Nuclear fuel assembly grid with enhanced mixing blades

A technology for nuclear fuel assemblies and fuel assemblies, which is applied to reactor fuel elements, nuclear engineering, nuclear power generation, etc., can solve problems such as weakening the mixing performance of mixing blades, and achieve the effects of ensuring mechanical strength, increasing choke area, and improving mixing disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A nuclear fuel assembly grid with enhanced mixing blades according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

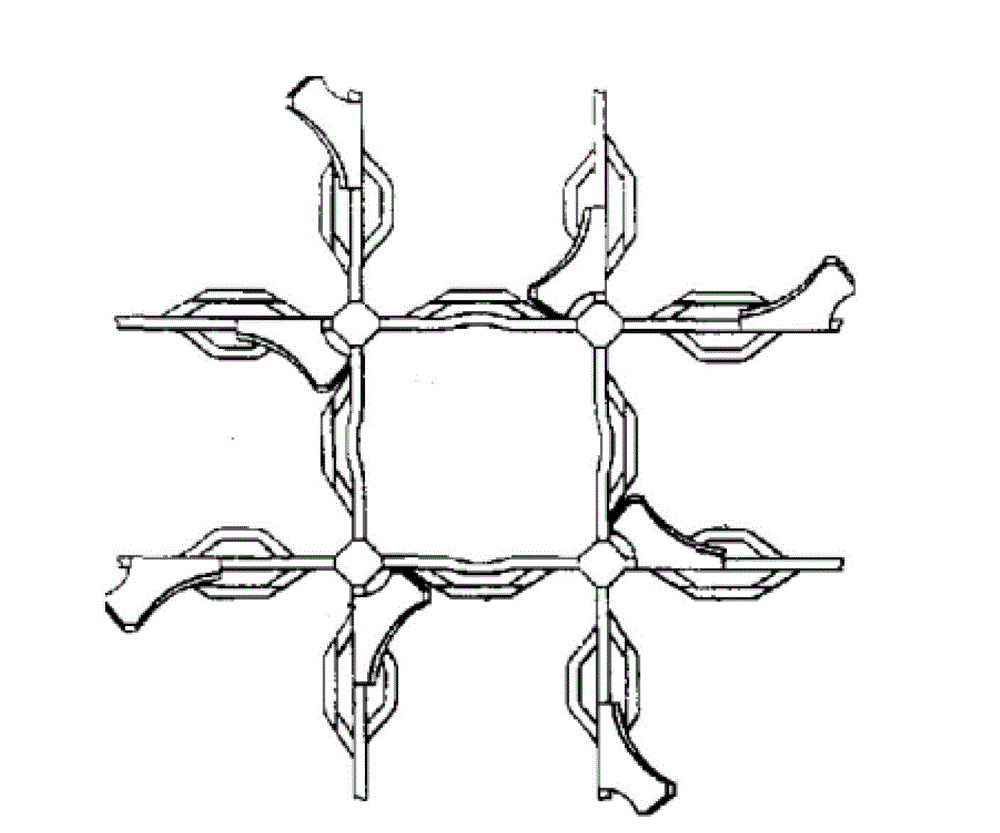

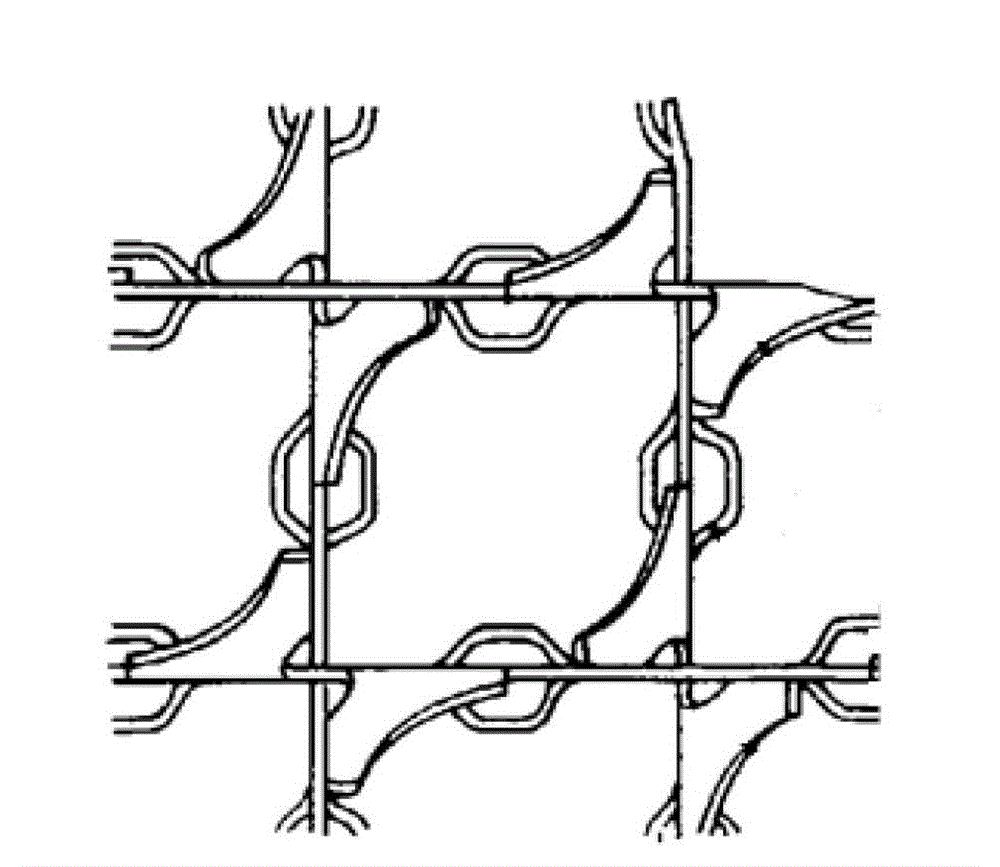

