Display device and manufacturing method thereof

A technology for display devices and display areas, applied in identification devices, sub-office equipment, instruments, etc., can solve problems such as increasing the thickness of the overall module, increasing the bonding process, and rainbow patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Such asfigure 1 As shown, the display device 100 provided by the embodiment of the present invention defines a display area 101 and a non-display area 102, and the non-display area 102 surrounds the display area 101.

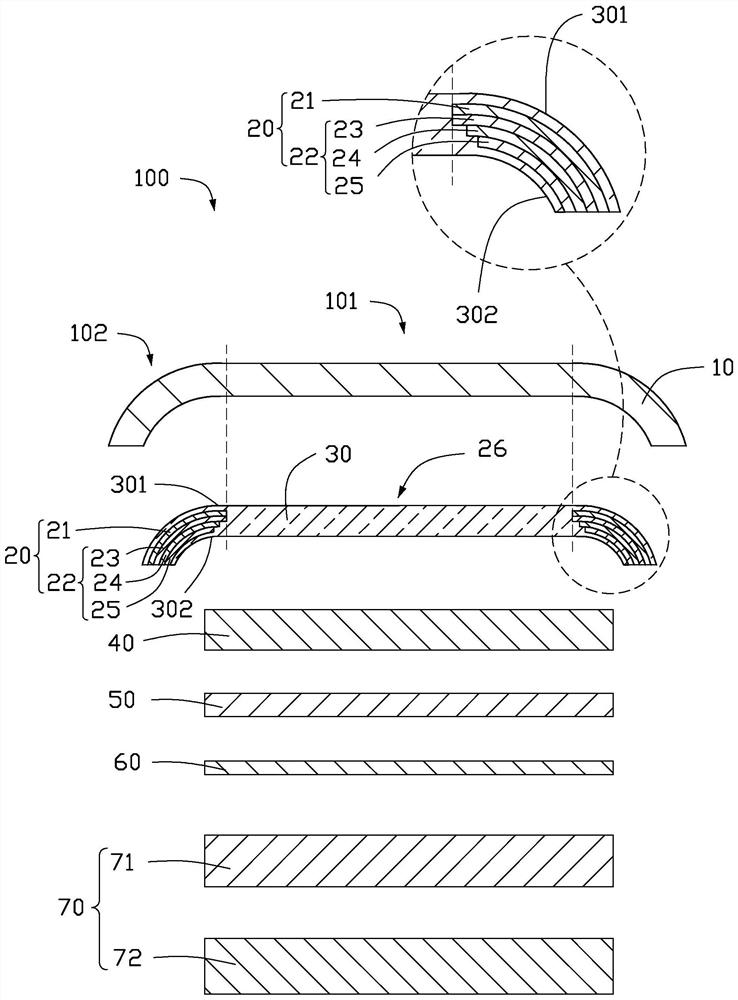

[0025]Such asfigure 2 As shown,figure 2 forfigure 1 Sectional view along the II-II tangent line. The display device 100 includes a cover plate 10, a decoration film 20, a first transparent insulating glue layer 30, a polarizer 40, a touch module 50, a second transparent insulating glue layer 60 and a display module 70. Wherein, the decorative film 20 is disposed corresponding to the non-display area 102 and surrounds the display area 101.

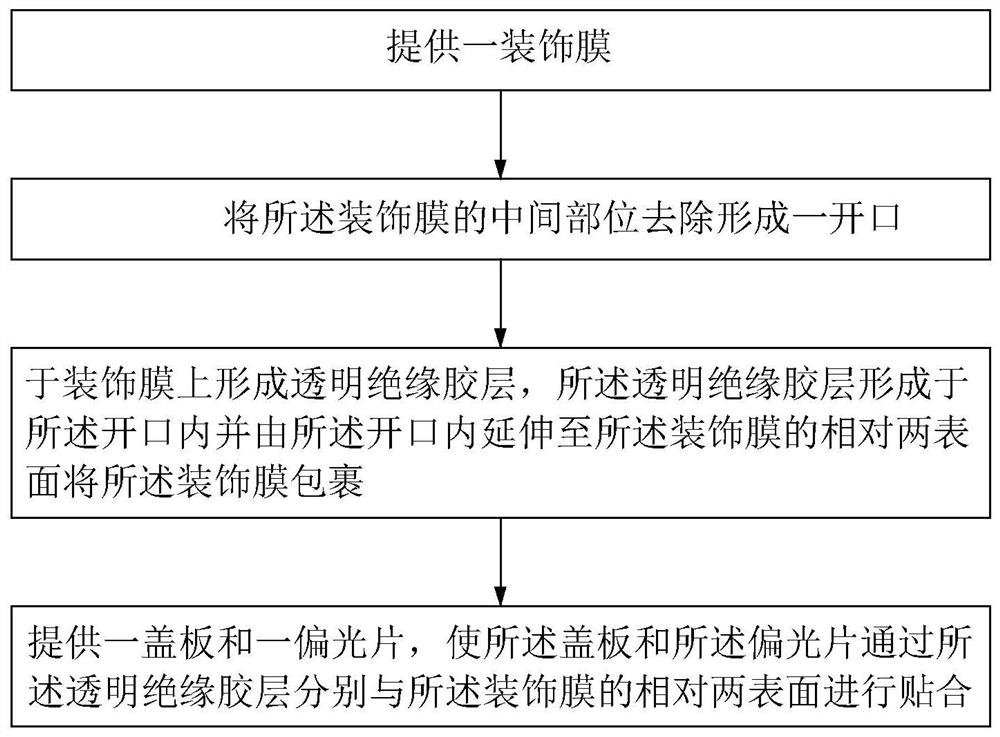

[0026]The first transparent insulating glue layer 30 is formed in the opening 26 and extends from the opening 26 to the non-display area 102 to wrap the opposite surfaces of the decoration film 20. The first transparent insulating glue layer 30 has a first side 301 and a first side 301 and 302 on both sides. The cover plate 10 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com