Tangential displacement testing device for building shock insulation rubber pipe

A vibration-isolating rubber, tangential displacement technology, applied in measuring devices, using stable shear force to test material strength, and using repeated force/pulse force to test material strength, etc., can solve the problem of low tangential displacement rate and time. Long, unreachable, etc., to achieve the effect of fast tangential displacement rate, reducing radial load and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

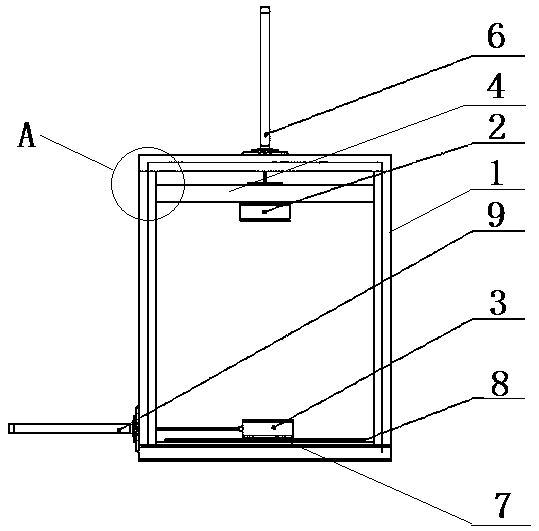

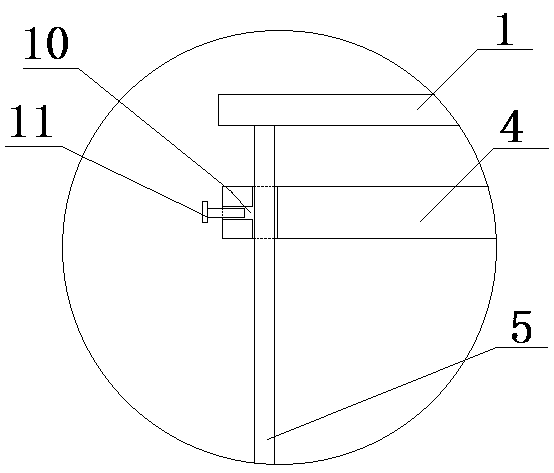

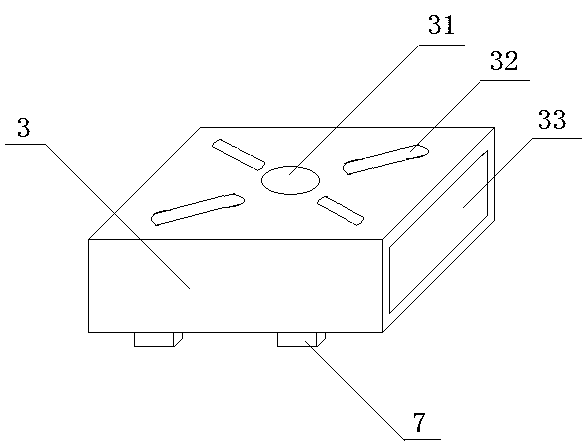

[0012] Such as Figure 1-3 Shown is a kind of tangential displacement testing device of building shock-isolation rubber tube of the present invention, can provide the tangential displacement of more than 10 centimetres; Seat 3; a limit slide plate 4 is fixedly arranged above the vertical mounting seat, and the limit slide plate slides on the vertical slide rails 5 on both sides of the stand, and the first hydraulic cylinder 6 is fixedly arranged above the stand, and the first hydraulic cylinder 6 The free end of the cylinder passes through the bench and is fixed to the slide plate; a slider 7 is fixed under the horizontal mounting seat, and the slider is slid on the horizontal slide rail 8 below the bench, and a second hydraulic pressure is fixed on one side of the bench. Cylinder 9, the free end of the second hydraulic cylinder passes through the stand and is fixed to the horizontal mounting seat; the opposite surface of the vertical mounting seat and the horizontal mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com