Board frame transmission mechanism of obliquely-vertical board collecting and placing machine

A technology of transmission mechanism and board release machine, which is applied in the field of mechanical equipment, can solve the problems of end face wear of printed circuit boards, hard material selection of board racks, and falling printed circuit boards, etc., and achieves the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

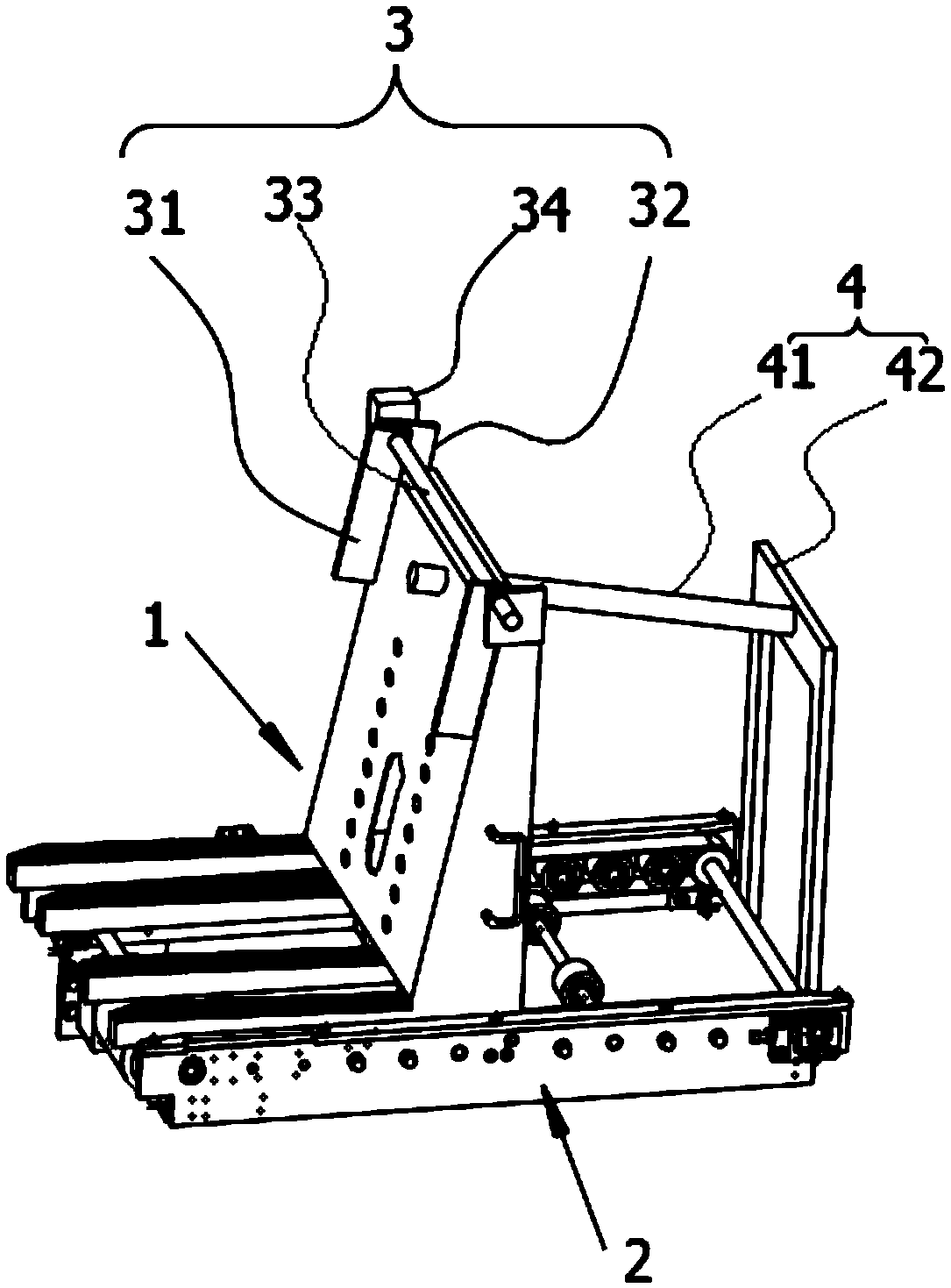

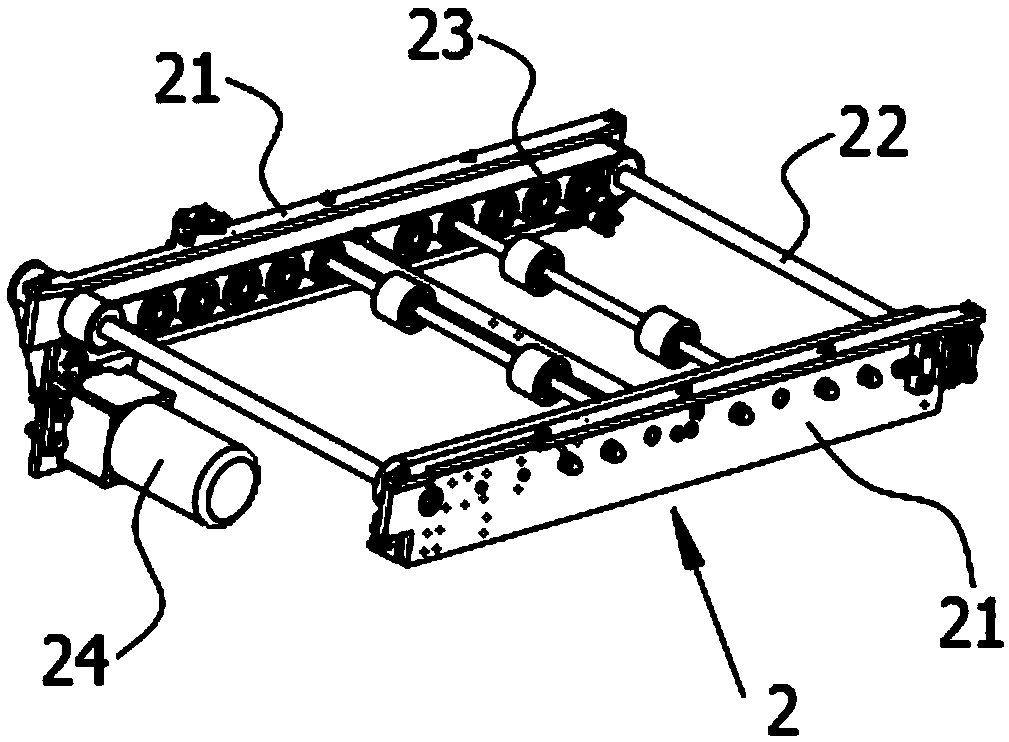

[0025] Embodiment: a plate frame transmission mechanism of an inclined vertical retractable trigger, such as Figure 1-Figure 3 As shown, the plate frame transmission mechanism includes a plate frame 1 and a transmission structure 2 that drives the plate frame to move forward and