Automatic magnet assembling mechanism of magnetic sheet building block toy and assembling process of automatic magnetic assembling mechanism

A technology of automatic assembly and assembly mechanism, applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of increased production cost of magnetic piece building blocks, high labor cost, and reduced production efficiency, reducing labor and Smooth connection and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

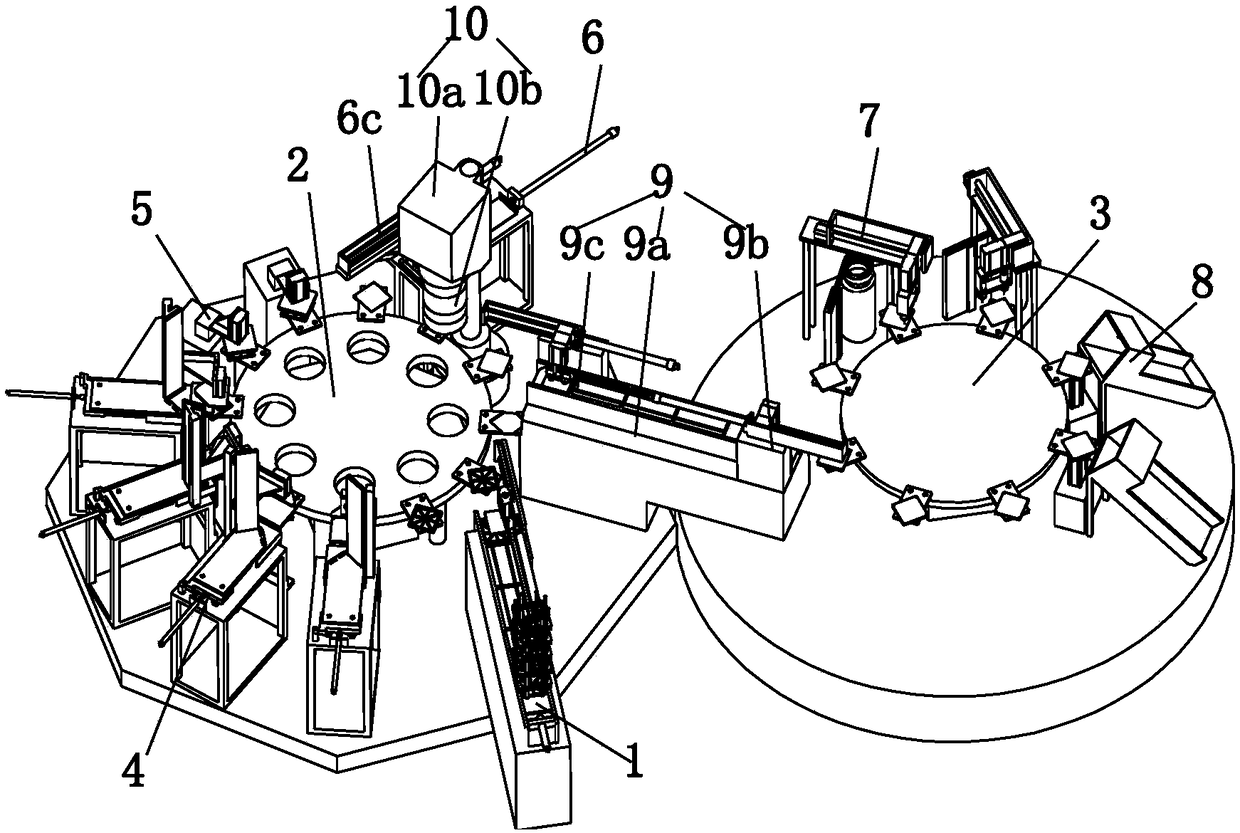

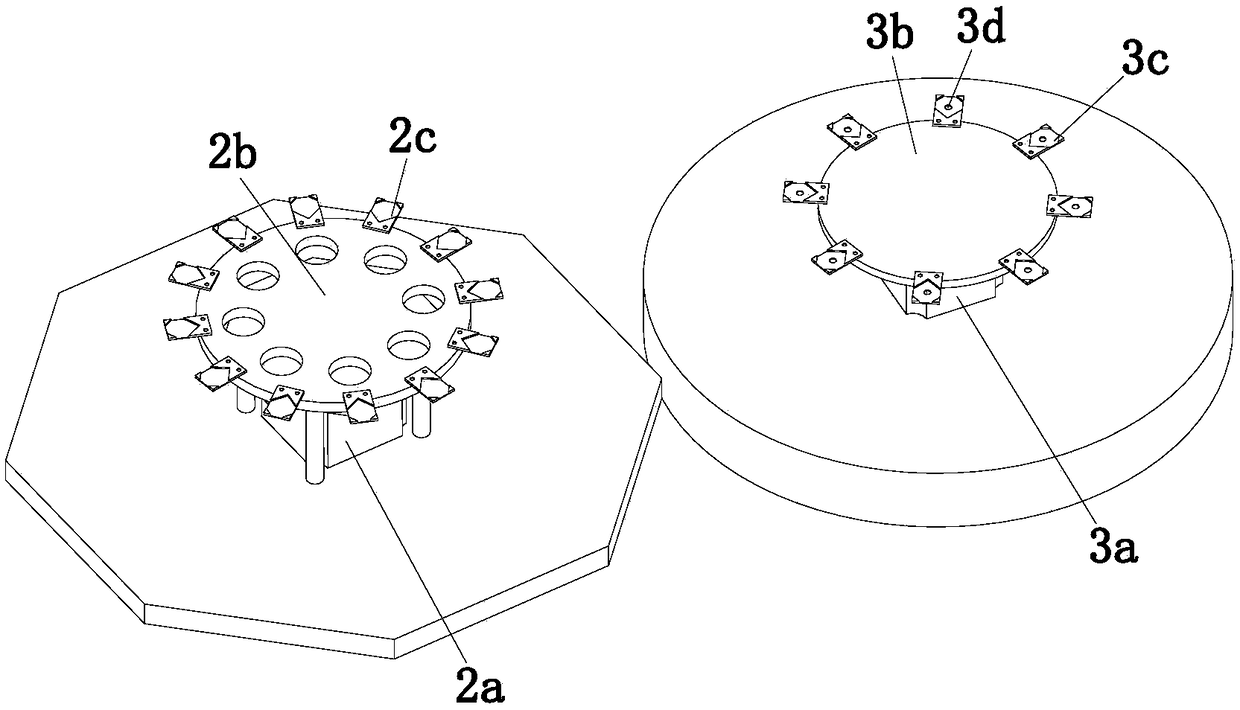

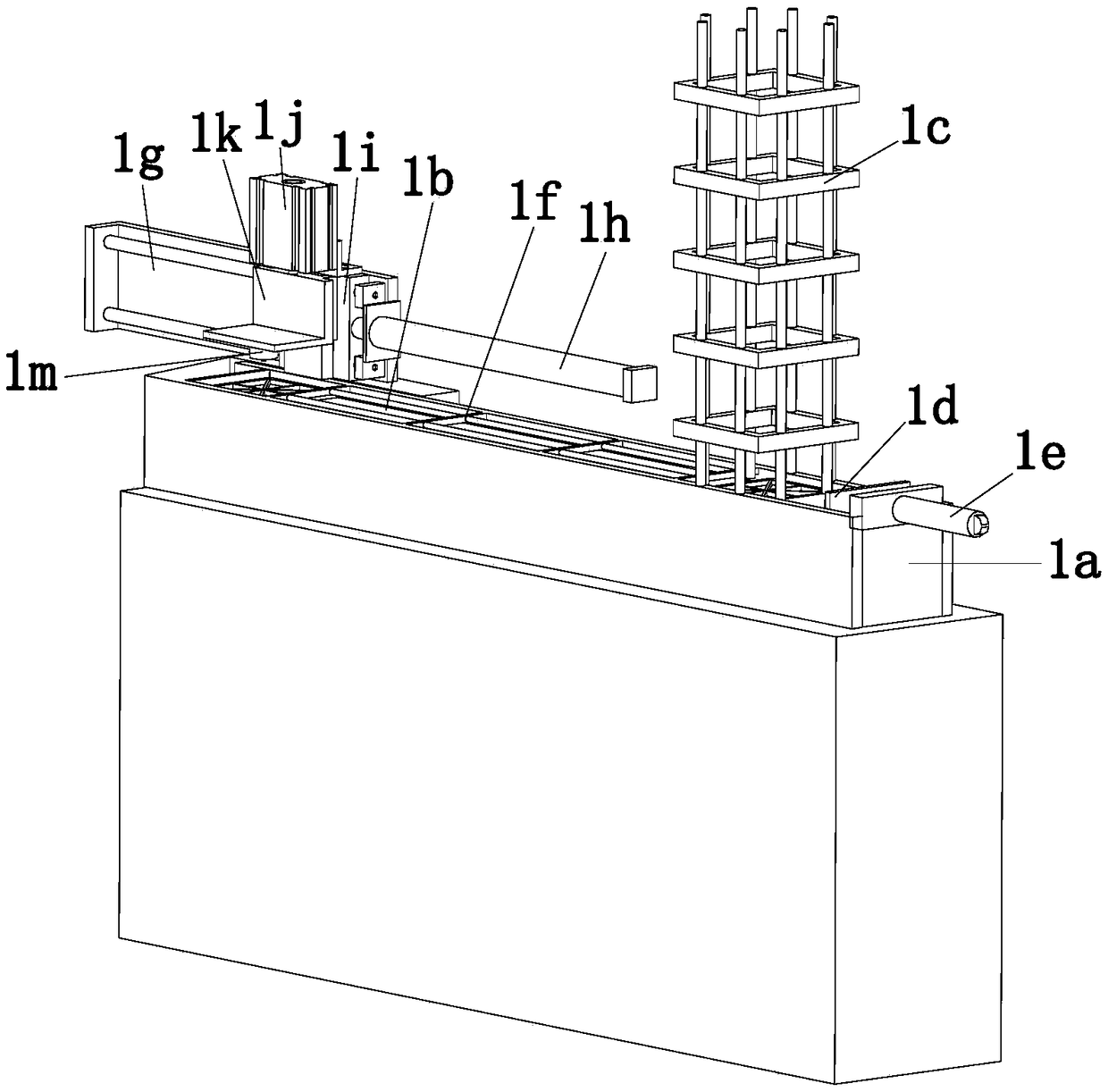

[0034] Such as Figure 1-Figure 9 As shown, the magnet automatic assembly mechanism of the magnetic piece building block toy includes a bottom shell feeding mechanism 1, a first rotating mechanism 2, a second rotating mechanism 3, a magnet assembly mechanism 4, a pressing mechanism 5, a