One machine and two wells production equipment and technology

An oil extraction device and oil pumping technology, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc., can solve the problems of hindering operation and construction, hindering construction operations, consuming manpower and material resources, etc., so as to improve the service life and reduce wear and tear. , the effect of reducing human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

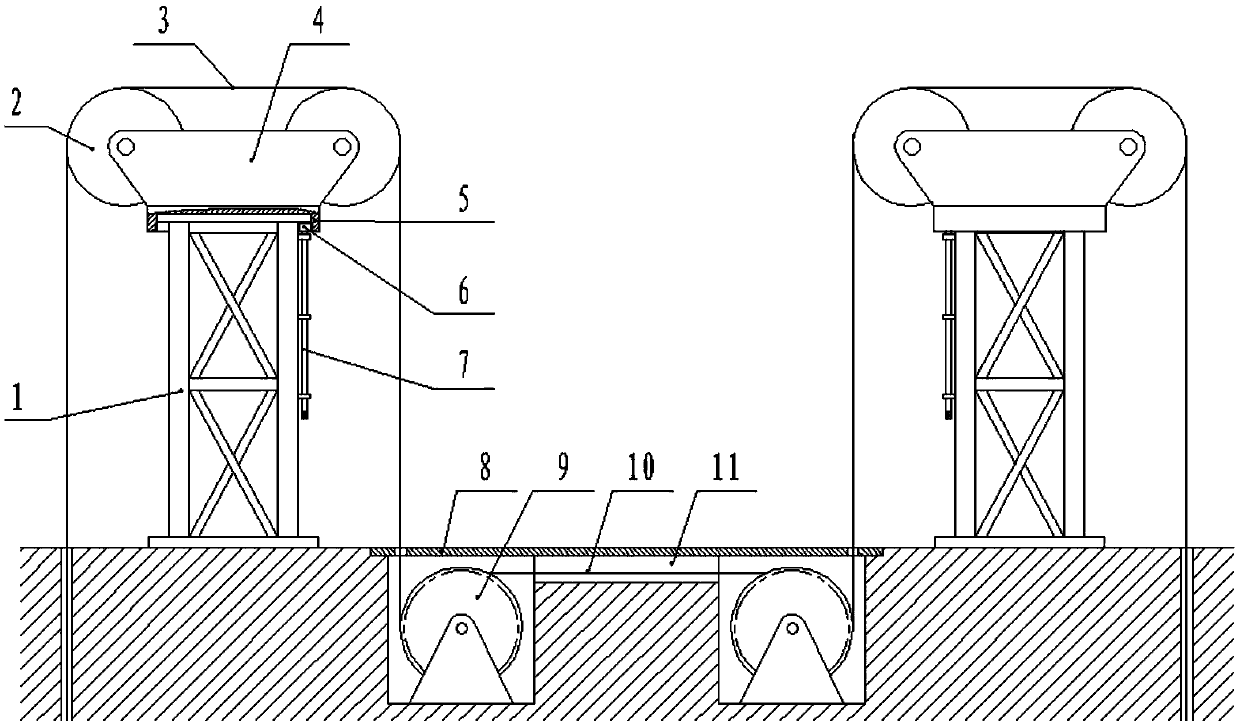

