can prevent non-charging vehicle from parking. Force parking management is executed and economic loss of power management and control enterprises can be reduced.

Owner:HUANTAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +2

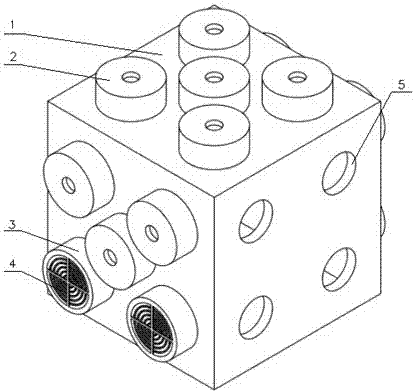

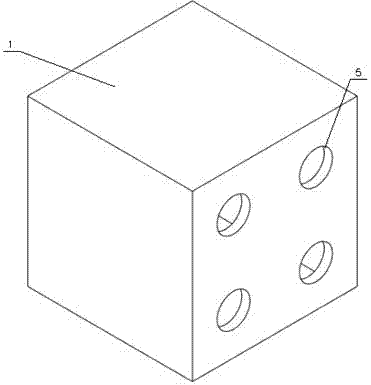

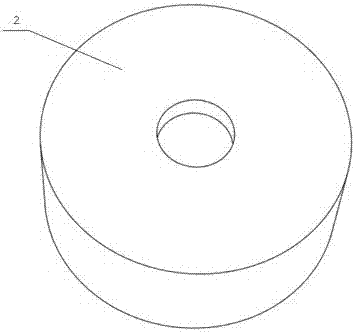

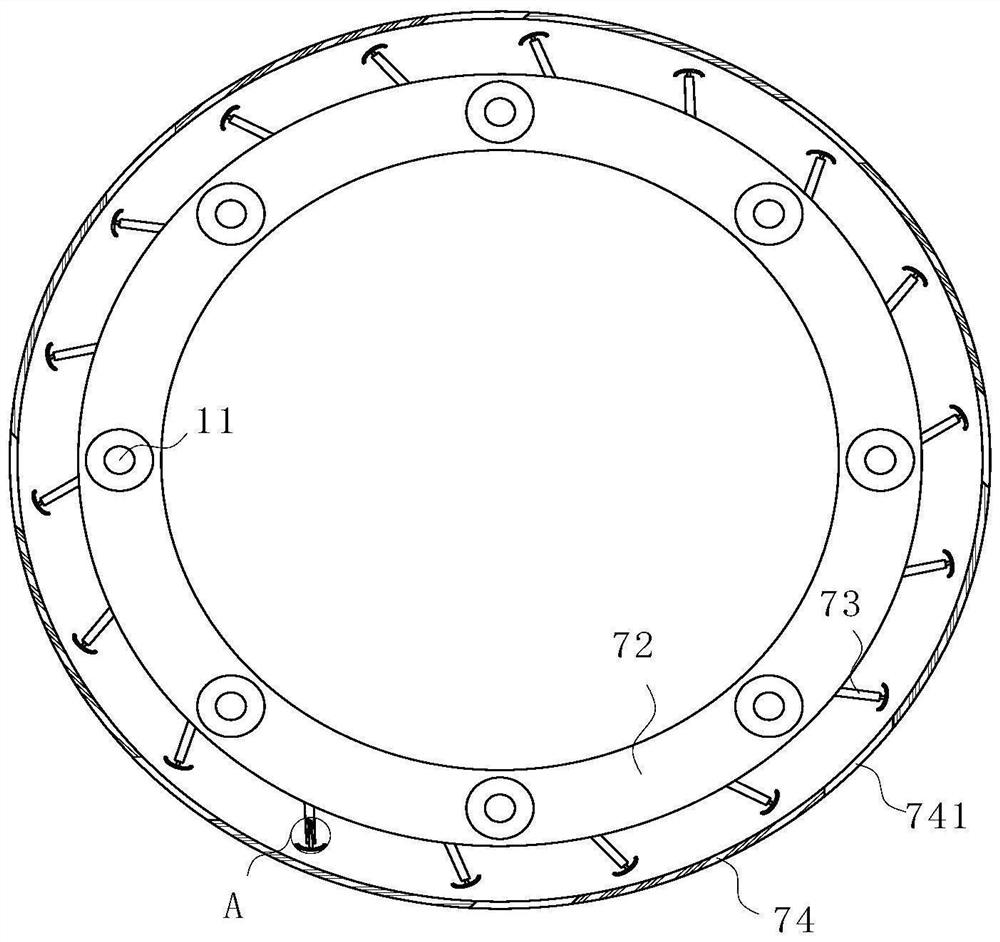

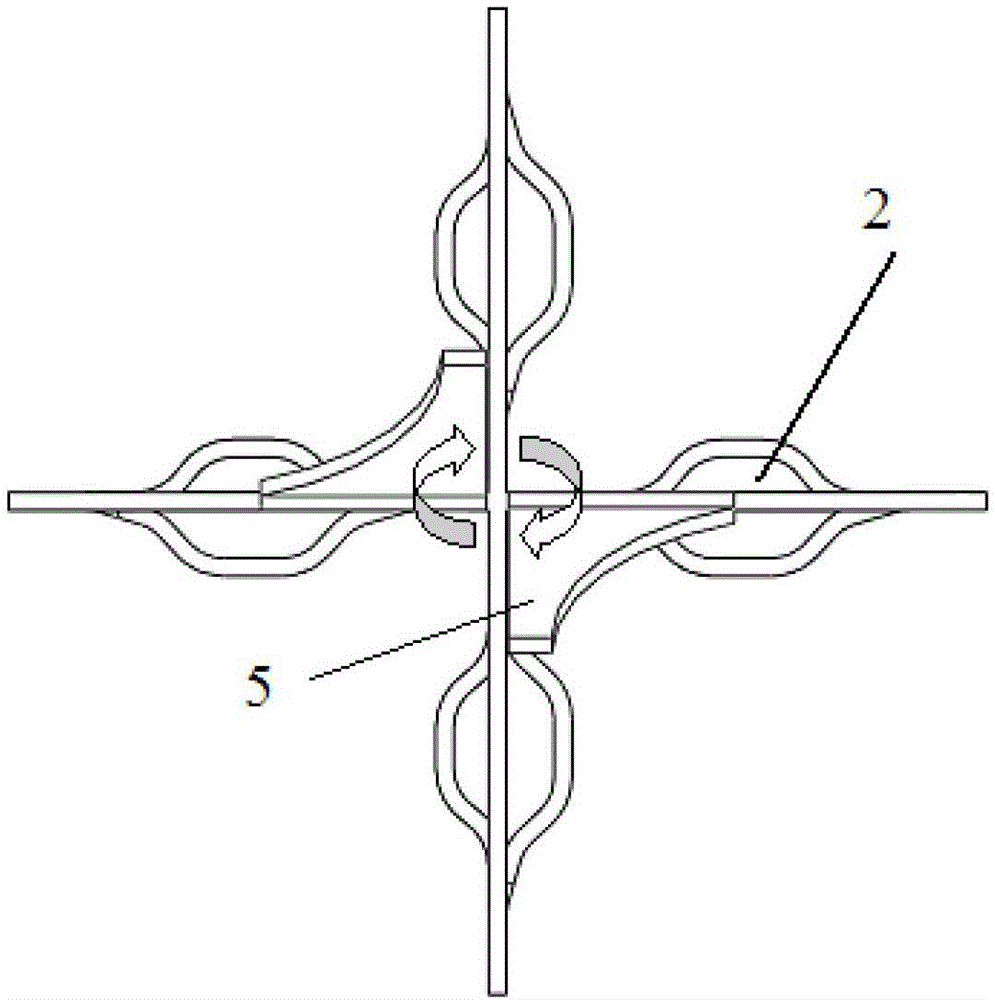

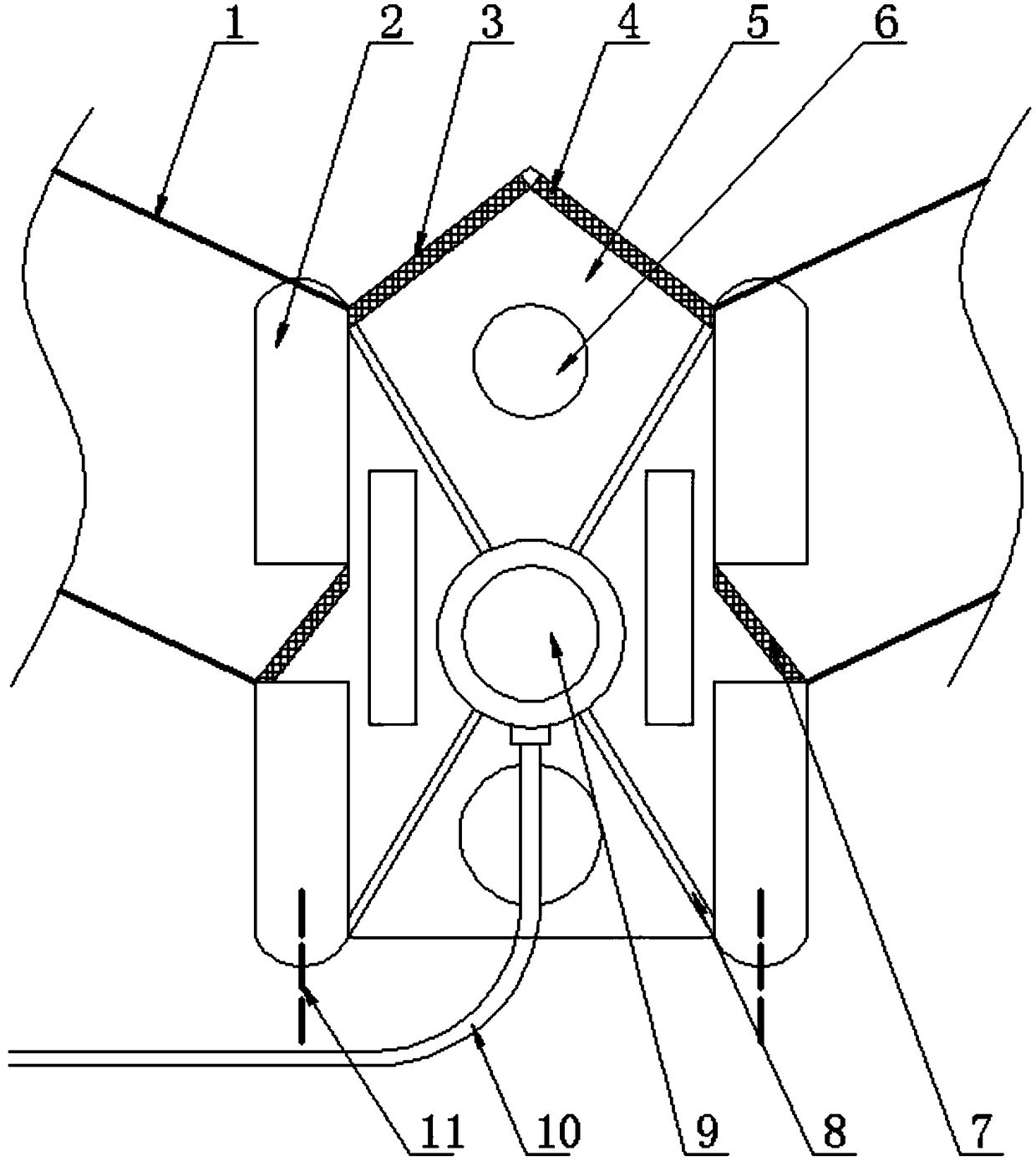

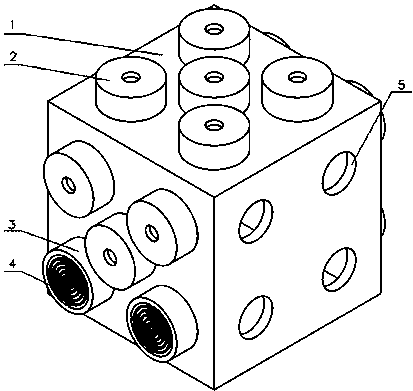

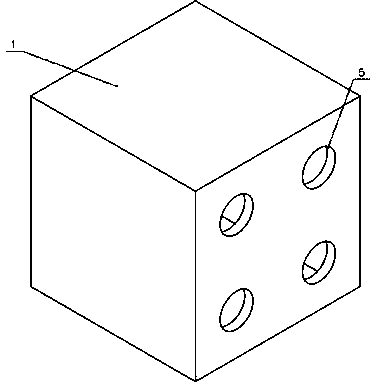

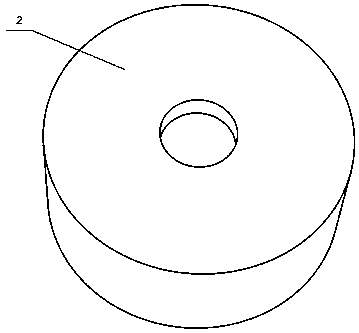

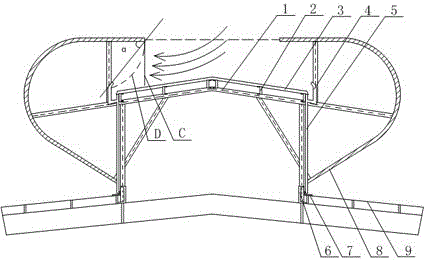

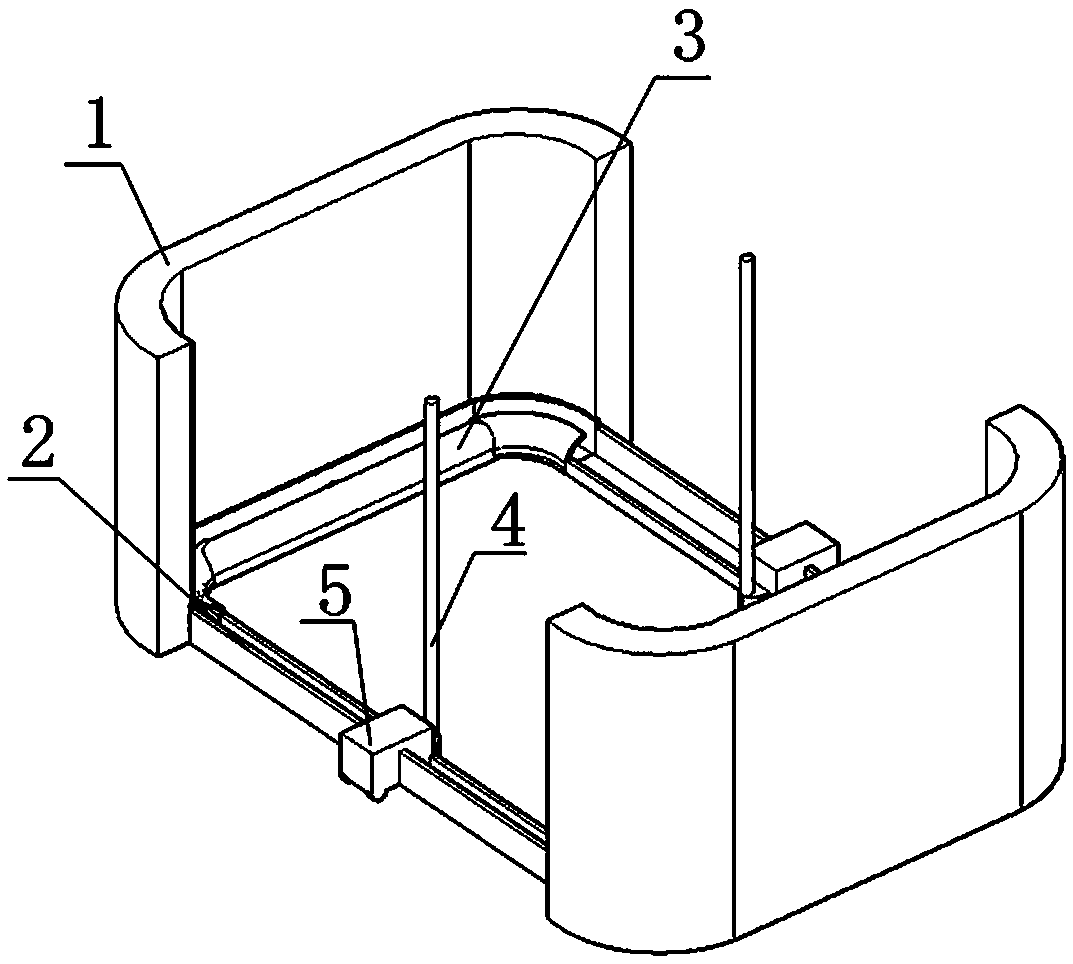

Composite type artificial fish reef

ActiveCN107242177ASolve pollutionIncrease frontal areaClimate change adaptationPisciculture and aquariaJuvenile fishTire shape

The invention relates to a composite type artificial fish reef which comprises a square frame reef, tire-shaped concrete components and a bait culture medium. The square frame reef is arranged in a hollow mode, the incident flow face and the reverse flow face of the square frame reef are symmetrically provided with circular open holes respectively, the tire-shaped concrete components are symmetrically arranged at the upper portion of the square frame reef, meanwhile, the multiple tire-shaped components and the bait culture medium are symmetrically arranged on the two side wall faces of the square frame reef, and shells are arranged in the bait culture medium. Obviously, while the composite type artificial fish reef solves the problem of tire reef pollution, the advantages of the tire reef are reserved, the formed flow field effect is good, larger upward flow and back eddy flow are formed, the reef influence range is enlarged, the better survival environment is provided for advanced fries and juvenile fish, the juvenile fish survival rate can be greatly increased, fishery culture and proliferation and aquatic organism diversity protection are facilitated, and the better application prospect is achieved.

Owner:OCEAN UNIV OF CHINA

Vertical net method for wind-proof and sand-controlling desertification prevention

InactiveCN1492108AExtended service lifeEffective sand protectionSoil preservationEngineeringDesertification

The windproof and sand-controlling desertification preventing method is fixing plastic nets via piles on desert and features that all the vertical plastic nets are connected to form several squared structures and fixed via piles. The said method is simple, saving in material, fast in acting, long in service life and obvious in windproof and sand-controlling effect.

