Wall tile surface concrete feeding and tiling device

A technology of concrete and conveying devices, which is applied in the direction of construction and building construction, which can solve problems such as uneven laying, long time required, and influence on the effect of posting, so as to achieve good paving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

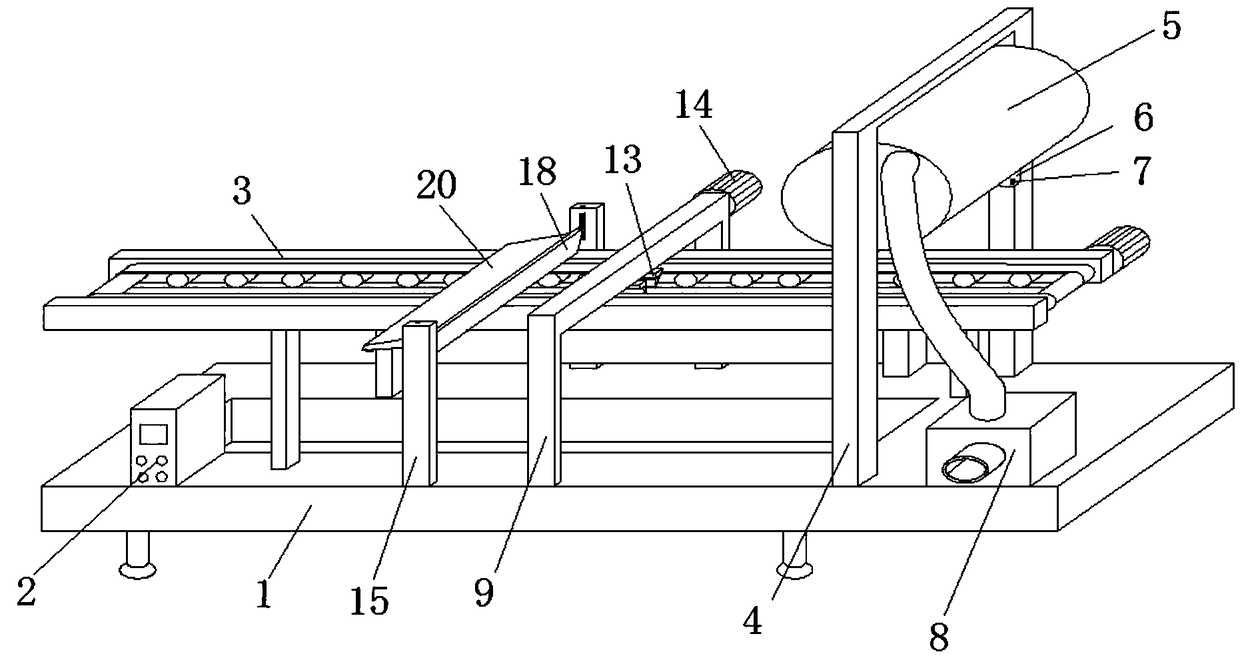

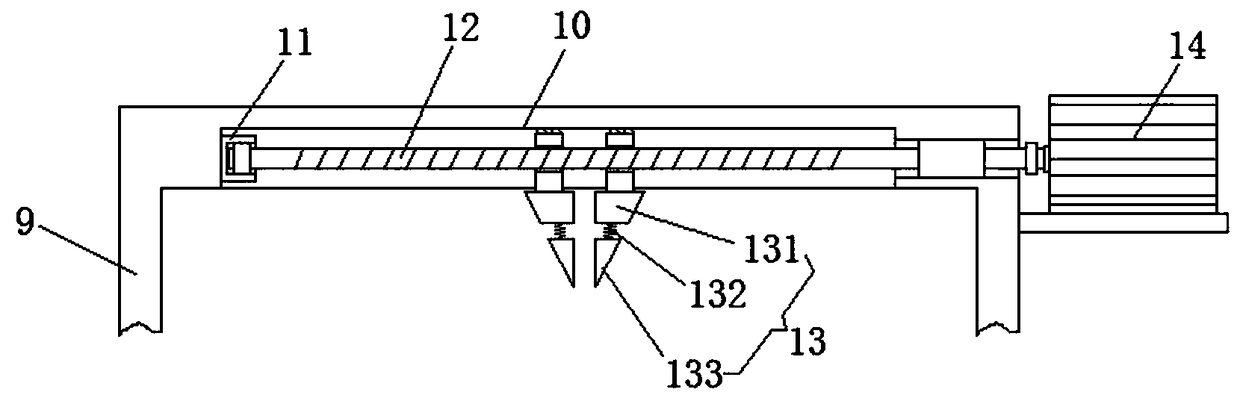

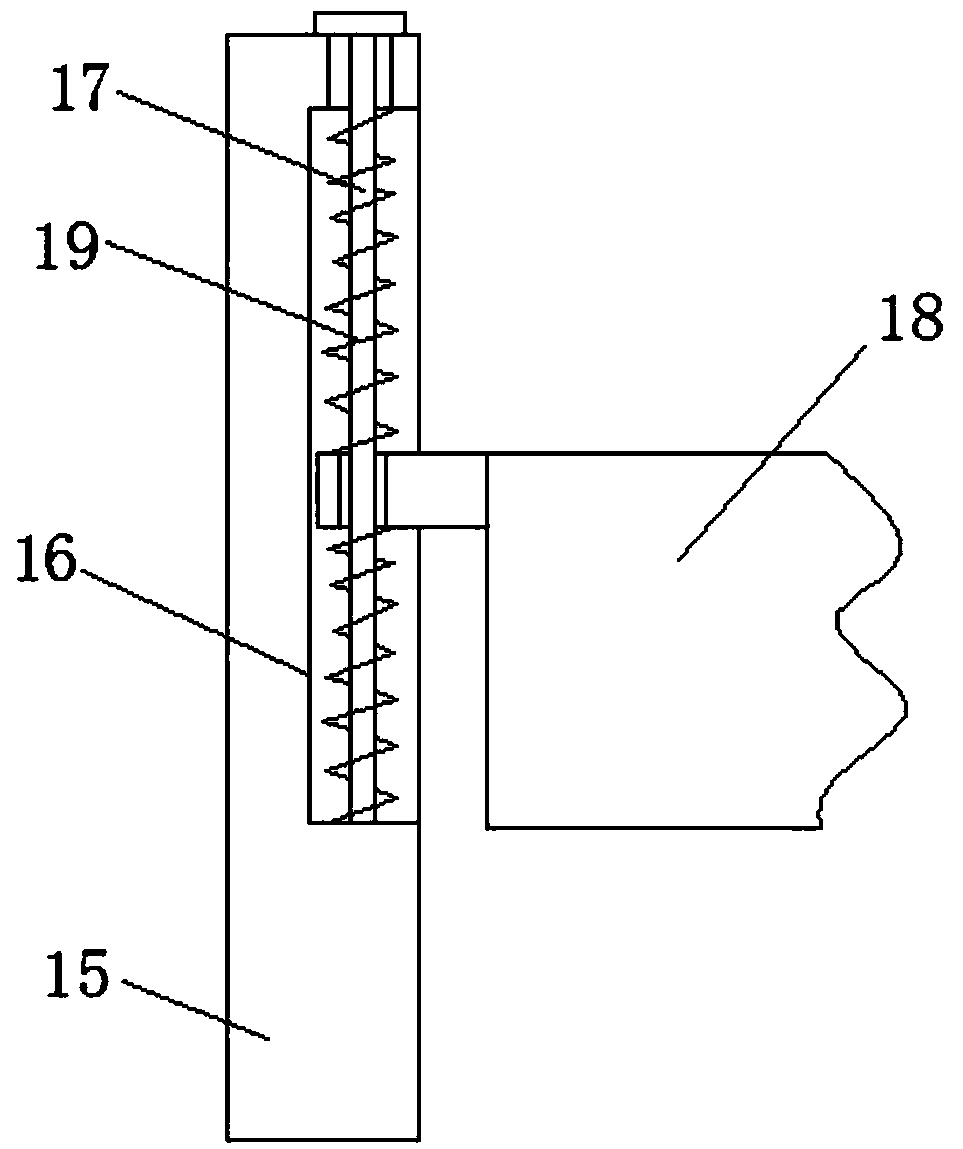

[0021] see Figure 1-4 , this embodiment provides a concrete feeding and tiling device on the surface of wall tiles, including a base 1, an electric control box 2 is fixedly installed on the top of the base 1, a conveying device 3 is fixedly installed on the top of the base 1, and the top of the base 1 is fixedly installed There is a fixed frame 4, and the conveying device 3 is located on the inner side of the fixed frame 4, and the inside top of the fixed frame 4 is fixedly connected with a sizing box 5 located above the conveying device 3, and the bottom of the sizing box 5 is provided with a spray pump 6, and the spray pump 6 One side of the base 1 is provided with a position sensor 7, the top of the base 1 is fixedly connected with a booster pump 8, the booster pump 8 communicates with the sizing box 5, and the front of the sizing box 5 communicates with a feeding pipe, and the feeding pipe connects with the booster pump 8 Connected, the top of the base 1 is fixedly instal...

Embodiment 2

[0024] see Figure 1-2 On the basis of Embodiment 1, a further improvement is made: the bottom of the base 1 is fixedly connected with a support leg, and the bottom of the support leg is fixedly connected with a rubber pad, and the shape of the rubber pad is an isosceles