Flowmeter

A flowmeter and fluid cavity technology, applied in the field of flowmeter, can solve the problems affecting the accuracy and real-time performance of data statistics, the problem of power supply can not be solved well, and the inconvenience of automatic meter reading system pre-laying and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

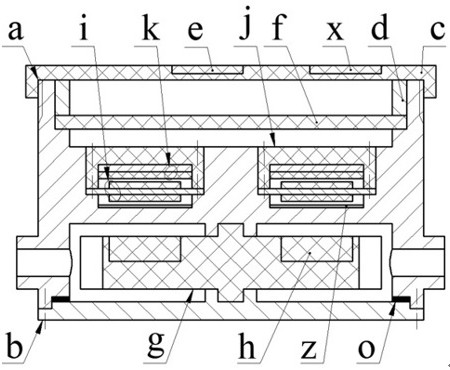

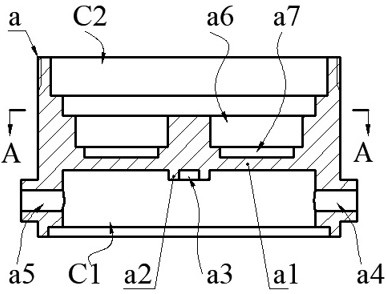

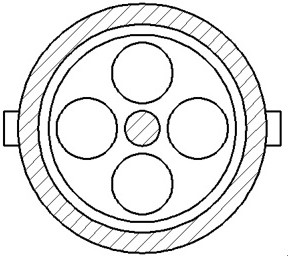

[0028] The partition a1 divides the housing a into a coaxial fluid chamber C1 and an electric control chamber C2. The electric control chamber C2 is a stepped chamber. The side of the partition a1 facing the fluid chamber C1 is called the bottom wall of the fluid chamber, facing the electric control chamber. One side of C2 is called the bottom wall of the electronic control chamber; the bottom wall of the fluid chamber is provided with an upper baffle a2 and an upper shaft hole a3, the upper shaft hole a3 is coaxial with the fluid chamber C1, and the upper shaft hole a3 is located on the upper baffle On a2; the side wall of the fluid chamber C1 is provided with a coaxial inlet a4 and outlet a5; the bottom wall of the electric control chamber is provided with an annular groove a6 and a sunken cavity a7, the width of the annular groove a6 is greater than the diameter of the sunken cavity a7, and the sunken cavity a7 The center of the cavity a7 is located on the center line of sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com