cover assembly mechanism 6 and a screw Screw mechanism 7, the first rotating mechanism 2 and the second rotating mechanism 3 are arranged adjacently, the bottom shell feeding mechanism 1, the magnet assembly mechanism, the pressing mechanism 5 and the cover assembly mechanism 6 are all arranged in the first rotating mechanism On the side of the mechanism 2, the screwing mechanism 7 is provided on the side of the second rotating mechanism 3, and the second rotating mechanism 3 is provided with a feeding mechanism 8 on the side. The first rotating mechanism 2 and the second A conveying mechanism 9 is provided between the rotating mechanisms 3, and a pressing mechanism 10 is provided between the co...

Embodiment 2

[0041] The assembly process of the magnet automatic assembly mechanism of the magnetic sheet building block toy described in the embodiment includes the following steps:

[0042] The first step is to put 11 yards of the bottom shell on the bottom shell frame 1c, and the pusher plate 1d is driven to move by the pusher cylinder 1e, and the pusher plate 1d pushes the bottom shell 11 from the loading table 1a to the first On the conveyor belt 1b, the bottom shell 11 is transported to the end through the first conveyor belt 1b, and the bottom shell 11 is clamped by the chuck 1m, and the bottom shell 11 is moved to the first jig 2c under the work of the first moving cylinder 1h on;

[0043] The second step is to drive the first rotating disk 2b to rotate through the work of the first rotating motor 2a, thereby driving the first jig 2c and the bottom shell 11 on the first jig 2c to rotate. The bottom shell 11 passes through the four magnet assembly components in turn , The bottom magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com