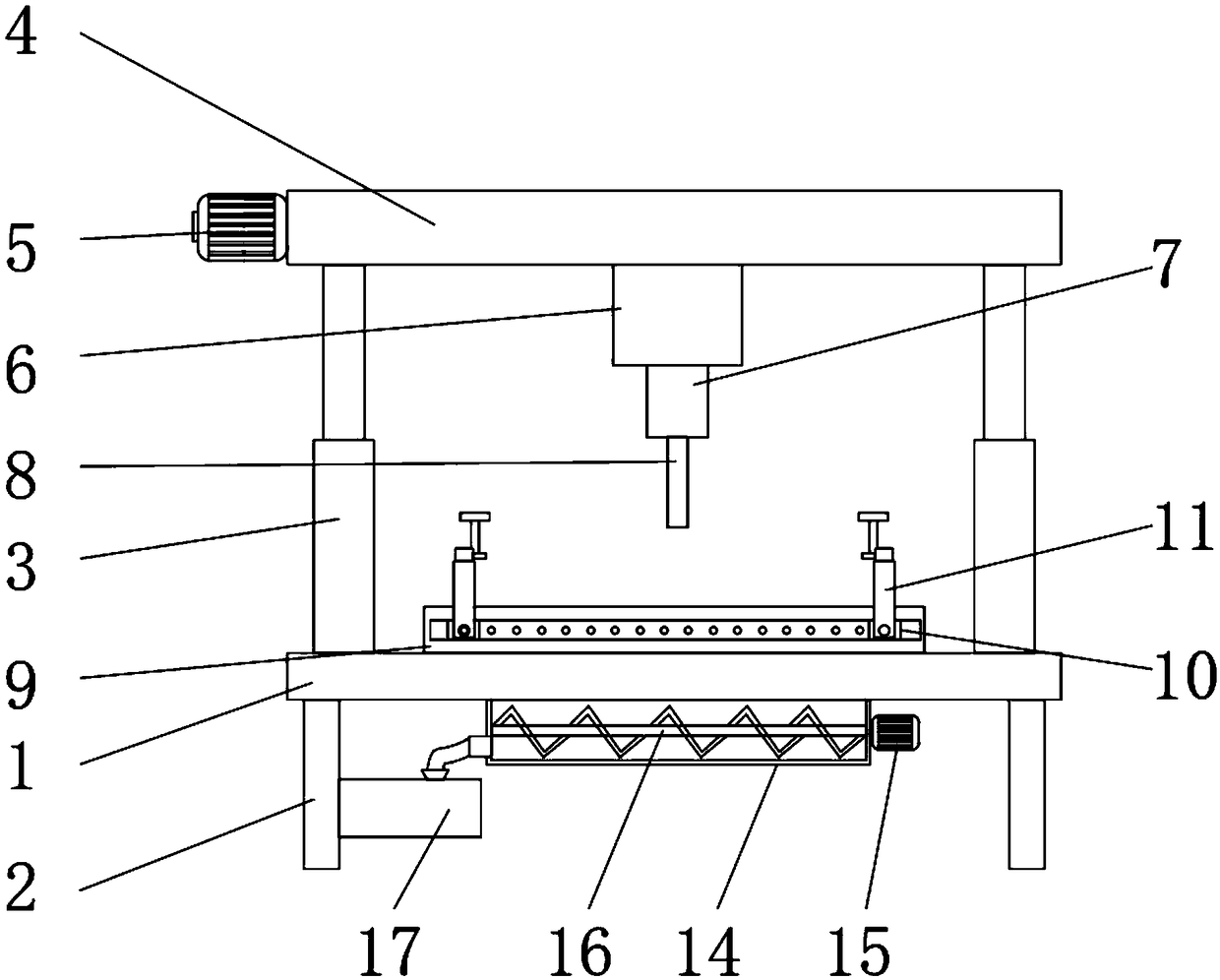

Plate shearing machine with waste collecting device

A waste collection and shearing machine technology, which is applied to shearing devices, accessories of shearing machines, shearing machine equipment, etc. Ensure the quality of the working environment, improve the cutting quality, and ensure the effect of the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