Owner:陈传标

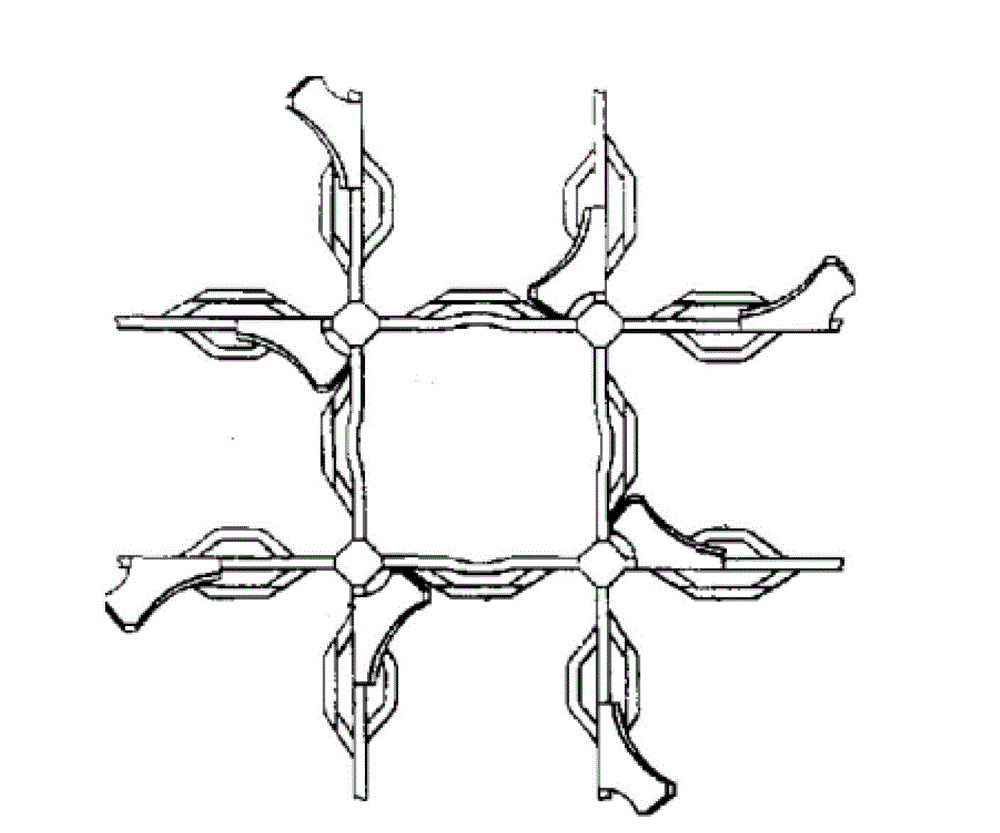

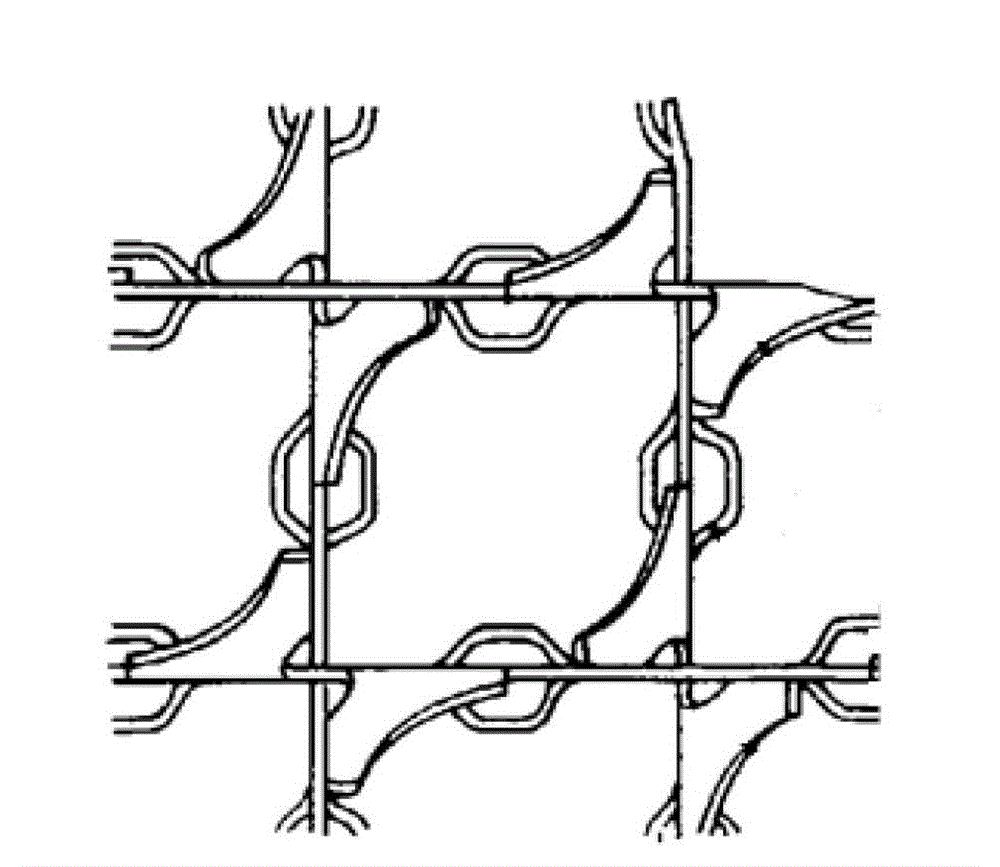

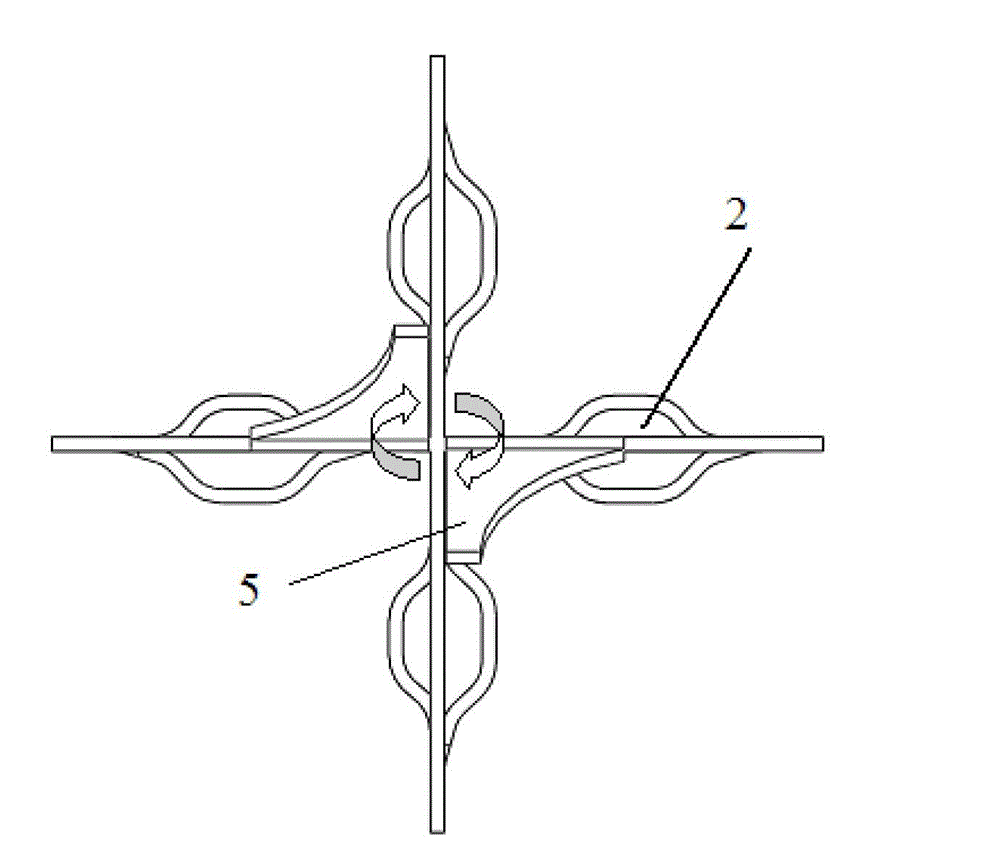

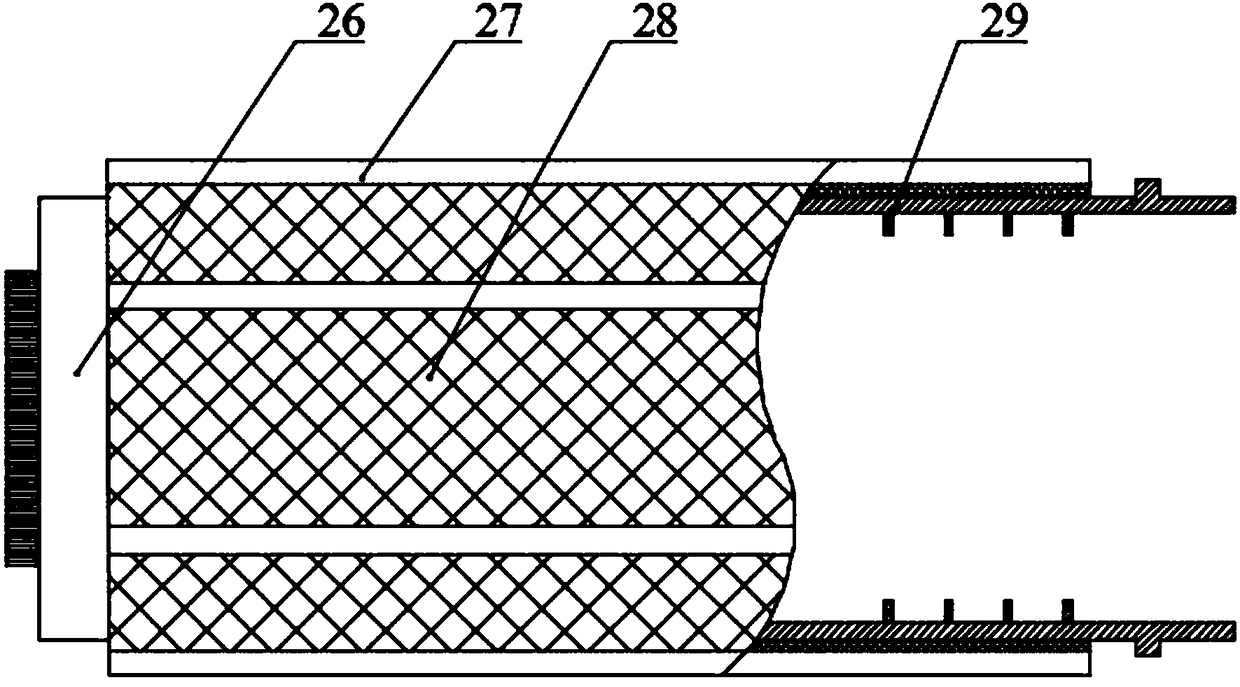

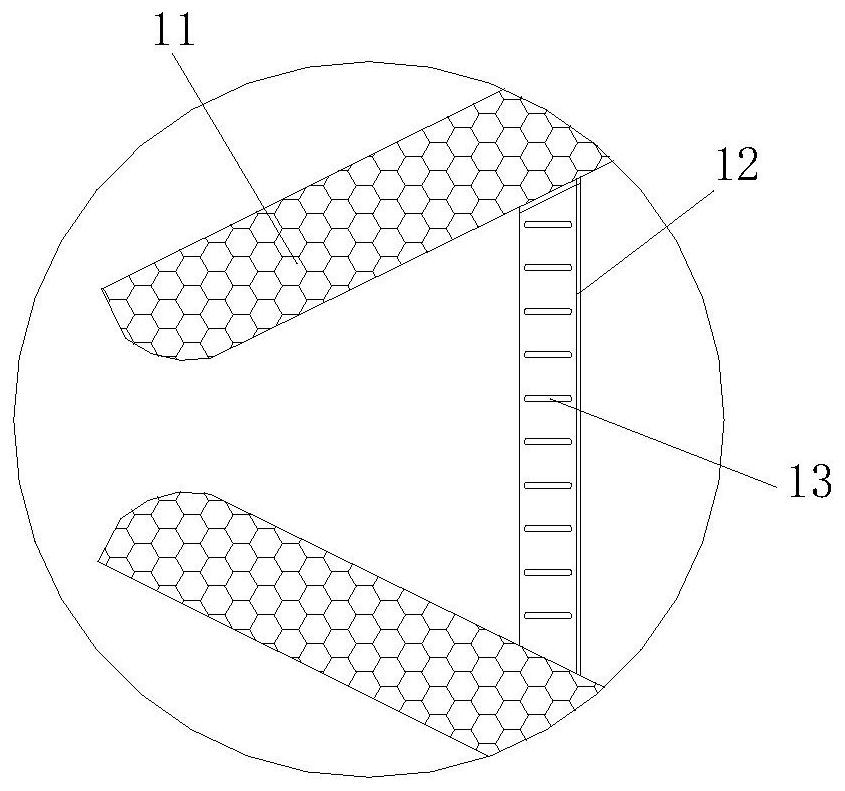

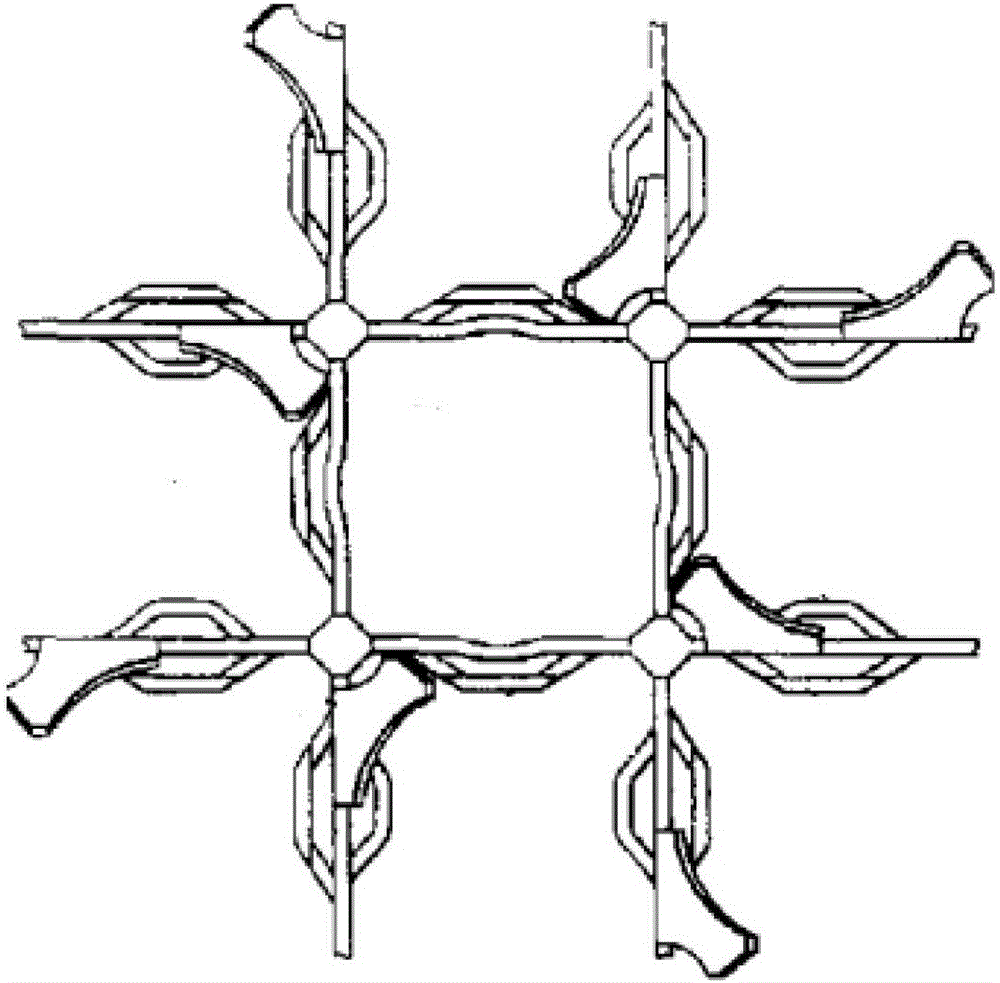

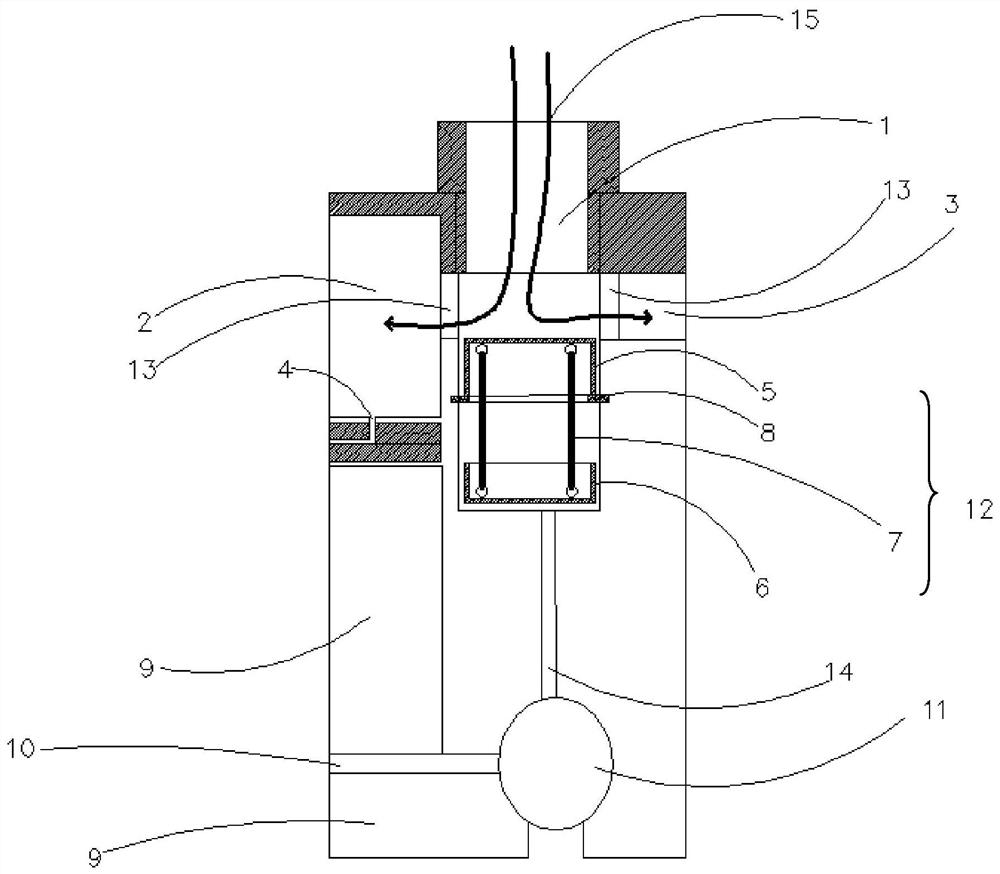

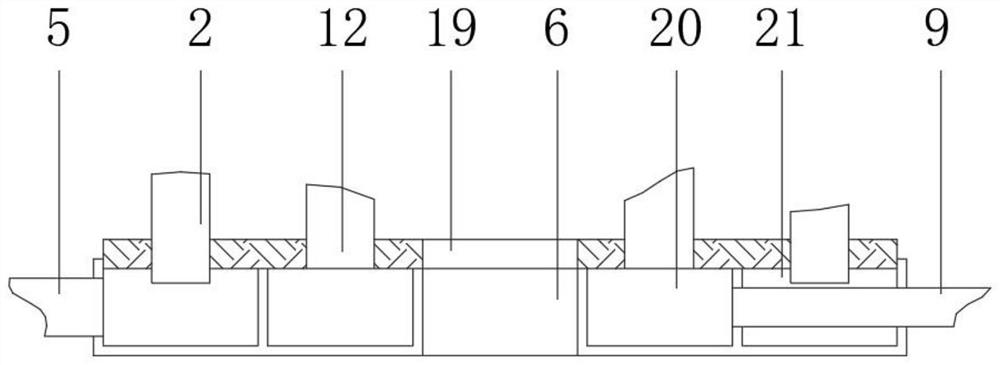

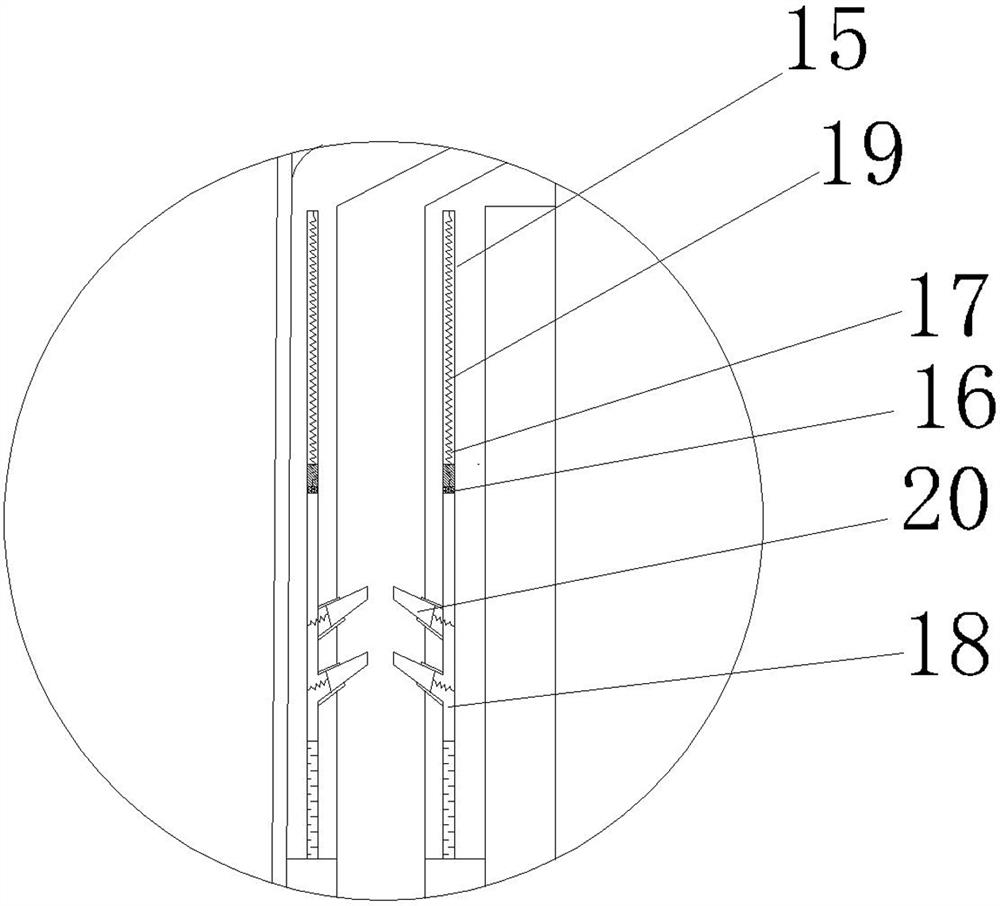

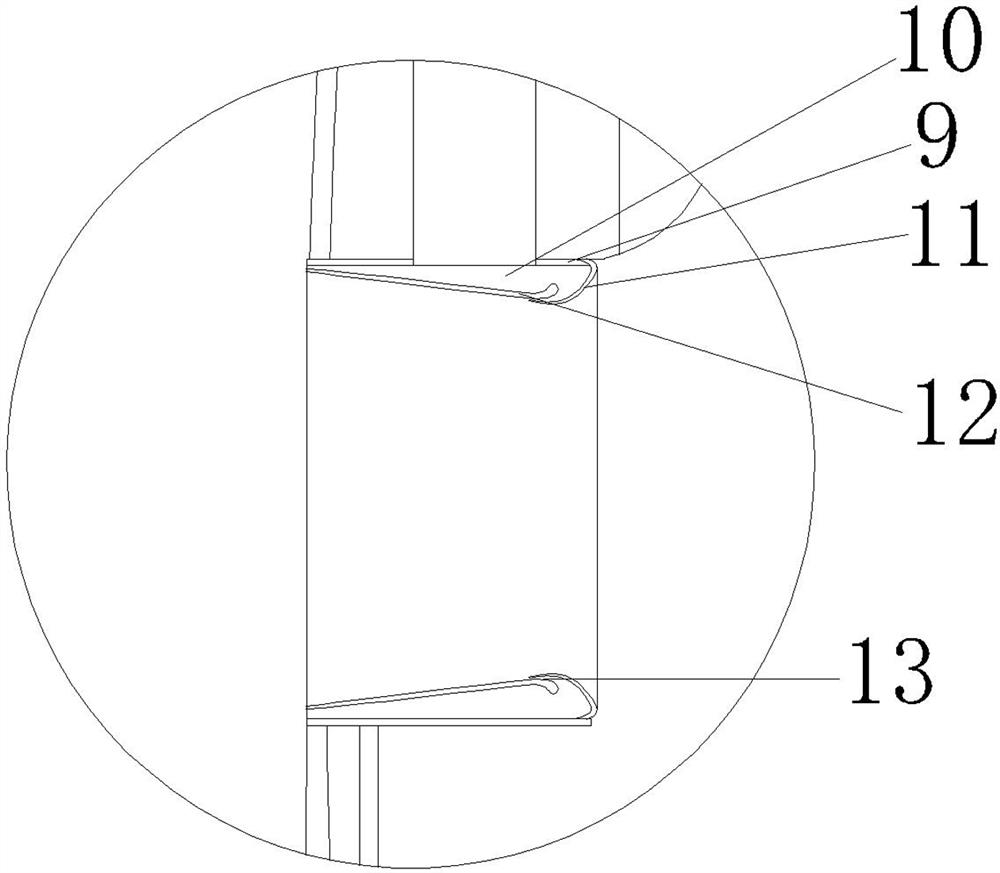

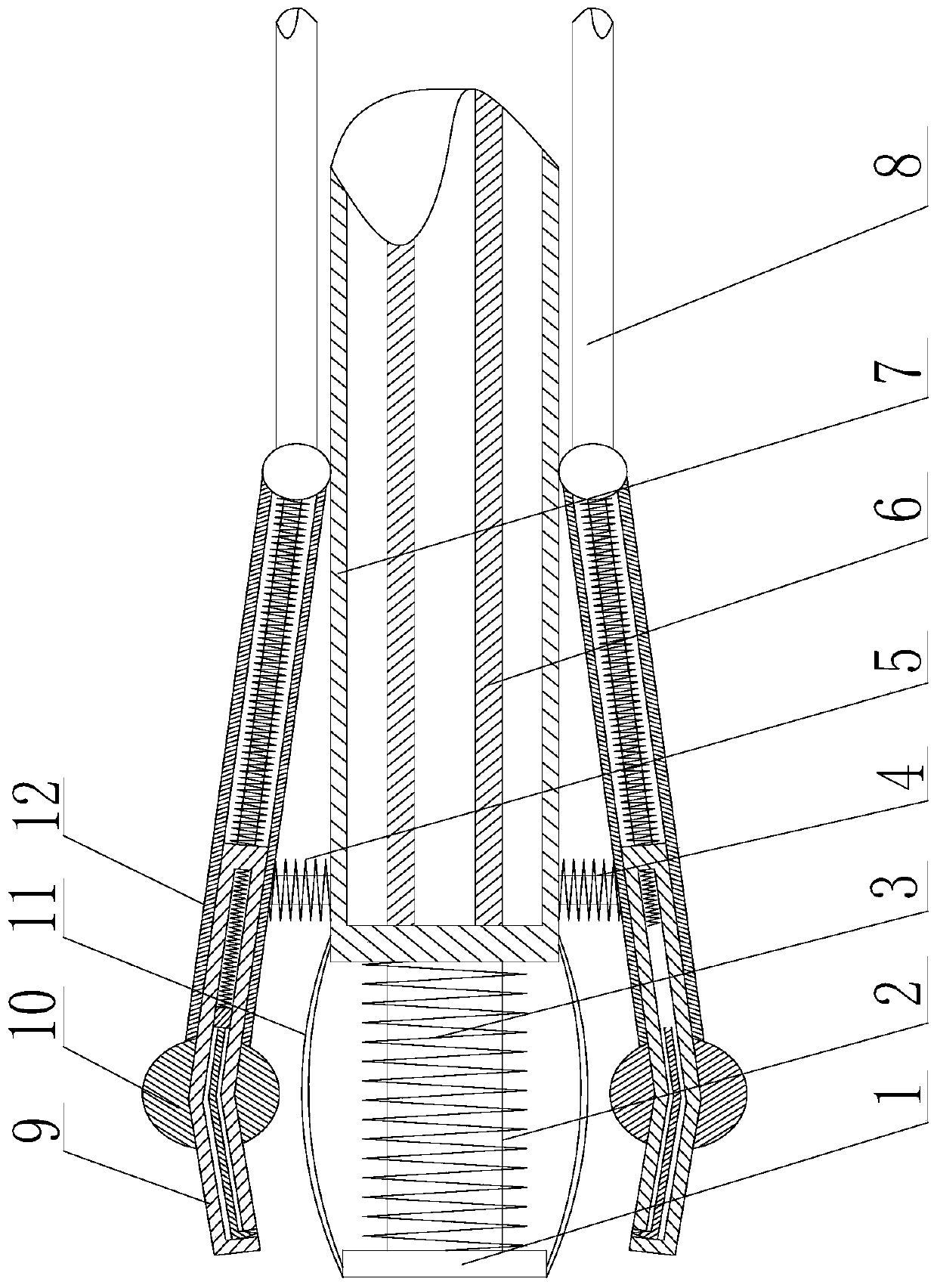

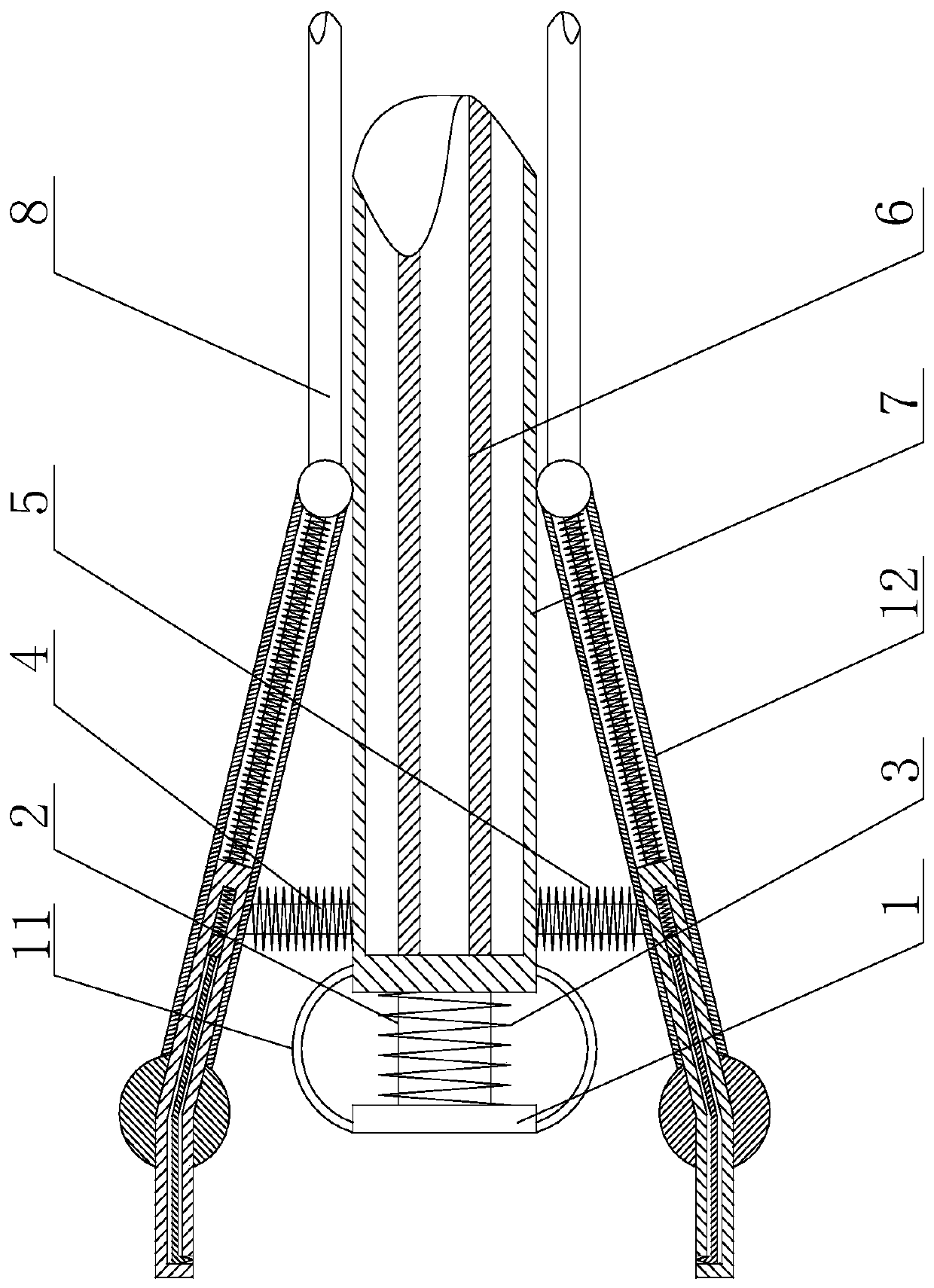

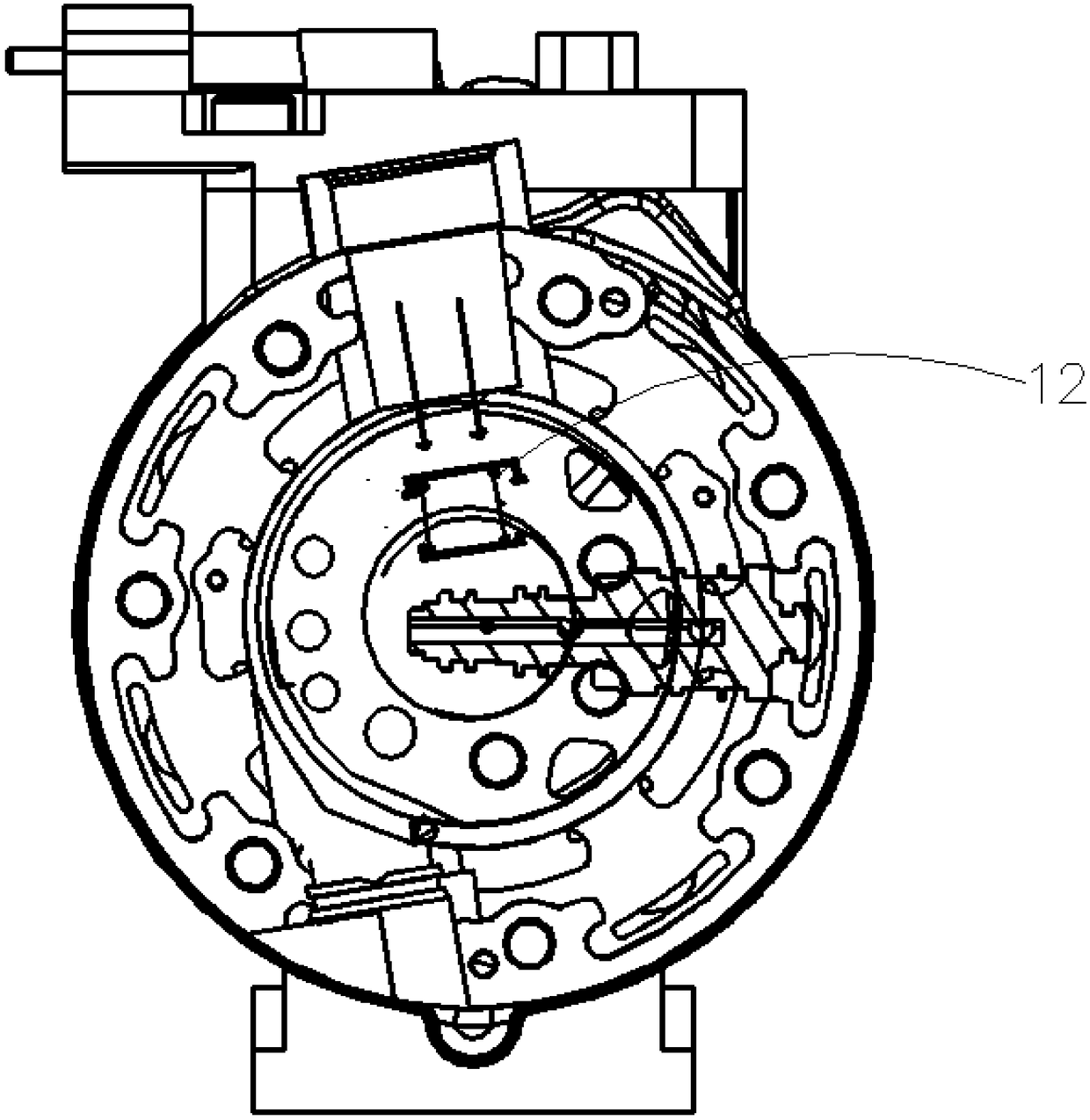

Nuclear fuel assembly grid with enhanced mixing blades

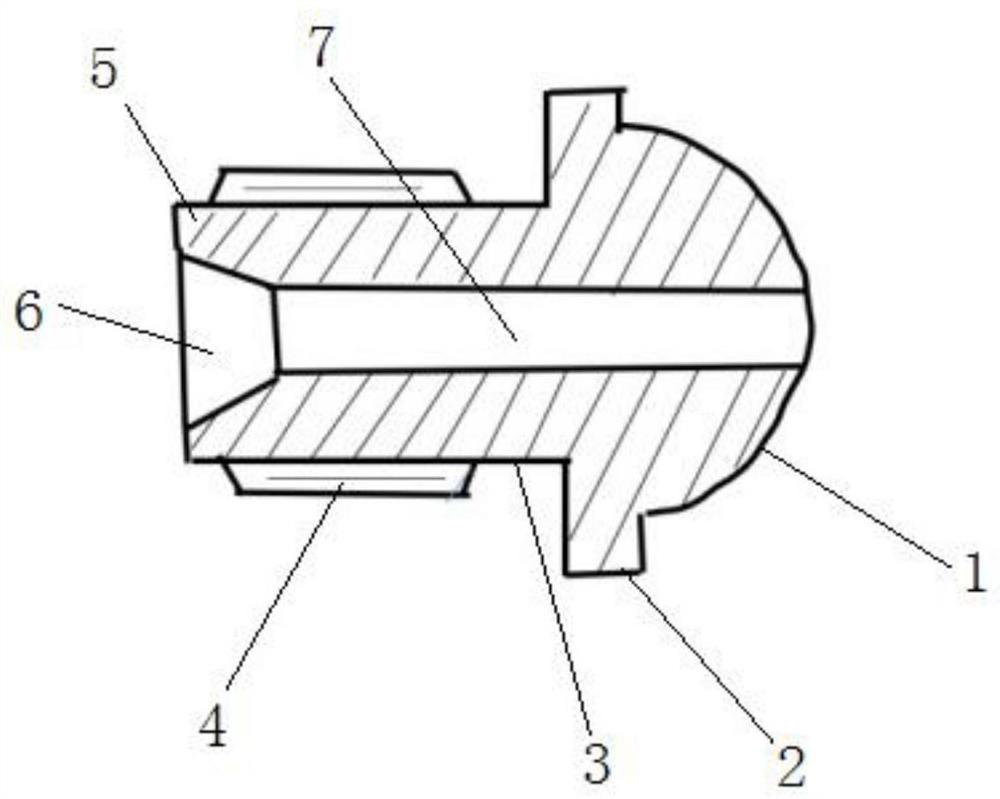

ActiveCN103187107AIncrease blocking areaIncreased turbulenceNuclear energy generationReactor fuel elementsEngineeringUltimate tensile strength

The invention provides a nuclear fuel assembly grid with enhanced mixing blades, wherein an upper rigid dimple and a lower rigid dimple and a spring between the upper rigid dimple and the lower rigid dimple are arranged on the side wall of each grid strip to clamp a fuel rod; a slot is formed below or above each grid strip, and the adjacent grid strips are connected in a vertical crossing manner through the slots; two corresponding enhanced mixing blades are arranged above a cross point of each two adjacent grid strips to mix fluid flowing by; each enhanced mixing blade is of a closed structure; a cavity is arranged on an axis wire which is within the range of 1-20 mm below the cross point of each two adjacent grid strips, and the grid strips are fixed through welding at the cavities. A closed area is formed at the cross part between each enhanced mixing blade and each strip, so that the mixing disturbance of the mixing blades on the fluid is remarkably improved. As the welding cavity is arranged below each mixing blade, the overall mechanical strength of the mixing grid is guaranteed.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

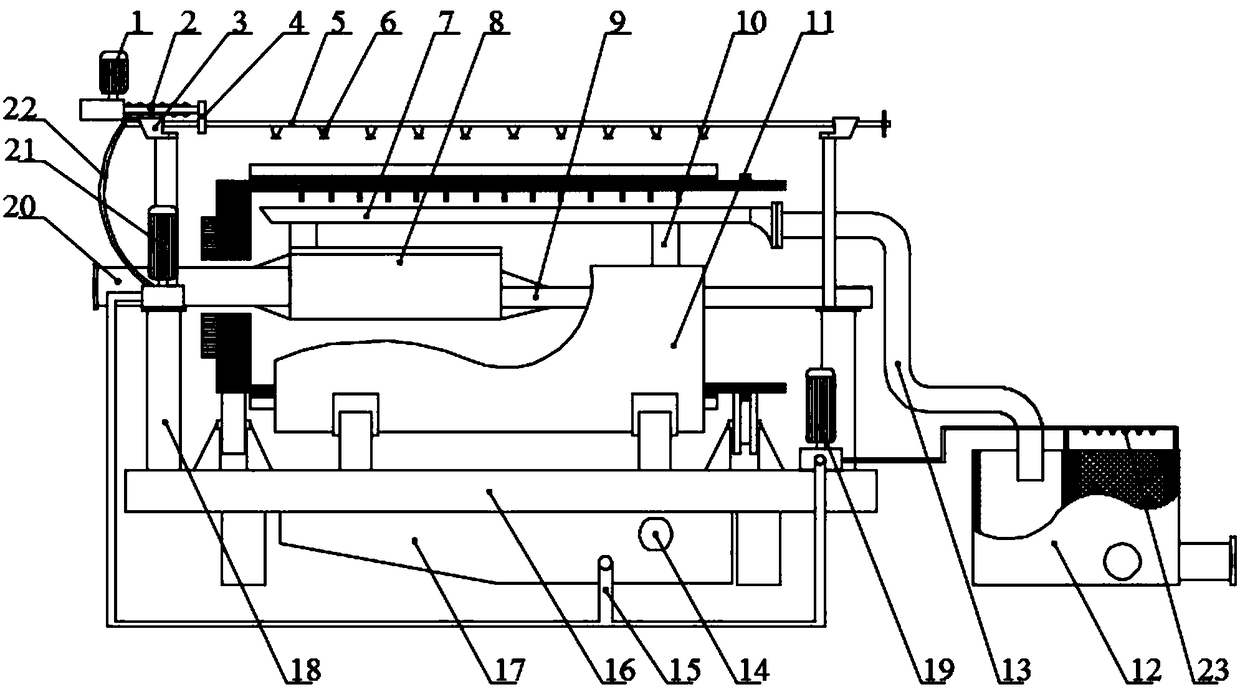

Algae water filter equipment with multistage filter function

PendingCN108661022AEffectively block and collectAvoid cloggingWater cleaningFiltration circuitsWater sourceWater filter

The invention discloses algae water filter equipment with multistage filter function. The equipment is characterized by comprising a water surface algae sucking device, a shore algae water filter anda second-stage filter box, wherein the water surface algae sucking device is floated on the water surface; the algae sucking device introduces sucked algae water into the shore algae water filter through a pipeline for filtration; and filtered concentrate algae pulp is introduced into the second-stage filter box for filtration by a pipeline. The algae water filter equipment with multistage filterfunction is special for an open channel and a narrower river channel; the algae sucking suspension height can be adjusted according to the thickness condition of a blue algae layer, so that the algaelayer is sucked by a non-blockage pump as much as possible, and the algae removing effect is excellent; the shore algae water filter can realize centrifugal filtration of algae water, can realize theequipment self-cleaning in the centrifugal filter process, and can perform the flushing cleaning on a filter screen of the second-stage filter box and a suspension fence; separated clear water is recycled by the flushing cleaning; and the filter equipment can save water sources and electric resources, and is convenient to operate, low in cost and suitable for wide-range popularization and application.

Owner:天津市引滦工程尔王庄管理处

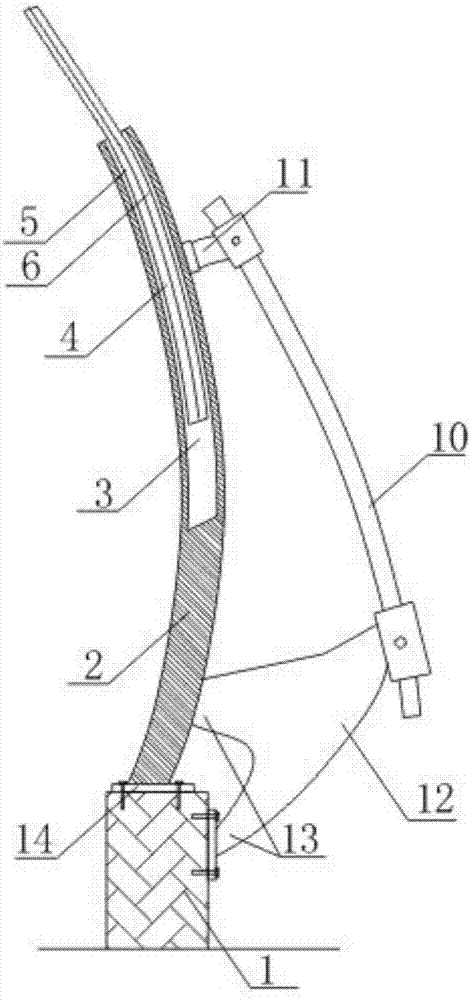

Sound insulation device for treating noise

InactiveCN106869043AAvoid harmImprove sound insulationNoise reduction constructionEngineeringAcoustic board

The invention describes a sound insulation device for processing noise, which includes a base pier and an arc-shaped sound insulation board arranged on the base pier. A groove is opened on the upper surface of the sound insulation board, and a groove matching the shape of the sound insulation board is slidingly arranged in the groove. The matching extension section, the extension section includes successively connected iron plates and rock wool layers, a dovetail groove is opened on the upper groove wall of the sound insulation board, a dovetail protrusion is installed slidingly in the dovetail groove, and a dovetail protrusion is set on one side of the upper end surface of the dovetail protrusion There are magnets that can be magnetically attached to the iron plate. The sound insulation board in the present invention can isolate the noise generated by the expressway, so as to avoid harm to the health of the human body. The extension section is slidingly installed in the sound insulation panel, and the height of the sound insulation can be adjusted according to the location of the noise source, so as to ensure that the noise generated by the road can be completely blocked and absorbed.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

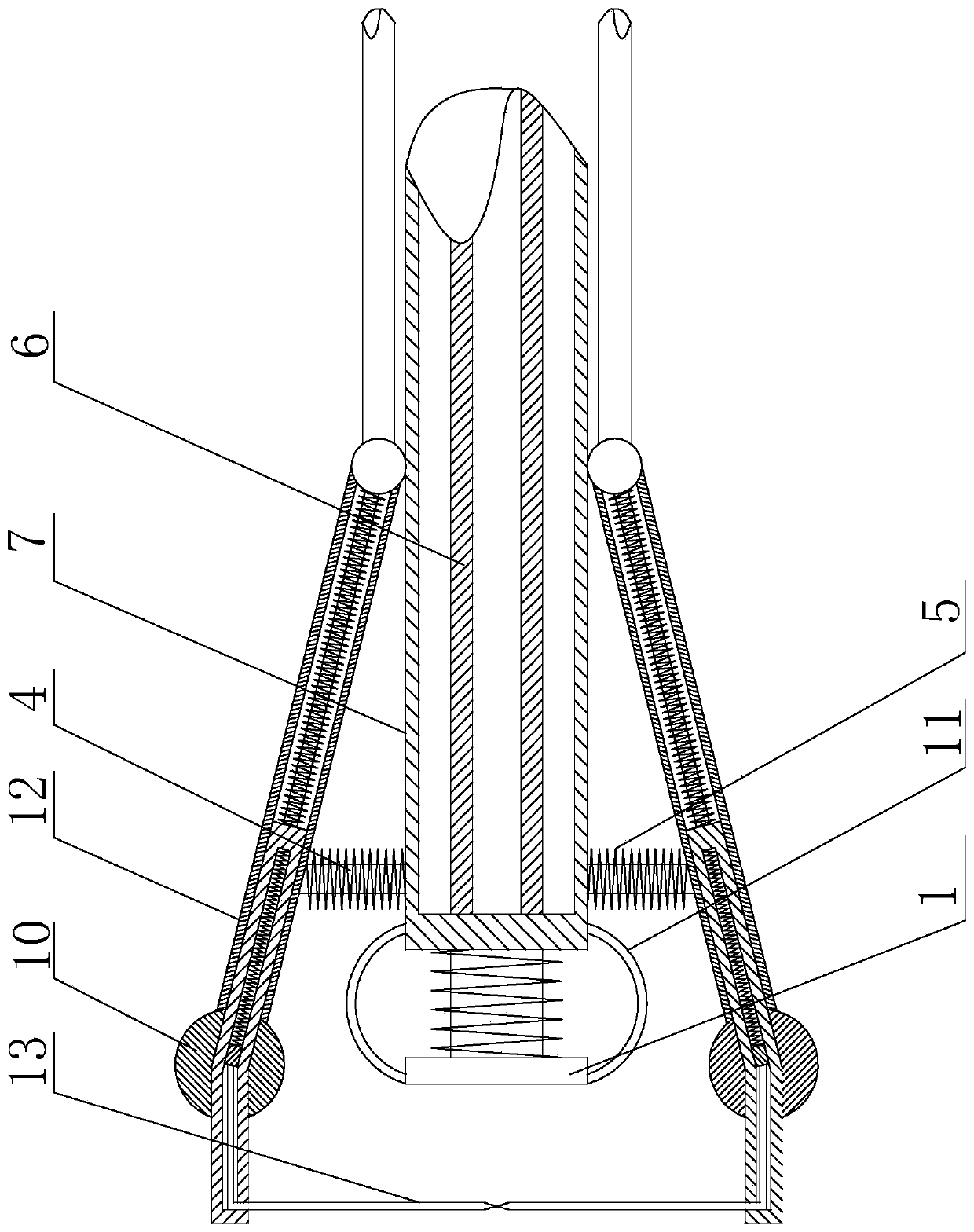

Anti-collision entrance guard

