An operation safety protection device for power equipment

A technology for safe operation and protective devices, which is applied in the substation/distribution device enclosure, cooling/ventilation, transportation and packaging of substation/switchgear, etc. It can solve problems such as high manual maintenance costs, hindering air flow, and affecting heat dissipation effects , to achieve the effect of improving heat dissipation, reducing air flow, and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and embodiments.

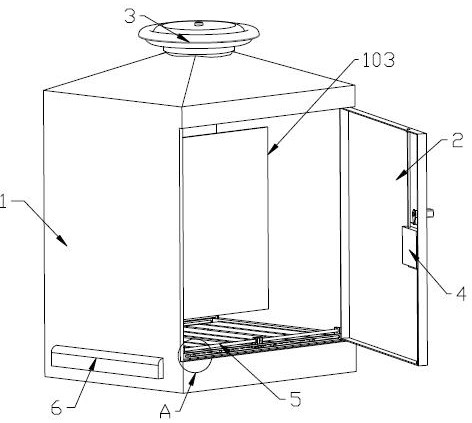

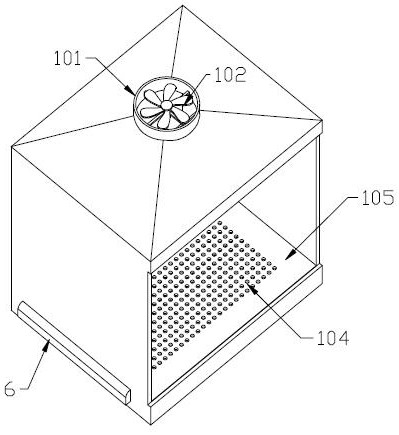

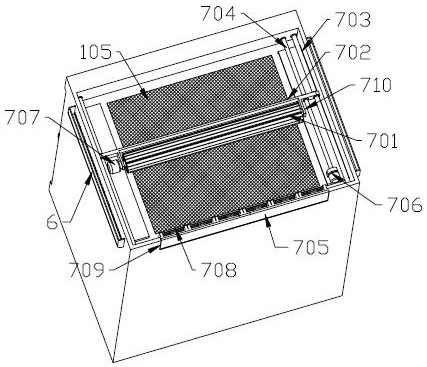

[0034] like Figures 1 to 3As shown, the operation safety protection device for electrical equipment includes a box body 1, a door panel 2 is hinged on the front side of the box body 1, and a power-on lock for locking or releasing between the door panel 2 and the box body 1 is arranged on the door panel 2. The power-on locking device 4 locks the door panel 2 and the box body 1 in the power-on state, and automatically releases the door panel 2 and the box body 1 after the power is turned off, so that the door panel can be opened, reducing safety. The top of the box body 1 is provided with an exhaust pipe 101 that communicates with it, the interior of the exhaust pipe 101 is provided with an induced draft fan 102, and the upper end of the exhaust pipe 101 is detachably installed with an exhaust mechanism 3; The interior of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com