Earth-work fabric of inter woven flat monofilament and split film yarn and its use

A technology of flat monofilament and geotextile, which is applied in the direction of fabrics, textiles, textiles and papermaking, etc. It can solve the problems of flat membrane filaments such as lack of hardness, soil erosion, silting, etc., to reduce the number of pores per unit area, increase drainage capacity, The effect of increasing the blocking area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

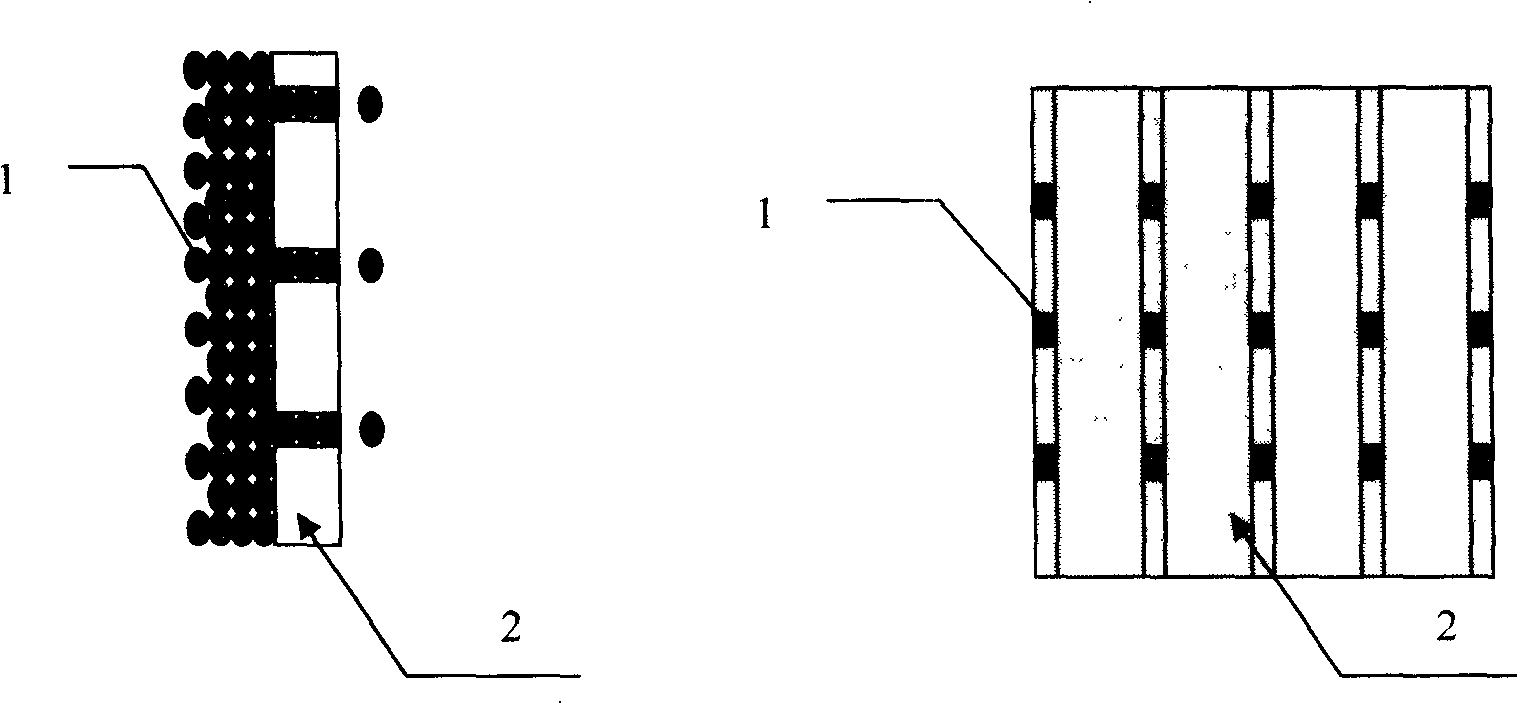

[0028] The fabric structure is: flat monofilaments with a cross section of 1.1mm wide on the long side and 0.27mm thick on the short side are used in the warp direction, and split film yarns with a density of 0.25g / m and a fineness of less than 0.4mm are used in the weft direction. After preparation, warping, Weaving, inspection, packaging, forming and other processes make woven fabrics with a structure of 2 / 2. The overlapping area of adjacent flat monofilaments accounts for 3.5% of the monofilament area. The weight of the fabric is 400 grams, the width of the door is 3.2 meters, the weft tensile strength: 70KN / m, the permeability coefficient> 4*10 -1 cm / s, equivalent aperture <0.4MM.