ActiveCN112681188AAct as decelerationPlay a buffer roleTraffic signalsRoad signsEngineeringStructural engineering

The invention discloses an anti-collision entrance guard, and the entrance guard comprises a base station; a speed reducer is arranged at the front end of the base station, a U-shaped frame is fixedly installed in the middle of the upper end of the base station, a sliding groove is formed in the middle of the upper end of the U-shaped frame, a sliding blocking device is arranged on the groove wall of the sliding groove, and a telescopic driving device is arranged on the upper portion of the opposite face of the sliding blocking device. The lower portions of the outer surfaces of the two telescopic driving devices are each provided with a buffer device, the middles of the opposite faces of the two sliding blocking devices are each provided with an access control device, a containing groove is formed in the front side of the middle of the upper end of the base table, and a protection device is arranged on the groove wall of the containing groove. According to the anti-collision entrance guard disclosed by the invention, the telescopic rod drives the L-shaped plate to move upwards, so the rubber layer moves upwards to be in contact with the rear side of the entrance guard gate when the connecting plate is driven to move upwards, and the arranged rubber layer plays a role in buffering when the entrance guard gate is impacted, so the entrance guard gate is protected, and the maintenance economic cost is reduced.

Owner:SHAOXING ZHONGCHUANG BUILDING INTELLIGENT TECH CO LTD

Ventilation mechanism for gas turbine air inlet system

PendingCN112302798AIncrease resistanceIncrease the lengthGas turbine plantsTurbine/propulsion air intakesNoise generationStructural engineering

The invention relates to the technical field of related composition mechanisms of gas turbine air inlet systems, and discloses a ventilation mechanism for a gas turbine air inlet system. The ventilation mechanism comprises a machine frame, wherein a mounting seat is mounted at a ventilation opening of the machine frame through a bolt, a vertical channel is arranged on the mounting seat, the otherend of the vertical channel is connected with a bent channel, the other end of the bent channel is connected with a transition channel, a ventilation filter frame is installed at the port, away from the bent channel, of the transition channel, a sealing opening and closing door used for overhauling is arranged on the front face of the ventilation filter frame, the end, away from the bent channel,of the vertical channel is sleeved with a flange connecting base, and two sealing bearings and two sealing rings are clamped between the inner side wall of the flange connecting base and the verticalchannel. The ventilation mechanism for the gas turbine air inlet system is different from a traditional ventilation mechanism noise reduction mechanism, the flow guide resistance and the circulation length of the ventilation filter frame are increased when external airflow is guided in, airflow noise generated by flow path reduction is reduced, and noise reduction treatment can be conducted on equipment from the noise generation position.

Owner:WUXI HUANAN STEEL STRUCTURE ENVIRONMENTAL

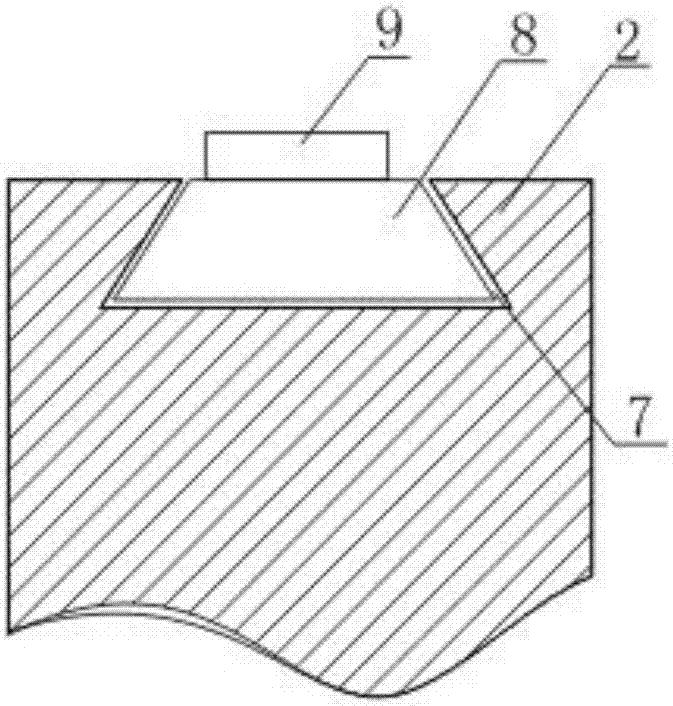

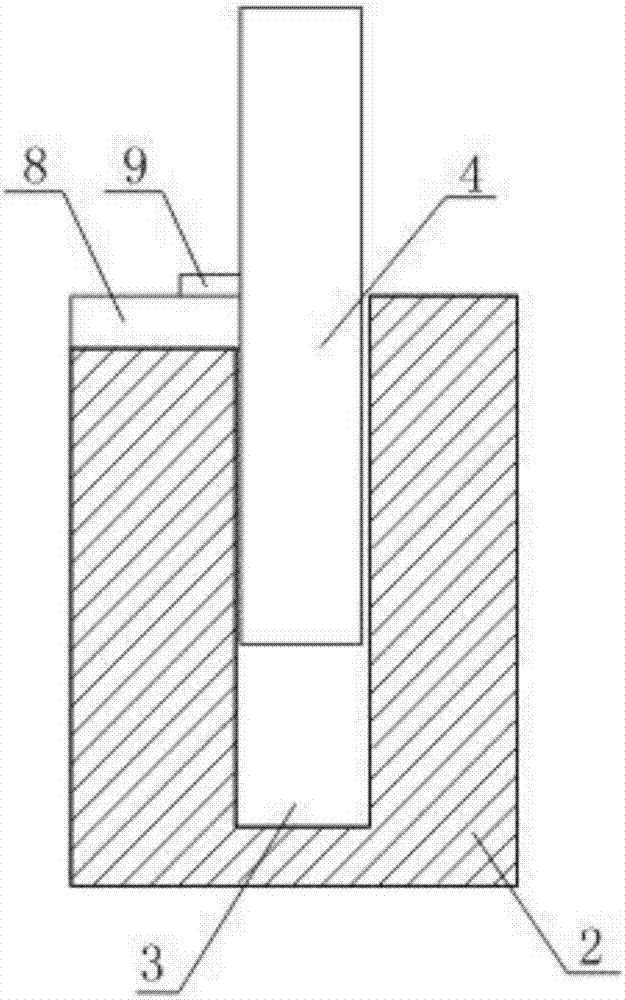

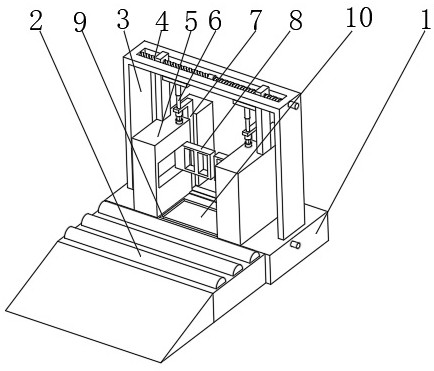

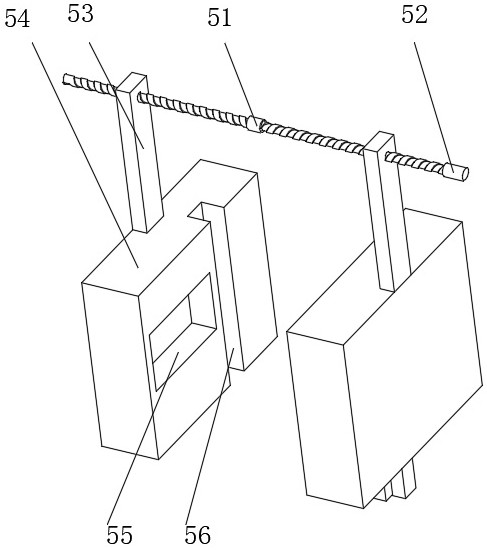

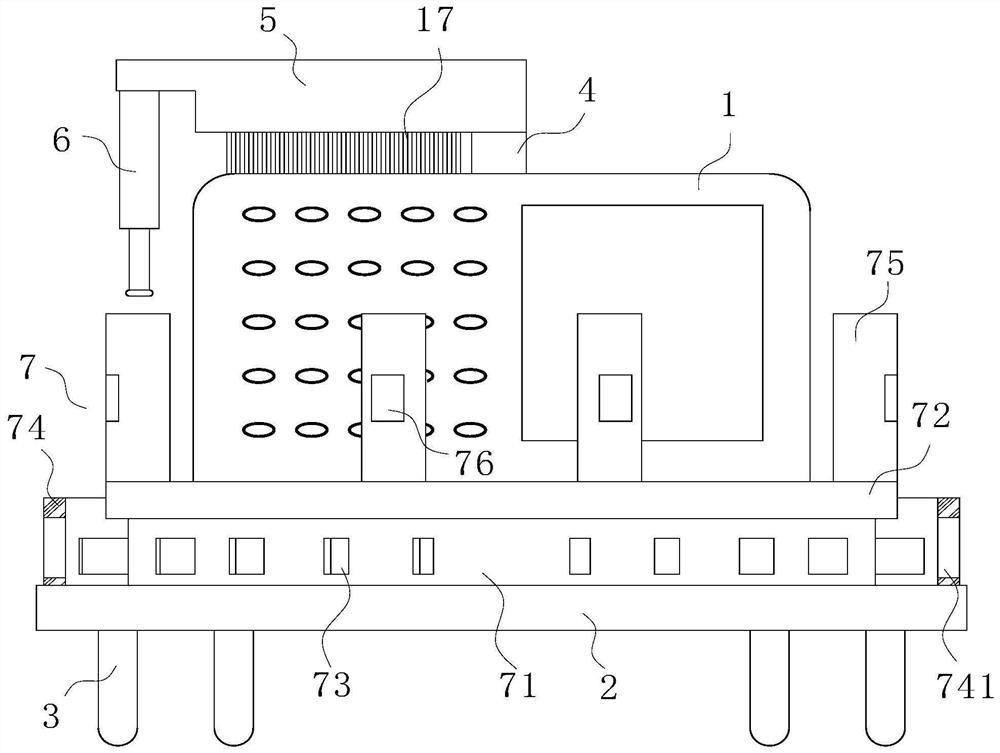

Pouring die storing device for steel manufacturing

Owner:金华市亚轮机械有限公司

Portable environment monitoring device

PendingCN114323125AImprove precipitation effectExtend the intervalMeasurement apparatus componentsCleaning using toolsEnvironmental monitoringPrecipitation

The invention belongs to the technical field of environment monitoring, and particularly relates to a portable environment monitoring device. The portable environment monitoring device comprises a detector body, a supporting table is arranged at the bottom of the detector body, and a clamping plate is arranged at the bottom of the supporting table; a rotating shaft is connected to the top of the detector body through a bearing, a strip-shaped plate is arranged at the top of the rotating shaft, a hydraulic rod is arranged at the end of the strip-shaped plate, and an exhaust pipe is installed in the hydraulic rod; a storage device is arranged on the top of the supporting table. An inclined plate is blown to move to drive an air storage cylinder filled with air to rotate, wind enables a hydraulic rod at the end of a strip-shaped plate to rotate to the leeward position of a detector main body, large particles in the air are gradually precipitated in the rotating process of the air storage cylinder, and meanwhile, particles in the air collide with the inner wall of the air storage cylinder, so that the precipitation effect is improved; impurities sucked into the detector main body can be reduced, the cleaning interval time is prolonged, and the probability that the end part of the exhaust pipe is blocked can be reduced.

