Ventilating skylight

A technology of ventilation skylights and skylights, which is applied in the direction of roofs, roofs, building components, etc., can solve the problems of flowing into the factory building, affecting the ventilation effect, and the leakage of ventilation skylights, so as to avoid water leakage and increase the blocking area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

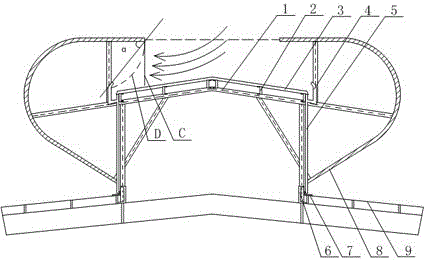

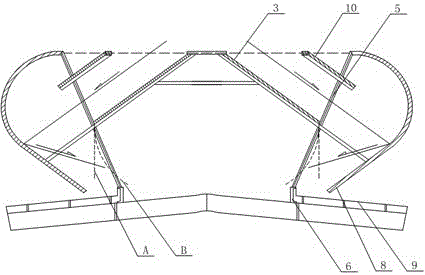

[0023] Such as figure 1 As shown, this embodiment includes a skylight frame 1 fixed at the air vent of the color steel roof 9 and a windshield 8 wrapped outside the skylight frame 1. The daylighting board 3 is laid on the skylight frame 1, and the top of the windshield 8 is There are tuyeres corresponding to the daylighting plate 3, and anti-overflow plates 4 are respectively arranged on both sides of the daylighting plate 3, one side of the anti-overflow plate 4 is vertically folded upwards and then connected to the bottom of the daylighting plate 3, and the anti-overflow plate 4 The other side is folded and extended vertically upwards, and also includes a drainage pipe 5, the upper section of the drainage pipe 5 communicates with the drainage hole opened on the overflow prevention plate 4, and the lower section of the drainage pipe 5 extends vertically downward to the color steel roof 9 superior.

[0024] In the prior art, in order to avoid poor air circulation and insuffi...

Embodiment 2

[0027] Such as figure 1 As shown, taking the plane where the tuyere is located as the horizontal plane, the line between the end point of the extension of the overflow prevention plate 4 and the inner wall of the tuyere forms a protective angle α with the horizontal plane, and satisfies 15°≤α≤ 45°.

[0028] After solving the problem that the drip line of the lighting panel 3 is distorted by the wind force, the tuyere is completely projected on the lighting panel 3, and in severe stormy weather, the drip line C formed at the inner edge of the tuyere will still be affected by the strong wind. The drip line D is formed by zigzagging, that is, the rainwater will slide along the inner wall of the windshield 8 into the vent, and in this embodiment, the connection line between the end point of the extension of the overflow prevention plate 4 and the inner wall of the tuyere and the horizontal plane form a protective clip Angle α, and satisfying 15°≤α≤45°, that is, under the conditi...

Embodiment 3

[0031] This embodiment is on the basis of embodiment 1, as figure 1 As shown, a plurality of purlins 2 are arranged on the skylight frame 1, daylighting panels 3 are laid on the purlins 2, a flashing board 7 is arranged on the color steel roof 9, and the lower end of the drainage pipe 5 Facing the flashing board 7.

[0032] The daylighting panel 3 is separated from the skylight frame 1 by the purlin 2, which reduces the blocking area when the light penetrates and improves the indoor lighting; and facilitates quick replacement of the daylighting panel 3; the flashing panel 7 provided can avoid the drain The rainwater gushing out of the 5 forms an impact on the color steel roof 9, while preventing the rainwater from splashing back into the air vent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com