Miniature irrigation and drainage pump

A small, pump body technology, applied in the field of machinery, can solve the problems of heavy and complex structure, increasing the volume and weight of the drainage and irrigation pump, and complex internal structure design of the pump cavity, and achieves the effect of convenient maintenance and light structure in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

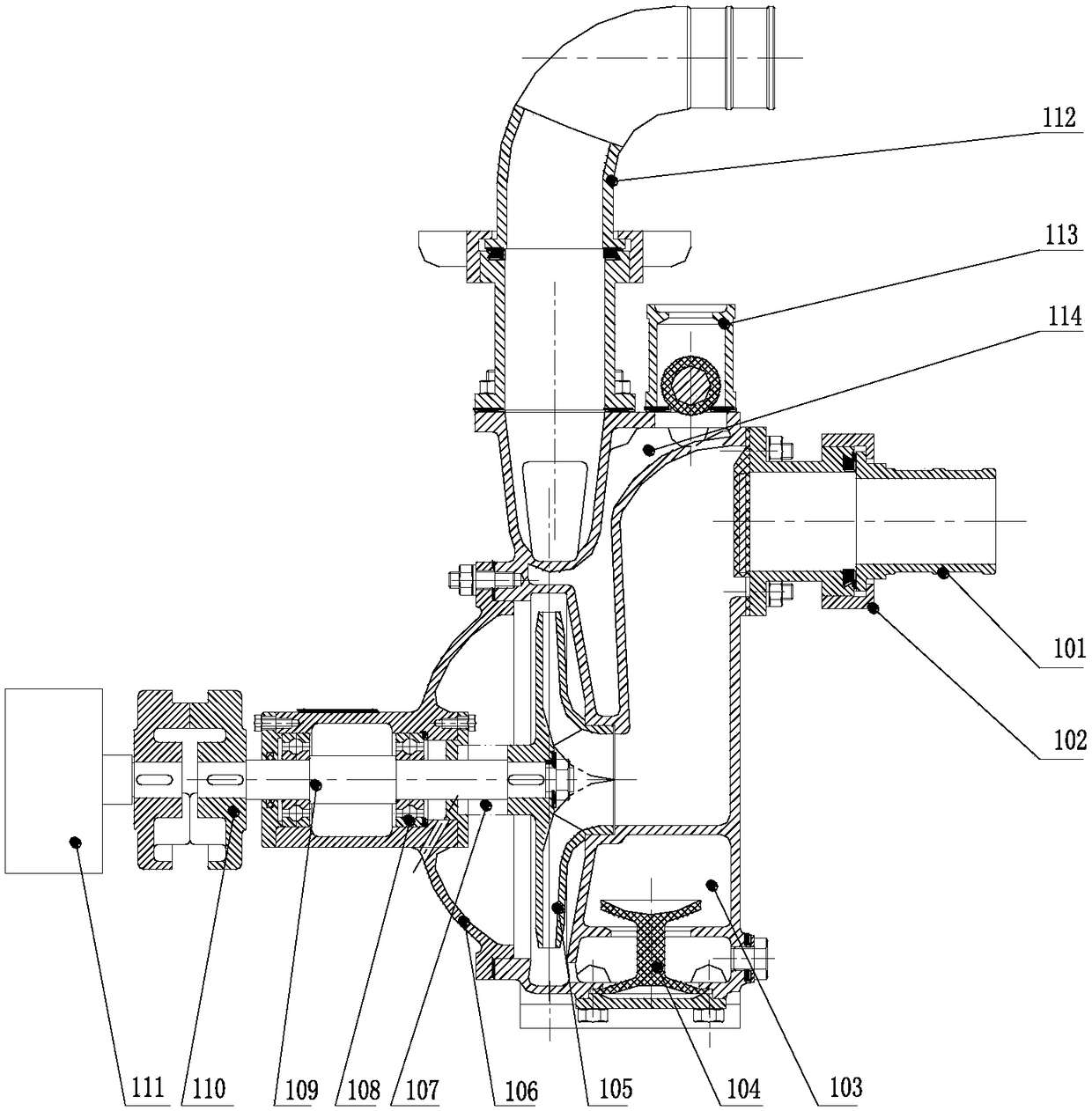

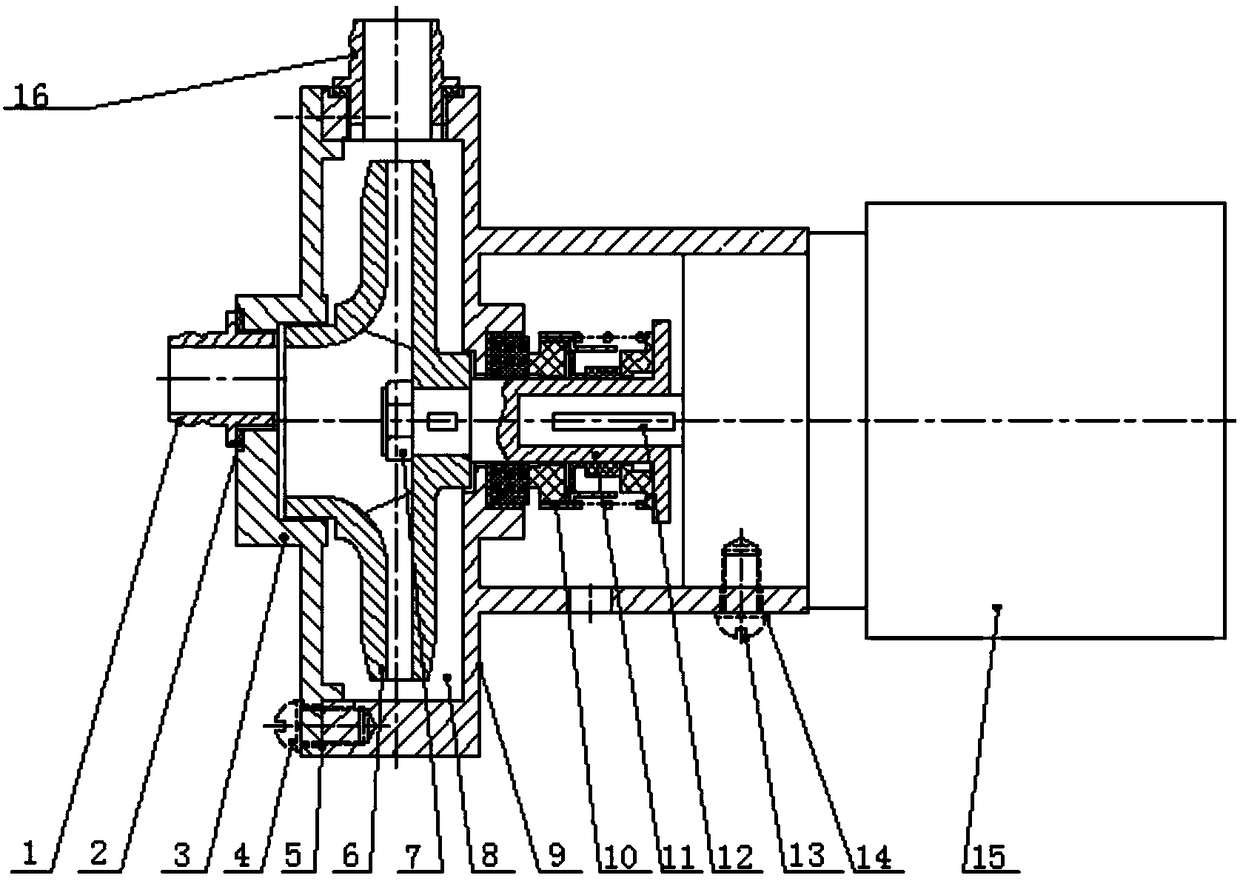

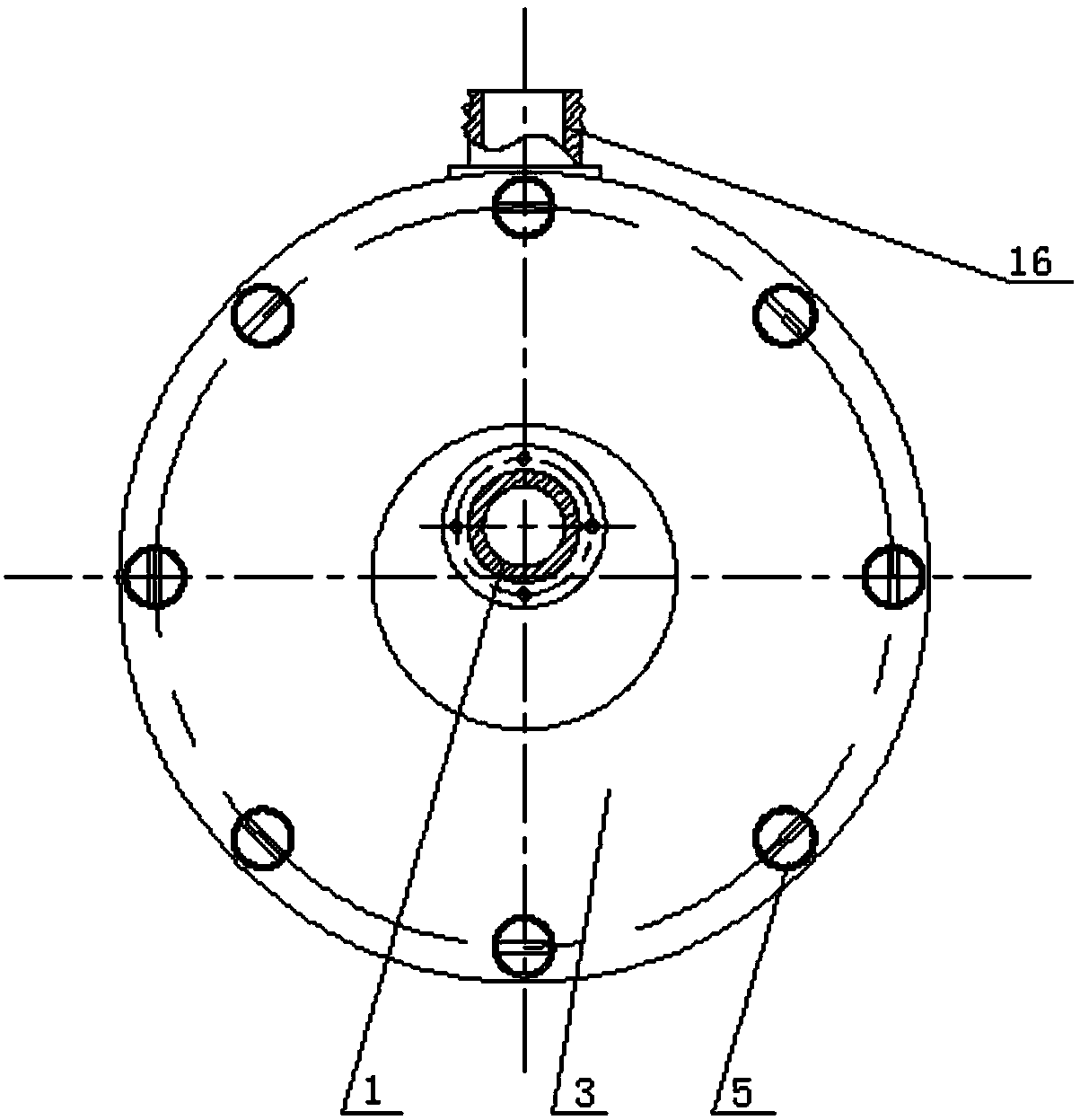

[0011] A small drainage and irrigation pump mainly consists of a water inlet pipe joint 1, a front cover plate 3, an impeller 6, a pump body 9, a pump shaft 11, a motor 15, and a water outlet pipe joint 16. The front cover plate 3 is integrated with the pump body 9 through semicircular bolts 4 to form a sealed pump chamber 8 . The impeller 6 is installed in the pump chamber 8, and its centerline coincides with the centerline of the front cover plate 3 and the pump body 9, and is connected with the pump shaft 11 through a key, and is fixed at the shaft end with the impeller nut 7. The water inlet pipe joint 1 is connected with the front cover plate 3 by bolts, and the bolts have a rubber sealing ring 2. The highest point of the inner diameter of the water inlet pipe joint is flush with the highest point of the inner diameter of the impeller inlet, and the lowest point of the inner diameter of the water inlet pipe joint is higher than the center line of the impeller inlet. . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com