Owner:广州保航网络科技有限公司

A grid of nuclear fuel assemblies with enhanced mixing blades

ActiveCN103187107BIncrease blocking areaIncreased turbulenceNuclear energy generationReactor fuel elementsUltimate tensile strengthMechanical engineering

The invention provides a nuclear fuel assembly grid with enhanced mixing blades, wherein an upper rigid dimple and a lower rigid dimple and a spring between the upper rigid dimple and the lower rigid dimple are arranged on the side wall of each grid strip to clamp a fuel rod; a slot is formed below or above each grid strip, and the adjacent grid strips are connected in a vertical crossing manner through the slots; two corresponding enhanced mixing blades are arranged above a cross point of each two adjacent grid strips to mix fluid flowing by; each enhanced mixing blade is of a closed structure; a cavity is arranged on an axis wire which is within the range of 1-20 mm below the cross point of each two adjacent grid strips, and the grid strips are fixed through welding at the cavities. A closed area is formed at the cross part between each enhanced mixing blade and each strip, so that the mixing disturbance of the mixing blades on the fluid is remarkably improved. As the welding cavity is arranged below each mixing blade, the overall mechanical strength of the mixing grid is guaranteed.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

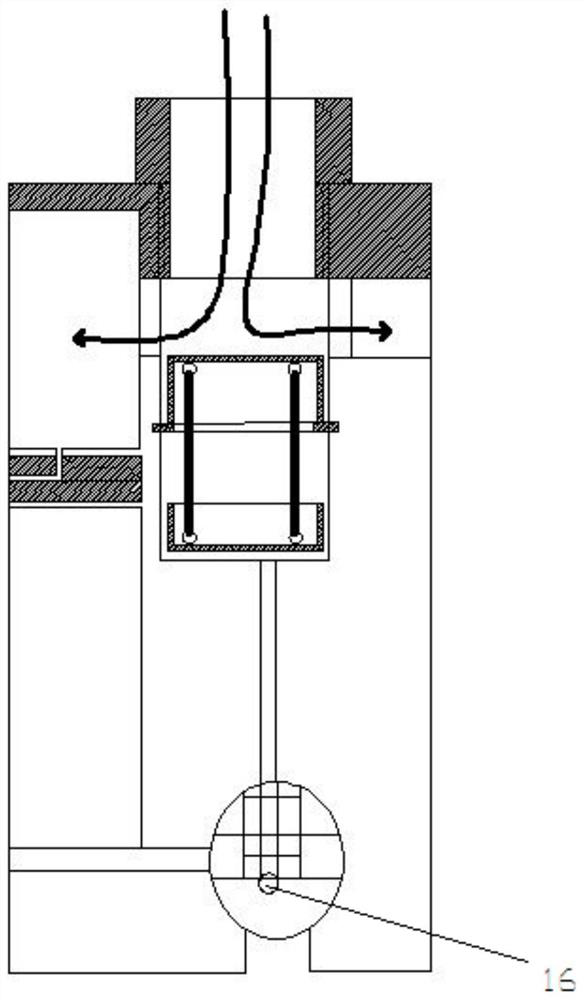

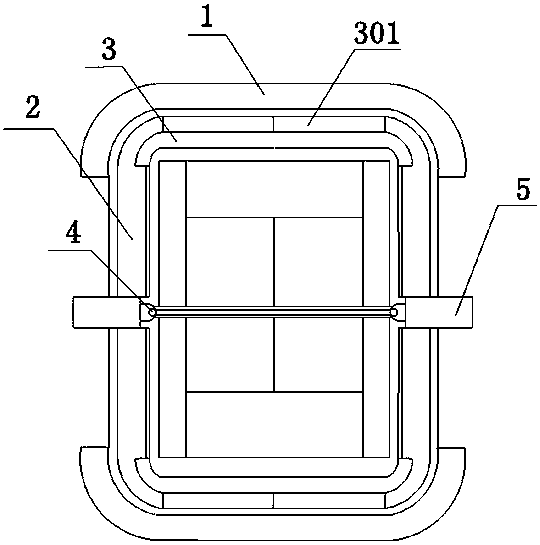

Compressors, air conditioning systems and vehicles

ActiveCN109505771BReduce noiseSimple internal structureAir-treating devicesVehicle heating/cooling devicesAir conditioningControl theory

The invention relates to the field of vehicle engineering, and provides a compressor, an air conditioning system and a vehicle. The compressor comprises an air suction passage and an air suction chamber, the air suction chamber communicates with the air suction passage through an air suction opening, a silencer structure is arranged in the air suction passage, the silencer structure is arranged tobe capable of moving in the air suction passage according to the exhaust volume of the compressor so as to adjust a blocking area of the air suction opening, and an opening area of the air suction opening adapts to the size of the exhaust volume of the compressor. According to the compressor, the structure of the position which a refrigerant of the compressor flows into under different loads canbe changed adaptively, so that noise of the compressor is effectively reduced; and moreover, the internal structure of the compressor is simple, the manufacturing and assembling difficulty is low, andthe cost is low.

Owner:GREAT WALL MOTOR CO LTD

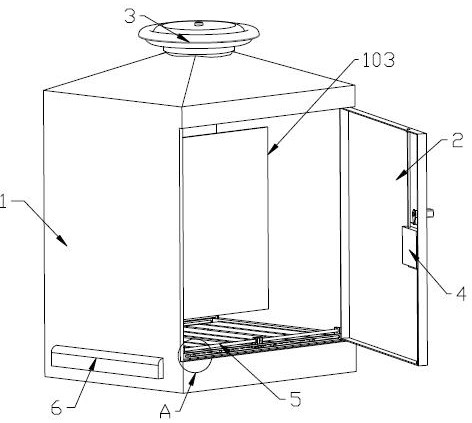

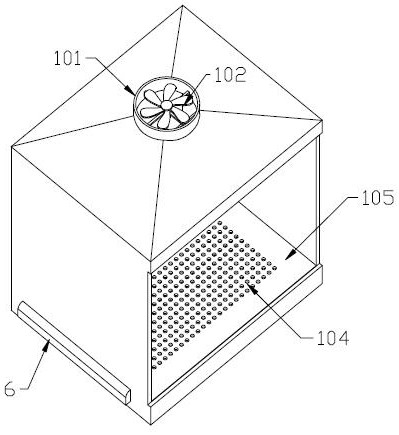

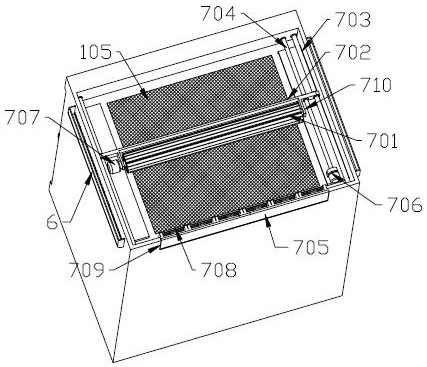

An operation safety protection device for power equipment

ActiveCN112448294BSpeed up the flowPlay a cooling roleDispersed particle filtrationTransportation and packagingElectric power equipmentDust control

The invention provides an operation safety protection device for electric equipment, comprising a box body, a door panel is hinged on the front side of the box body, and a power-on locking device for locking or releasing between the door panel and the box body is arranged on the door panel; The top of the body is provided with an exhaust pipe that communicates with it, the interior of the exhaust pipe is provided with an induced draft fan, and the upper end of the exhaust pipe is detachably installed with an exhaust mechanism; the interior of the box is divided into two upper and lower cavities by an orifice plate The bottom of the orifice plate is provided with a dust filter, and the top of the orifice plate is provided with a baffle mechanism; the box above the orifice plate is provided with a mounting plate, and the two sides of the box below the orifice plate are provided with air intake cavities. A dust removal mechanism is arranged inside the box body; in the present invention, the air flow inside the box body is driven by an induced draft fan, and the external air enters the bottom of the orifice plate in the box body from the air inlet cavity, and is filtered by the dust filter screen and discharged upwards by the exhaust mechanism. The air with a lower temperature outside the box is introduced into the box, which can play a role in cooling the power equipment.

Owner:河南工学院

A mobile communication antenna applied to 5g communication

ActiveCN111416209BSolve the problem of difficult conversionSolve shipping problemsPhotovoltaic supportsAntenna supports/mountingsTelecommunicationsSlide plate

The invention belongs to the field of mobile communication technology and relates to a mobile communication antenna for 5G communication, including a base plate and a communication antenna, a first mounting plate is fixedly mounted on the base plate, a third mounting plate is fixedly mounted on the first mounting plate, The third mounting plate, the bottom plate and the first mounting plate are fixedly installed with a push-lift conversion device, the lower surface of the bottom plate is symmetrically fixed with rollers, the bottom plate is provided with a first limit chute, and the bottom plate is symmetrically fixed with a limit block. The first threaded post is rotated on the bit block, and the two ends of the first threaded post are symmetrically threaded with adjusting nuts; the upper end of the second mounting base is threaded with a third threaded post, and the front end of the third threaded post is rotated with an adjusting connecting rod , the end face of the adjustment connecting rod is hinged on the adjustment slide plate; the invention solves the problems that the traditional device is difficult to transport when the road is damaged and difficult to fix in the field.

Owner:肖鹏

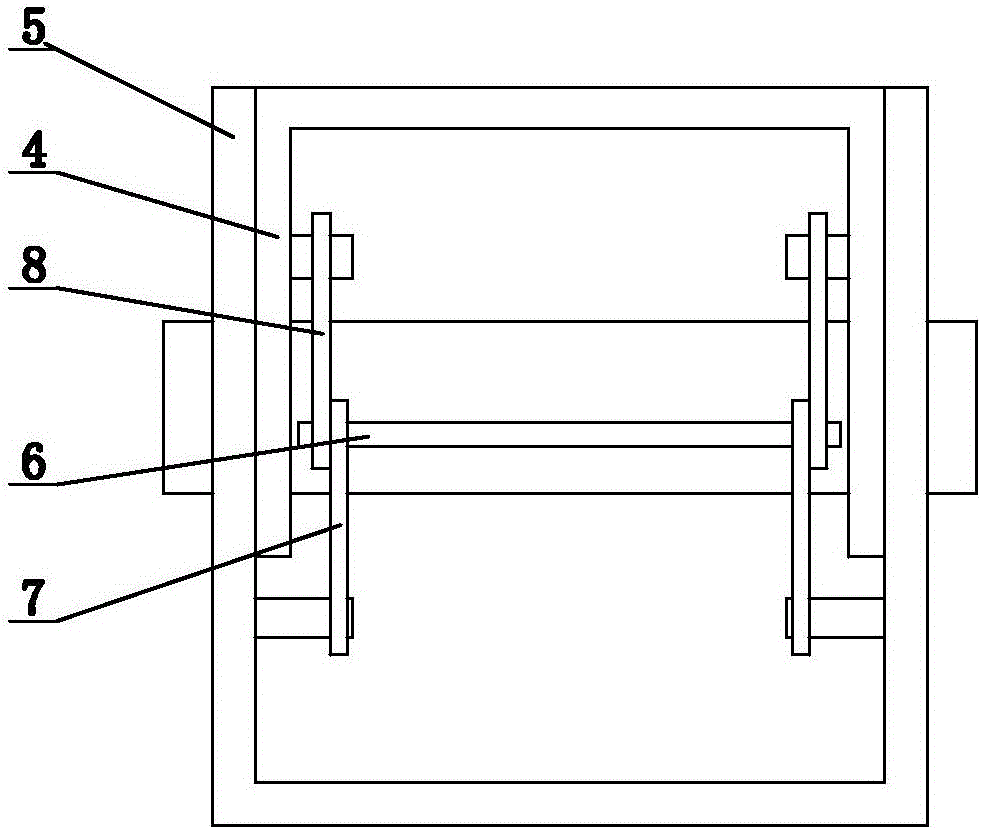

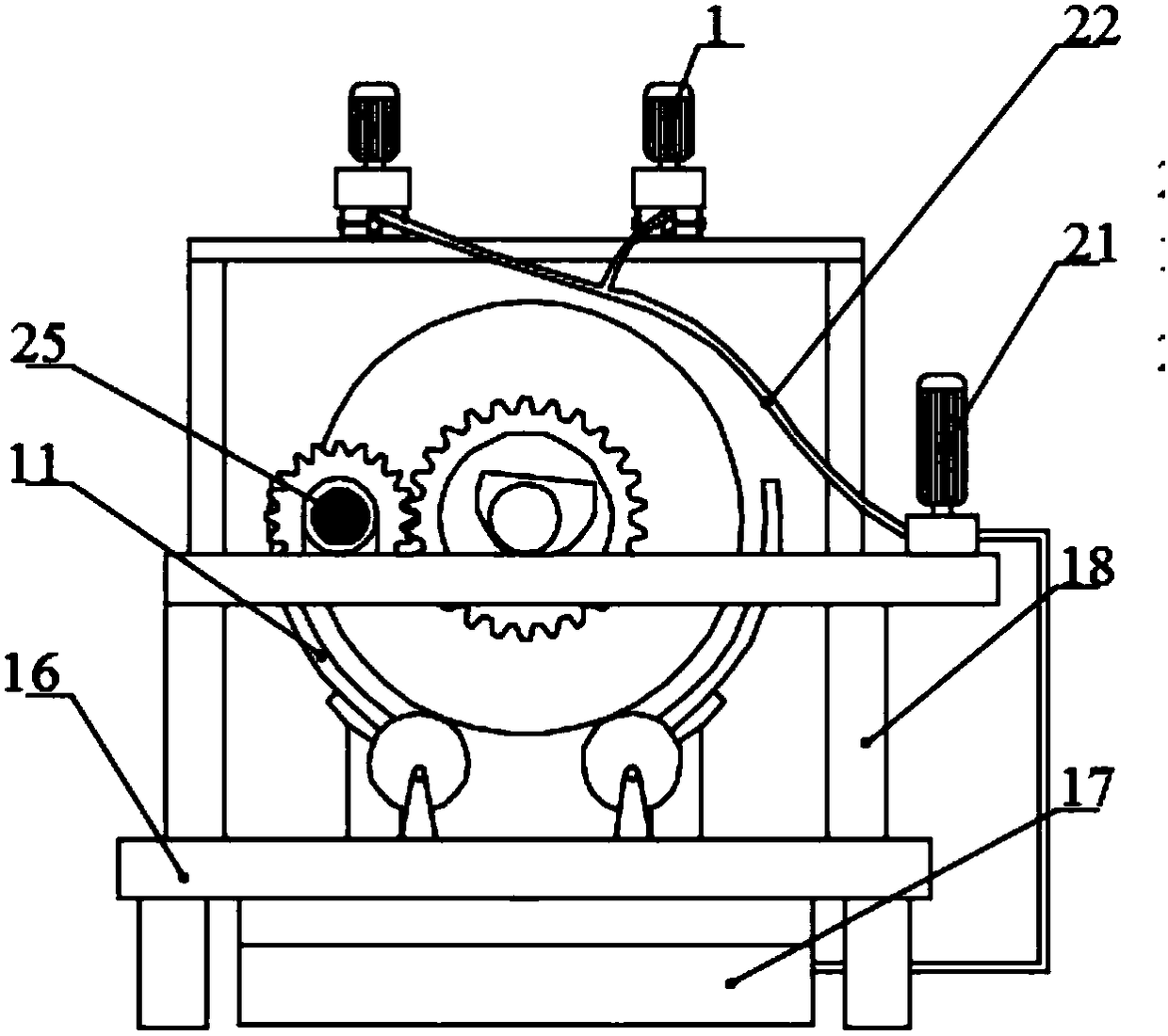

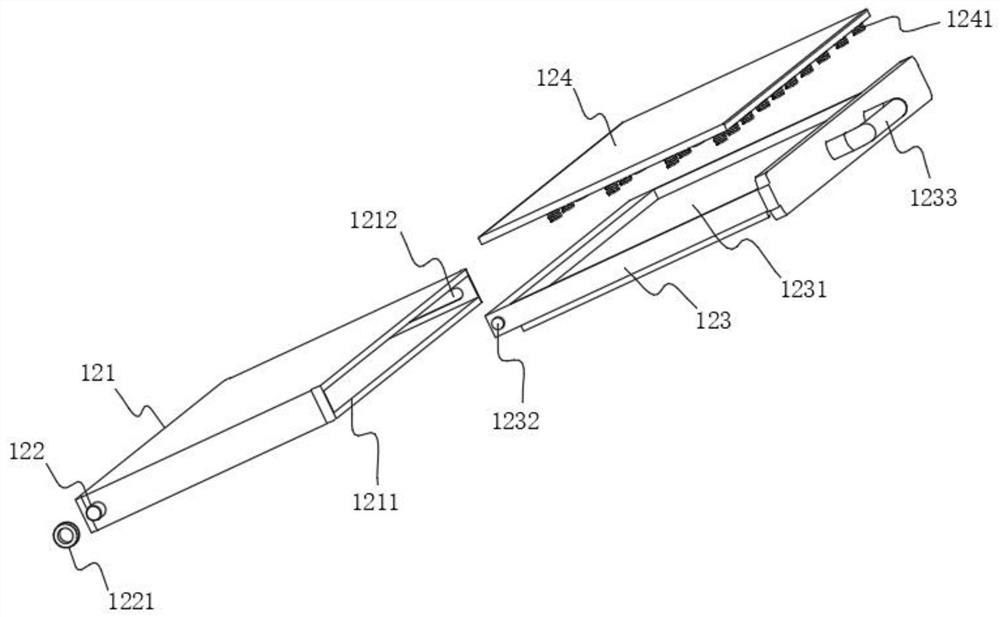

Labor-saving wing gate with function of automatically opening door in case of power failure

ActiveCN113699917AOvercoming work problemsAvoid entanglementTraffic restrictionsTraction cordMachine

The invention discloses a labor-saving wing gate with the function of automatically opening a door in case of power failure, which comprises a case provided with a rack, wherein a guide rail is arranged on the front side of the rack; a wing plate, wherein the side, opposite to the rack, of the wing plate is fixedly connected with a guide wheel; a driving mechanism is arranged in the case and used for driving the wing plates to swing outwards out of the case or retract inwards; a power-off switching-off mechanism comprises a traction rope, an electromagnet attraction piece, a large gravity block arranged on the electromagnet attraction piece and an electromagnet installed below the bottom end of the guide rail; when the wing gate is powered on after being powered off, the wing plate swings outwards out of the machine box, the electromagnet attraction piece is synchronously driven by the traction rope to move upwards to make contact with the electromagnet, the electromagnet is powered on, when the wing gate is powered off after being powered on, the electromagnet is powered off, and the large gravity block drives the wing plate to retract inwards into the machine box through the traction rope. The invention has the beneficial effects of automatically opening the door and closing the gate without effort when power is off.