[0017] Such as Figure 3 to Figure 5 As shown, a nuclear fuel assembly grid with enhanced mixing blades according to the present invention, which forms a grid-like structure through cross-connection of several grid strips.

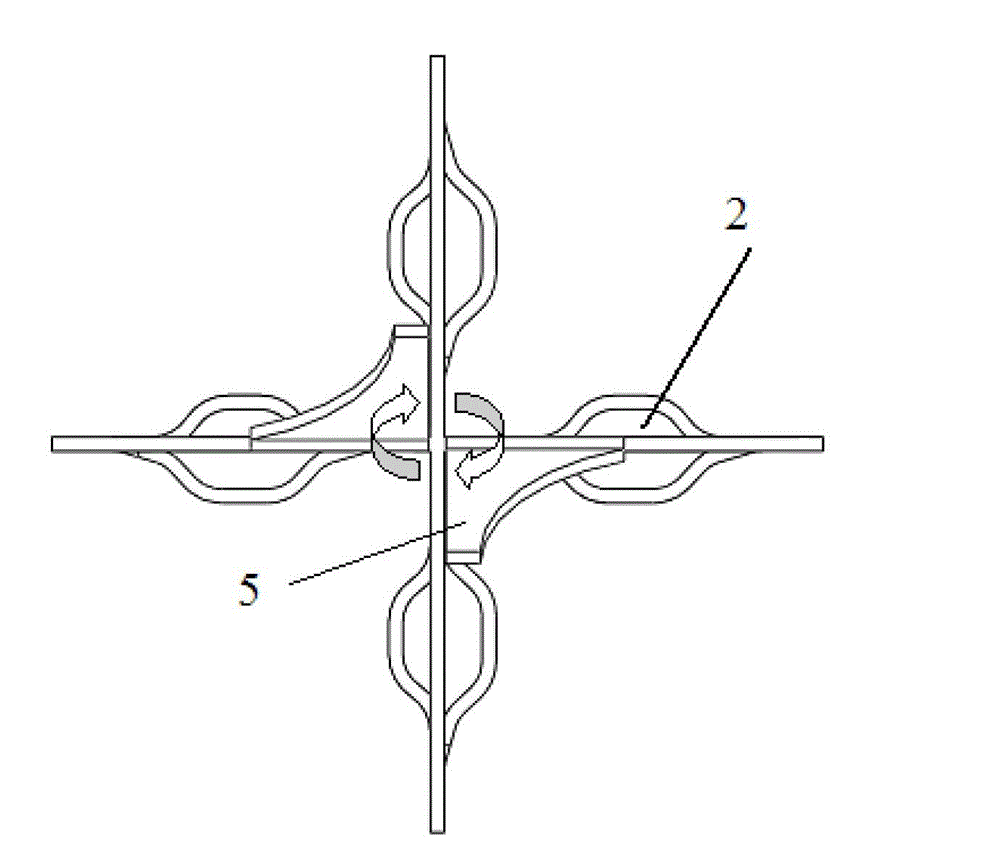

[0018] On the side wall of each grid strip, there are two upper and lower rigid projections 2 and a spring 1 between the two rigid projections 2 to clamp the fuel rods.

[0019] A groove 3 is opened below or above each grid strip, and adjacent grid strips are cross-connected up and down through the groove 3 to form a grid. The width of the groove 3 is between 0.2 mm and 0.8 mm, and the length is between 5 and 40 mm.

[0020] Two corresponding enhanced mixing blades 5 are fixedly connected above the crossing points of the grid strips to stir the passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com