Multifunctional water film generation experiment device and method

An experimental device and multi-functional technology, applied in measuring devices, fluid dynamics tests, instruments, etc., can solve the problem that the thickness and uniformity of water film are difficult to control, cannot accurately simulate flow phenomena such as aircraft wing water film breakage, and cannot provide High-speed air flow field environment and other issues, to achieve good water supply stability, convenient installation, and good thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used in the present invention and are not intended to limit the scope of the present invention.

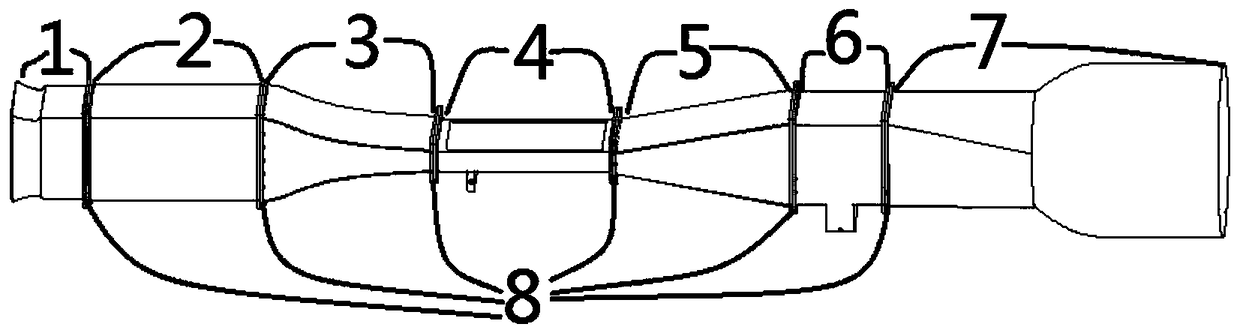

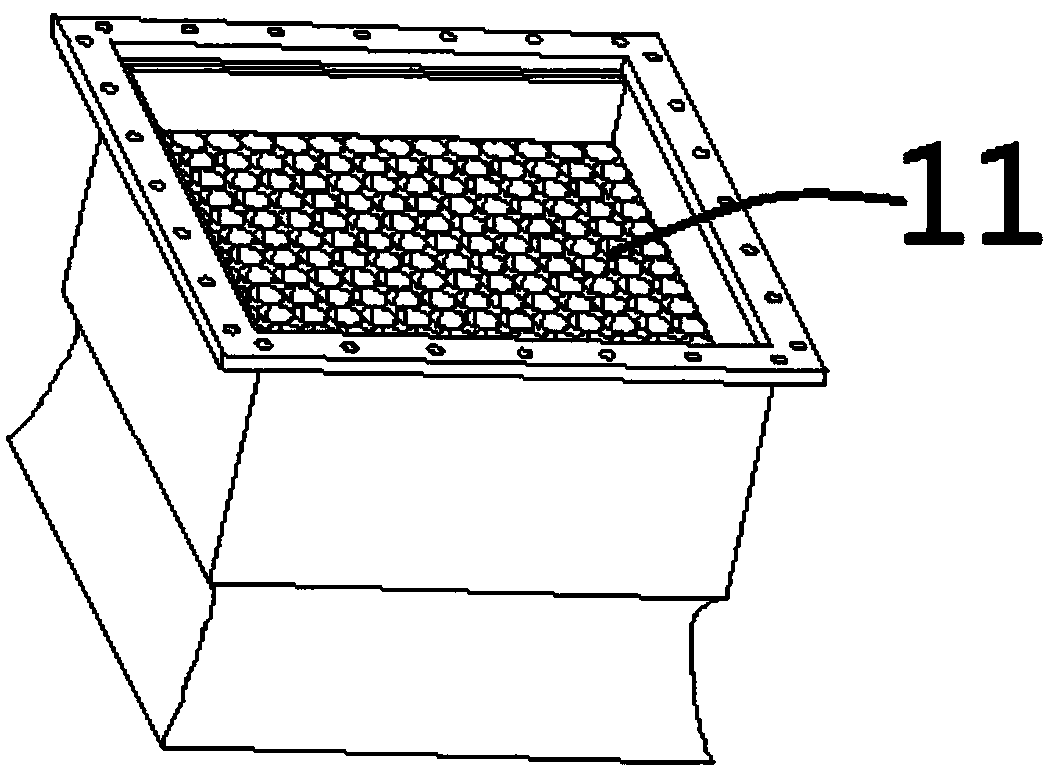