Owner:北京中成科信科技发展有限公司

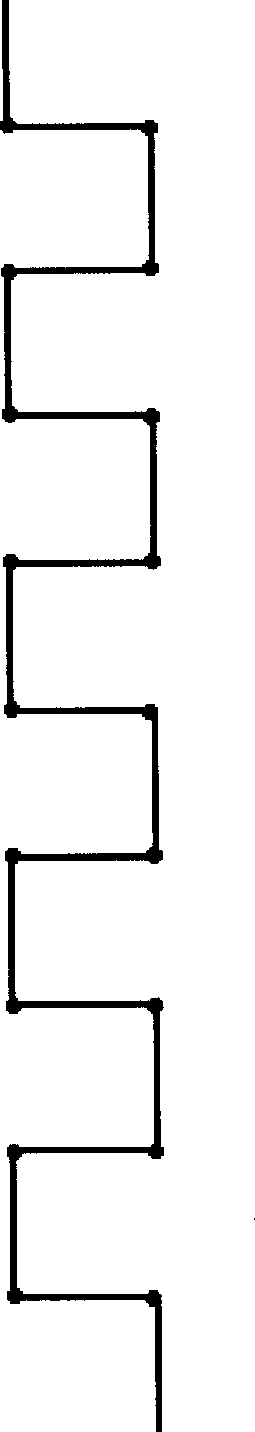

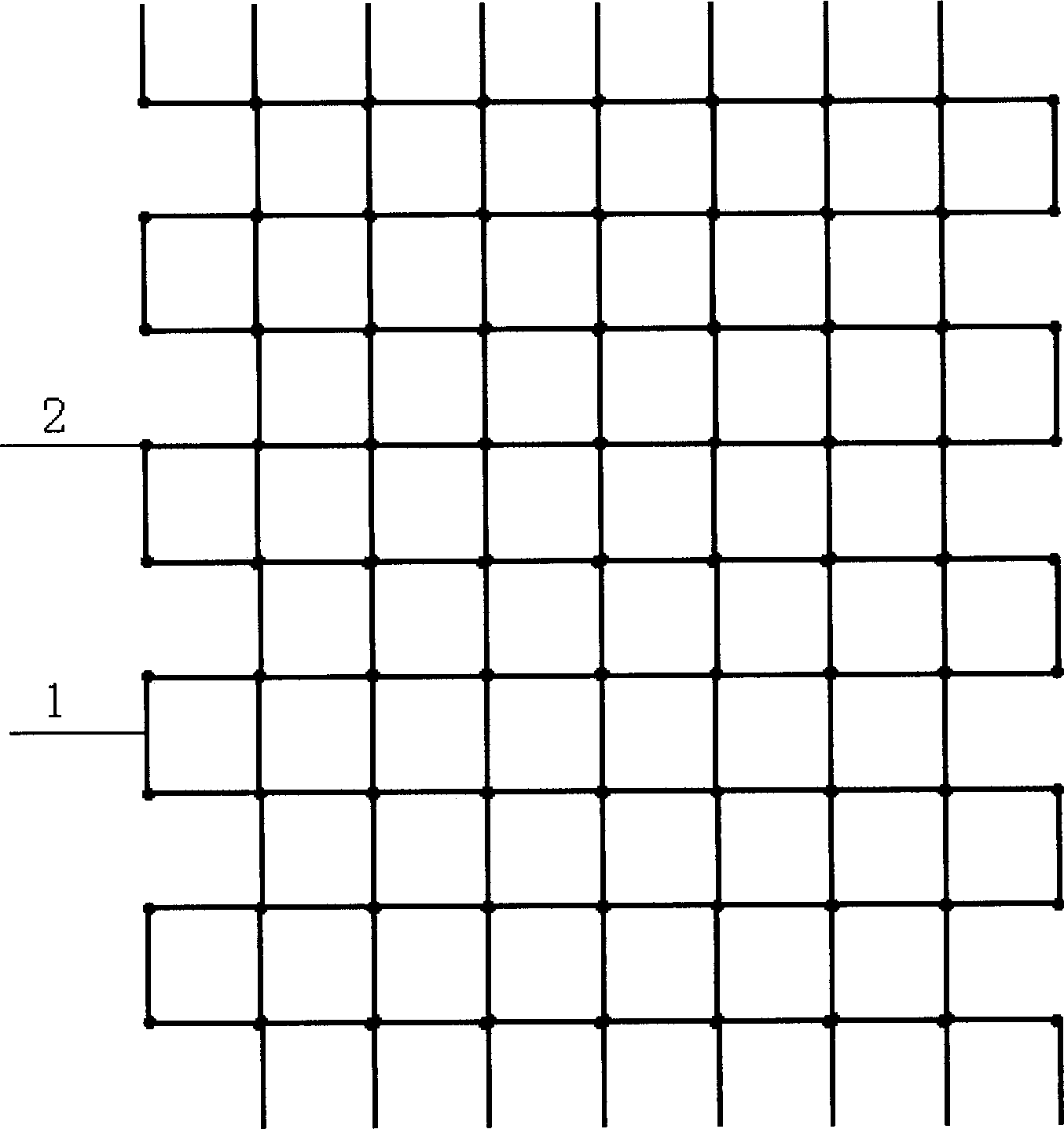

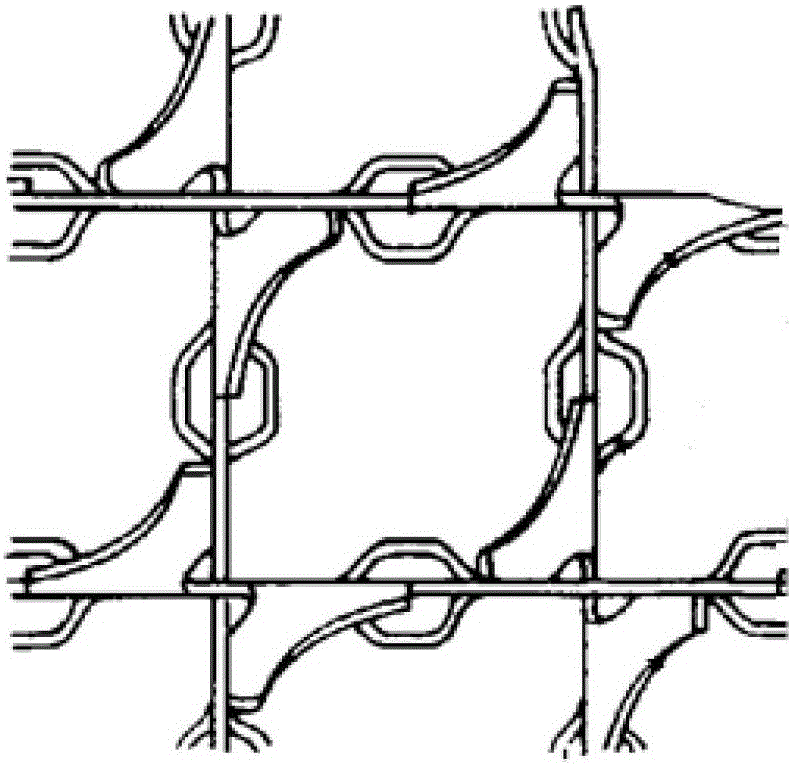

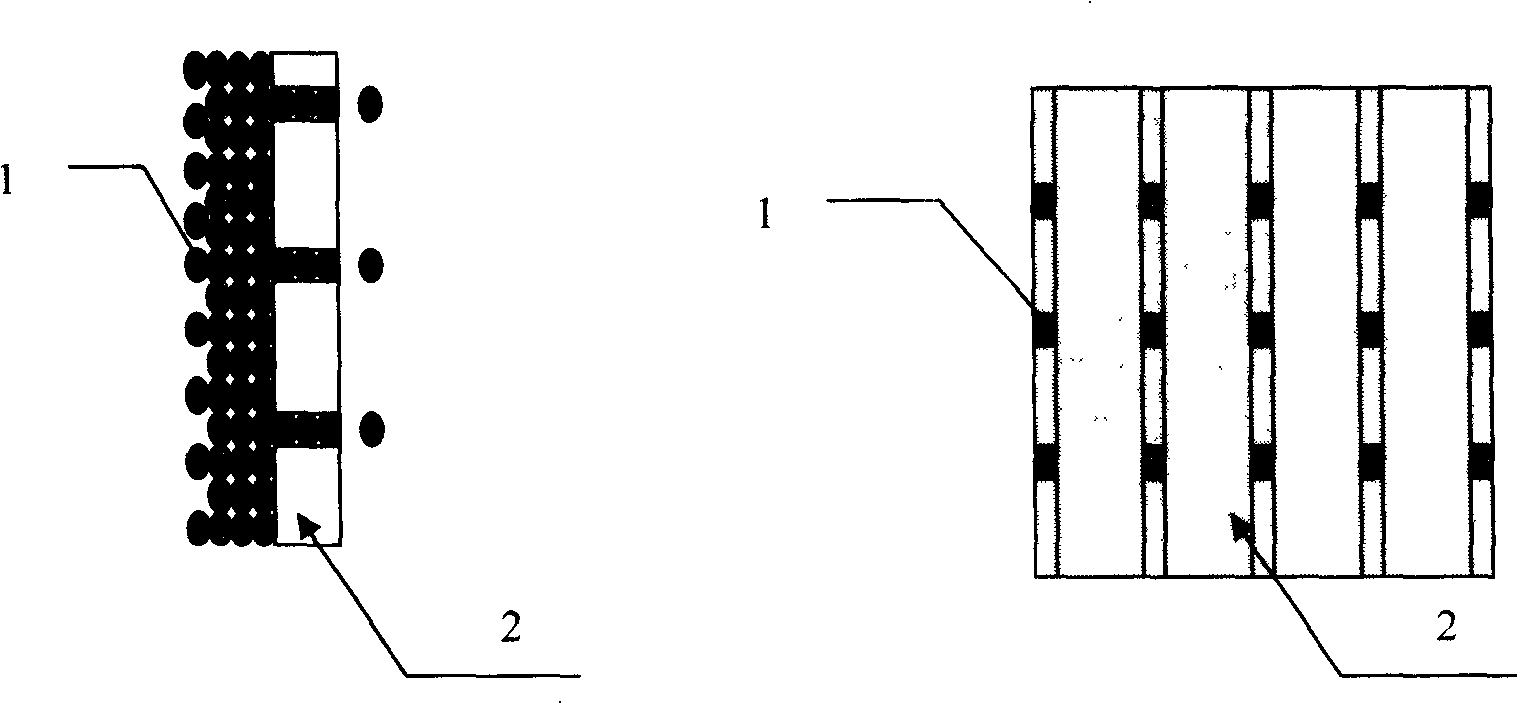

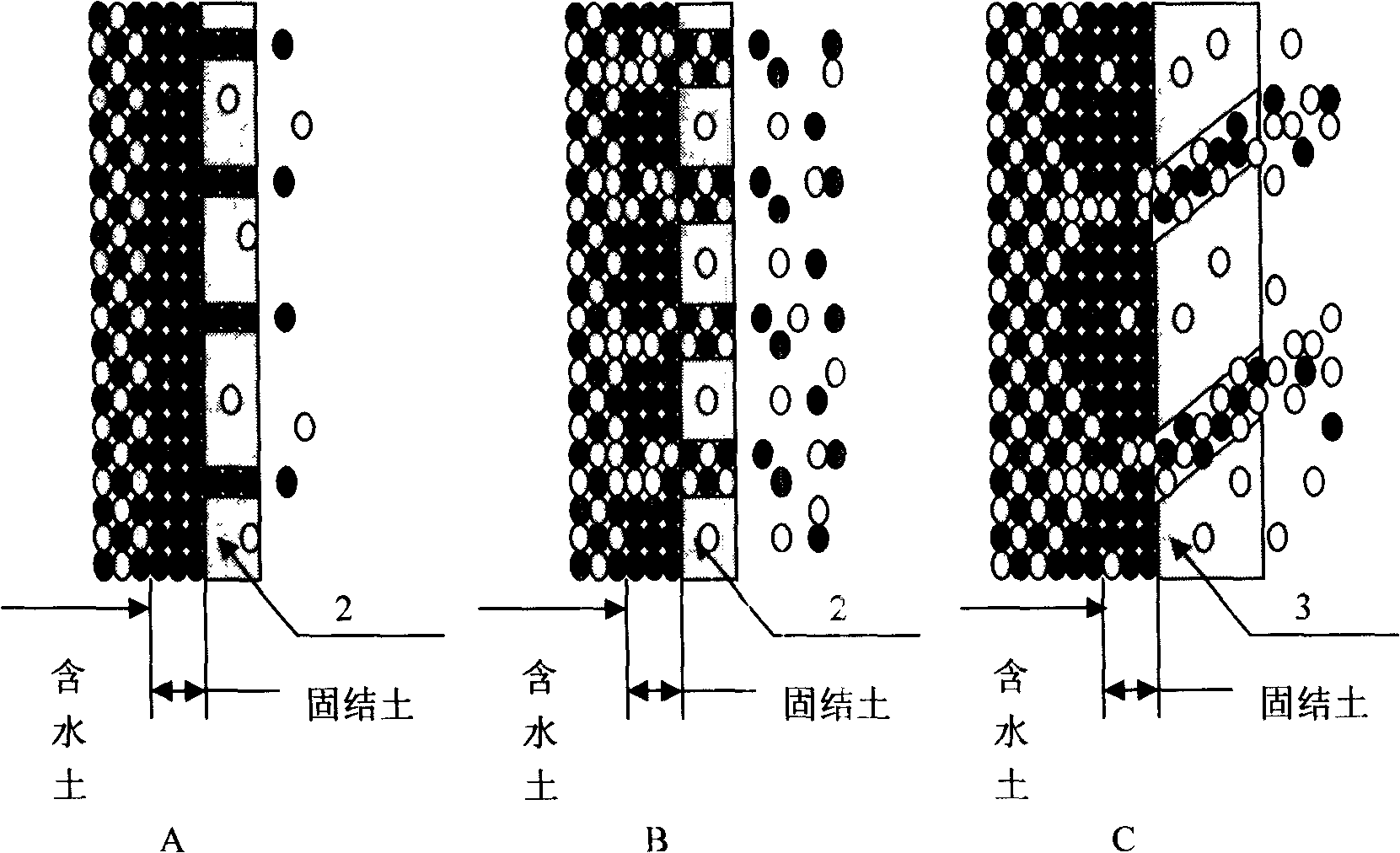

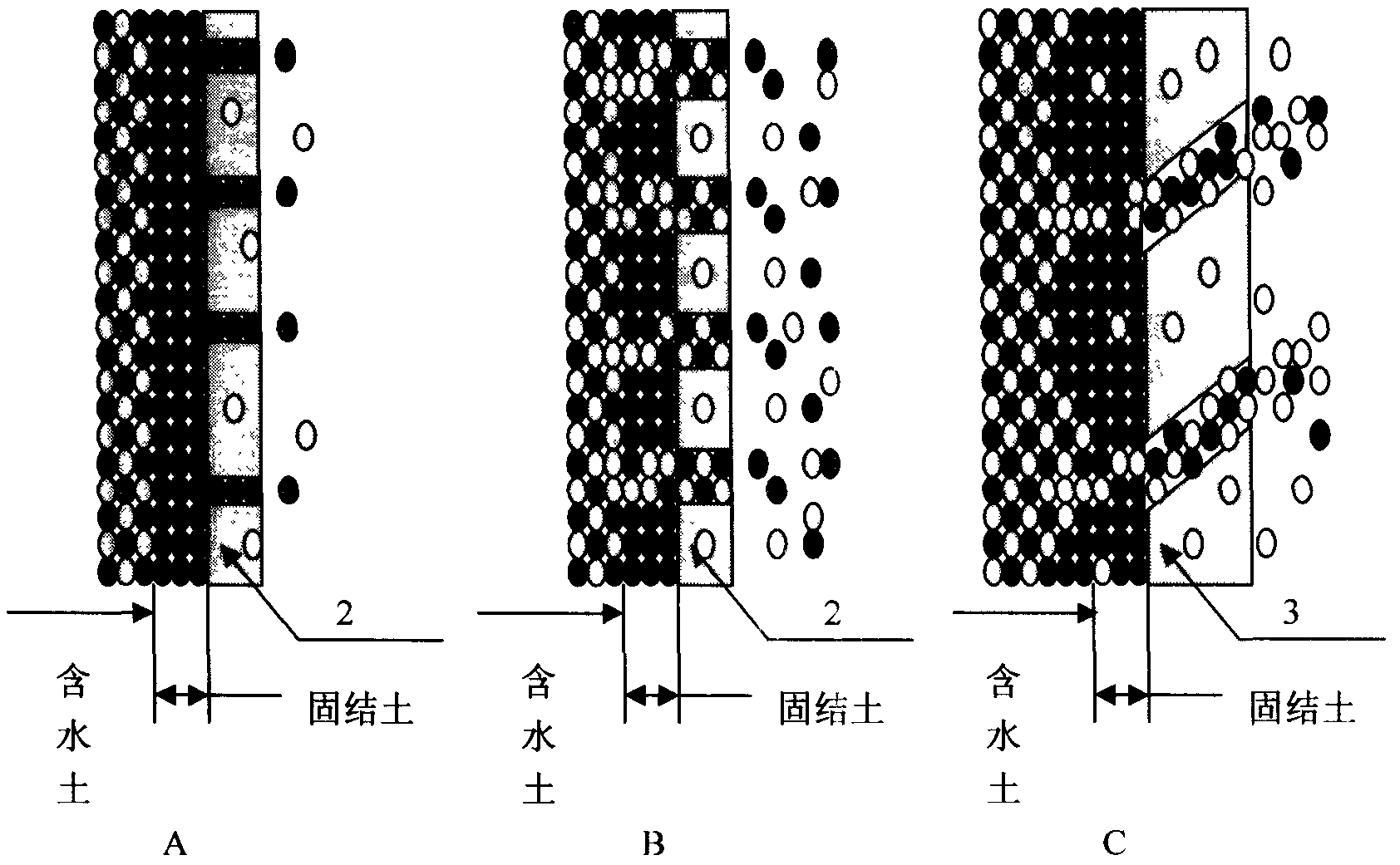

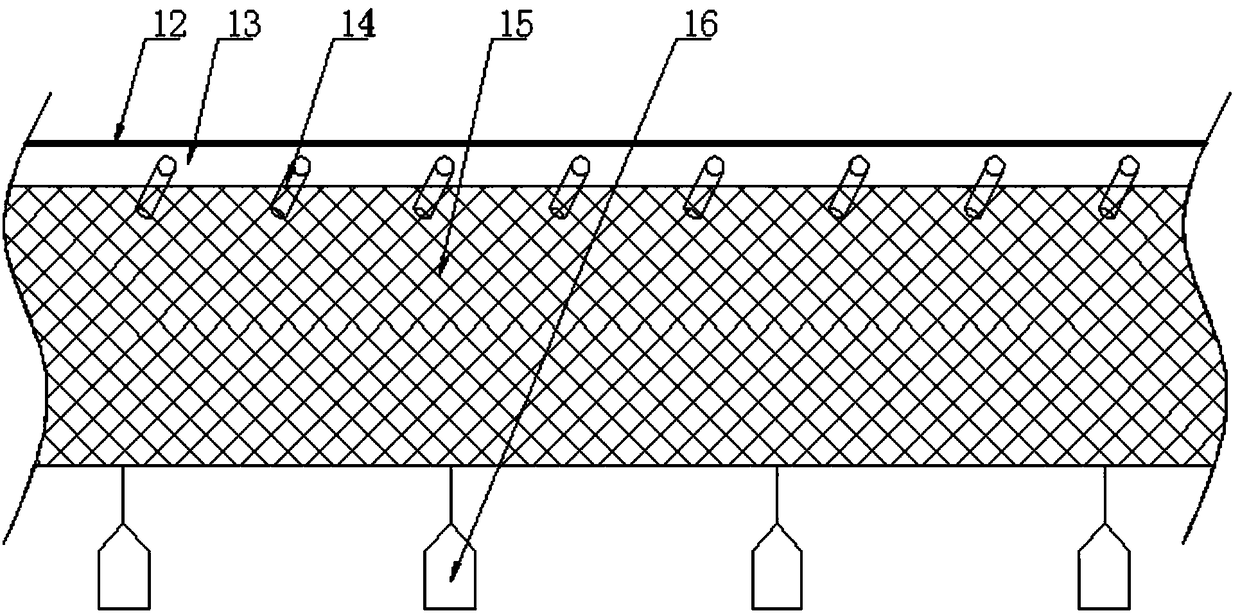

Earth-work fabric of inter woven flat monofilament and split film yarn and its use

InactiveCN1944008BImprove protectionImprove adsorption capacityWoven fabricsPolymer scienceSynthetic resin

The present invention relates to earth-work fabric technology, and is especially one kind of earth-work fabric with interwoven flat monofilament and split film yarn. The earth-work fabric is made with synthetic resin as raw material and has stereo opened netted structure with flat monofilament as warp yarn and split film yarn as weft yarn. The earth-work fabric has initial speeded water draining effect, and can form solidified colloidal earth layer in the earth side to produce friction resistance to other earth, reduce earth motion and form water draining passage in the interwoven parts.