Embodiment 2

[0030] The fabric structure is: flat monofilaments with a cross section of 0.94mm wide on the long side and 0.34mm thick on the short side are used in the warp direction, and split film yarns with a fineness of 0.32g / m and a fineness of less than 0.4mm are used in the weft direction. After preparation, warping, Weaving, inspection, packaging, forming and other processes are made into woven fabrics with a structure of 2 / 1. The width of the fabric is 2.8 meters, and the overlapping area of adjacent flat monofilaments accounts for 10% of the area of the monofilaments.

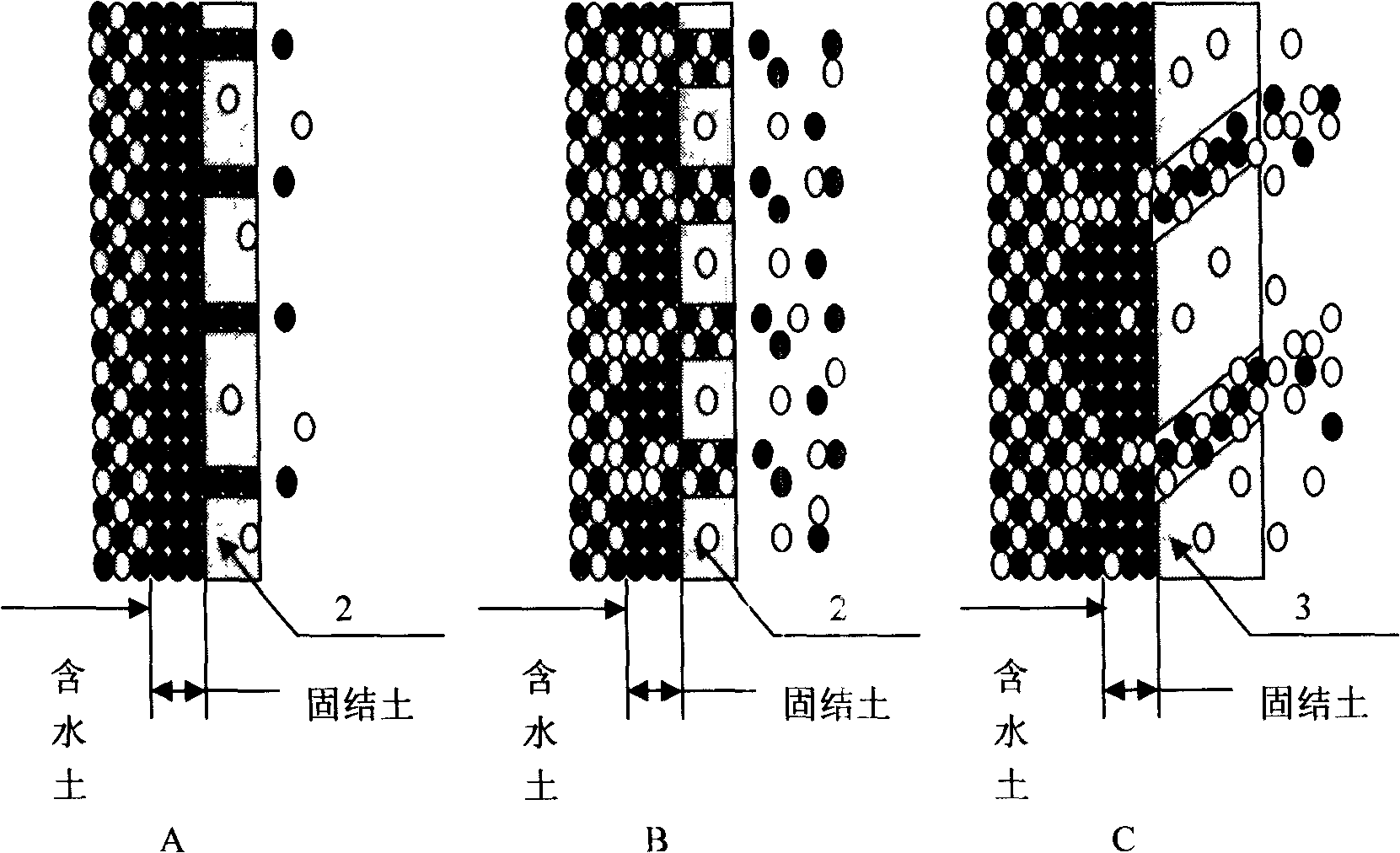

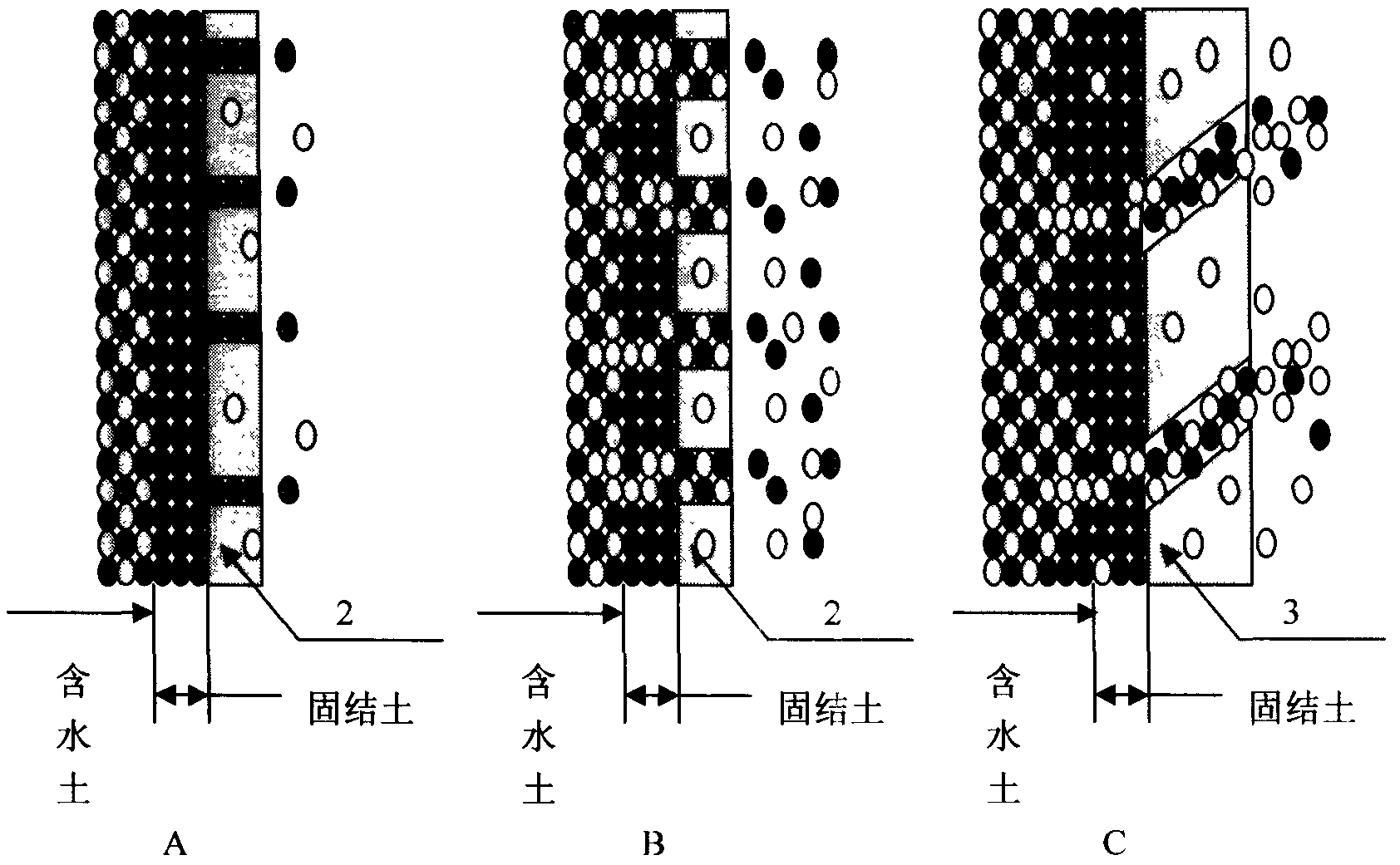

[0031] The above fabrics are used as the flushing bag body of the mud flushing bag to treat the mud geology, and carry out soil work such as reverse filtration and drainage of the mud. The results show that: in the on-site flushing and irrigation test, effective drainage can be formed in just a few days, and it is effective for a long time. There is a small amount of turbid water in the first few days, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com