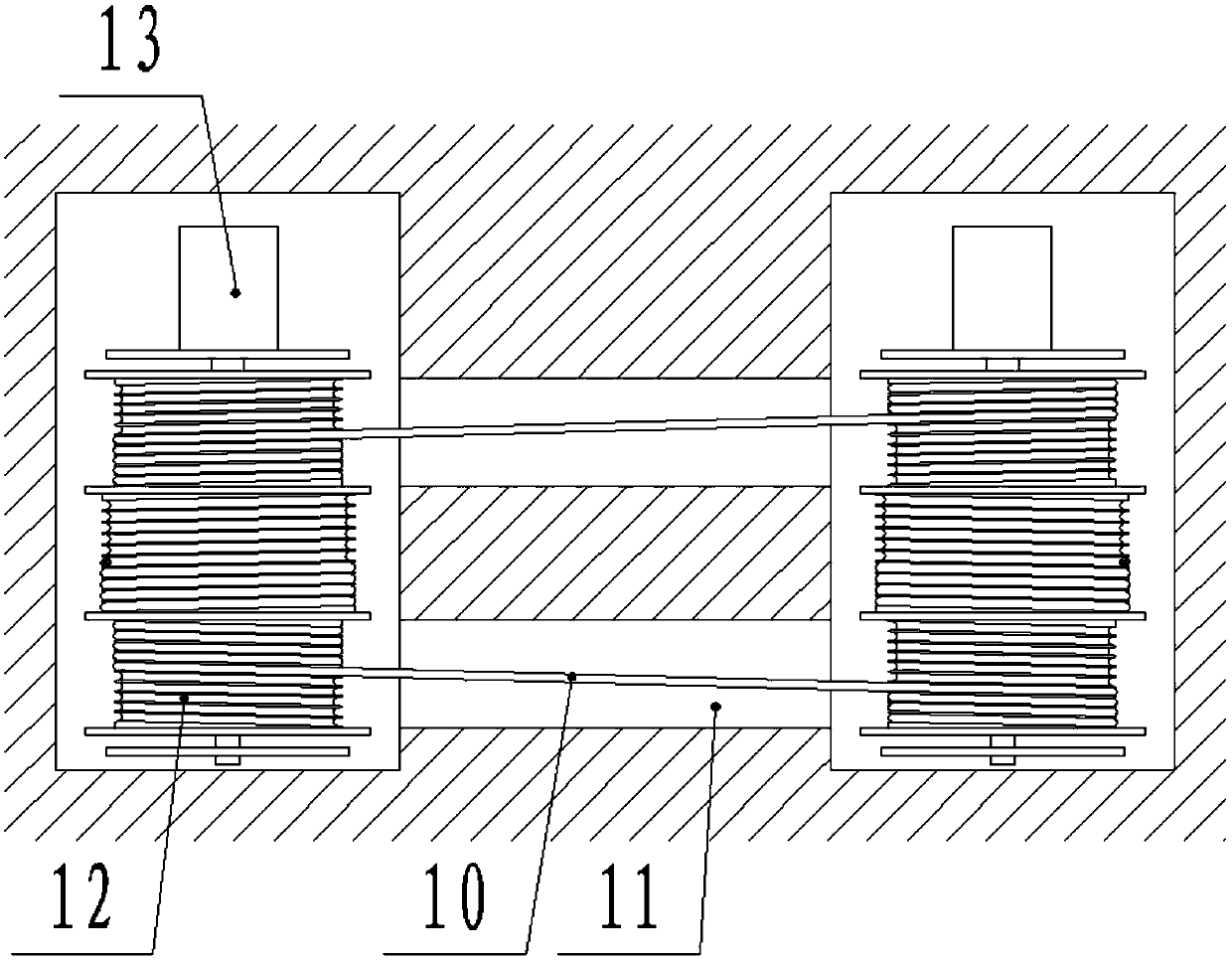

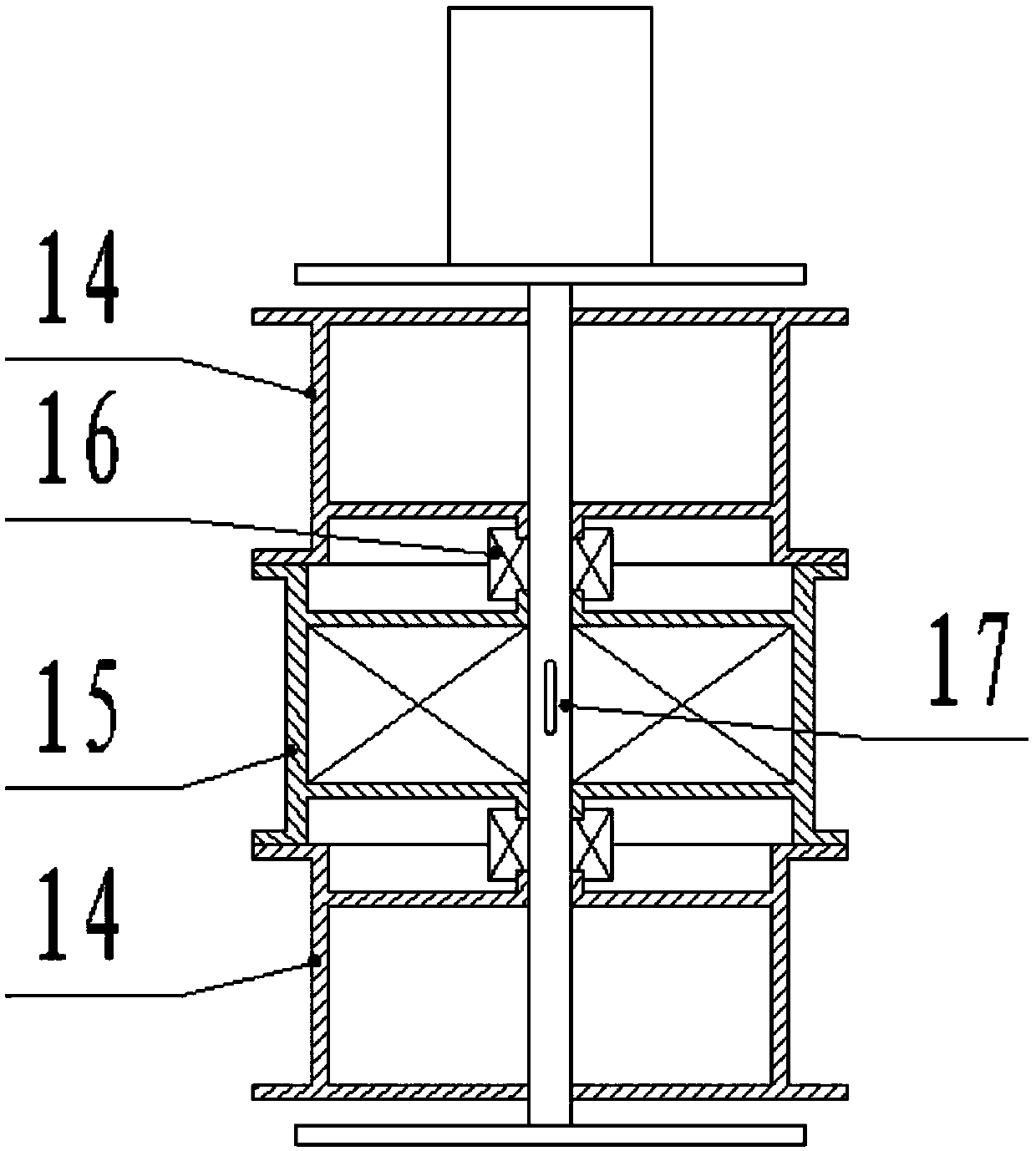

[0026] In this embodiment, a one-machine double-well oil production device includes two derricks 1, two sets of driving mechanisms and two oil extraction ropes 3. A fixed pulley bracket 4 is installed on the upper end of each derrick 1, and each fixed pulley bracket Two fixed pulleys 2 are symmetrically installed on the upper 4. The driving mechanism includes a drum 9 and a motor 13. A gear reduction mechanism is arranged inside the drum 9. The motor 13 drives the drum 9 to rotate through the gear reduction mechanism. The oil wick 3 One end is fixedly connected to the drum 9, and the other end bypasses the fixed pulley 2 and extends downhole to connect with the downhole sucker rod. The oil rope 3 is retracted under the drive of the drum 9 to drive the sucker rod. Do up and down reciprocating motion. The above are existing structures in the prior art, and will not be repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com