Owner:SHANGHAI NEW TECHTEXTILES

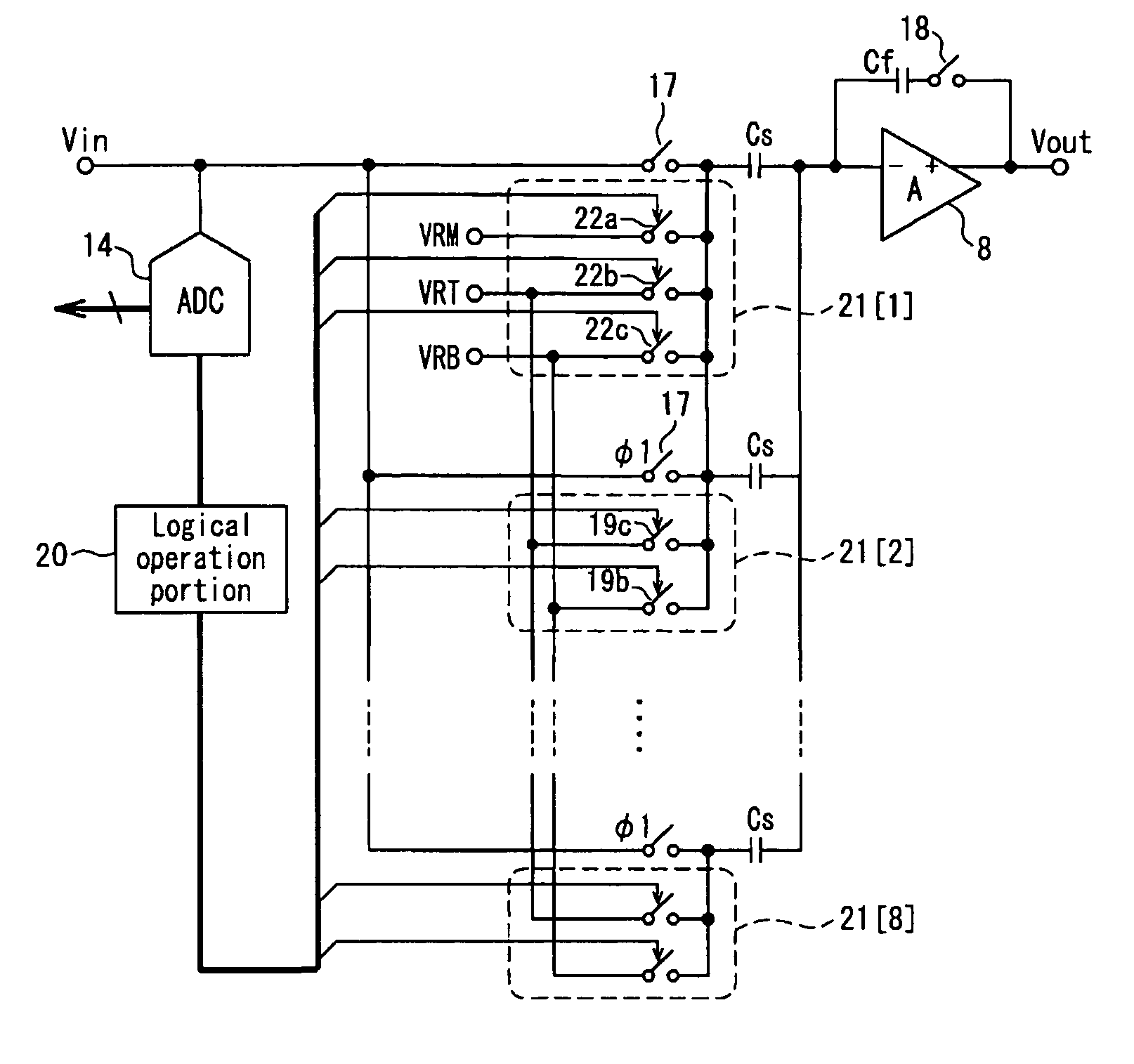

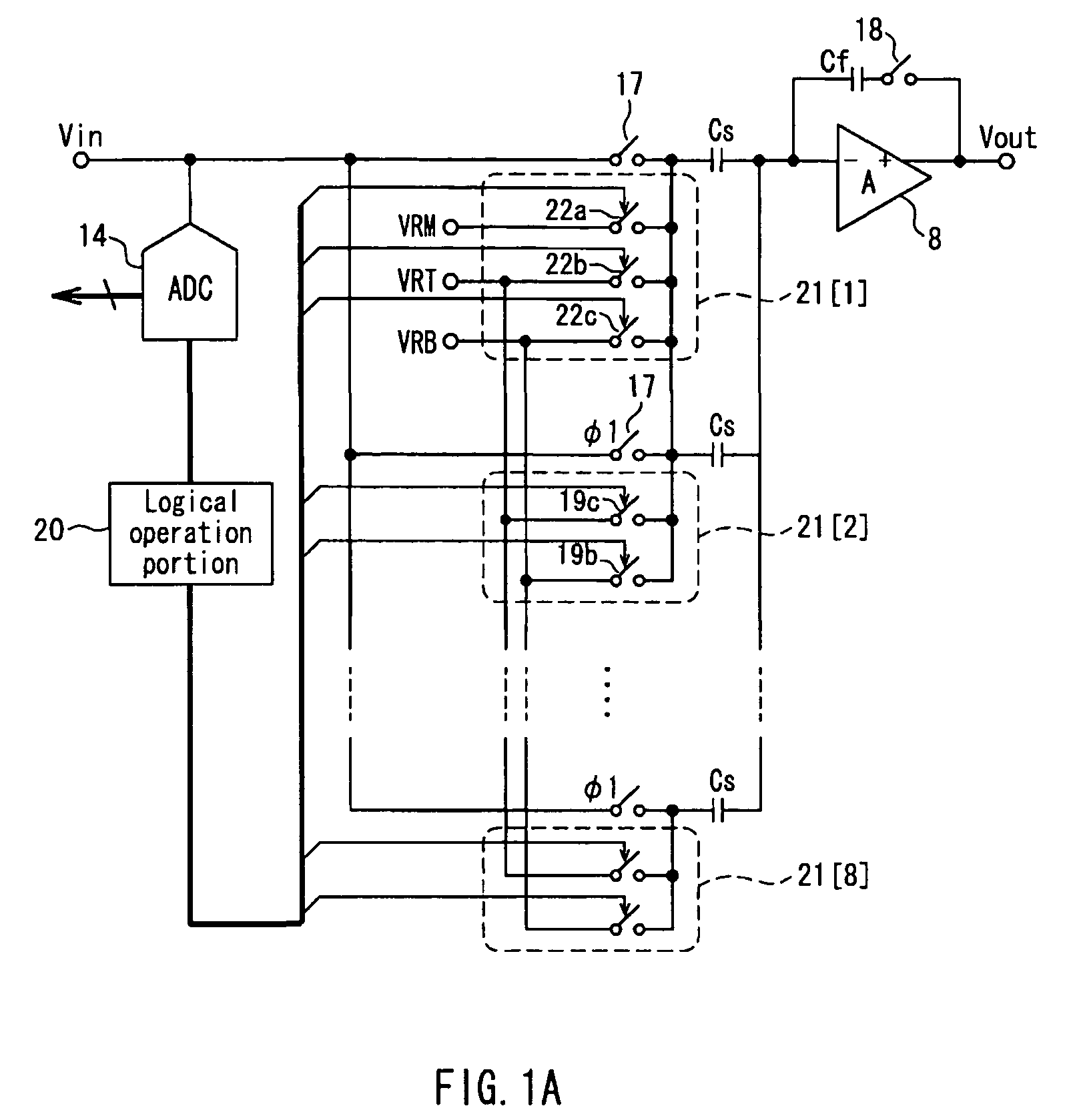

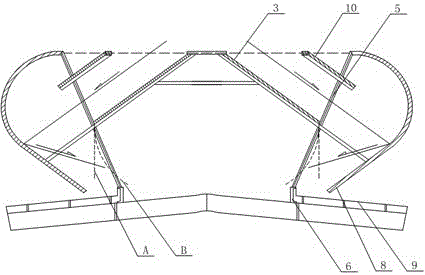

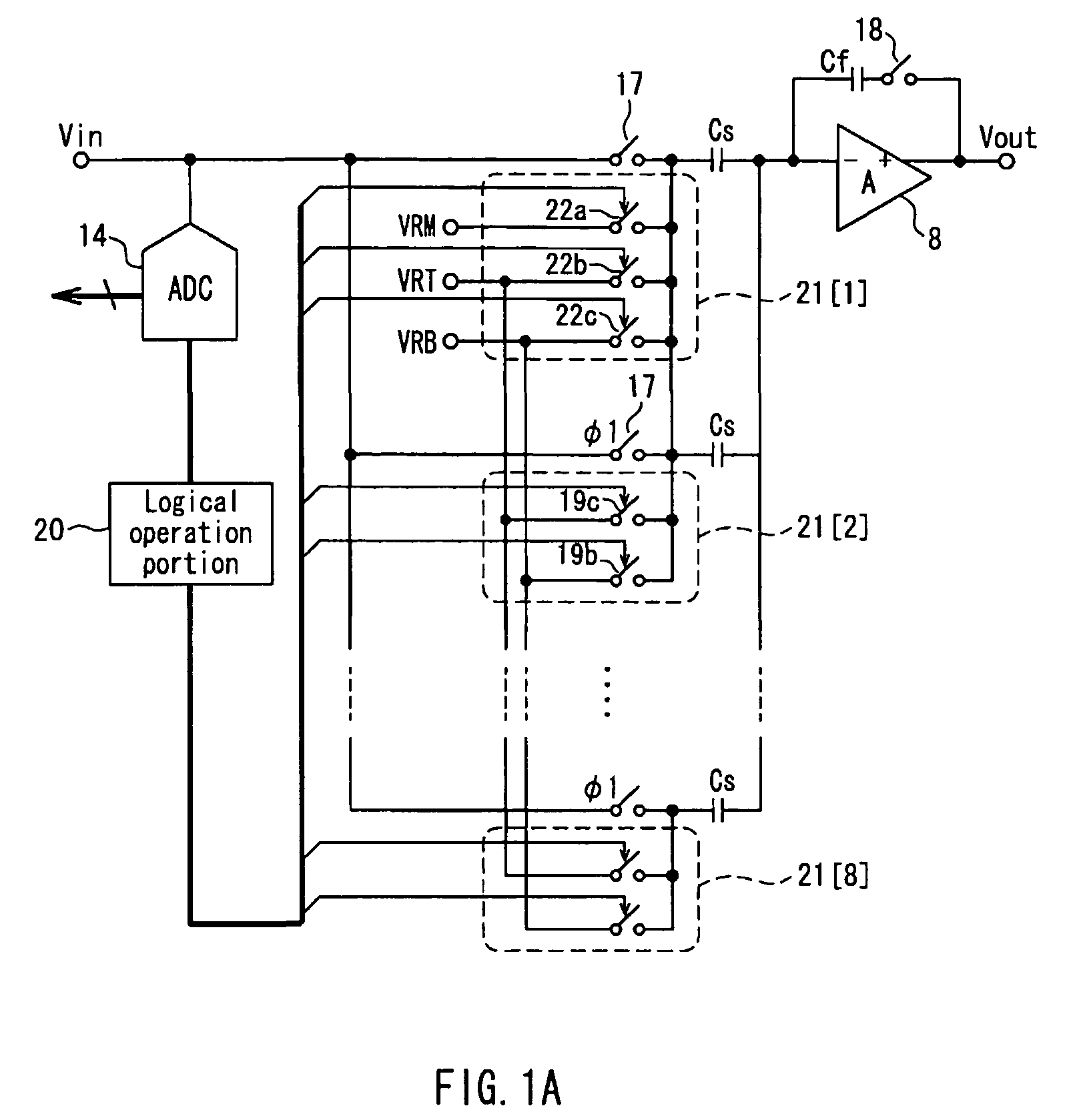

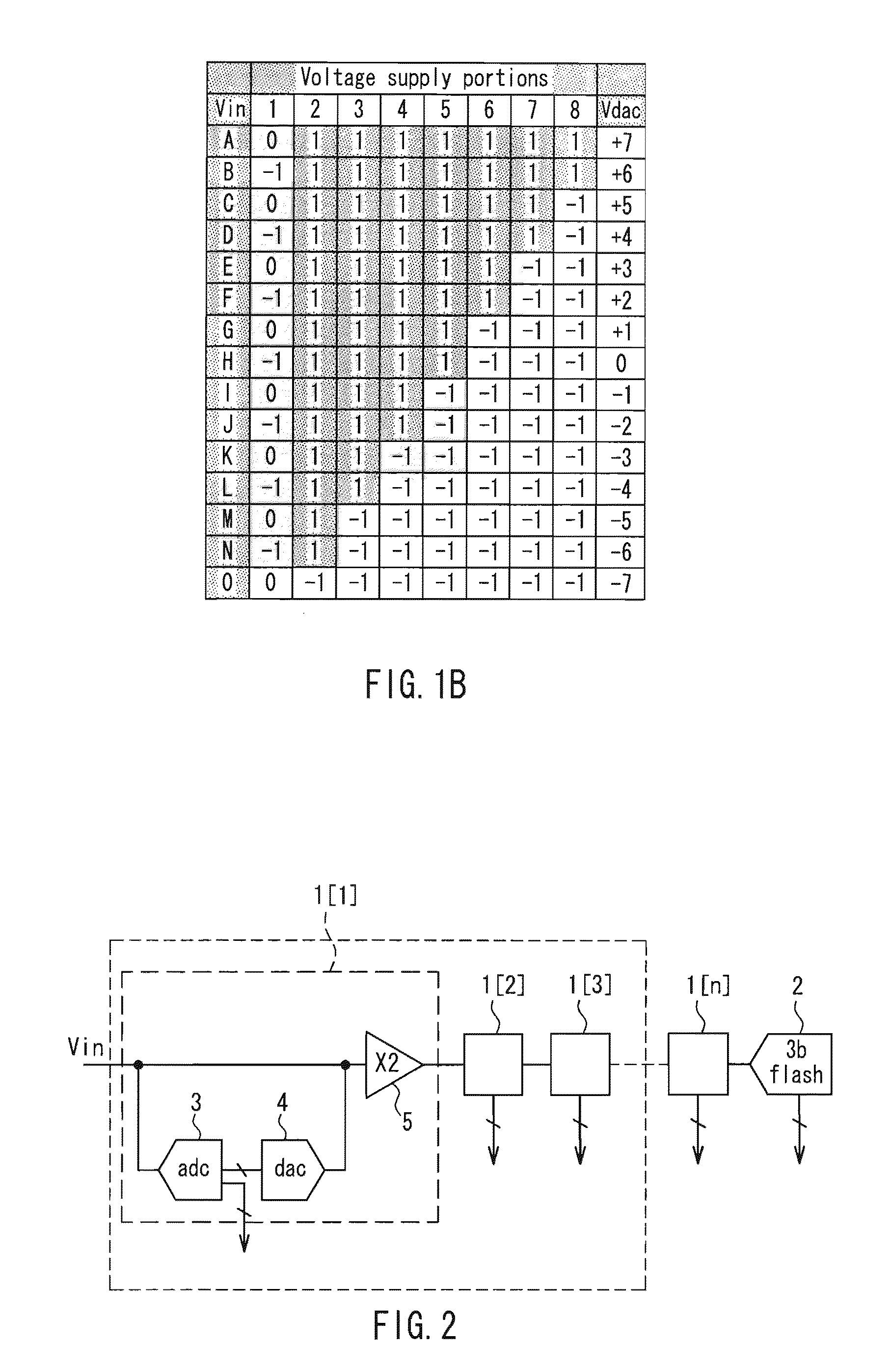

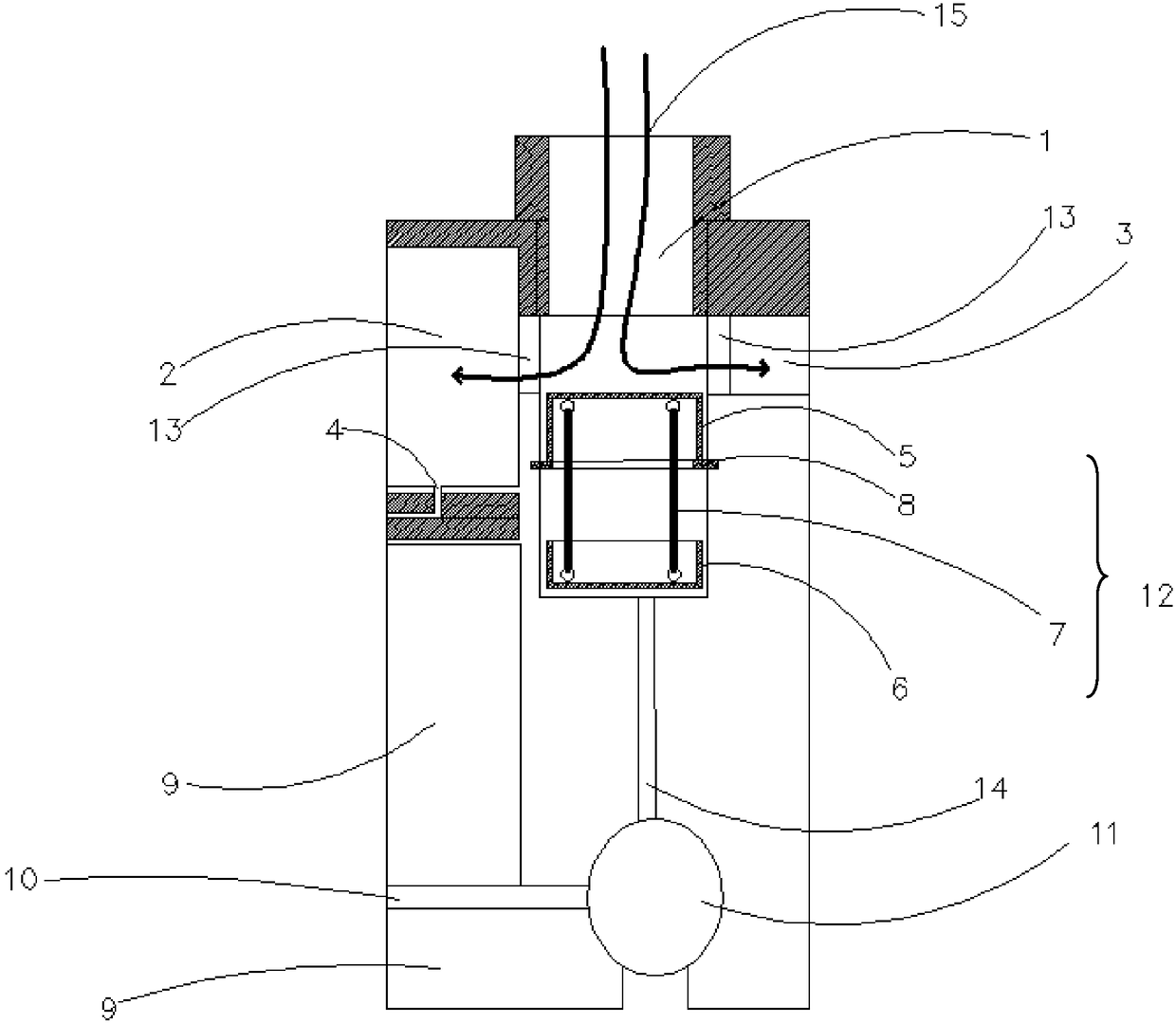

Pipeline A/D converter and digital camera

ActiveUS7812756B2Increase the areaReduce power consumptionTelevision system detailsElectric signal transmission systemsBuck converterĆuk converter

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

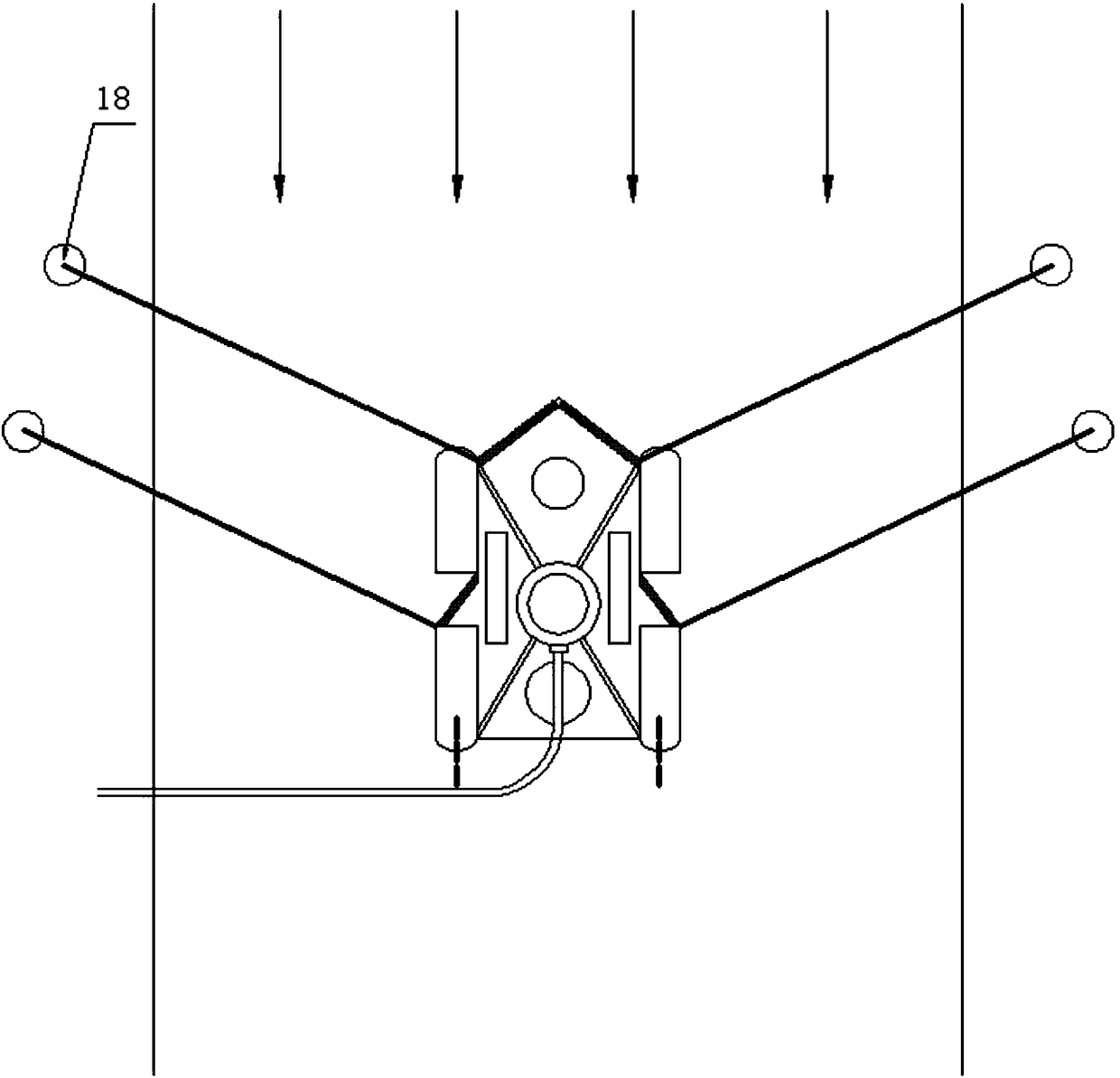

Suspension pump type algae suction device

The invention discloses a suspension pump type algae suction device. The suspension pump type algae suction device comprises a floating body, floating boxes, suspension type fences and a clog-free pump. A front portion algae inlet and side algae inlets are formed in the front portion and the middle of the floating body correspondingly. The floating boxes are arranged at four corners of the bottomof the floating body correspondingly. The clog-free pump is mounted in the middle of the floating body. One end of each suspension type fence is arranged on a bank foundation, and the other ends of the suspension type fences are arranged at the connecting position of the front portion algae inlet and the floating body and the connecting positions of the side algae inlets and the floating body. According to the suspension pump type algae suction device, the front portion algae inlet and the side algae inlets are adopted to be matched with the two suspension type fences matched with the algae inlets, and therefore, algae water can be blocked and collected more effectively; and the good foundation is laid for subsequent filtration and elimination.

Owner:天津市引滦工程尔王庄管理处

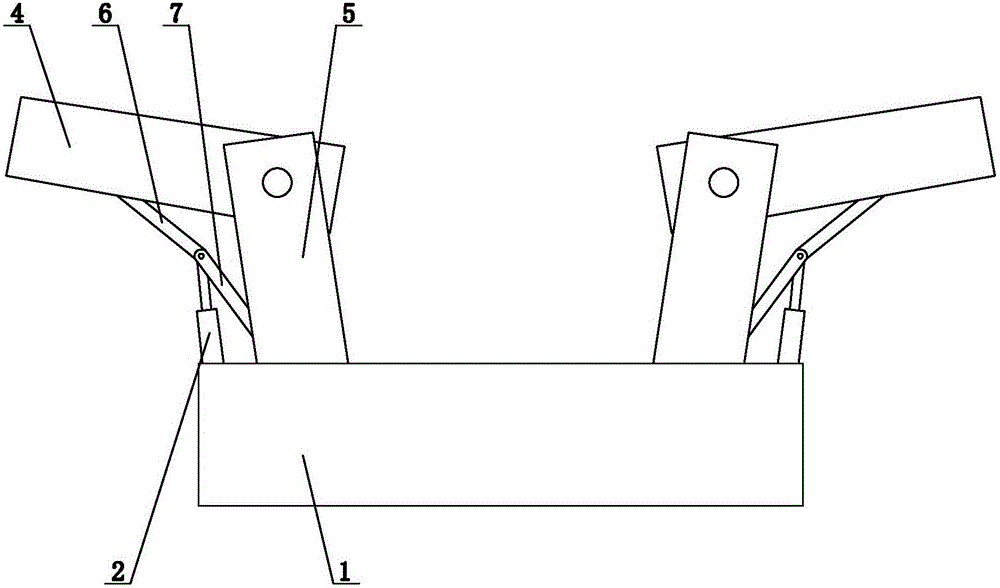

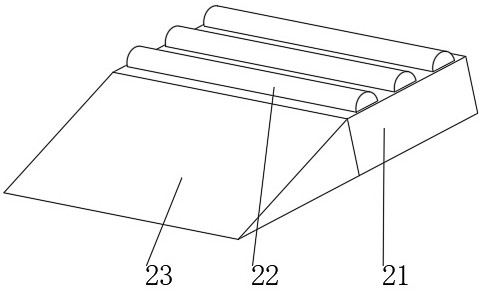

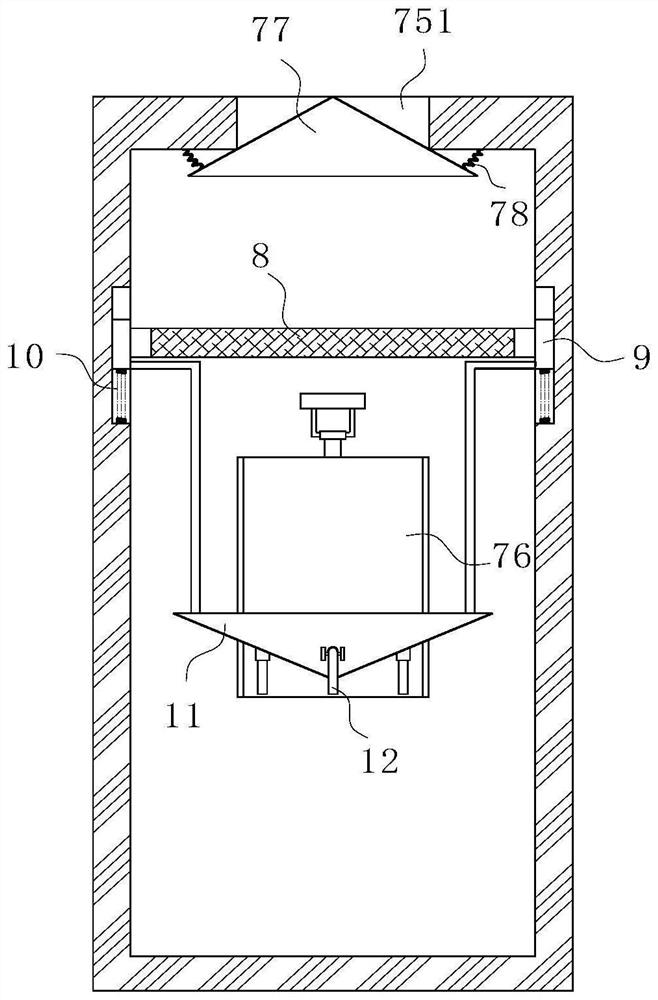

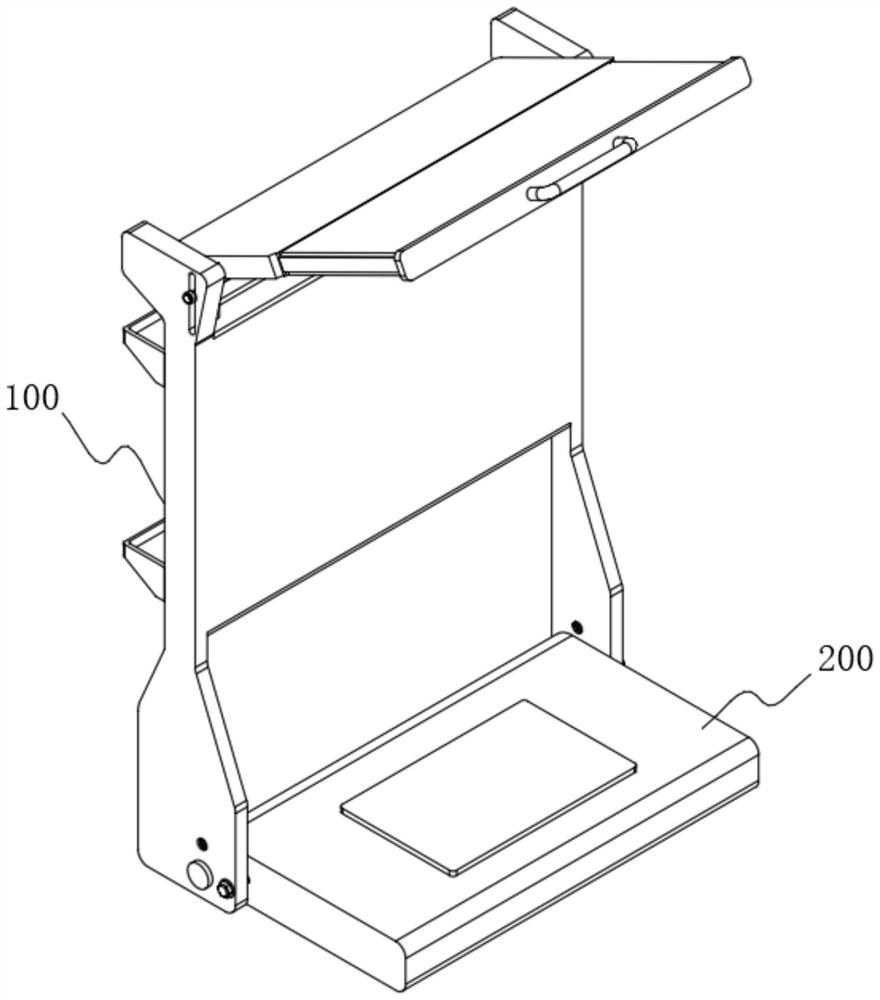

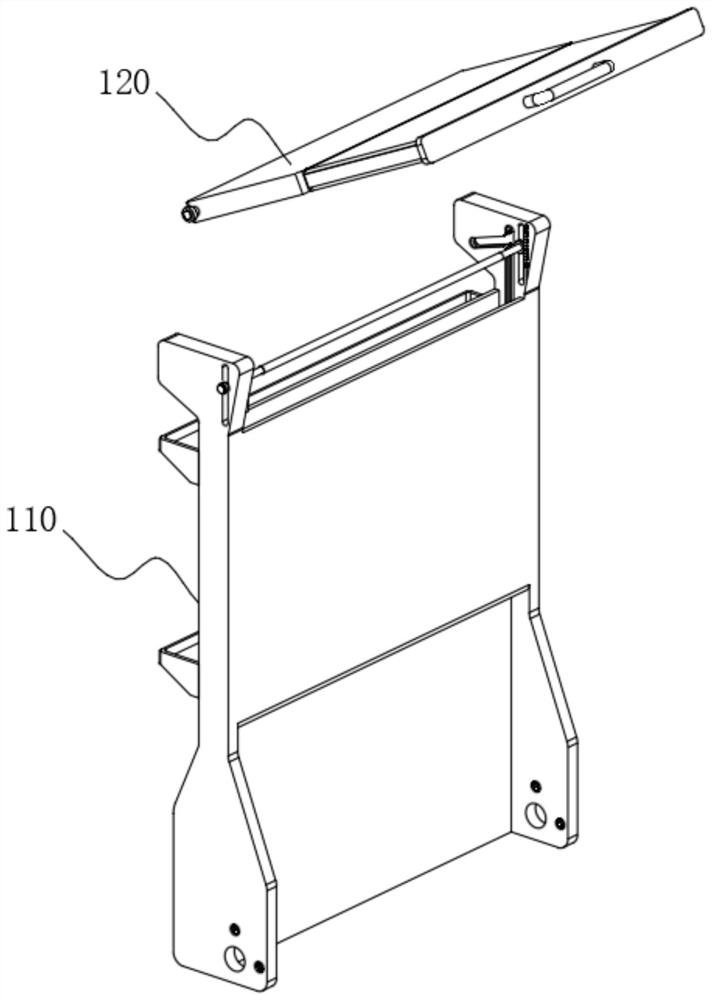

A kind of canopy for charging pile installed in retractable and foldable way

ActiveCN112721682BSolve the problem of reducing the irradiation area of solar panelsAvoid damageCharging stationsGeneral water supply conservationStructural engineeringMechanical engineering

The present invention relates to the technical field of charging piles, in particular to a canopy for charging piles that is retracted and folded. It includes an overturned fluid blocking device and an overturning plate arranged at the bottom of the overturned fluid blocking device to support it. In the present invention, rainwater is blocked by the resistance effect of the storage plate, so as to prevent the rainwater from directly contacting the charging column at the bottom thereof, thereby preventing the solar panel installed outside the solar panel from being damaged due to water ingress, so as to prevent the solar panel for the charging pile from raining. In addition, it is stored through the storage cavity to save the occupied area of the storage board, and at the same time, there is no shelter on the top of the charging pile after storage, so as to provide enough irradiation area for the solar panels installed outside it, and then Solve the problem that the general rain shelter reduces the irradiation area of the solar panel.

Owner:国网安徽省电力有限公司定远县供电公司

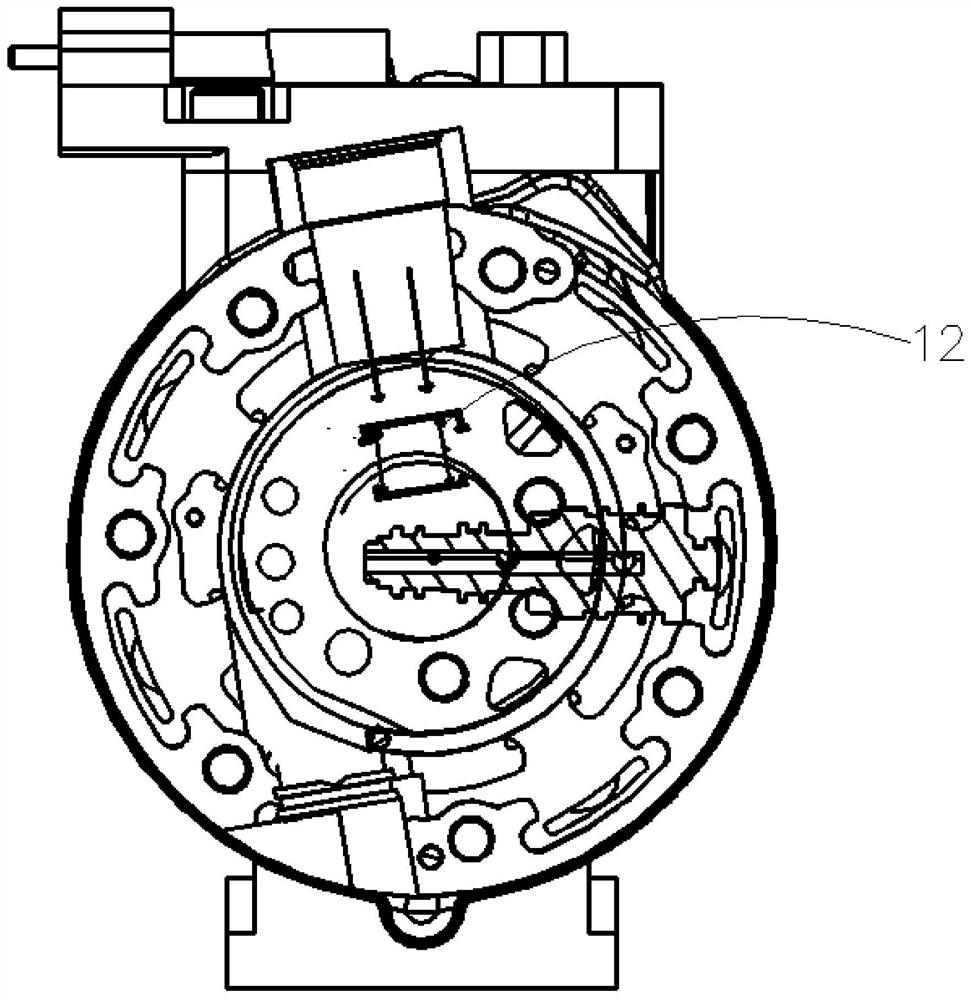

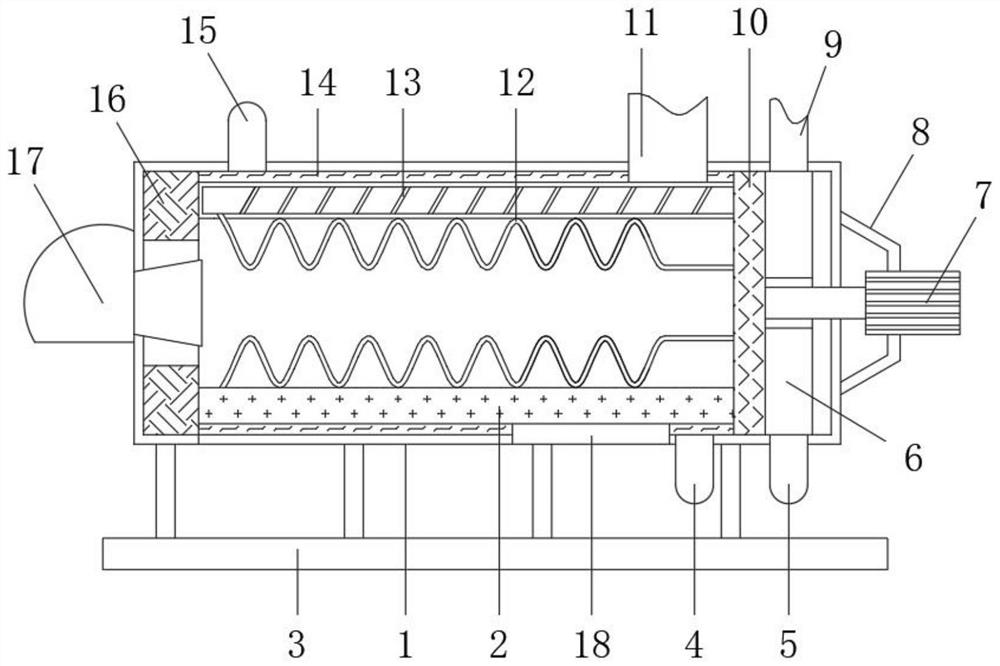

Biomass particle conduction oil boiler

InactiveCN114440456AExtended pathFull heat absorption and heat exchangeStorage heatersRotary device cleaningCombustorElectric machine

The invention belongs to the technical field of biomass fuel, particularly relates to a biomass particle heat-conducting oil boiler, and aims to solve the problems of low heat exchange efficiency and heat waste caused by short heat exchange time of existing heat-conducting oil, and provides the following scheme: the biomass particle heat-conducting oil boiler comprises a supporting base, and a boiler body is fixedly mounted at the top end of the supporting base; a combustor is fixedly installed at the upper middle end of the outer wall of one side of the furnace body, a fixing frame is fixedly installed on the outer wall of the other side of the furnace body, a driving motor is fixedly installed in the middle of the fixing frame, and a middle oil tank and a fixing plate are sequentially arranged at the output end of the driving motor. Low-temperature heat conduction oil enters the cooling oil cavity from the oil inlet pipe and is guided into the heat exchange shell along the coil pipe, finally, the high-temperature heat conduction oil after heat exchange is gathered in the high-temperature oil cavity and is guided out of the oil outlet pipe, meanwhile, flowing cooling water is arranged in the water cavity cover, and the water cavity cover, the heat exchange shell and the coil pipe are sequentially arranged from inside to outside. And the coil pipe, the heat exchange shell and the water cavity cover have the effect of layer-by-layer heat transfer and exchange.

