Automobile fastener

A technology for fasteners and automobiles, applied in the directions of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of single fastener structure, inconvenient disassembly and assembly, general fastening performance, etc. Work efficiency, not easy to loosen, improve the effect of tightening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

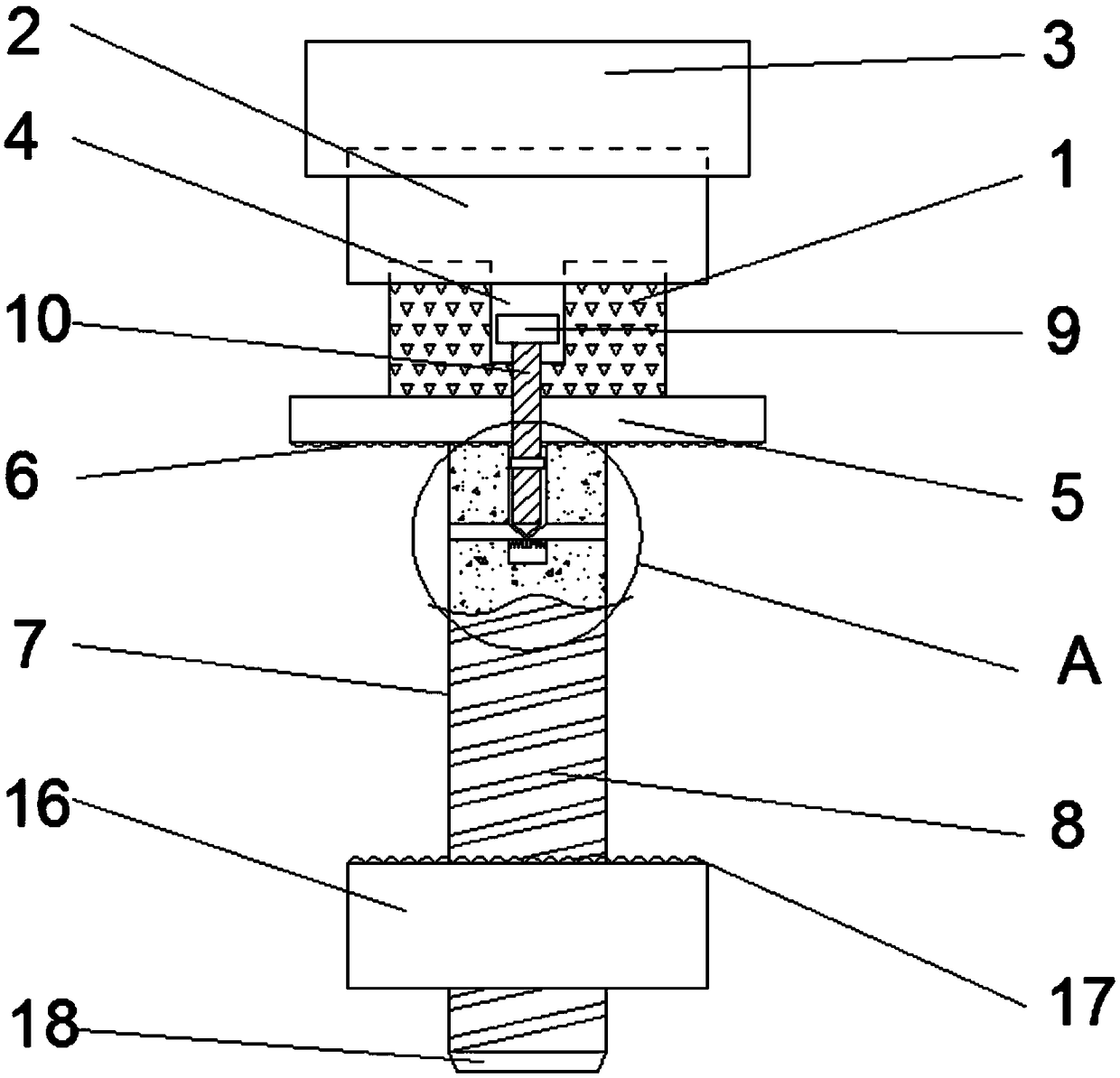

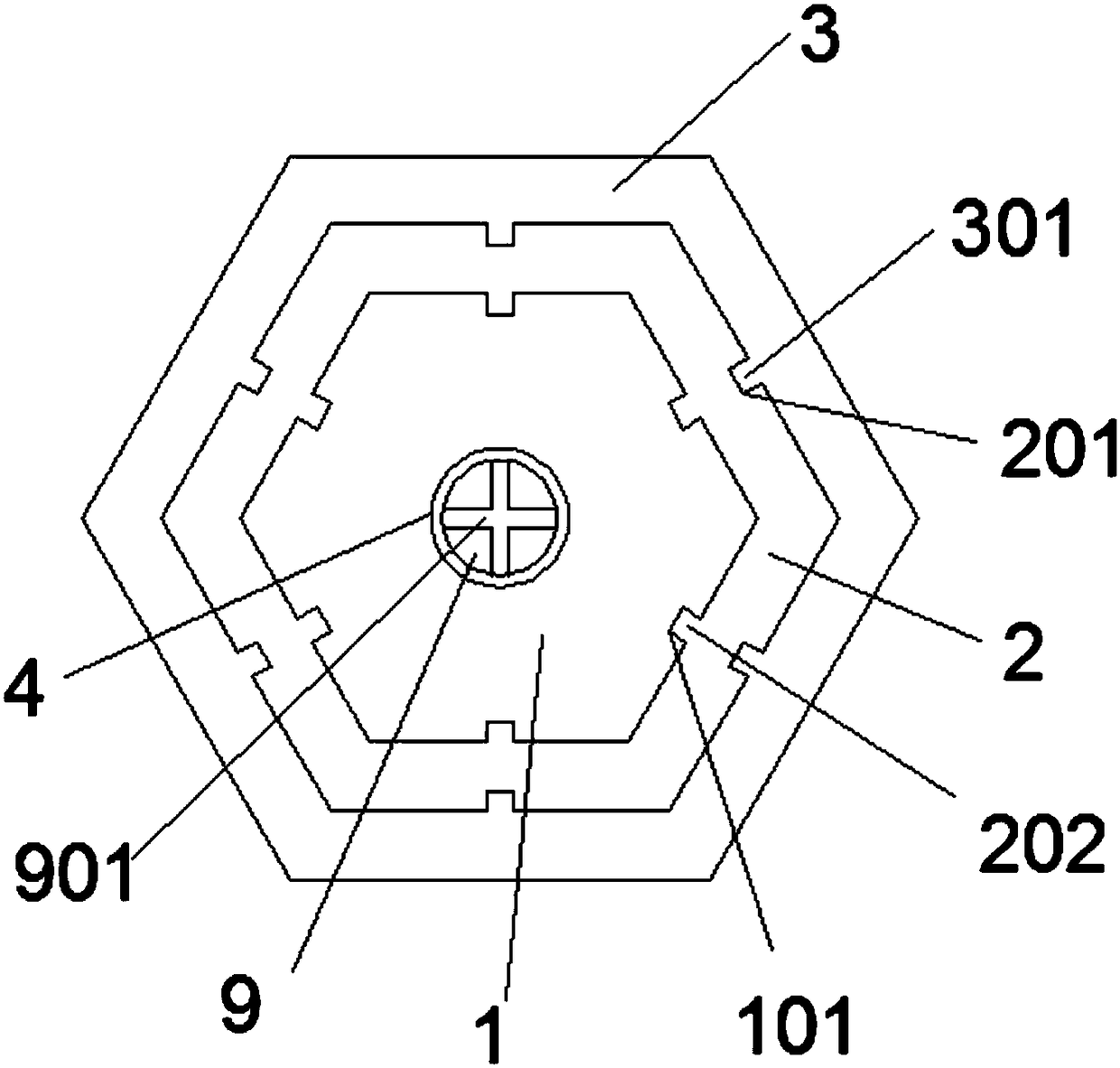

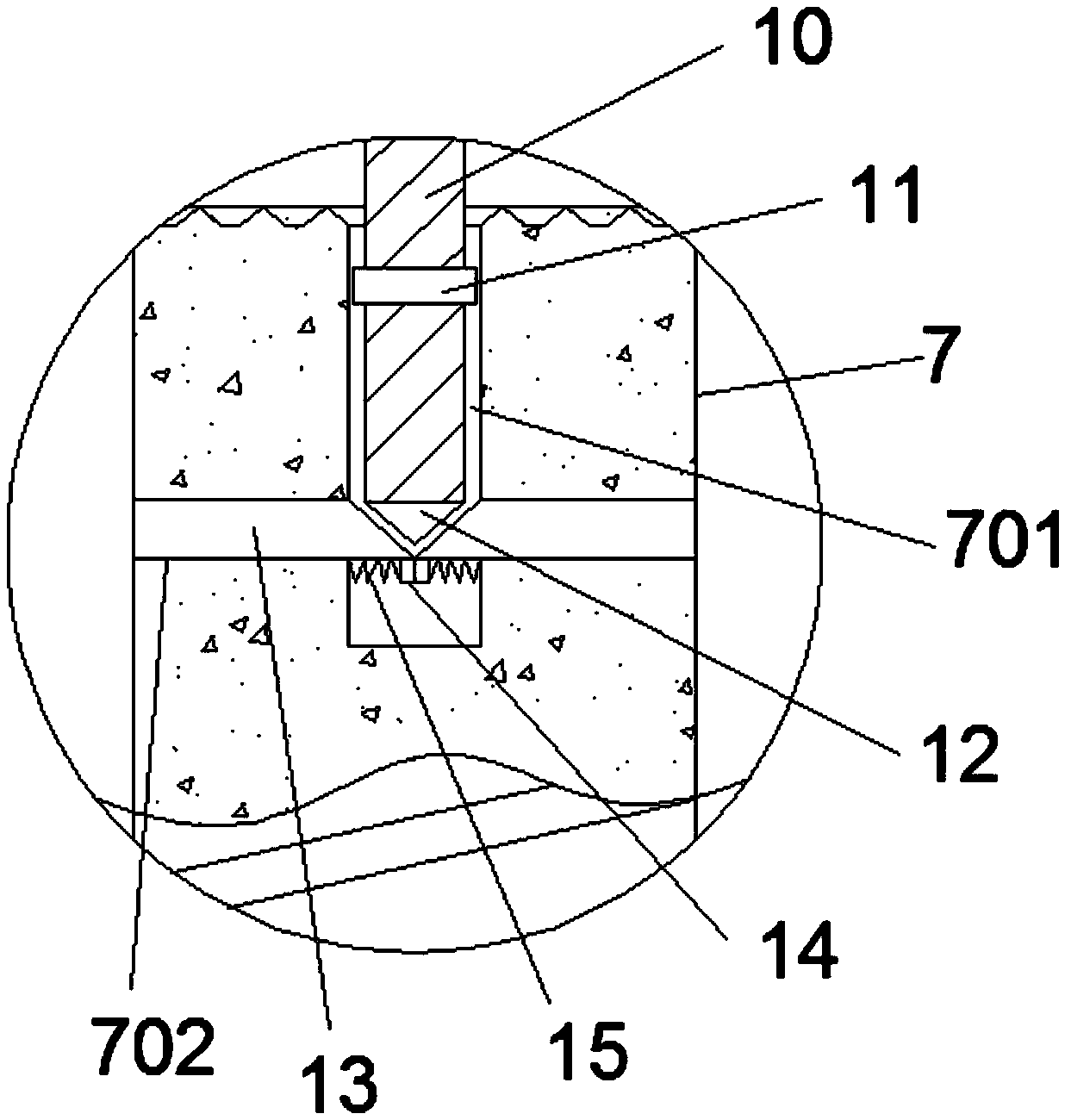

[0020] Such as Figure 1-Figure 3 As shown, a kind of automotive fastener proposed by the present invention includes a screw head 1, a groove 4, a screw shaft portion 7, a cavity 701, a sliding part 13, a screw cap 16 and an inverted conical part 18, and the outer side of the screw head 1 slides The first screw head cover 2 is connected, and the outside of the first screw head cover 2 is slidably connected to the second screw head cover 3. The lower end of the screw head 1 is connected to the gasket part 5, and the lower end surface of the gasket part 5 is provided with a first anti-slip stripe 6, and the gasket part 5. The middle part of the lower end is connected to the screw rod part 7, and the lower end of the screw rod part 7 is provided with an inverted cone 18, and the outer side of the screw rod part 7 is sleeved with a screw cap 16, and the upper surface of the screw cap 16 is provided with a second anti-slip stripe 17.

[0021] The middle part of the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com