Rationed conveying and stirring equipment for blended raw materials for baijiu processing

A mixing equipment and raw material technology, applied in the field of liquor blending, can solve the problems of economic loss, slow blending process, low work efficiency, etc., and achieve the effect of convenient use and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

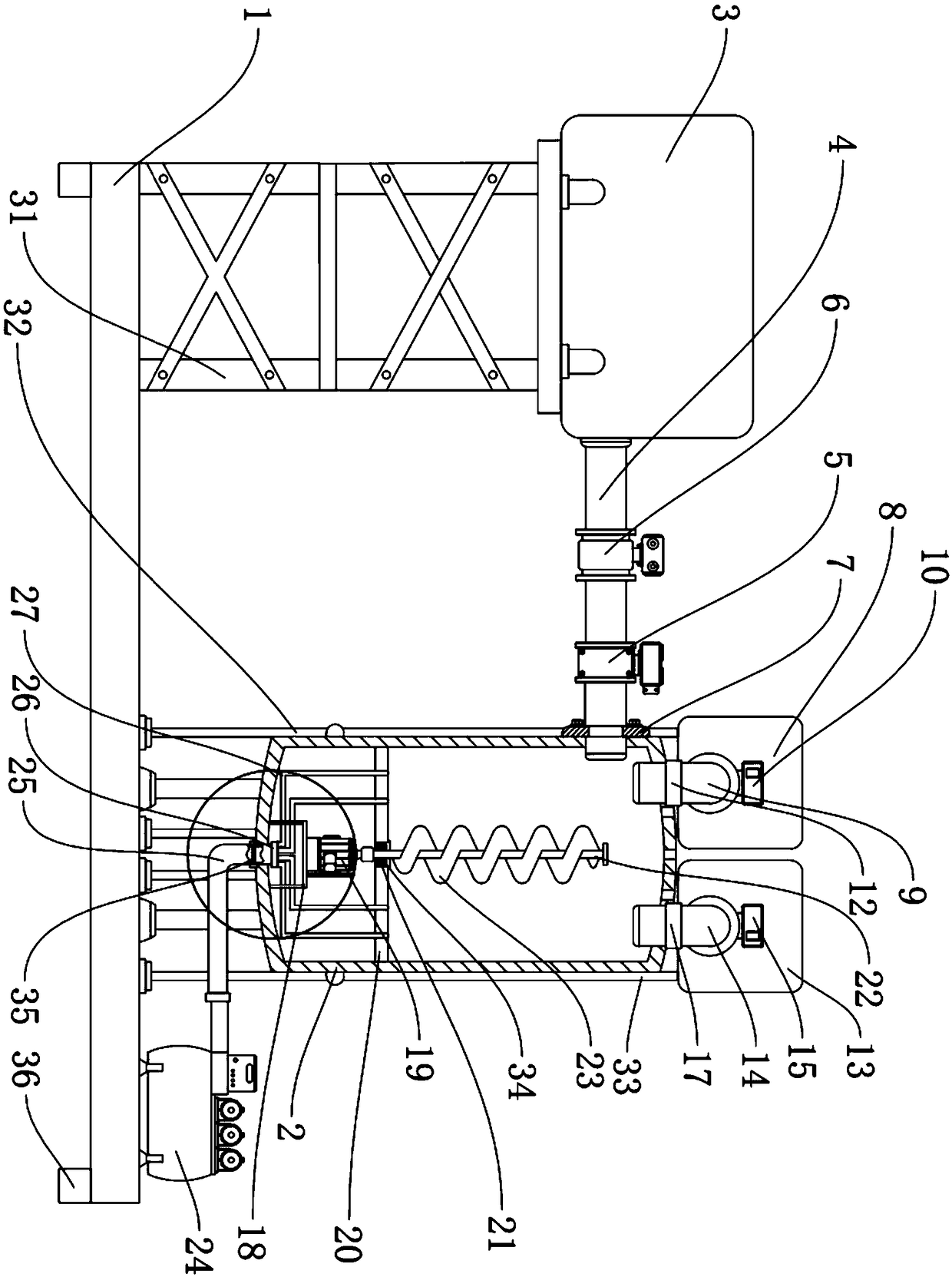

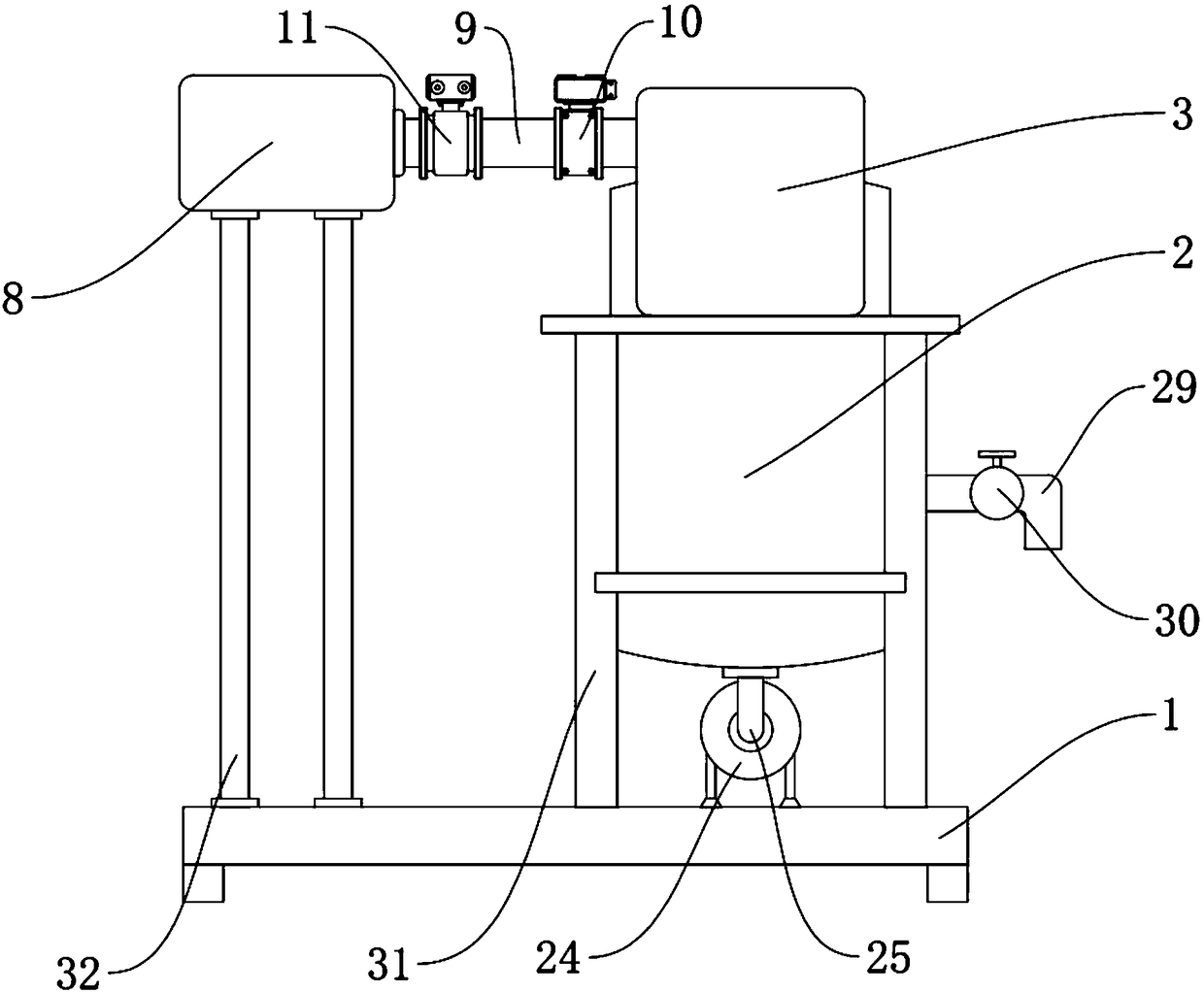

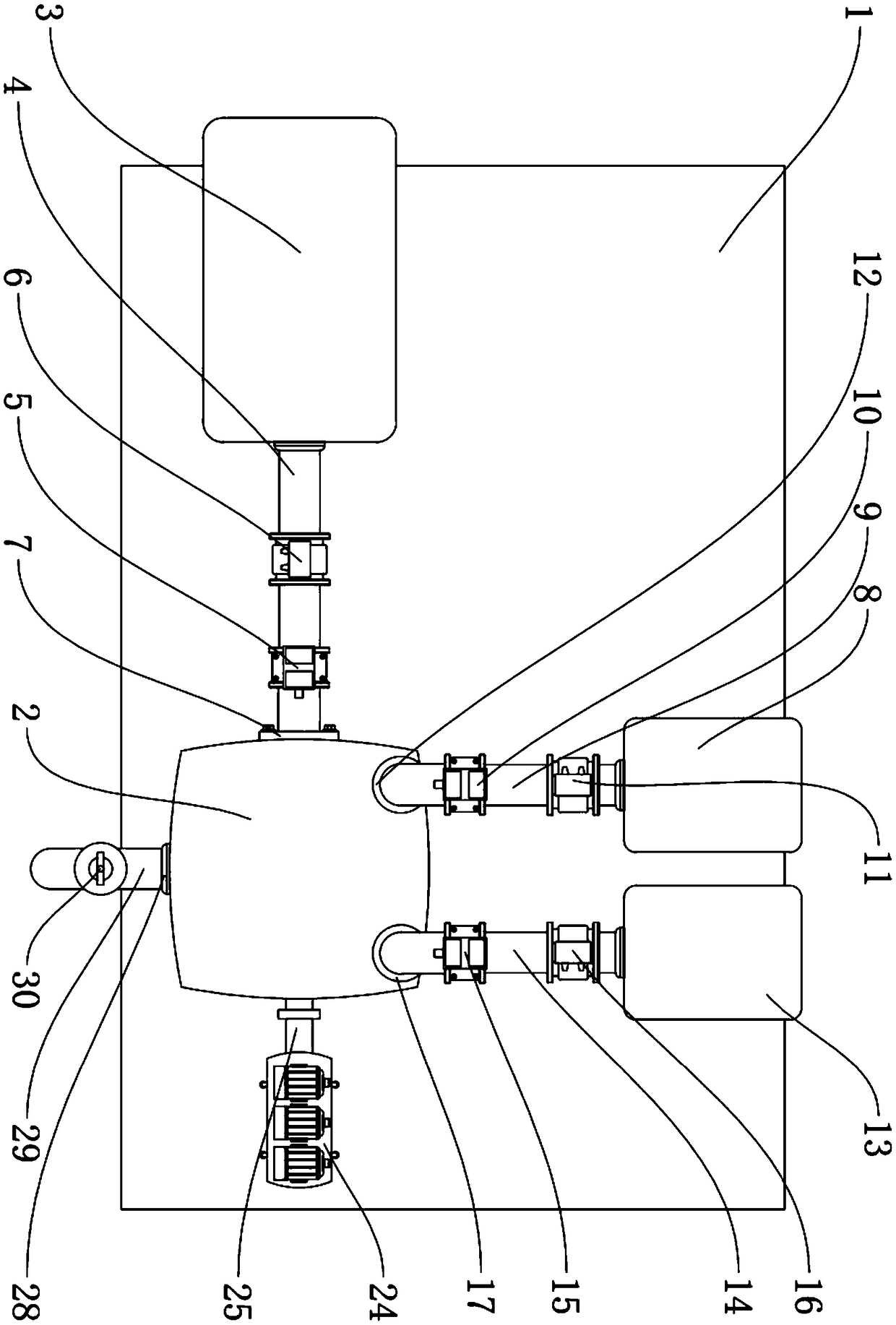

[0052]Embodiment: Before blending, the worker pumps the base wine into the first storage box 3 as a backup, and pumps the flavored wine and soft water into the second storage box 8 and the third storage box 13 respectively, and the first storage box 3 The first fixing frame 31 is installed, while the first fixing frame 31 plays a fixing role, the height of the first material storage box 3 is raised to make it higher than the height of the blending box 2 to facilitate feeding, and the fluid is left by gravity to save costs , the first material storage box 3 and the blending box 2 are connected through the first feed pipe 4, and the first interface 7 is installed on the first feed pipe 4, which facilitates the installation of the first feed pipe 4 and prevents wine slurry Outflow, the first electromagnetic valve 5 is installed on the first feeding pipeline 4, the first electromagnetic flow meter 6 is installed between the first electromagnetic valve 5 and the first material stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com