Owner:毛善军

A composite artificial fish reef

ActiveCN107242177BSolve pollutionImprove survival rateClimate change adaptationPisciculture and aquariaJuvenile fishMechanical engineering

The invention relates to a composite type artificial fish reef which comprises a square frame reef, tire-shaped concrete components and a bait culture medium. The square frame reef is arranged in a hollow mode, the incident flow face and the reverse flow face of the square frame reef are symmetrically provided with circular open holes respectively, the tire-shaped concrete components are symmetrically arranged at the upper portion of the square frame reef, meanwhile, the multiple tire-shaped components and the bait culture medium are symmetrically arranged on the two side wall faces of the square frame reef, and shells are arranged in the bait culture medium. Obviously, while the composite type artificial fish reef solves the problem of tire reef pollution, the advantages of the tire reef are reserved, the formed flow field effect is good, larger upward flow and back eddy flow are formed, the reef influence range is enlarged, the better survival environment is provided for advanced fries and juvenile fish, the juvenile fish survival rate can be greatly increased, fishery culture and proliferation and aquatic organism diversity protection are facilitated, and the better application prospect is achieved.

Owner:OCEAN UNIV OF CHINA

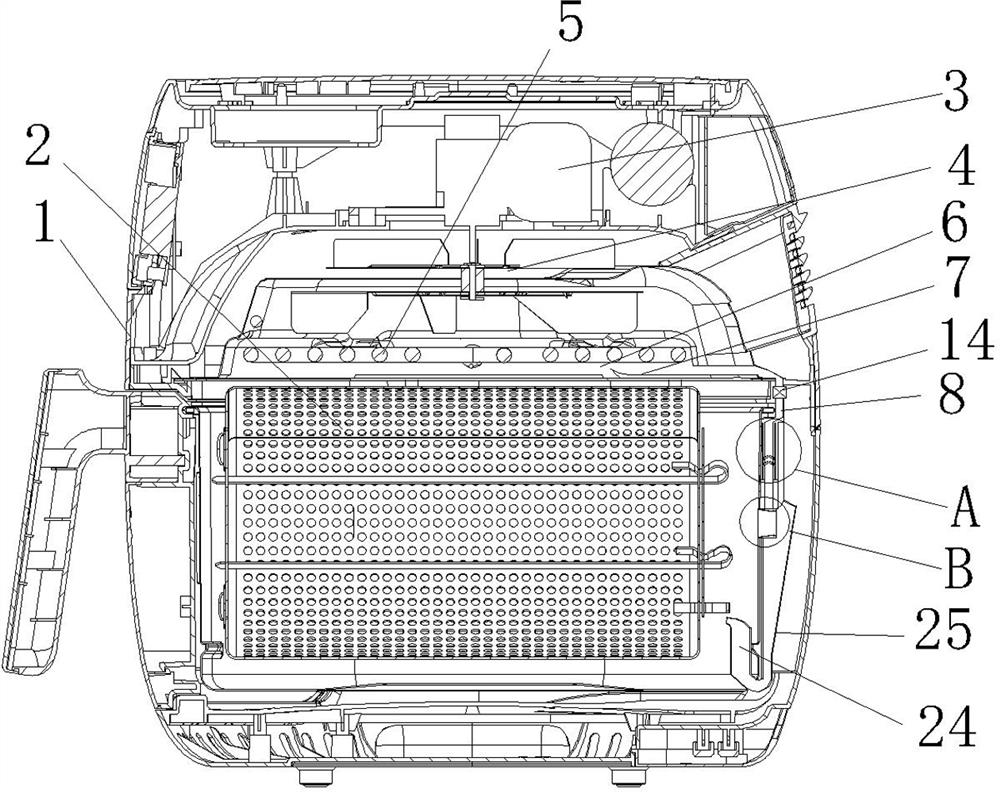

A scorching-proof air fryer

The invention discloses an anti-scorch air fryer, which comprises a pot body; a driving motor is installed on the upper part of the pot body, a fan is installed on the output shaft of the driving motor, an electric heating wire is installed under the fan, and a heating wire is installed on the upper part of the pot body to facilitate the flow of hot air. There is a blower on one side of the blower, a deflector is provided on one side of the blower, and a side air pipeline connected to the upper area of the guide is provided on one side of the pot body. For the middle part of the food rack, an annular cavity is arranged in the horizontal air blowing pipe, and the outer side of the annular cavity is externally connected to the bottom of the pot body through the return line; It is composed of a tapered inner wall adjacent to the side of the inner cavity of the pot. The invention solves the problem that the existing anti-scorch air fryer has uneven heat on the top and bottom of the air fryer due to the blocking and heat absorption of food, and the food on the top is easy to burn, while the bottom of the air fryer is easy to burn. The defect of the situation where the food is still undercooked.

Owner:宁波曼华电器有限公司

Cleaning device applied to thrombus prone to falling off in blood vessel

The invention discloses a cleaning device applied to thrombus prone to falling off in a blood vessel. The cleaning device comprises an interventional tube, a first telescopic tube is arranged at the interventional end of the interventional tube and can stretch out and draw back in the axial direction of the interventional tube, one end of the first telescopic tube is connected with the interventional tube, a connecting block is arranged at the other end of the first telescopic tube, and multiple elastic baffles are arranged between the connecting block and the interventional tube; a pluralityof inner supporting plates are further arranged on the circumferential outer wall of the interventional tube; one end of each inner supporting plate is hinged to the interventional tube, an inner supporting ball is arranged at the other end of each inner supporting plate, a movable assembly is arranged between each inner supporting plate and the interventional tube, an elastic first movable plateis arranged in each inner supporting plate, an elastic second movable plate is arranged in each first movable plate, and each first movable plate is further provided with an outlet matched with the corresponding first movable plate. When thrombus which is easy to move in a blood vessel is cleaned, the blood vessel can be expanded, the thrombus is prevented from being pushed to move in the blood vessel, and the thrombus can be conveniently and rapidly cleaned out of the blood vessel.

Owner:HEBI CITY PEOPLES HOSPITAL

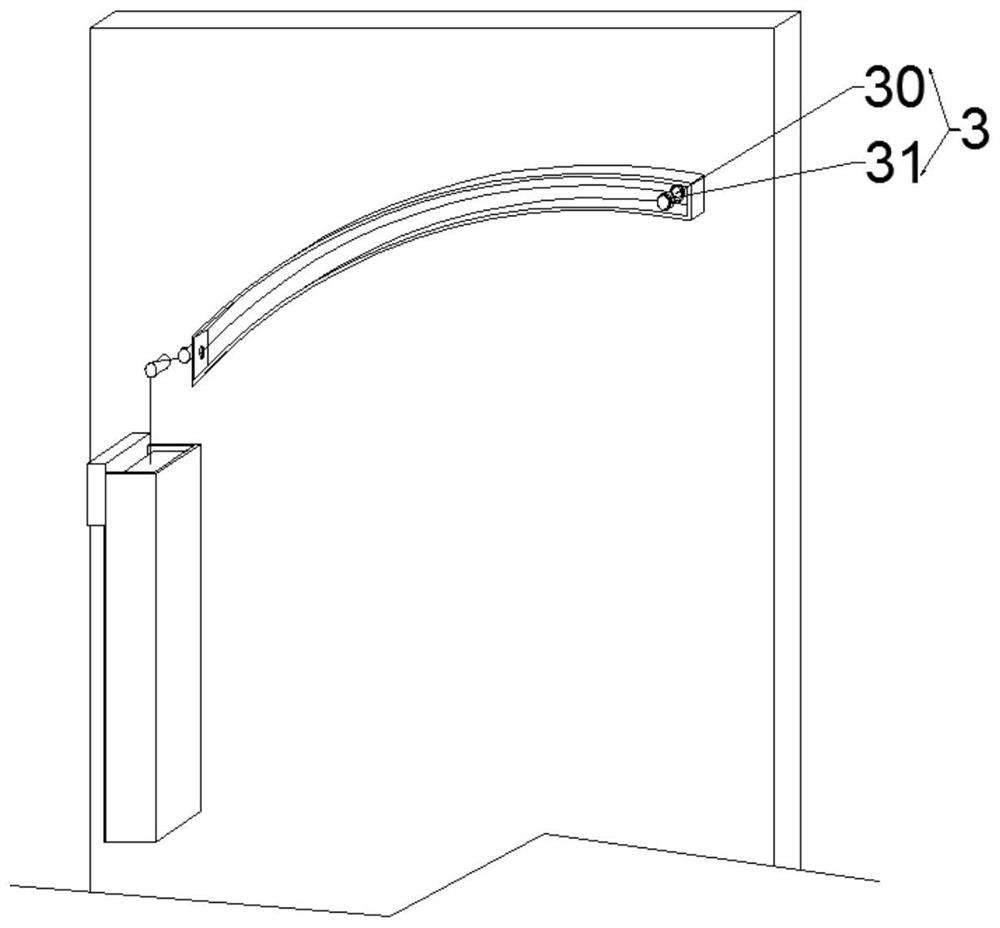

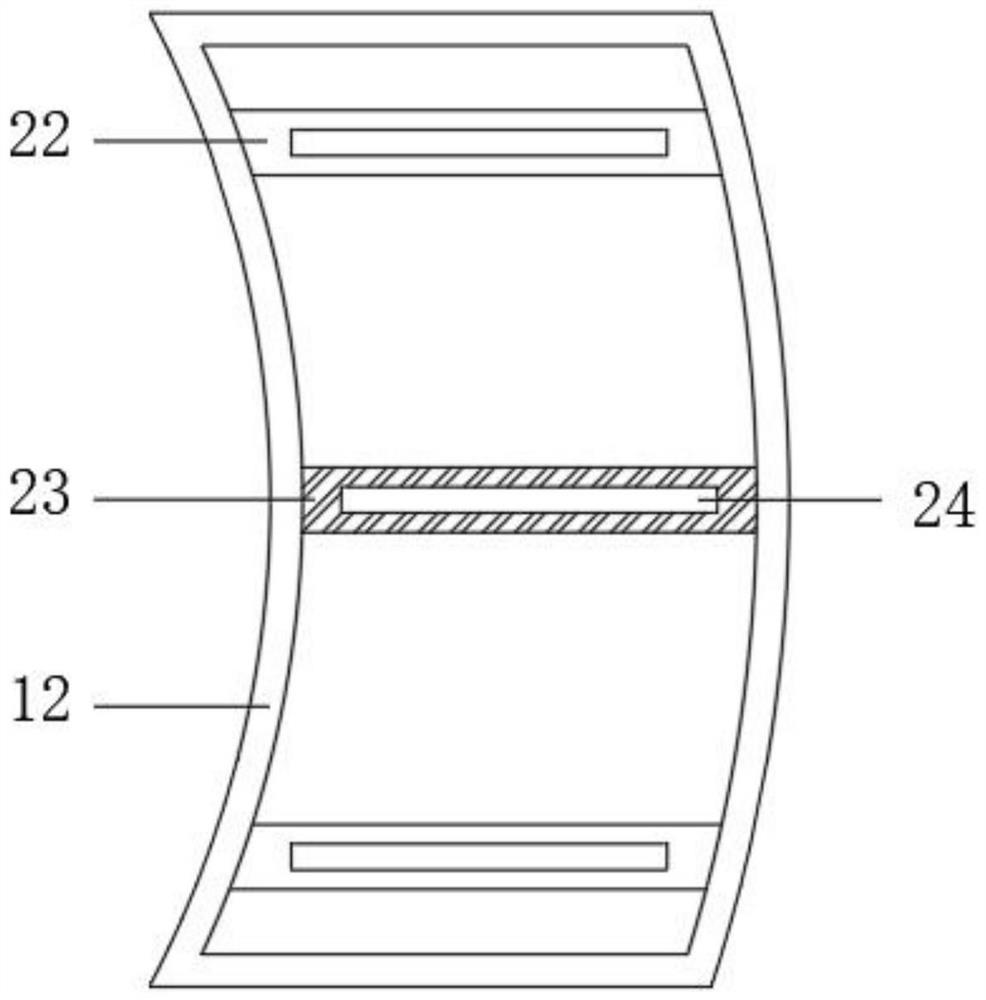

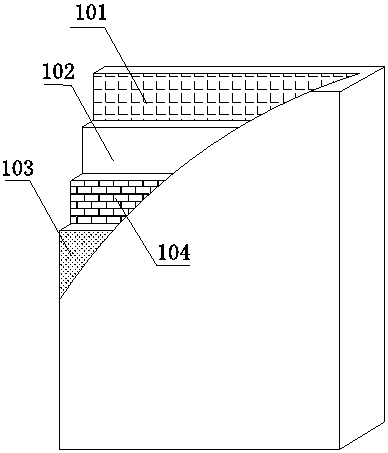

Ventilating skylight

InactiveCN106013576AIncrease blocking areaPrevent water leakageBuilding roofsRoof drainageAirflowEngineering

The invention discloses a ventilation skylight, which comprises a skylight frame and a windshield. The skylight frame is laid on the skylight frame. The top of the windshield is provided with an air outlet corresponding to the skylight, and overflow prevention plates are arranged on both sides of the skylight. One side of the anti-overflow board is folded vertically upward and connected to the bottom of the lighting board, the other side of the anti-overflow board is folded and extended vertically upward, the upper section of the drain pipe is connected with the drainage holes opened on the anti-overflow board, and the lower section of the drain pipe is vertical It extends straight down to the color steel roof. In stormy weather, one side of the anti-overflow board is folded upward to connect with the bottom of the lighting board, while the other side of the anti-overflow board is folded and extended vertically upwards, and when the air flow is too strong, it can be folded along with the airflow. The flowing rainwater is blocked, collected in the anti-overflow board, and discharged from the drainage pipe to the color steel roof, that is, the organized gravity drainage is formed in the wind deflector to prevent water leakage in the workshop.

Owner:CHINA MCC5 GROUP CORP

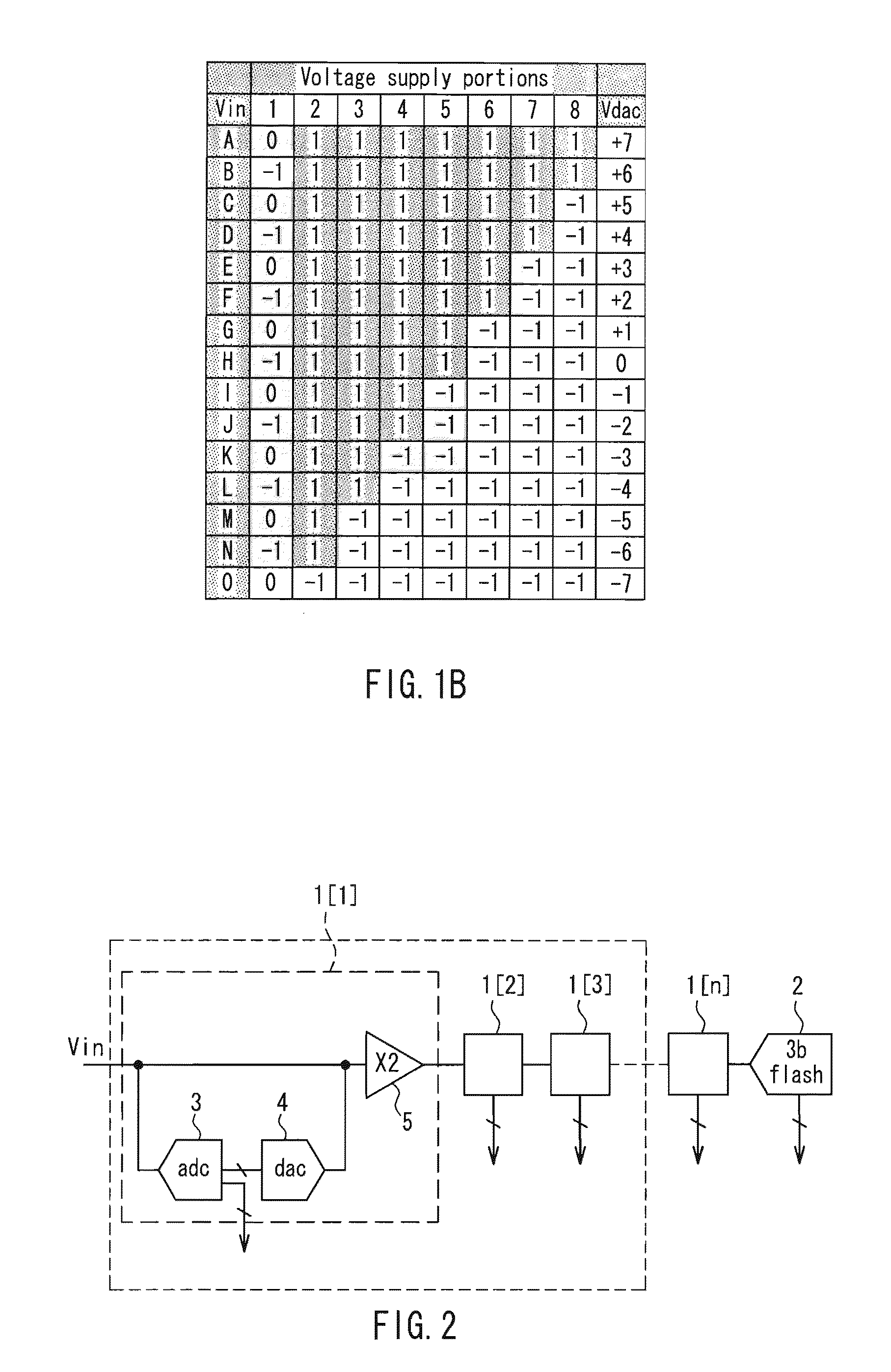

Pipeline a/d converter and digital camera

ActiveUS20090225185A1Increase the areaReduce power consumptionTelevision system detailsElectric signal transmission systemsVoltage referenceAnalog signal

In each of a plurality of stages, an input analog signal is quantized, so that a digital signal corresponding to each part of bits is generated. A DA conversion portion generates an analog reference signal based on the digital signal, and a remainder operation portion performs addition / subtraction and amplification by a predetermined factor with respect to the input analog signal. Then, the signal thus obtained is supplied to a subsequent stage. The DA conversion portion in the first stage where A / D conversion of a plurality of bits is performed includes primary voltage supply portions capable of outputting a reference voltage at one of a plurality of levels, and an auxiliary voltage supply portion capable of outputting a reference voltage at an auxiliary level different from the above-described level. The respective voltage supply portions selectively output the reference voltages based on a digital signal generated by an AD conversion portion. Based on a combination of the output reference voltages, the analog reference signal in accordance with the digital signal is generated. It is possible to reduce power consumption while suppressing an increase in the area of an element.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Compressor, air conditioning system and vehicle

ActiveCN109505771AReduce noiseSimple internal structureAir-treating devicesVehicle heating/cooling devicesRefrigerantMuffler

The invention relates to the field of vehicle engineering, and provides a compressor, an air conditioning system and a vehicle. The compressor comprises an air suction passage and an air suction chamber, the air suction chamber communicates with the air suction passage through an air suction opening, a silencer structure is arranged in the air suction passage, the silencer structure is arranged tobe capable of moving in the air suction passage according to the exhaust volume of the compressor so as to adjust a blocking area of the air suction opening, and an opening area of the air suction opening adapts to the size of the exhaust volume of the compressor. According to the compressor, the structure of the position which a refrigerant of the compressor flows into under different loads canbe changed adaptively, so that noise of the compressor is effectively reduced; and moreover, the internal structure of the compressor is simple, the manufacturing and assembling difficulty is low, andthe cost is low.

