Environment-friendly sound insulation floor and preparation method thereof

An environmentally friendly flooring technology, applied in the field of flooring, can solve the problems of high price and poor sound insulation effect, achieve low cost, reduce floor sound insulation, and reduce plastic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

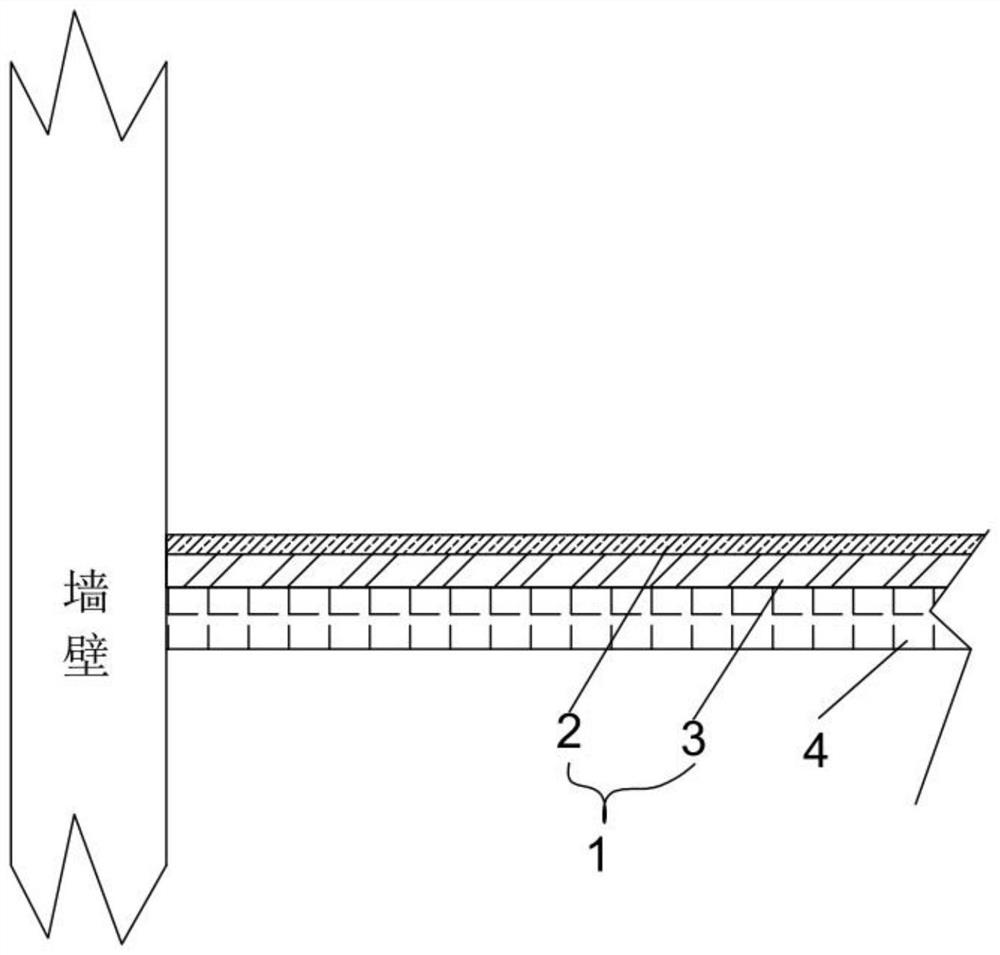

[0029] like figure 1 As shown, an environmentally friendly sound insulation floor disclosed in this embodiment includes a main body 1, the main body 1 includes a sound insulation buffer layer 3 located above a reinforced concrete floor 4, and cement powder is arranged on the sound insulation buffer layer 3 Light layer 2, wherein the sound insulation and buffering material layer 3 includes raw materials according to the following proportions: 20-30 parts of PE waste plastic, 10-30 parts of PVC waste plastic, 20-40 parts of floor recycled material, foaming 2-6 parts of fire retardant, 2-6 parts of fire retardant, 2-6 parts of aluminum hydroxide and 8-12 parts of calcium carbonate.

[0030] Preferably, the sound insulation and buffering material layer 3 includes raw materials in the following proportions: 35 parts of PE waste plastic, 30 parts of PVC waste plastic, 30 parts of new recycled materials, 5 parts of foaming agent, and 5 parts of fire retardant. parts, 5 parts of alum...