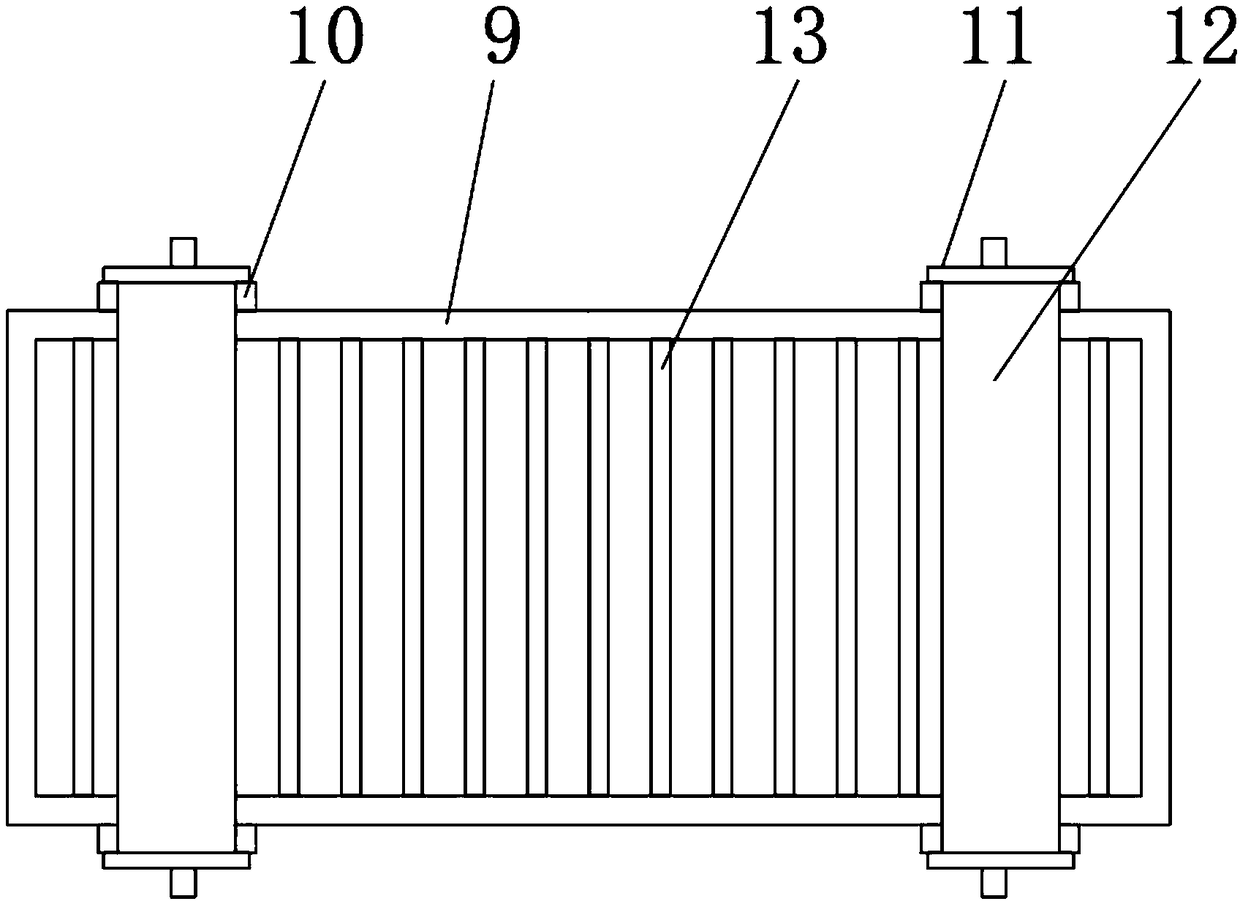

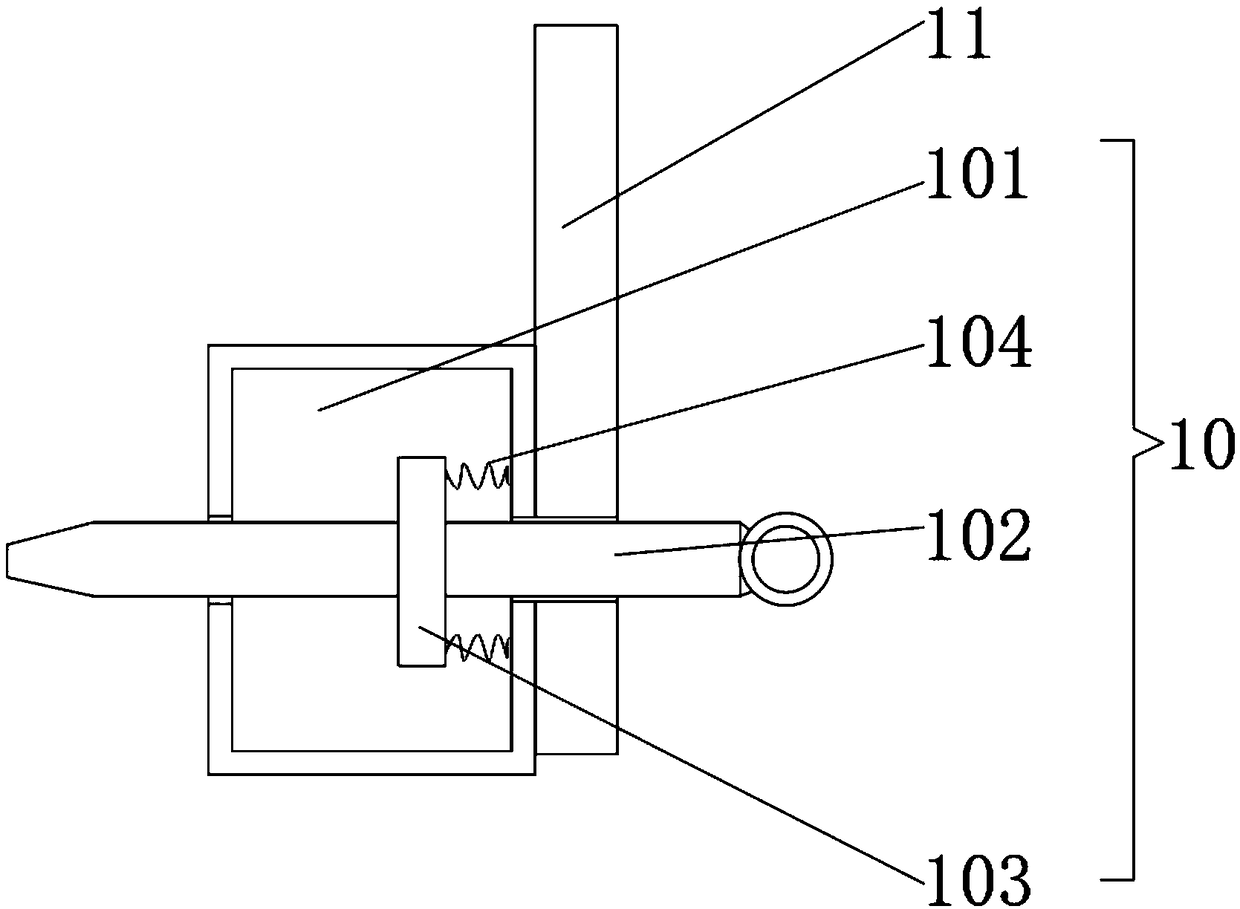

[0026] Embodiment: When in use, place the plate workpiece on the top of the receiving seat 9, and pull the pull rod 102 outward according to the position of the plate workpiece, so that the pull rod 102 is separated from the fixed through hole on the transverse chute, and the moving slide block 101 drives the workpiece to be fixed When the device 12 is in a suitable position, the pull rod 102 is loosened so that the pull rod 102 is engaged with the fixed through hole, and the screw rod 123 is rotated downward to make the fixed plate 124 downward so that the plate workpiece is fixed on the top of the receiving seat 9, and then according to the cutting position, start the servo motor 5 to drive the lead screw forward and reverse, move the movable block 6 to the designated position, start the hydraulic telescopic rod 3 downward, and start the fan 125 at the same time, cut the plate workpiece through the upper blade 8, and the fan 125 starts to make Negative pressure is generated a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap