Fiber cloth twill weaving process

A fiber cloth and twill technology, applied in the field of fiber cloth twill weaving technology, to achieve the effects of wide application range, fast impregnation and high breaking strength

Active Publication Date: 2018-12-21

JUSHI GRP CO

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005]

The present invention aims

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

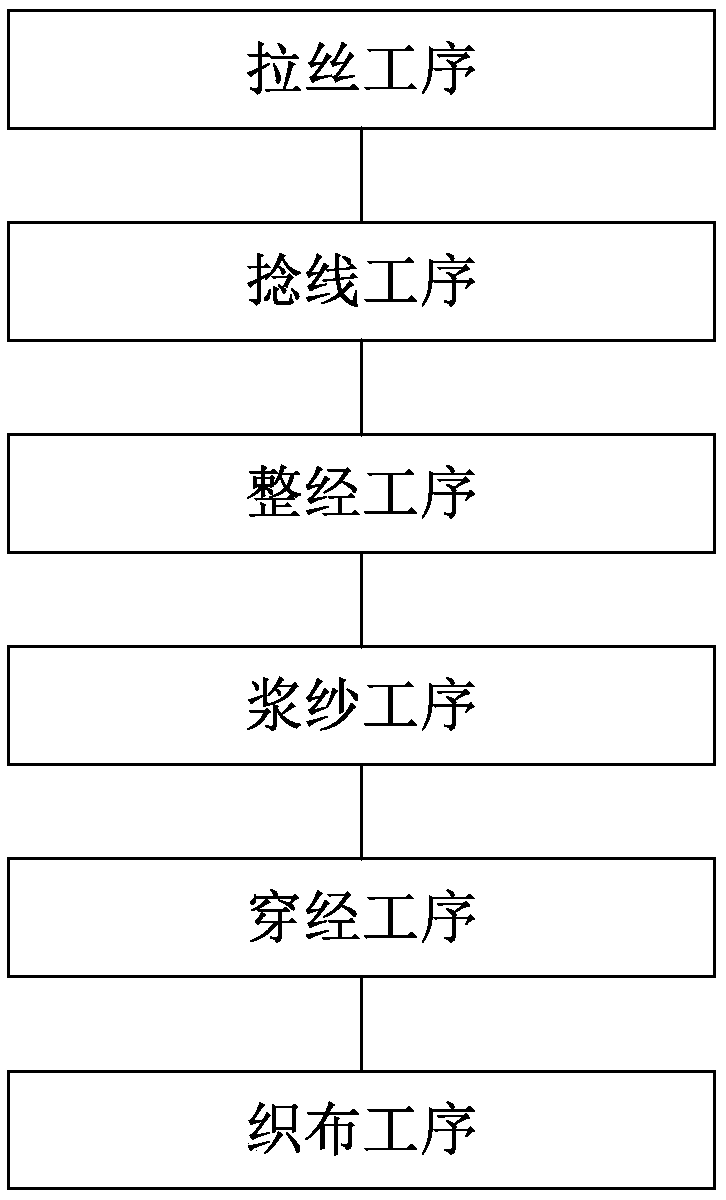

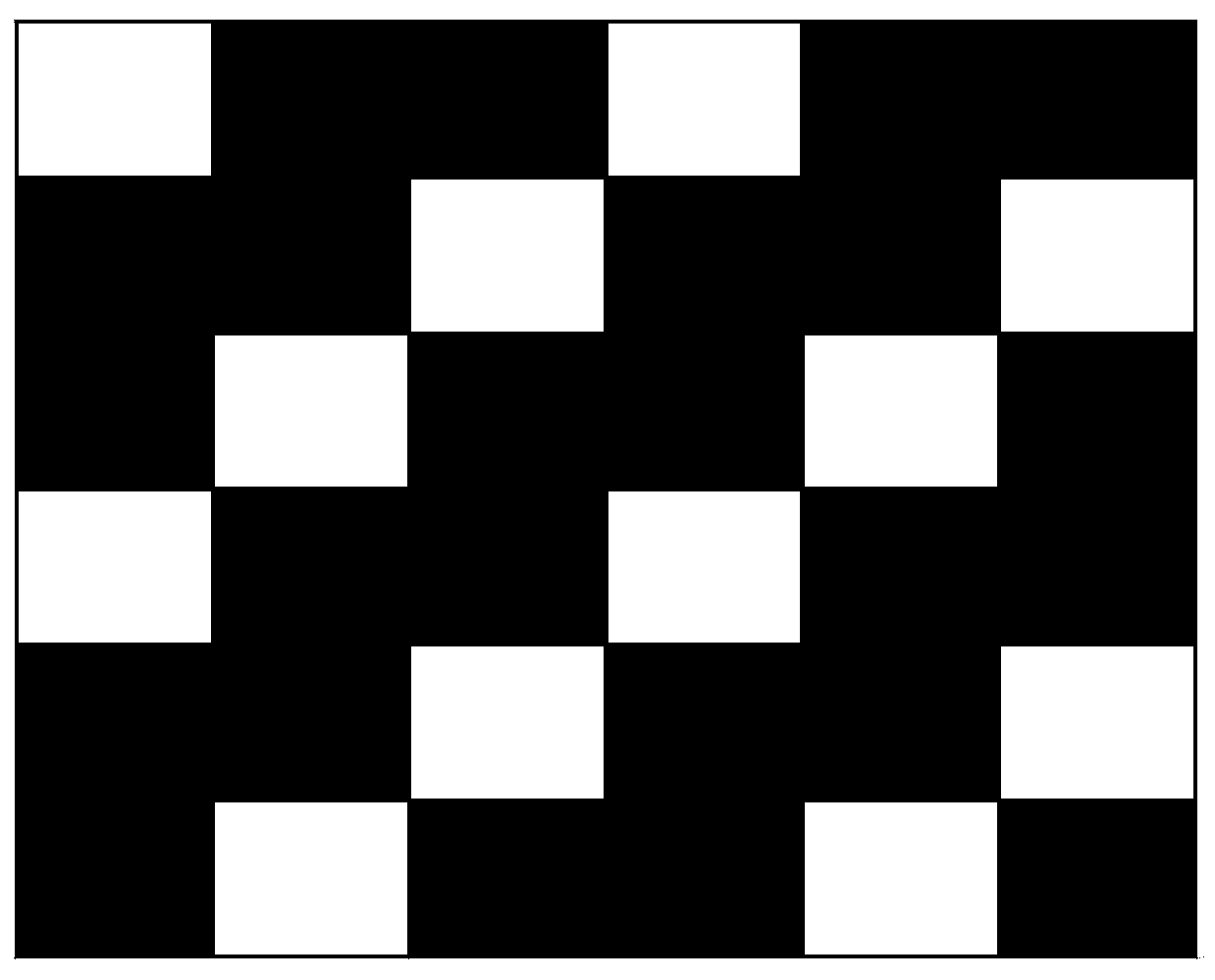

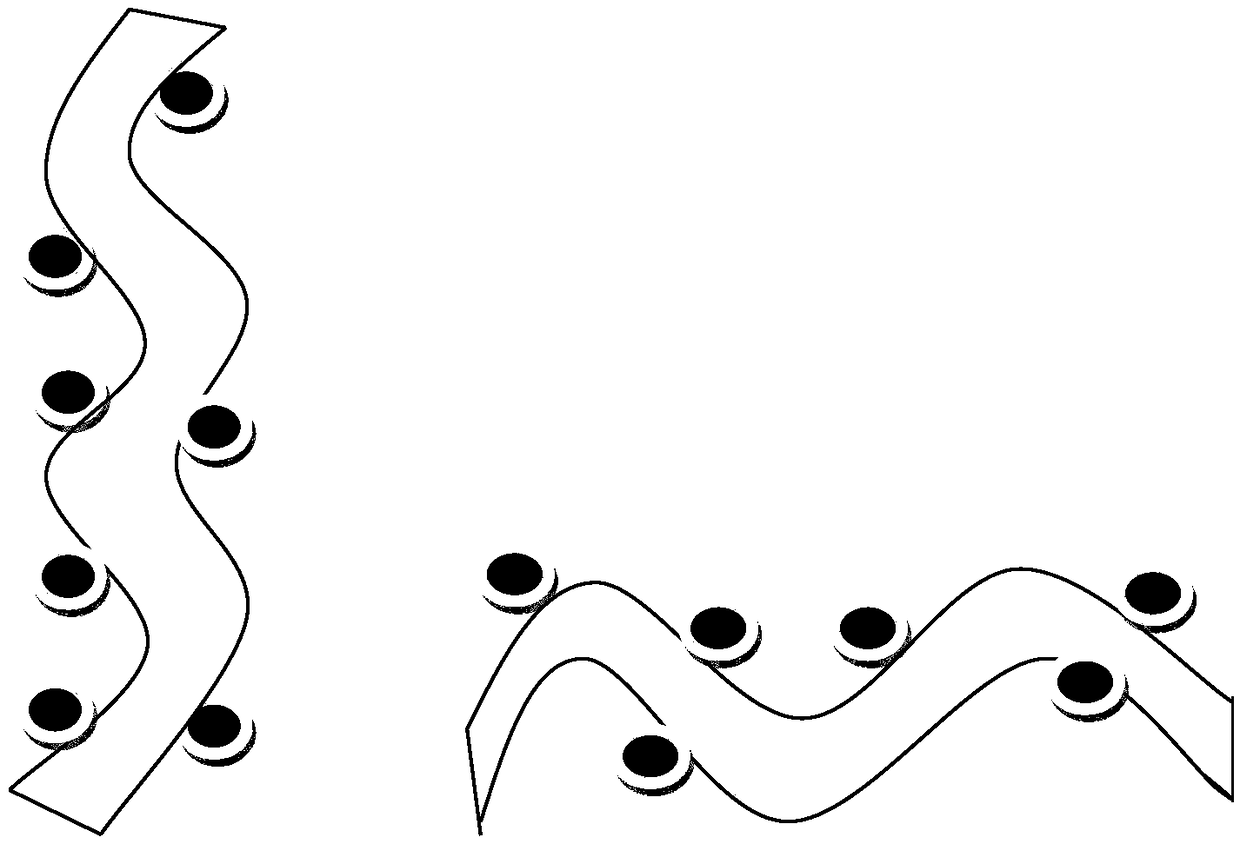

The invention discloses a fiber cloth twill weaving process. The process includes the following steps of warping, sizing, drawing-in and weaving. According to the process, an air-injection loom is adopted for adjusting twill obtained by means of bobby shedding. The process has the