trapezoid, and the rubber pad can affect the whole device. sloshing, etc., and setting it into an isosceles trapezoid can increase the contact area with the ground and make the whole more stable. The inner wall of the rotating seat 11 is provided with a bearing, and the connection between the screw rod 12 and the mounting frame 9 is provided with a bearing. The rod 12 is socketed with the inner edge of the bearing, and the connection between the screw rod 12 and the bearing has a smooth surface, and the bearing can make the rotation of the screw rod 12 smoother, reducing the load of the servo motor 14 .

[0025] Wherein, conveying device 3 comprises conveying frame, and the inboard of conveying frame is provid...

Embodiment 3

[0027] see figure 1 , 2Or 4, a further improvement is made on the basis of Embodiment 1: the spreader assembly 13 includes a moving plate 131, and the thread directions inside the two moving plates 131 are opposite, and the bottom of the moving plate 131 is fixedly connected with a second spring 132, The bottom of the second spring 132 is fixedly connected with a spreading plate 133. During the flattening process, the screw rod 12 rotates to drive the two moving plates 131 to move relative or opposite to each other, so that the moving plate 131 can drive the spreading plate 133 to reciprocate , and the second spring 132 can make the flattening effect better.

[0028] Wherein, the lowest points of the paving roller 21, the scraper 18 and the brush plate 20 are on the same horizontal plane, after the coagulation map is initially paved by the scraper 18, the unevenness is further paved by the paving roller 21, and finally The brush plate 20 is further scraped, so that the pavin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com