Disk brake capable of monitoring force of disk spring in real time and monitoring method

A disc brake, real-time monitoring technology, applied in the field of sensors, can solve the problem of inability to accurately monitor the positive brake pressure and errors, and achieve the effects of wide practicability, improved reliability, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

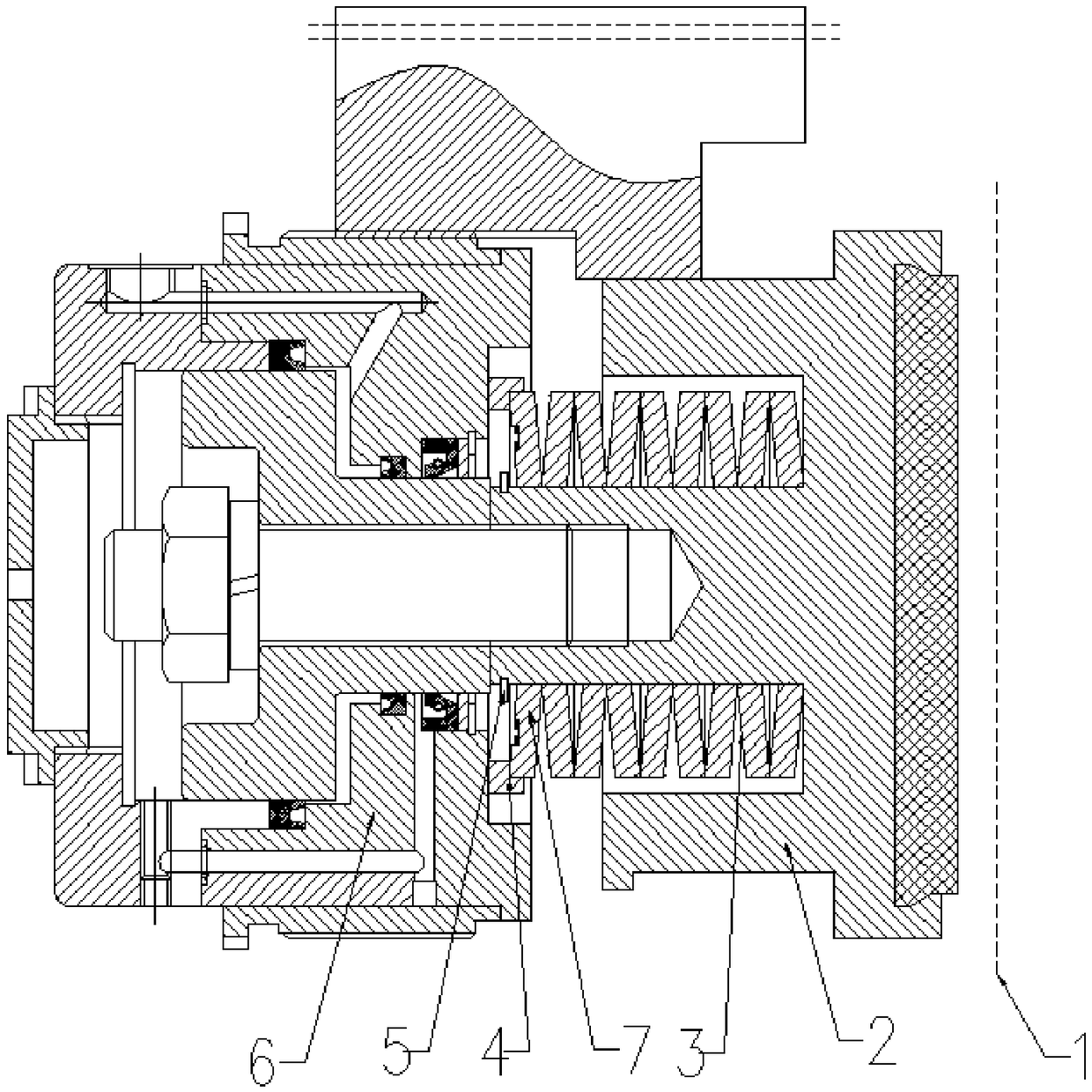

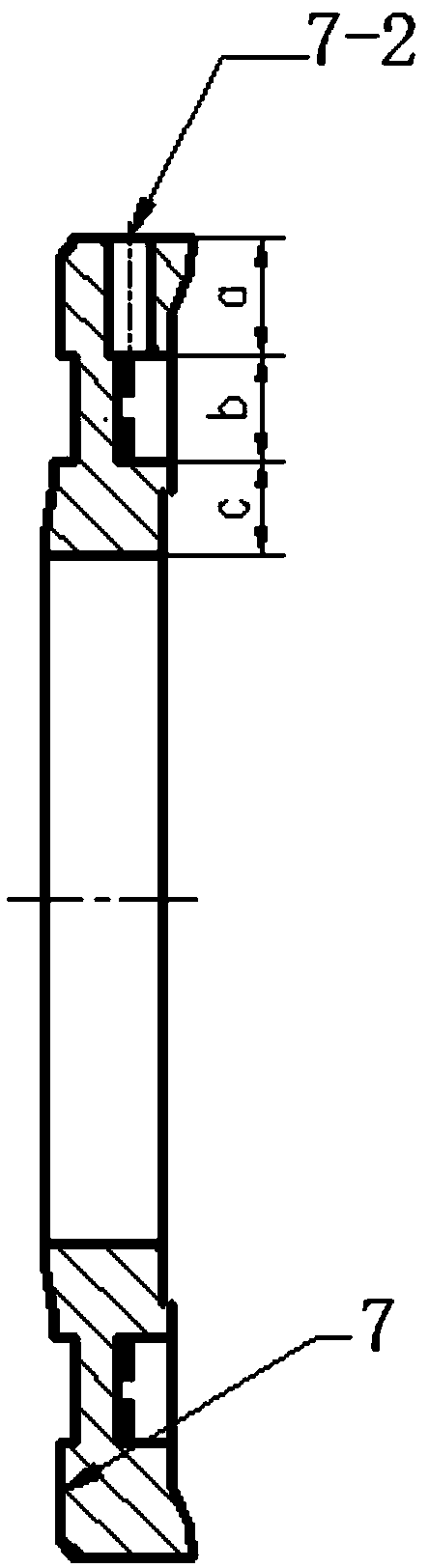

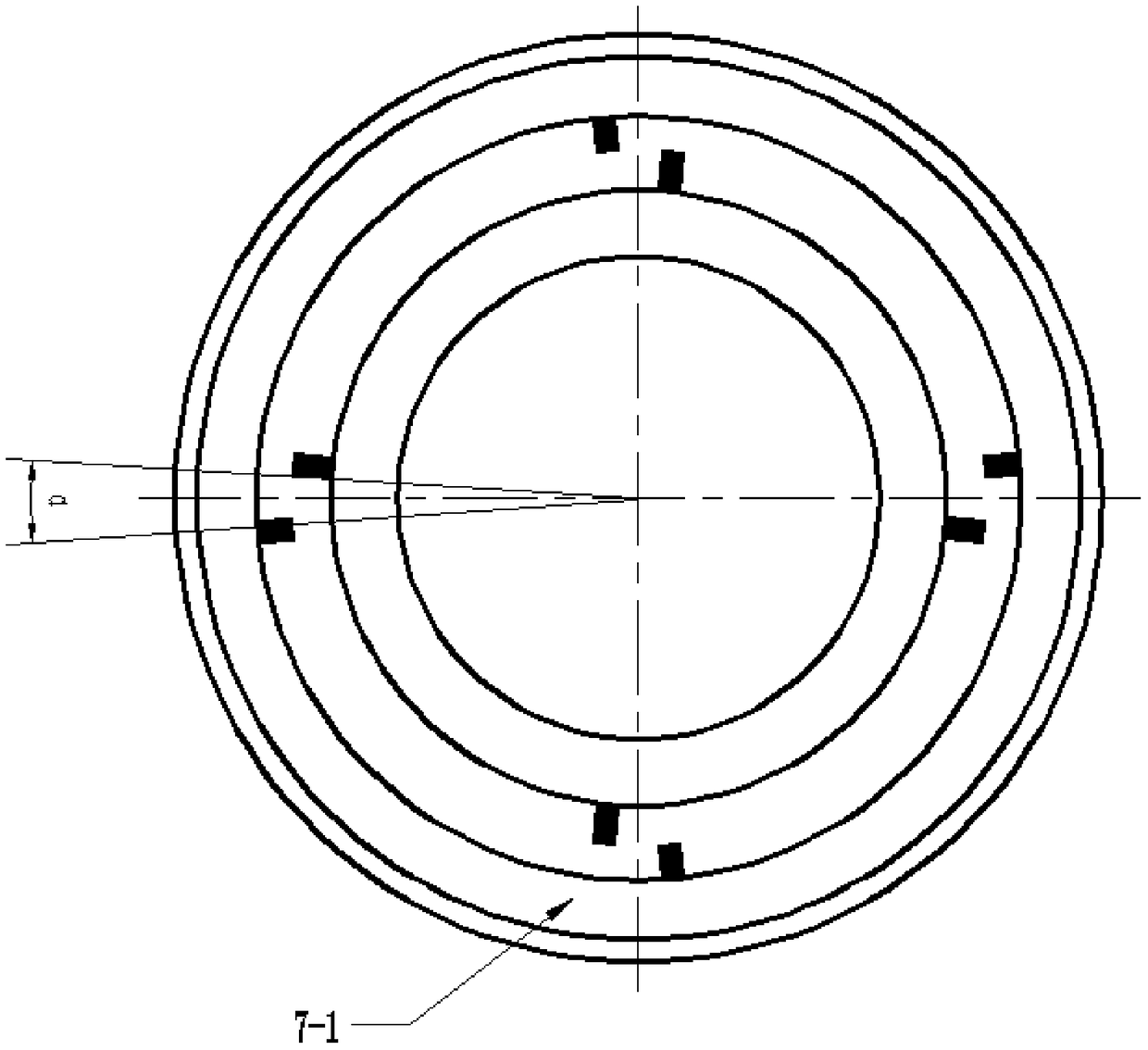

[0015] like figure 1 As shown, the disc brake of the present invention for monitoring disc spring force is mainly composed of a brake disc 1, a brake shoe assembly 2, a disc spring 3, a disc spring seat 4, a disc spring snap ring 5 and a hydraulic cylinder 6. A disc spring sensor 7 is provided between the disc spring seat 4 and the disc spring 3, and the external dimensions of the disc spring sensor 7 are the same as the disc spring 3, as figure 2 image 3 As shown, there are annular grooves on the opposite end faces on both sides of the disc spring sensor 7, and a plurality of strain gauges 7-1 arranged in pairs in the groove facing the end face of the disc spring seat 4, the paired arrangement The number of multiple strain gauges 7-1 is 6-10, which is determined according to the actual situation. figure 2 The a, b, and c shown in indicate the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com