Welding manufacturing method of hinge support

A hinged support and vertical connection technology, applied in welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as poor mechanical properties, hidden safety hazards of mechanical properties, and castings that cannot meet the requirements, and achieve improved quality and accurate size. , the effect of controllable deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the welding manufacturing method of the hinge support of the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

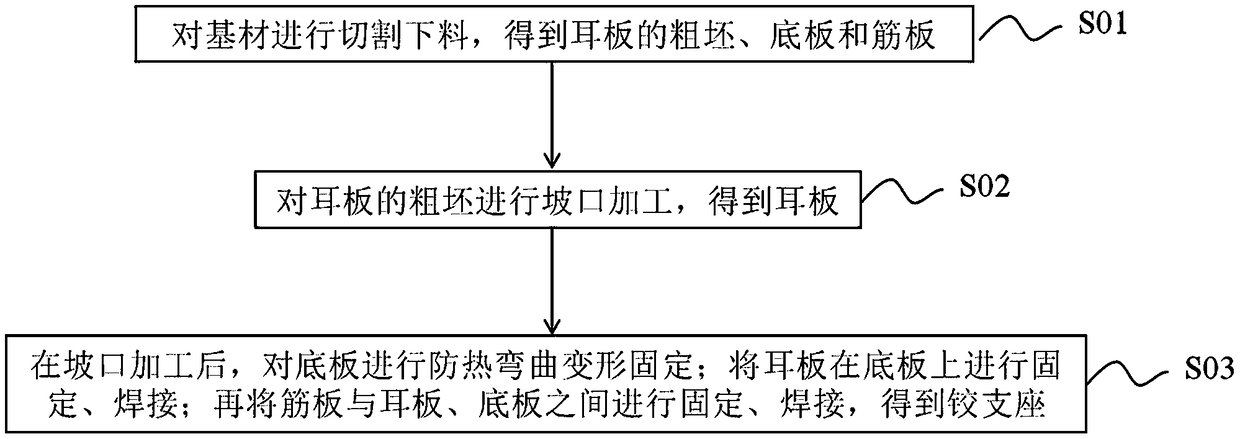

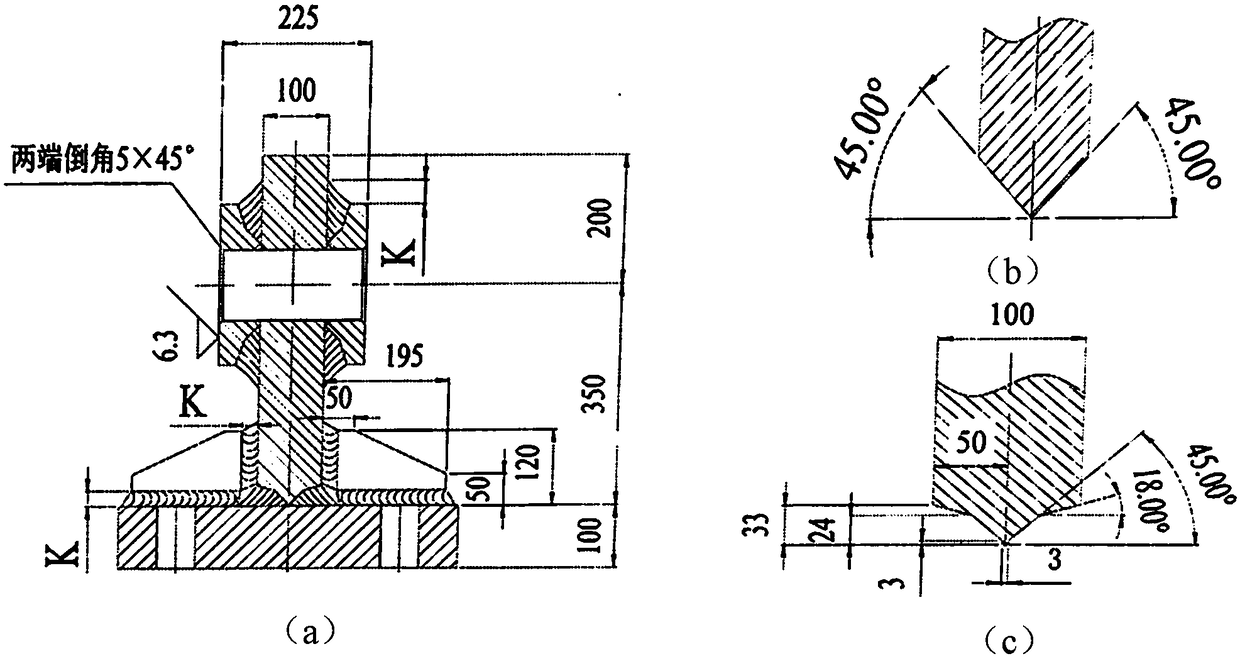

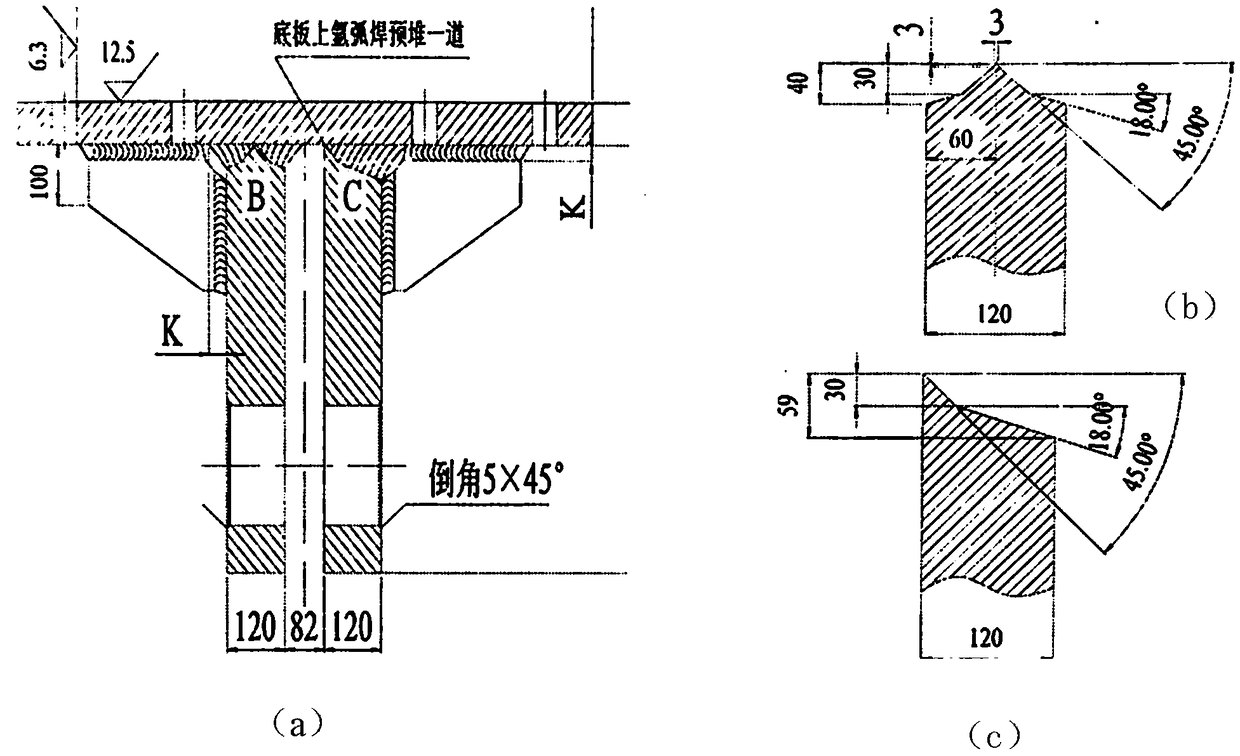

[0035] figure 1 A schematic flow chart showing a welding manufacturing method of a hinge support according to an exemplary embodiment of the present invention is shown. figure 2 A schematic diagram showing the groove and welding form of one ear plate of the hinge support of the present invention. image 3 A schematic diagram showing the groove and welding form of the two lug plates of the hinge support of the present invention. Figure 4 A schematic diagram showing the groove and welding form of the three lug plates of the hinge support of the present invention. Figure 5 It shows a schematic diagram of fixing the bottom plate against thermal bending and deformation in the present invention. Figure 6 A schematic diagram of the ear plate of the present invention is shown. Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com