Embodiment 2

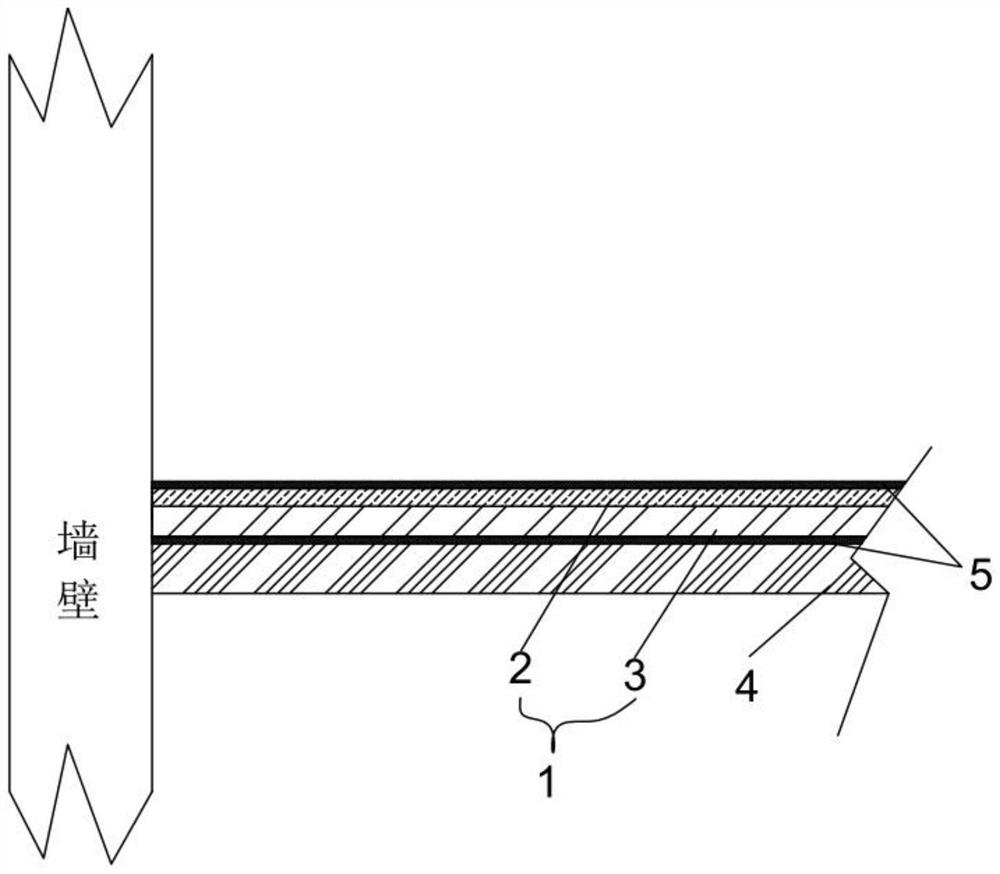

[0040] like figure 2 As shown in the figure, an environmentally friendly sound insulation floor disclosed in this embodiment, further, a waterproof layer 5 is arranged above the cement powder light layer 2 and below the sound insulation buffer layer 3, and the waterproof layer 5 is added to improve the waterproof performance. sex.

Embodiment 3

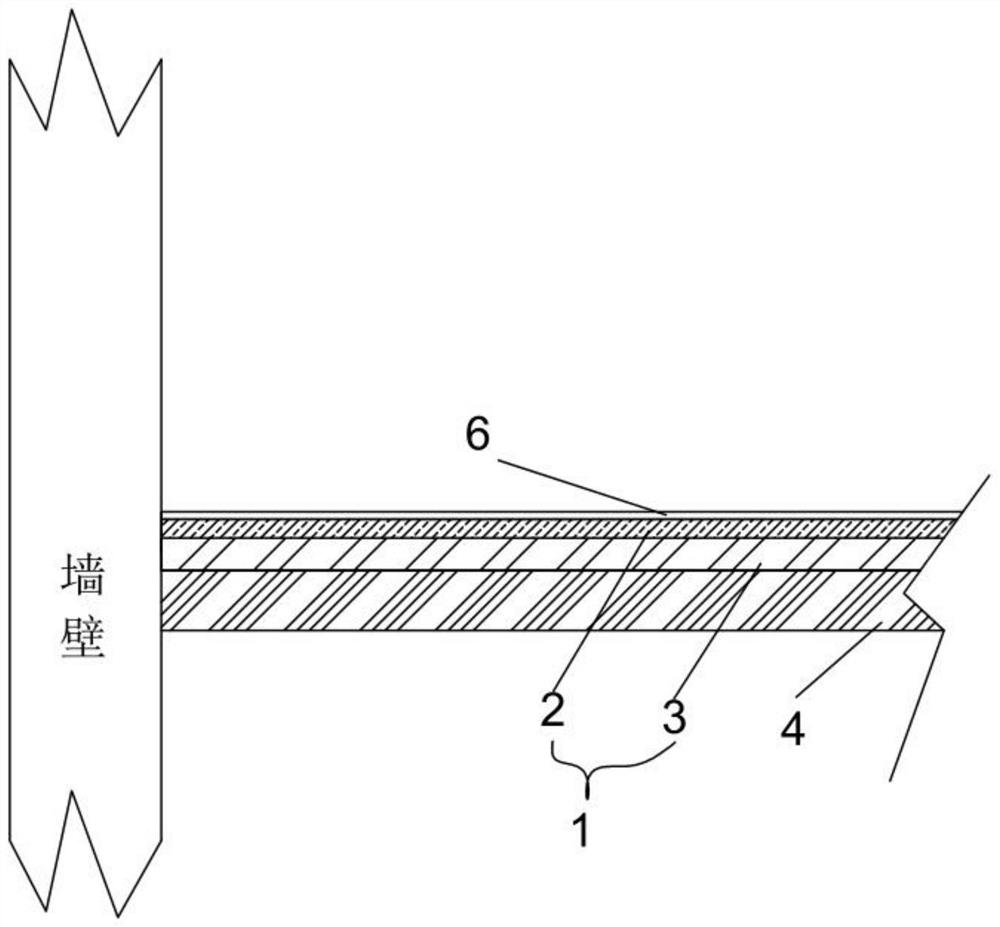

[0042] like image 3 As shown, the present embodiment discloses an environment-friendly sound insulation floor, further, an anti-slip layer 6 is provided above the cement powder light layer 2 , and the anti-slip effect is improved by adding the anti-slip layer 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com