Special regenerated modified plastic particles for automobile and preparation method

A technology of plastic granules and modification, applied in the field of recycled modified plastic granules for automobiles and their preparation, can solve the problems of poor weather resistance, low thermal deformation temperature and flammability, and achieve the effects of reducing plastic pollution, and having toughness and flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

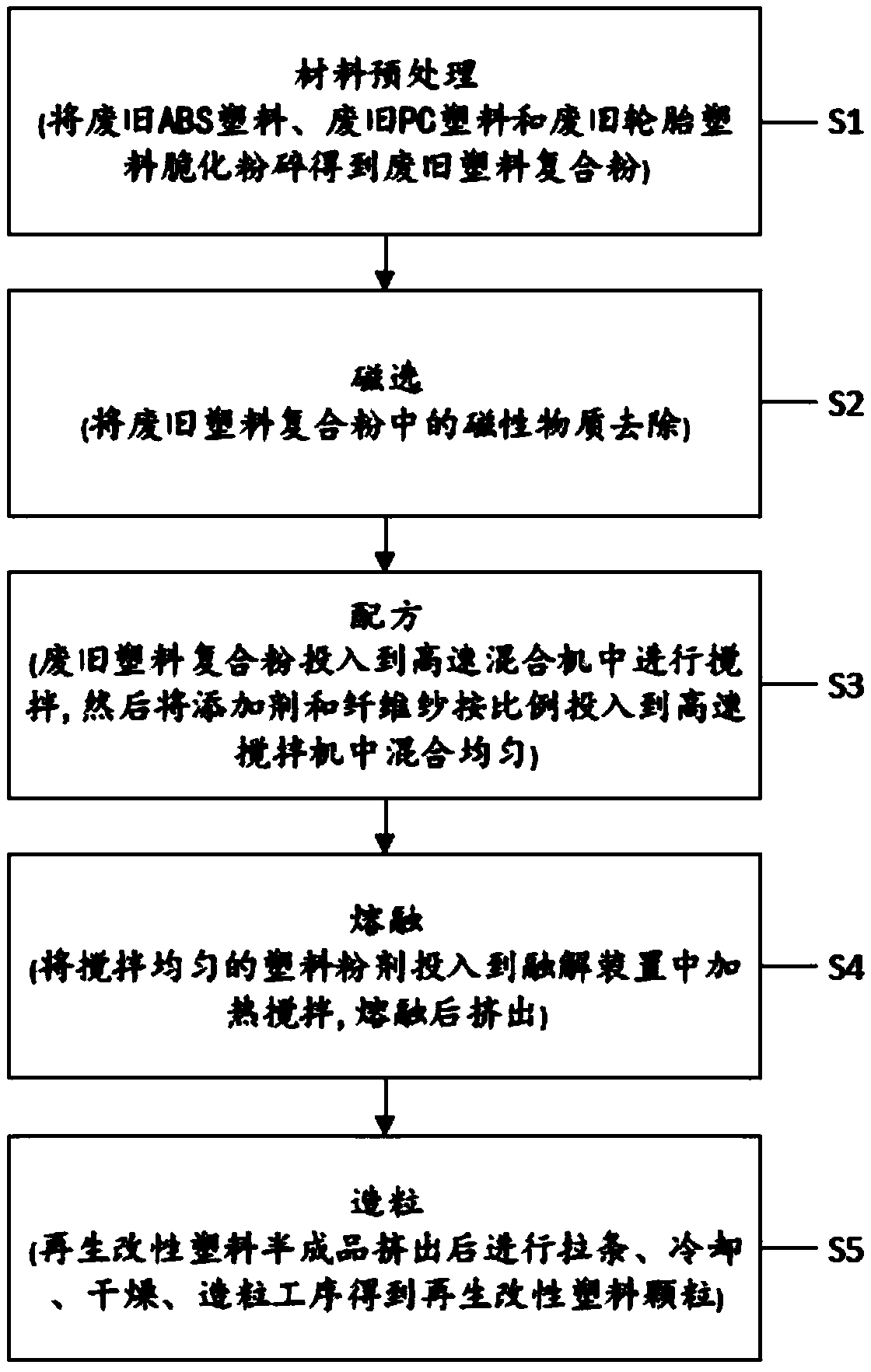

[0027] See figure 1 , the present embodiment provides a special regenerated modified plastic granule for automobiles and a preparation method thereof. The regenerated modified plastic granule includes the following components by weight: 50-70 parts of waste ABS plastic, 50-75 parts of waste PC plastic, 10-75 parts of auxiliary materials 25 parts, 10-26 parts of polypropylene compound, 10-24 parts of additives, auxiliary materials include waste tire plastic and fiber yarn, additives include 1-4 parts of flame retardant, 1-6 parts of compatibilizer, 0.1-1 part of lubricant , 0.6-3 parts of plasticizer, 0.1-6 parts of antioxidant, 8-20 parts of waste tire plastic, and 2-5 parts of fiber yarn.

[0028] In a preferred embodiment of the present invention, the above-mentioned preparation method comprises the following steps:

[0029] S1: Material pretreatment, wash and dry the waste ABS plastic, waste PC plastic and waste tire plastic, and then put the dried waste ABS plastic, waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com