Rolling mill arch hoisting method

A rolling mill archway and hoisting method technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of inconvenient removal, assembly and use of rolling mill archway hoisting tools for undisclosed rolling mill archway, shorten the hoisting time, The effect of reducing difficulty and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

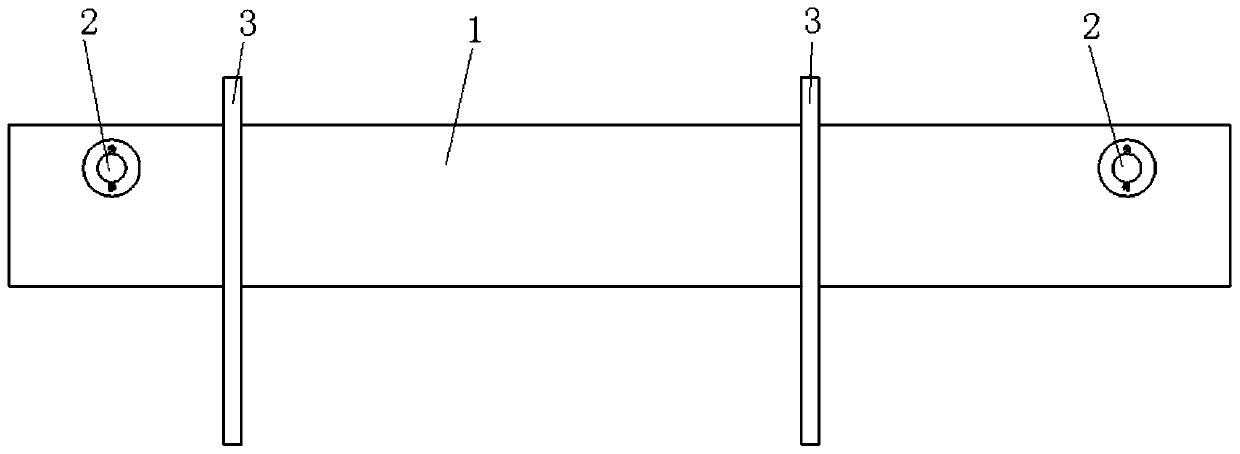

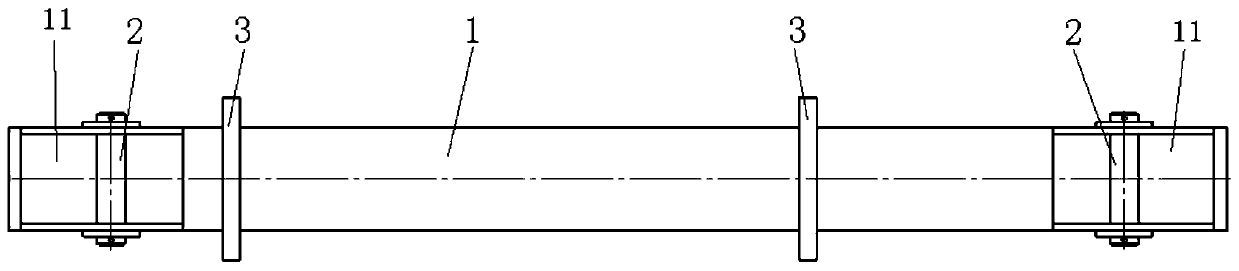

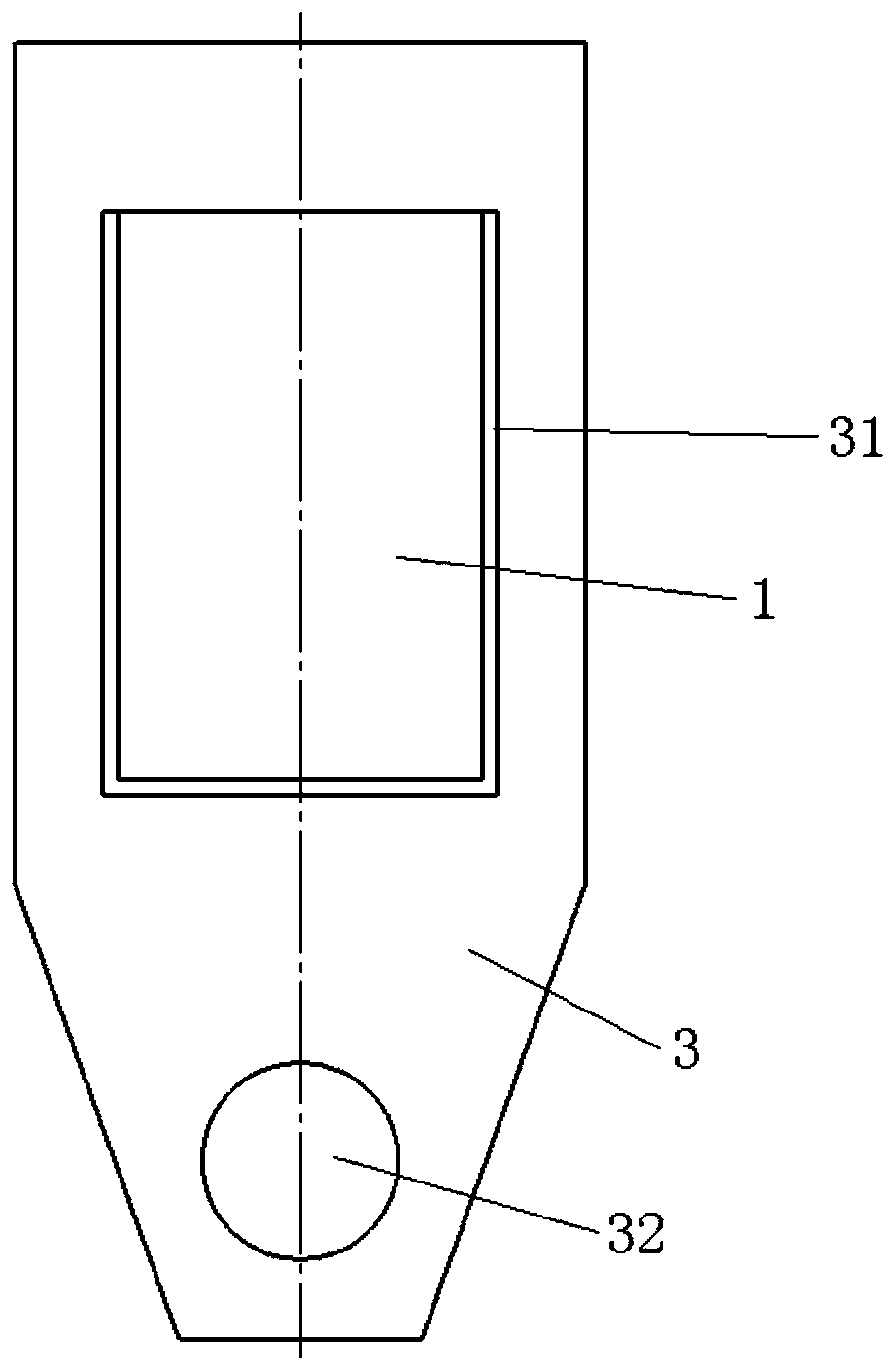

[0038] The present invention needs to use rolling mill arch hoisting tool to realize. like Figure 1 to Figure 3 As shown: the hoisting tool for the rolling mill archway includes a beam 1, two hook shafts 2 and two hoisting plates 3; the cross-sectional shape of the beam 1 is a hollow rectangle whose height is greater than the width; The crossbeam 1 is connected, and the upper surface of the crossbeam 1 is provided with a hook hole 11 corresponding to the position of the hook shaft 2; the hoisting plate 3 is provided with a hoisting plate rectangular hole 31 and an arch trunnion hole 32 located below the hoisting plate rectangular hole 31, and the hoisting plate 3 is set on the beam 1 through the rectangular hole 31 of the lifting plate, and the lifting plate 3 can move along the beam 1.

[0039] like Figure 4 and Figure 5 As shown: the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com