Pure steam or injection water all-in-one machine

A technology of pure steam and water injection, which is applied in the field of pure steam or water injection all-in-one machine, which can solve the problems that the equipment cannot meet the use requirements and cannot provide industrial steam, etc., and achieve the reduction of installation space requirements of the factory building, good steam separation effect, and optimized structure streamlined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described now in conjunction with accompanying drawing.

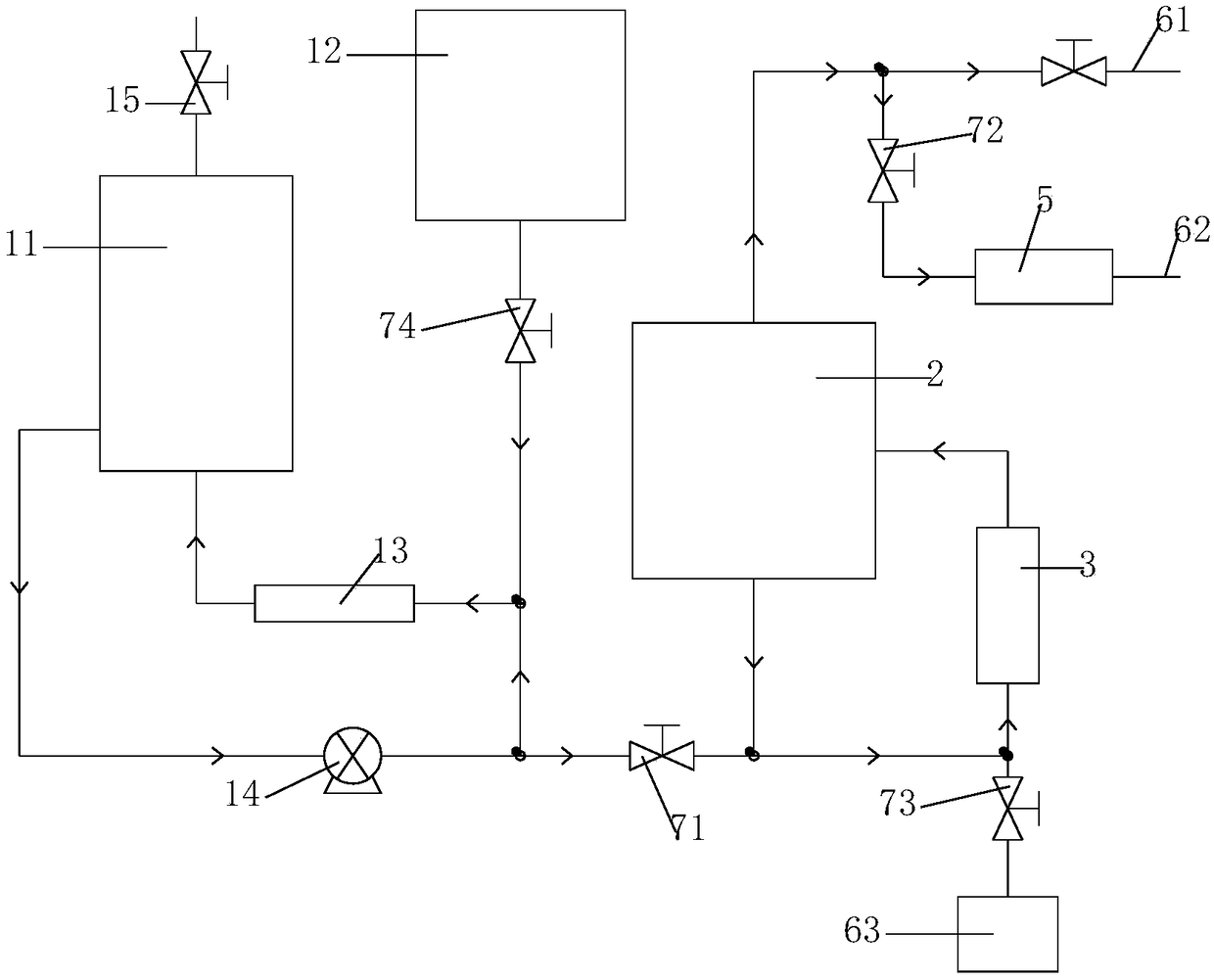

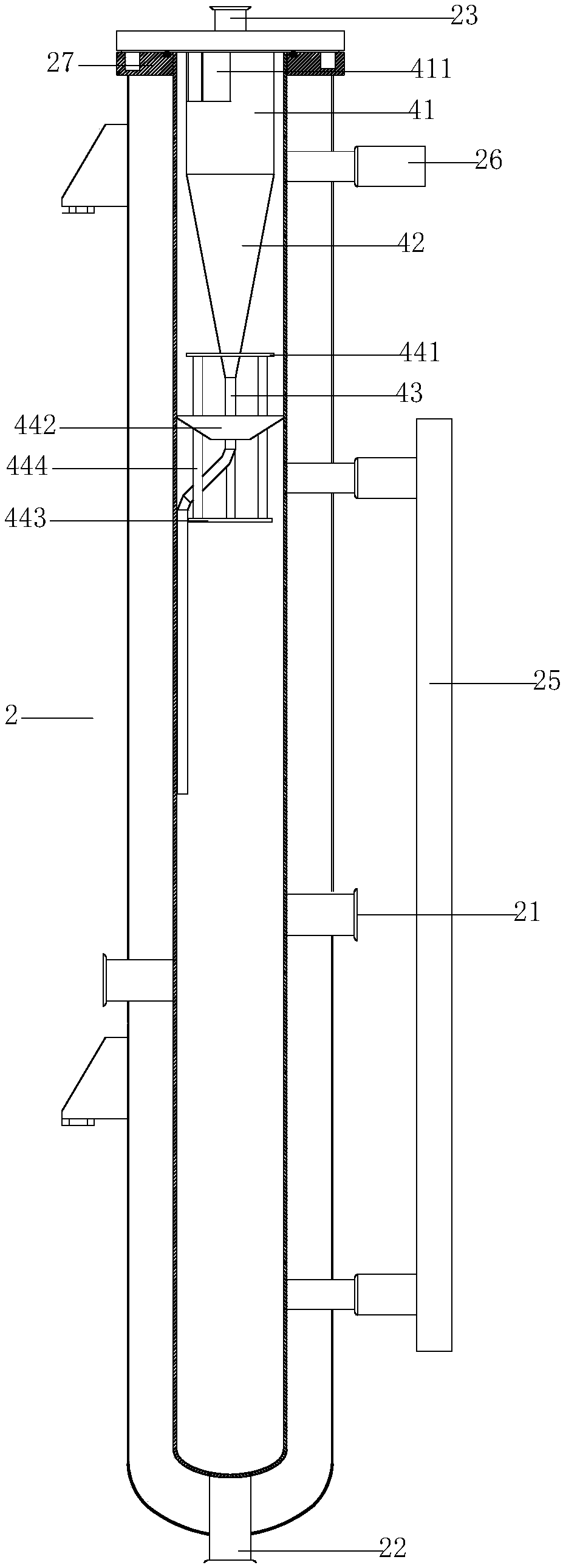

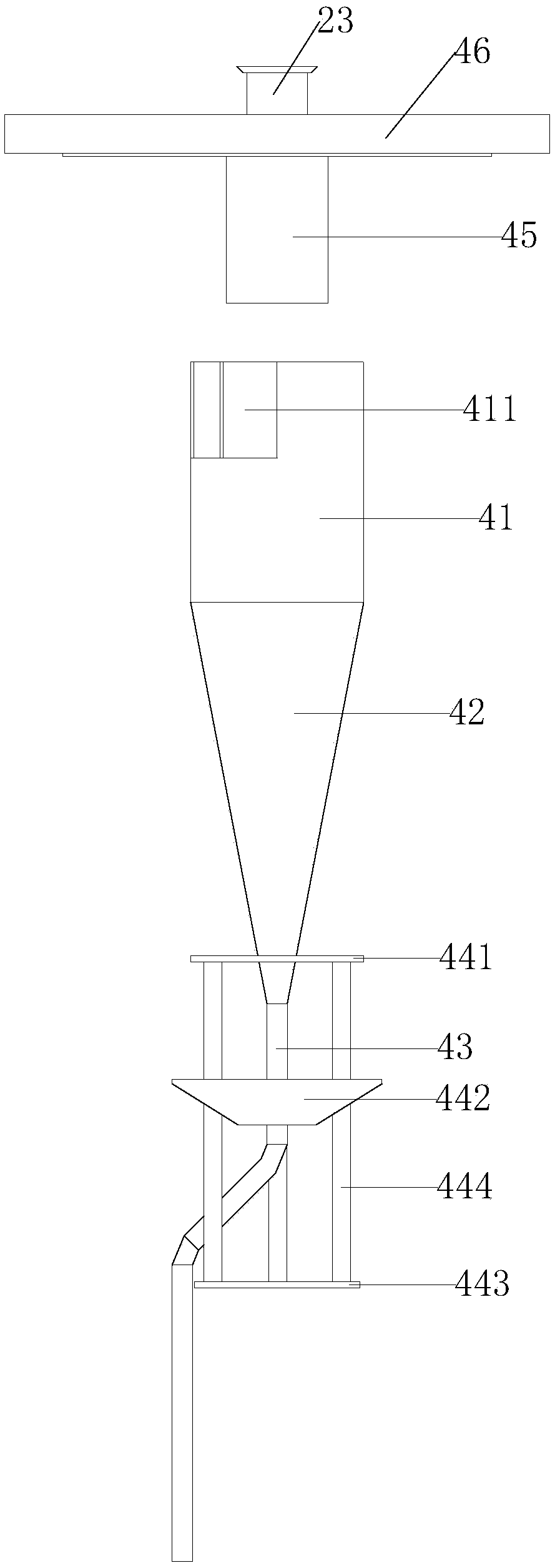

[0038] Such as Figure 1 to Figure 5 As shown, the pure steam or injection water all-in-one machine includes a purified water tank 12, an electric heating water tank A13, an electric heating water tank B3, a water pump 14, a heat exchanger 5, a preheating tank 11, a steam tank 2 and a vapor-liquid separation device.

[0039] The electric heating water tank A13 has the same structure as the electric heating water tank B3, including a water tank and an electric heating tube, the electric heating tube is installed inside the water tank, and the electric heating tube heats the water in the water tank. Both the electric heating water tank A13 and the electric heating water tank B3 are existing mature products, and will not be described in detail here.

[0040] The preheating tank 11 is a vertical tank, and the top of the preheating tank 11 is equipped with a needle valve 15, a ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com