backward. Roller 22, the transmission belt 23 that is wound between two transmission rollers and driven by the transmission roller and the first motor 24 that drives at least one transmission roller to rotate, one end of the transmission roller is connected to the output shaft of the first motor Fixedly connected, the first motor is fixed on the frame; the plate frame is located above the transmission belt;

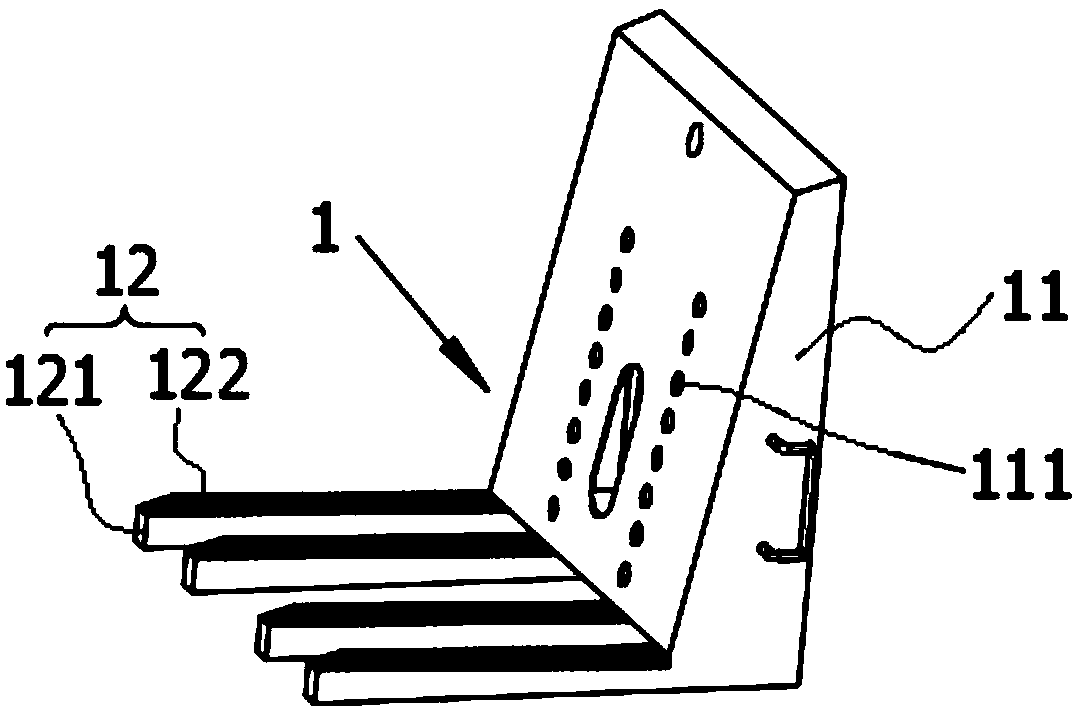

[0026] The plate frame includes a back plate 11 and a lower support plate 12, the back plate is provided with at least one row of blind holes 111 filled with adsorption fillers in the holes distributed along the height direction of the back plate; the lower support plate Both include a rigid sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com