advantages that the gram weight is high, the breaking strength is high and the softness is high. The time for soakingin resin is short, the quality of a product can meet the requirements of customers, and the demands of a glass fabric high-end application domain can also be met. Meanwhile, by adopting the process, the running efficiency of the loom can be improved, the workload is reduced, and the efficiency is improved.

Description

technical field [0001] The invention relates to the weaving field, in particular to a fiber cloth twill weaving process. Background technique [0002] Glass fiber cloth has a wide range of uses and can be used in Teflon, fiberglass cloth, fireproof board base cloth and other fields. With the development of production, the field of development and use of glass fiber cloth has become wider and wider. [0003] At present, the air-jet looms used in the industry to weave glass fiber cloth electronic cloth warp beams are conventional G-series yarns. It is difficult to weave glass fiber cloth with high breaking strength and short cloth surface soaking time. The production of high breaking strength yarns on looms requires With a coarse yarn counting machine, the large vibrating parts are easy to wear, which will affect the quality of the cloth surface and reduce the operating efficiency of the equipment; and the cost is high, the labor force is increased, and the shutdown time is i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D03D15/00D03D47/30D03D15/217D03D15/267D03D15/275D03D15/283

CPCD03D15/00D03D47/30D03D15/267

Inventor 陈惠梅张时晶王富峰

Owner JUSHI GRP CO

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com