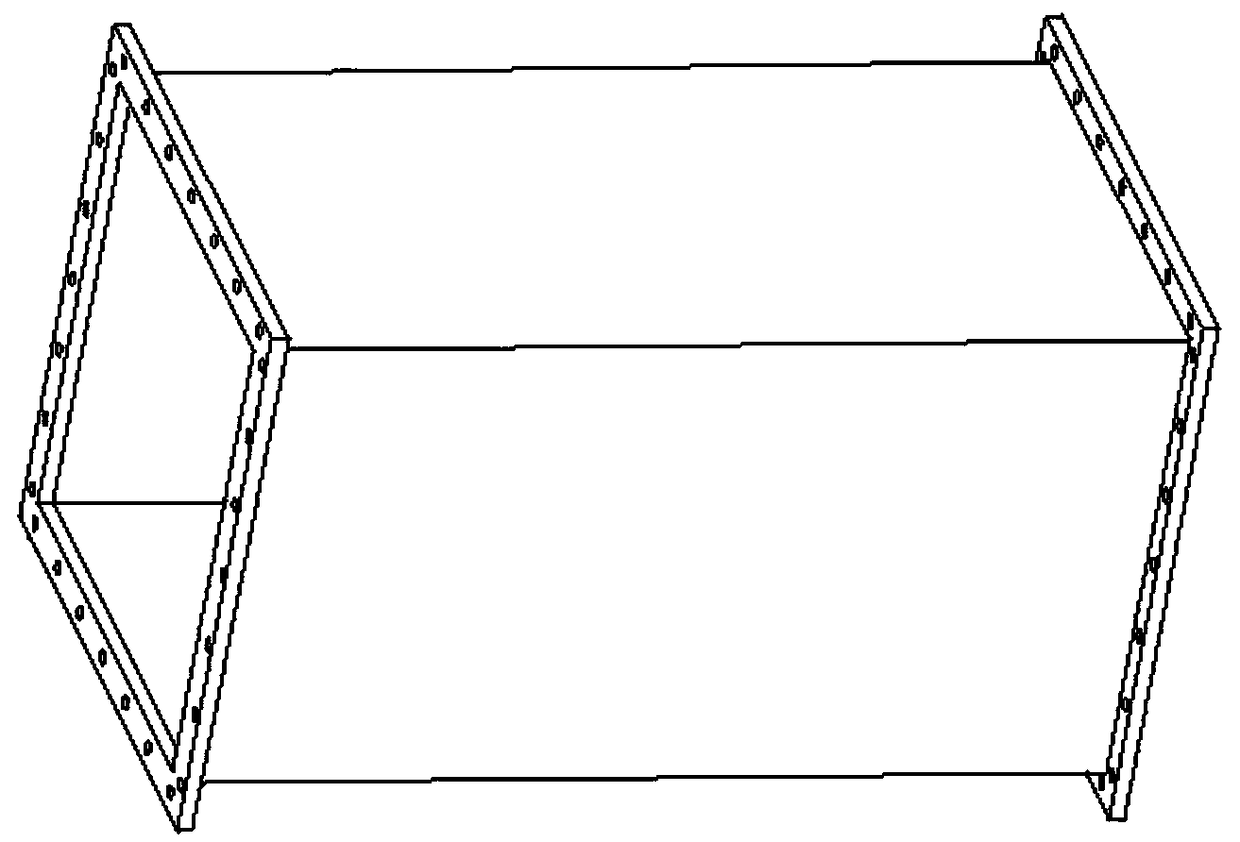

[0027] It can be seen from the accompanying drawings that a multifunctional flat water film generator is composed of a direct-flow air duct, a water injection device, an experimental metal plate, and a water return device. The direct air duct forms a stable flow field, forming a uniform and stable airflow in the test section. The sealing gasket plays the role of sealing the wind tunnel and helps the wind tunnel to form a uniform and stable airflow. Water is now pumped into the sump via the pneumatic connection. When the water overflows the tank, the overflowing water will form a water film on the metal plate under the effect of a uniform flow field. By changing the amount of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com