Owner:GREAT WALL MOTOR CO LTD

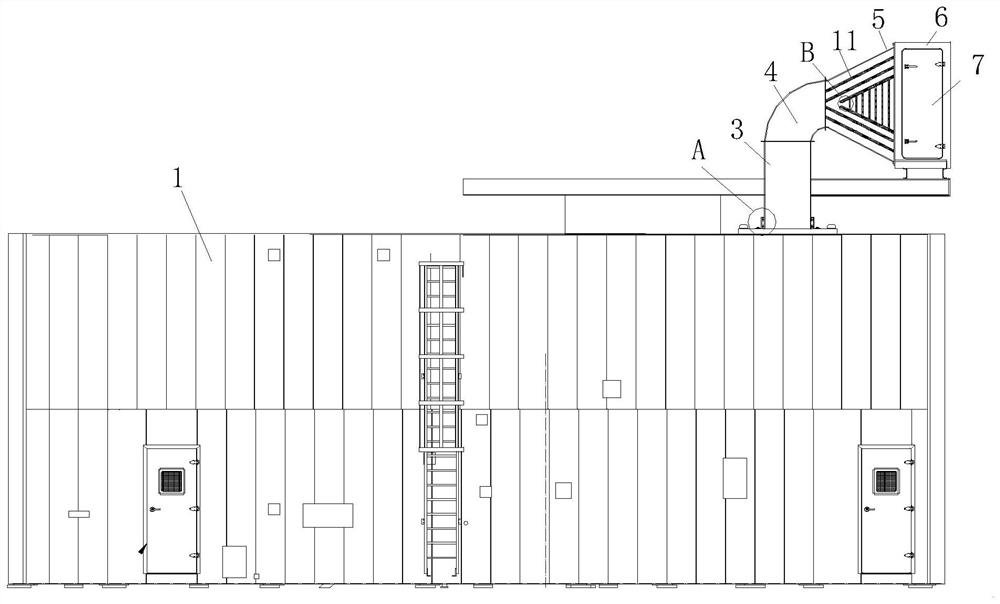

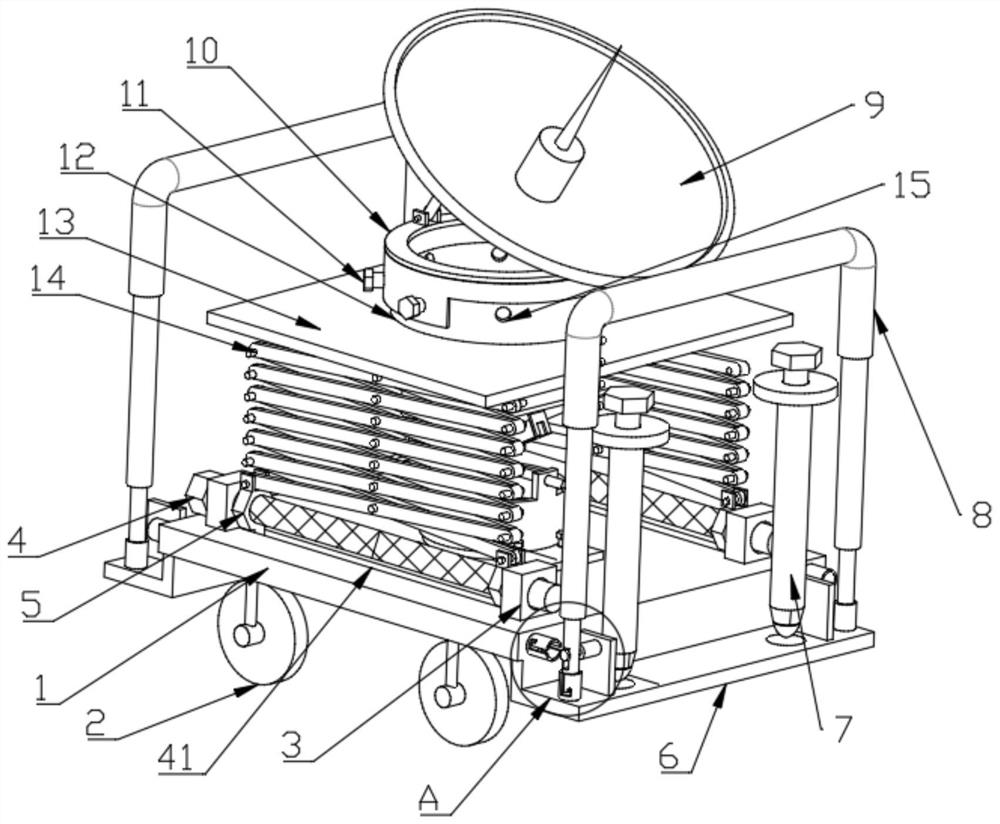

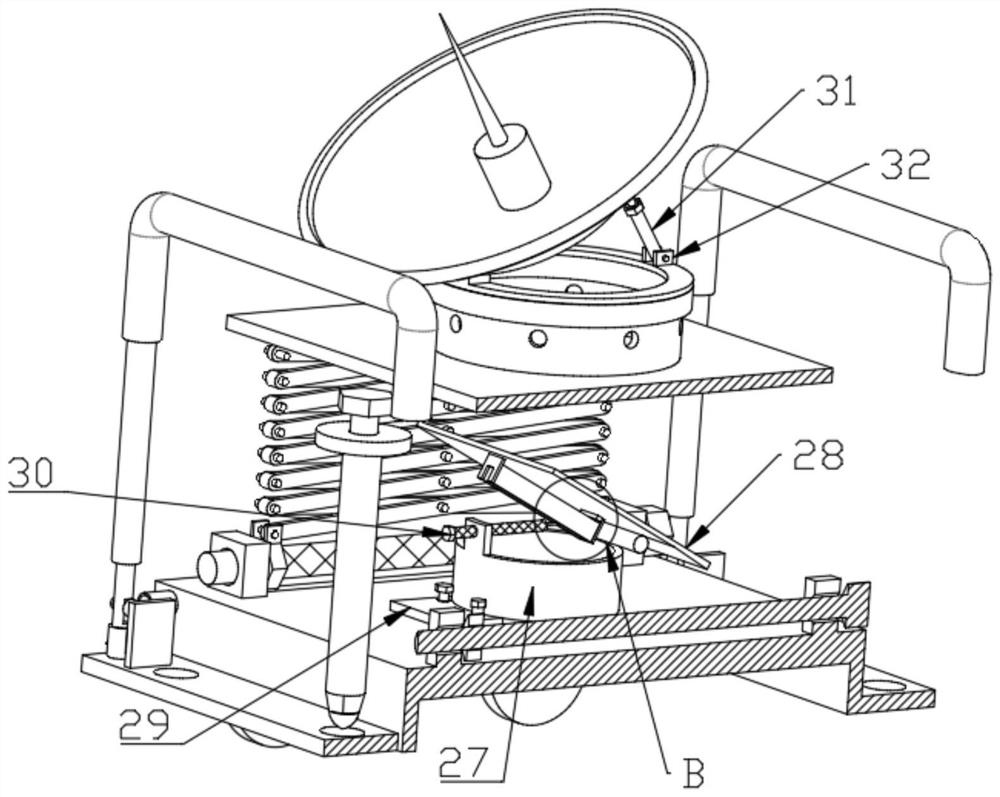

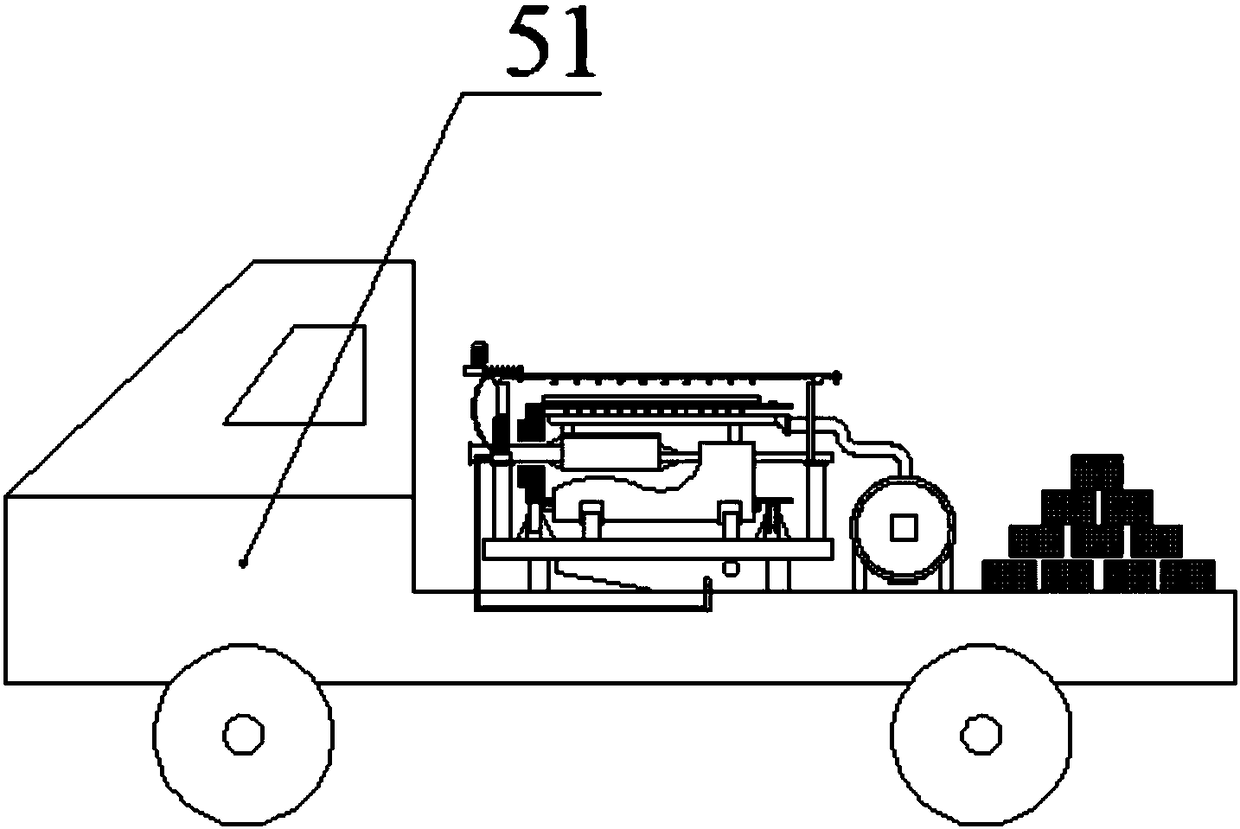

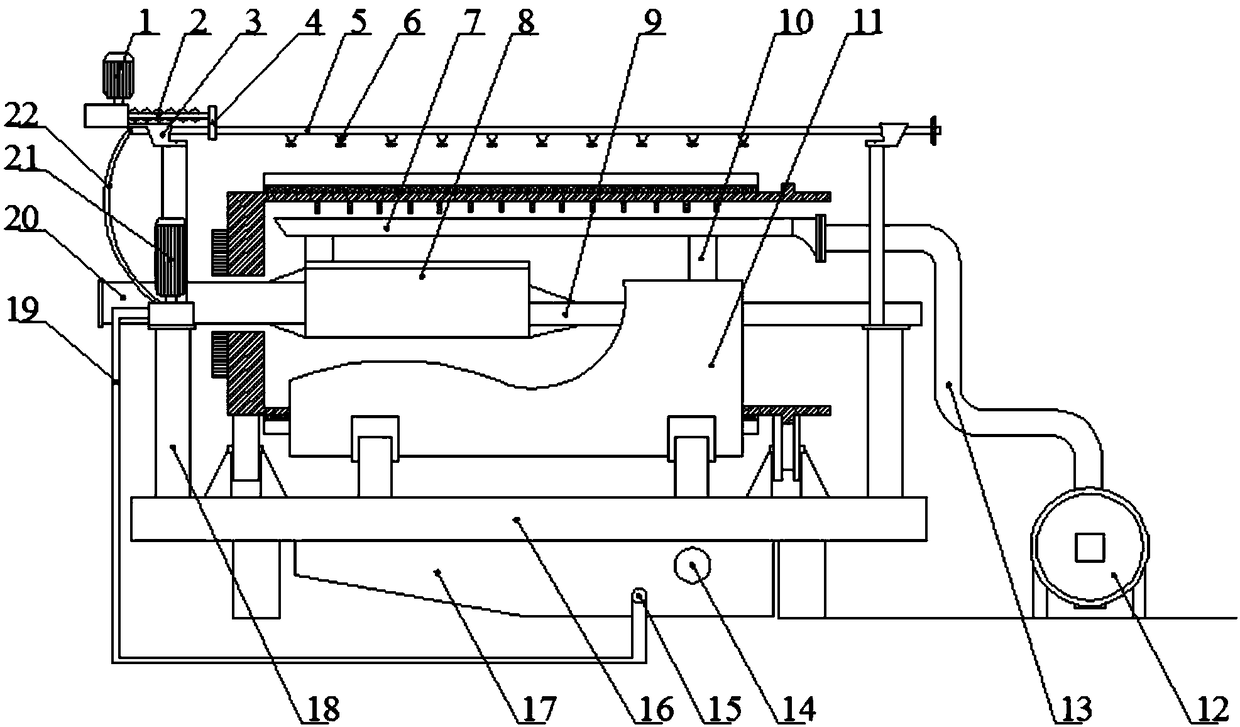

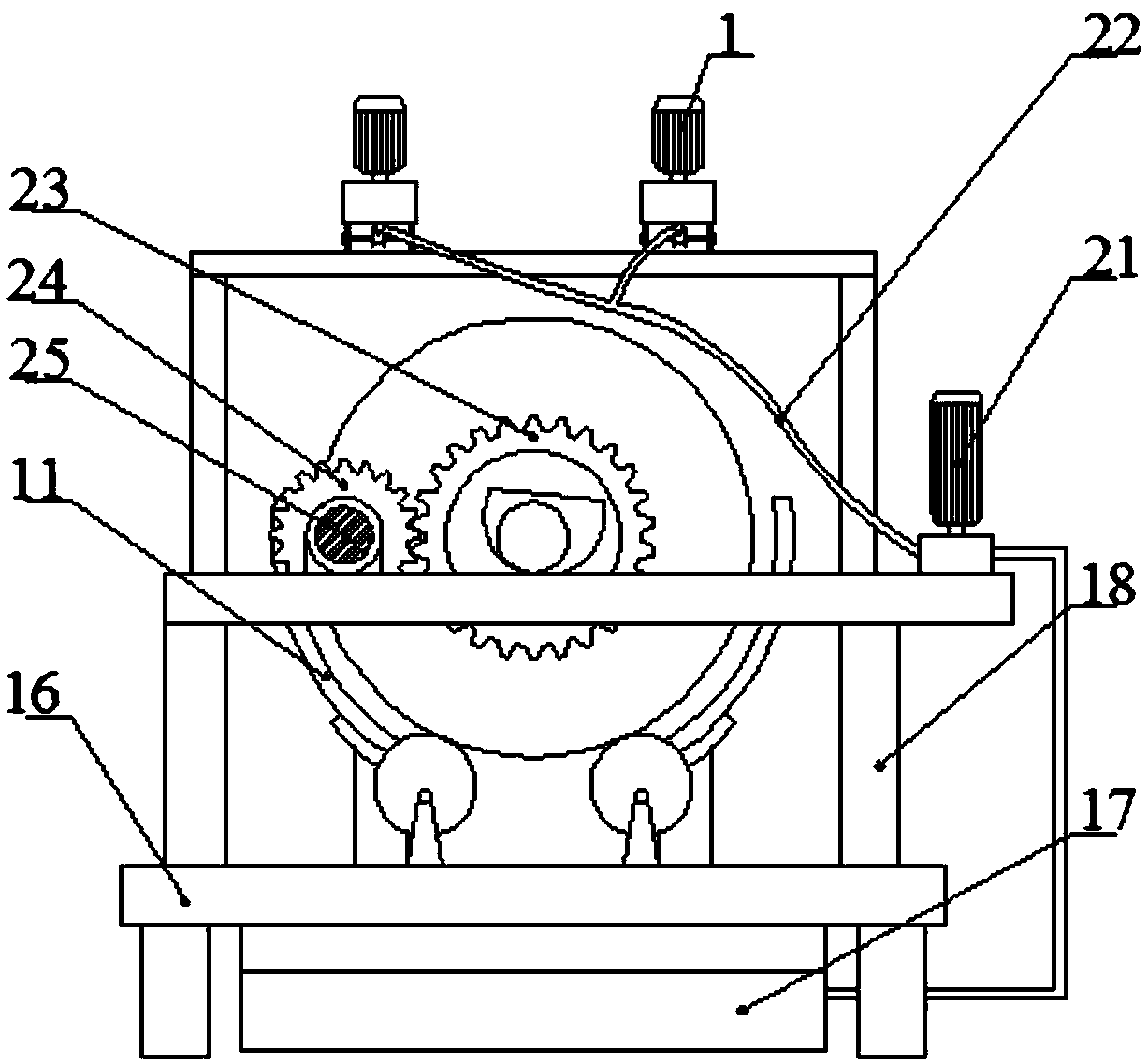

Multistage algal water filtering apparatus capable of realizing suspension type algae suction

PendingCN108654199AEffectively block and collectAvoid cloggingWater/sewage treatment by centrifugal separationWater cleaningRiver routingWater filter

The invention provides a multistage algal water filtering apparatus capable of realizing suspension type algae suction. The multistage algal water filtering apparatus comprises an operation vehicle, awater-surface algae suction device and a vehicle-mounted algal water filter, wherein the water-surface algae suction device is specially applied to open channels and narrow rivers. The multistage algal water filtering apparatus can adjust the suspension height of algae suction according to the thickness of a blue algae layer so as to allow the blue algae layer to be sucked by a clog-free pump asmuch as possible, and suspension type fences fixed at a river bank are cooperatively used, so the apparatus is reasonable in structural layout, simple to operate and good in algae removing effect; thevehicle-mounted algal water filter can realize centrifugal filtration of algal water and self-cleaning of the apparatus in the process of centrifugal filtration; a cleaning system can cyclically useseparated clear water; and the multistage algal water filtering apparatus can save water resources and power resources, has the advantages of simple structure, convenient operation and low cost, can be promoted and applied in a wide range, and is especially applicable to large-scale algal water filtering in narrow water areas like open channels and rivers.

Owner:天津市引滦工程尔王庄管理处

Flexible nozzle head of core making machine and mounting method of flexible nozzle head and mold

The invention relates to the technical field of core making machines, and discloses a flexible nozzle head of a core making machine. The flexible nozzle head comprises a shell, the shell comprises an arc-shaped nozzle head and a connecting body which are integrally connected, a conical hole and a straight hole which are communicated with each other are arranged in the shell, and the conical hole is arranged in the connecting body; the connecting body comprises a clamping plate section, a cutter groove section, a lengthened thread section and an extension section which are connected in sequence, the diameters of the extension section and the cutter groove section are smaller than the diameter of the lengthened thread section, and the diameter of the lengthened thread section is smaller than the diameter of the clamping plate section; and the shell is made of wear-resistant and temperature-resistant plastic. The nozzle has certain flexibility, so that when the flexible nozzle head is combined with the mold, the nozzle head can be automatically closed by utilizing the pressure between the flexible nozzle head and the mold, a dislocation gap caused by clamping the mold is solved, the damage of the nozzle head and the damage of the mold caused by material leakage are avoided, the effect of quickly positioning the mold and the nozzle head is achieved, the butt joint time of the mold and the flexible nozzle head is shortened, and the working efficiency is improved.

Owner:AECC AVIATION POWER CO LTD

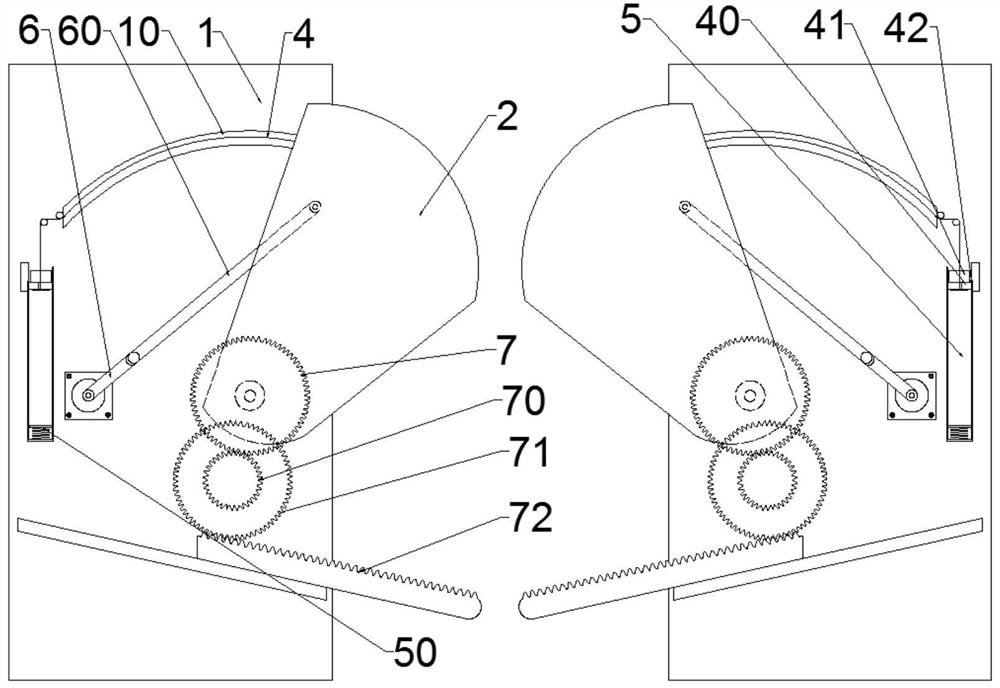

Tennis frame with tennis ball collection function

InactiveCN107812363AEasy to collectReduce exerciseSki bindingsBall sportsDemarcation pointEngineering

The invention discloses a tennis frame with a tennis ball collection function. The tennis frame with the tennis ball collection function is used for being placed on a tennis court to collect tennis balls which fly out of the court, and includes composite baffles which are arranged at the two ends of the tennis court respectively, the side, facing the tennis court, of each composite baffle is provided with a ball collection tank, the two ends of the ball collection tanks are connected with ball conveying grooves along the edges of the two sides of the tennis court, the other end of each ball conveying groove is connected with a support base, and the side, facing the tennis court, of each support base is provided with a support column; the inner side of each ball collection tank is providedwith inclined blocks, wherein the inclined blocks are inclined to the two ends of the ball collection tank by taking the center of the ball collection tank as a demarcation point respectively, the end, close to the support base, of each ball conveying groove is provided with a tennis ball hole, and each tennis ball hole is connected with a ball net. The tennis frame with the tennis ball collectionfunction reduces ball picker' physical strength waste caused by ball picking-up, collection of the tennis balls is facilitated, and the tennis trainers' practice efficiency is improved.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

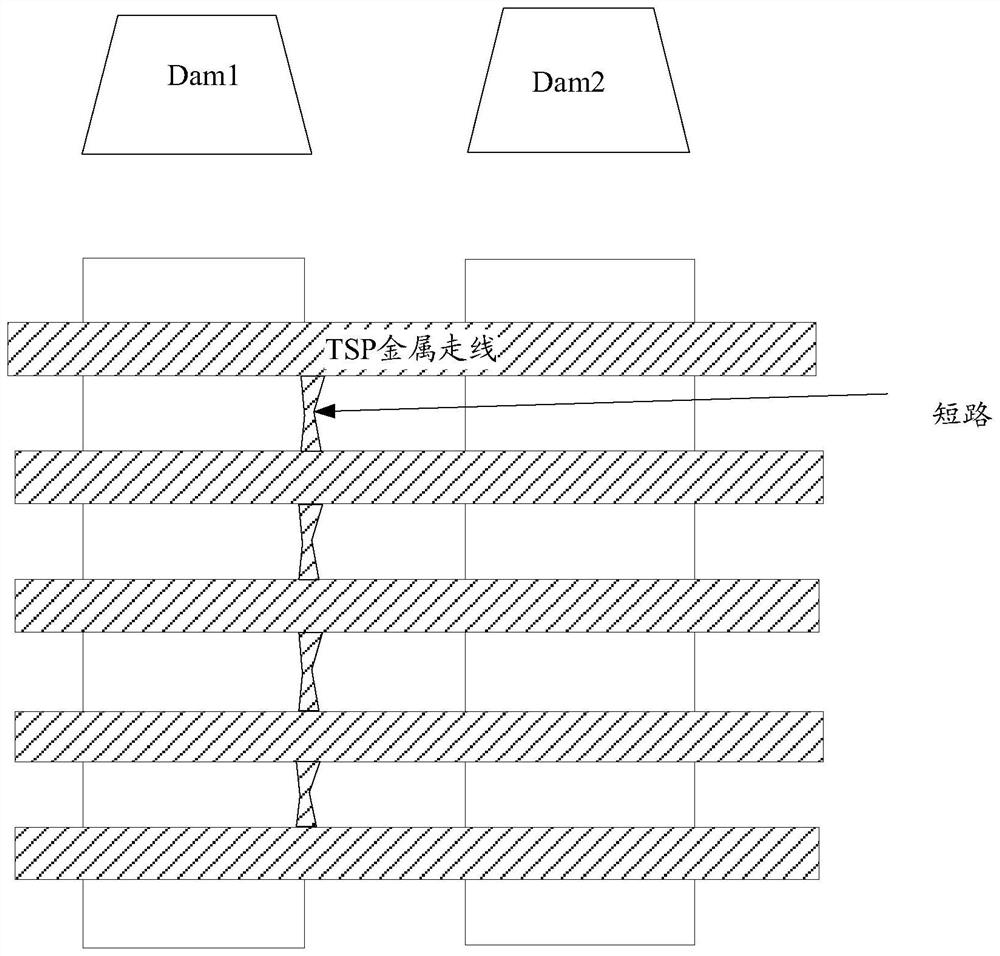

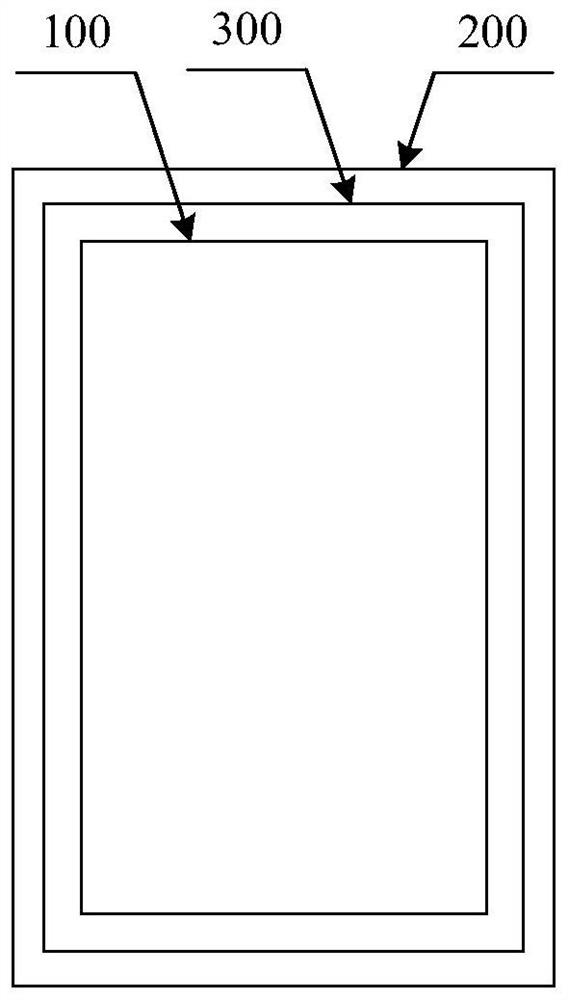

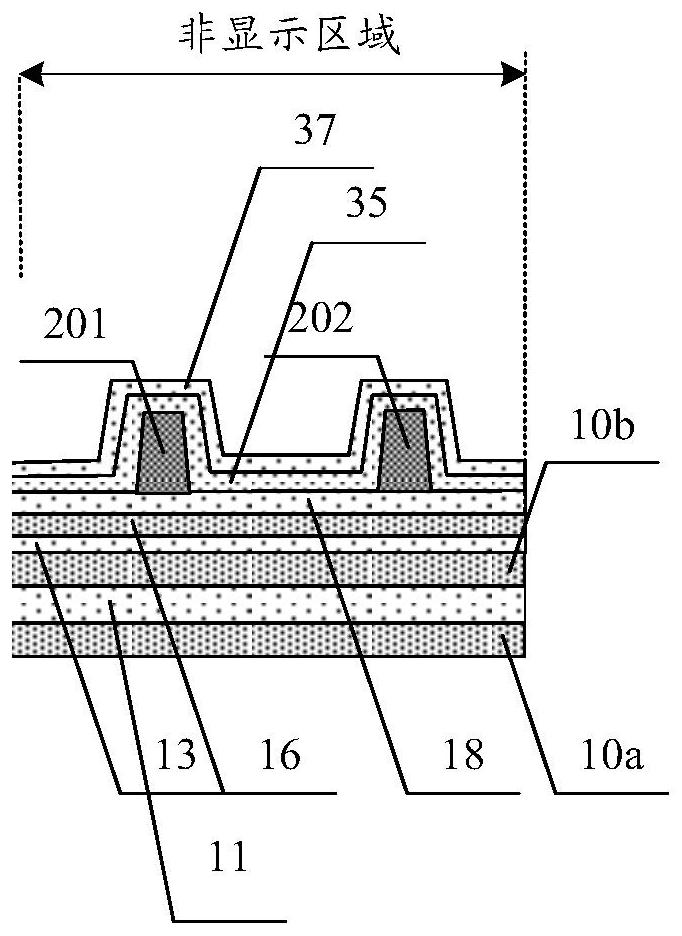

A display substrate, its preparation method, and a display device

ActiveCN110518042BIncrease short distanceIncrease blocking areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTouchscreen

The present application discloses a display substrate, a preparation method, and a display device. The display substrate includes a display area and a non-display area. The non-display area includes a functional layer, a retaining wall arranged on the functional layer, and layer and the encapsulation layer of the retaining wall, the retaining wall includes a bottom surface close to the functional layer, a top surface opposite to the bottom surface, and opposite two sides, at least one side has a recessed structure, and the recessed structure makes the On a plane parallel to the display substrate, the length of the side on the plane is greater than the length of the side on the plane parallel to the display substrate when the side is a plane. In the embodiment of the present application, by adding a recessed structure to the retaining wall and changing the edge shape of the retaining wall, the short-circuit distance between two touch screen panel traces is increased and the risk of short-circuit is reduced.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com