Flexible nozzle head of core making machine and mounting method of flexible nozzle head and mold

A nozzle head and core-making machine technology, which is applied to manufacturing tools, molding machines, casting and molding equipment, etc., can solve problems such as slurry leakage, avoid damage and mold damage, accelerate slurry flow, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

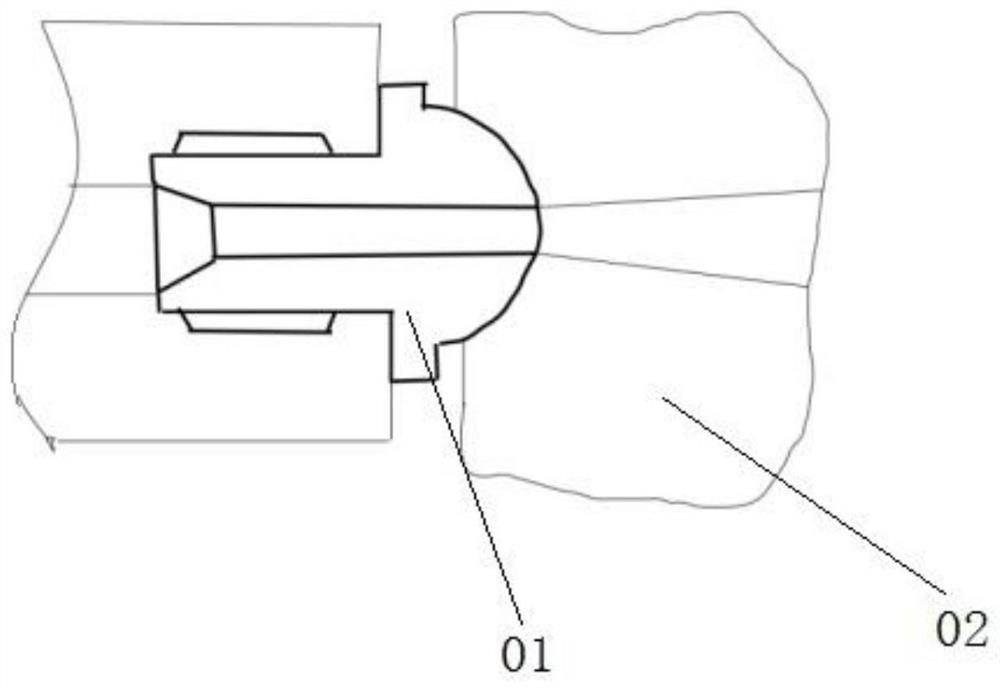

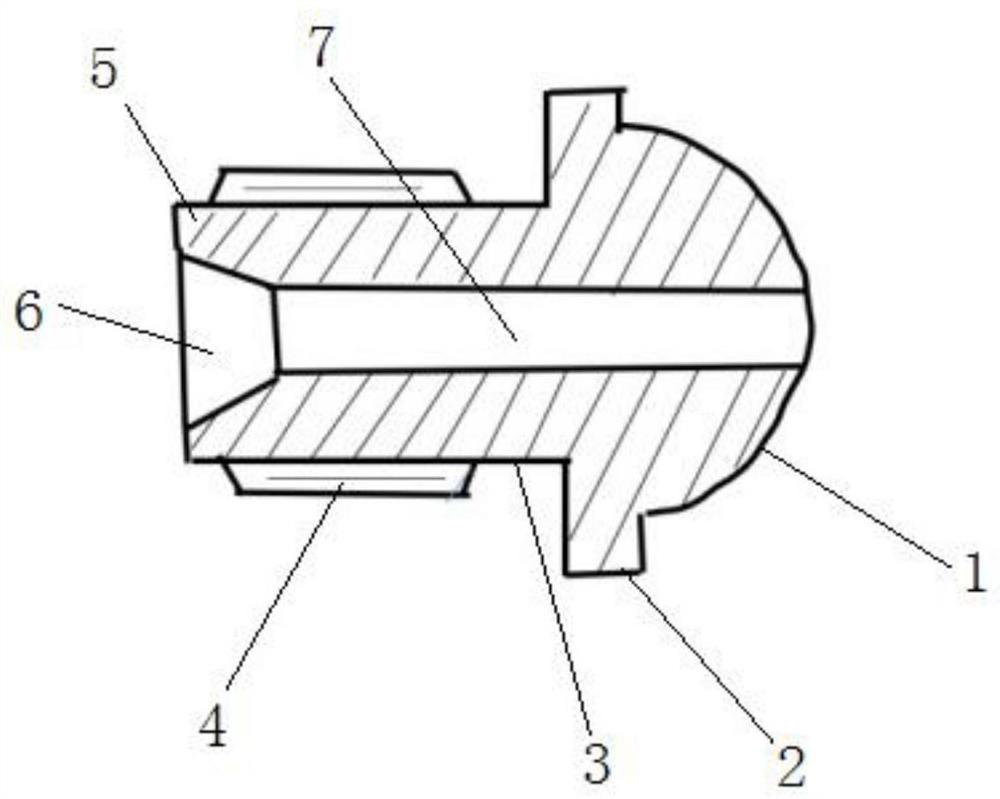

[0029] like figure 2 As shown, the present invention discloses a flexible nozzle head of a core making machine, which includes a housing, the housing includes an integrally connected arc-shaped nozzle head 1 and a connecting body, and a conical hole 6 and a straight hole communicating with each other are opened in the housing 7. The tapered hole 6 is opened in the connection body; the connection body includes the splint section 2, the sipe section 3, the extended thread section 4 and the extension section 5 connected in sequence, and the diameters of the extension section 5 and the sipe section 3 are smaller than the extension thread The diameter of the section 4, the diameter of the lengthened threaded section 4 is less than the diameter of the clamping plate section 2; the whole shell is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com