Dry granular, dry granular glaze and dry granular glazed tile

A dry-grain glaze, dry-grain technology, applied in the field of dry-grain, dry-grain glaze and dry-grain glazed tiles, can solve the problems of easy sticking and absorbing dirt on the surface, so as to solve the problem of no sticking and absorbing dirt in the gap, and the glaze surface Soft and comfortable to the touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

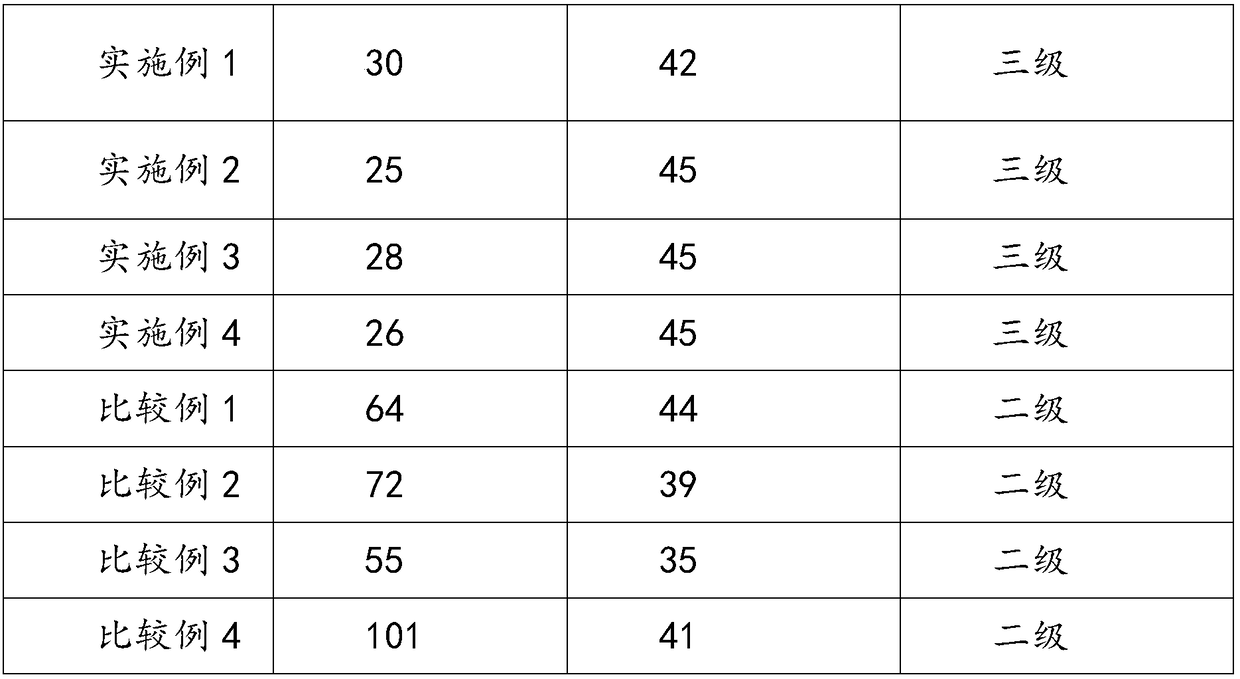

Embodiment 1

[0035] Follow the steps below to prepare dry grain glazed tiles:

[0036] 1. The bricks laid by the press are dried to remove the free water inside, so that the moisture content of the bricks is less than 0.5%. After the bricks leave the drying kiln, water is sprayed on the surface of the bricks to form a layer of water film on the surface;

[0037] 2. Then pour the bottom glaze on the surface of the green body, the amount of glaze is 87g (340*670 tray); the bottom glaze includes SiO by mass percentage 2 40%, Al 2 o 3 15%, CaO10%, MgO8%, ZnO15%, K 2 O6%, Na 2 O3%, BaO3%;

[0038] 3. The inkjet machine sprays the pattern and dries it in the second drying kiln to shorten the drying time of the ink;

[0039] 4. Spray dry granular glaze; the flow rate of dry granular glaze is 26s, the specific gravity is 1.27g / ml, the glaze amount is 67g (340*670 tray), and the fineness is 0.4% by weight of dry material after passing through a 200-mesh sieve; Granular glaze is calculated in ...

Embodiment 2

[0046] Follow the steps below to prepare dry grain glazed tiles:

[0047] 1. The bricks laid by the press are dried to remove the free water inside, so that the moisture content of the bricks is less than 0.5%. After the bricks leave the drying kiln, water is sprayed on the surface of the bricks to form a layer of water film on the surface;

[0048] 2. Then pour the bottom glaze on the surface of the green body, the amount of glaze is 93g (340*670 tray); the bottom glaze includes SiO by mass percentage 2 55%, Al 2 o 3 13%, CaO8%, MgO5%, ZnO10%, K 2 O5%, Na 2 O2%, BaO2%;

[0049] 3. The inkjet machine sprays the pattern and dries it in the second drying kiln to shorten the drying time of the ink;

[0050] 4. Spray dry granular glaze; the flow rate of dry granular glaze is 31s, the specific gravity is 1.23g / ml, the glaze amount is 73g (340*670 tray), and the fineness is 0.6% by weight of dry material after passing through a 200 mesh sieve; Granular glaze is calculated in p...

Embodiment 3

[0057] Follow the steps below to prepare dry grain glazed tiles:

[0058] 1. The bricks laid by the press are dried to remove the free water inside, so that the moisture content of the bricks is less than 0.5%. After the bricks leave the drying kiln, water is sprayed on the surface of the bricks to form a layer of water film on the surface;

[0059] 2. Then pour the bottom glaze on the surface of the green body, the amount of glaze is 90g (340*670 tray); the bottom glaze includes SiO by mass percentage 2 54%, Al 2 o 3 10%, CaO9%, MgO7%, ZnO14%, K 2 O4%, Na 2 O1%, BaO1%;

[0060] 3. The inkjet machine sprays the pattern and dries it in the second drying kiln to shorten the drying time of the ink;

[0061] 4. Spray dry granular glaze; the flow rate of dry granular glaze is 29s, the specific gravity is 1.25g / ml, the glaze amount is 70g (340*670 tray), and the fineness is 0.5% by weight of dry material after passing through a 200-mesh sieve; Granular glaze is calculated in p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com