An electrical cabinet with segmented self-locking and fixed circuit units

A circuit unit and segmented technology, applied in the field of electrical cabinets, can solve problems such as inability to assemble machines, heavy weight of circuit breakers, troublesome installation, etc., and achieve the effects of improving convenience, compact connection, and reducing overweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

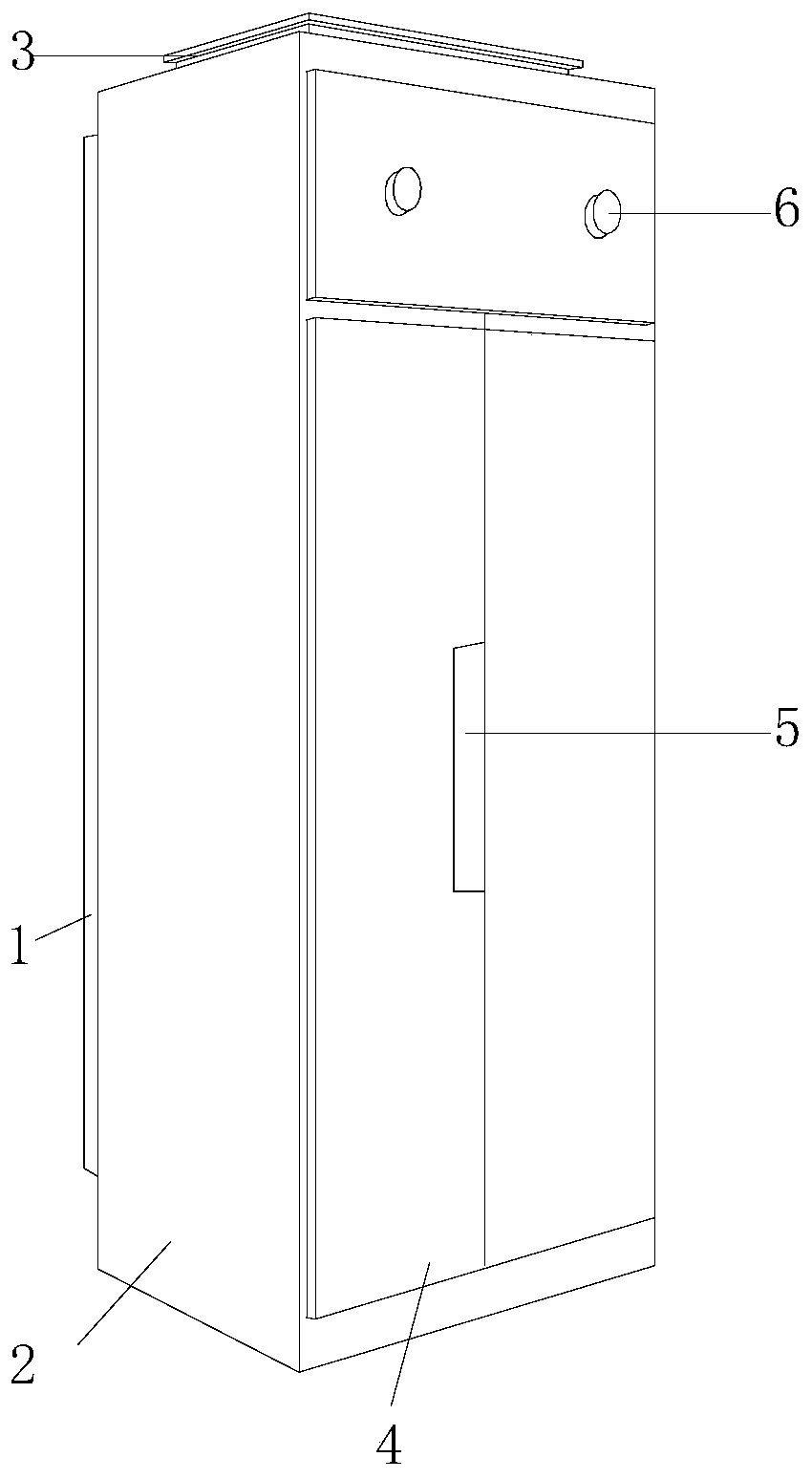

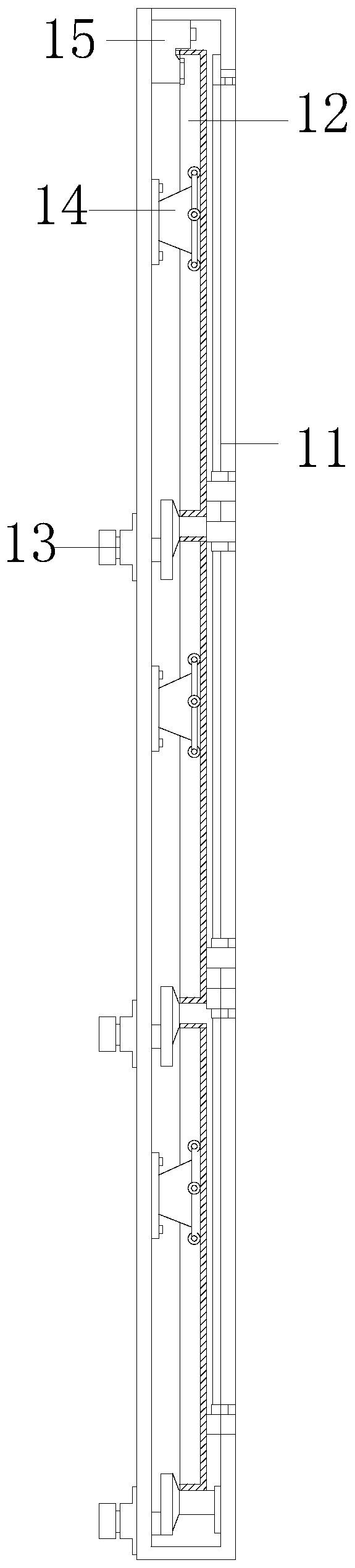

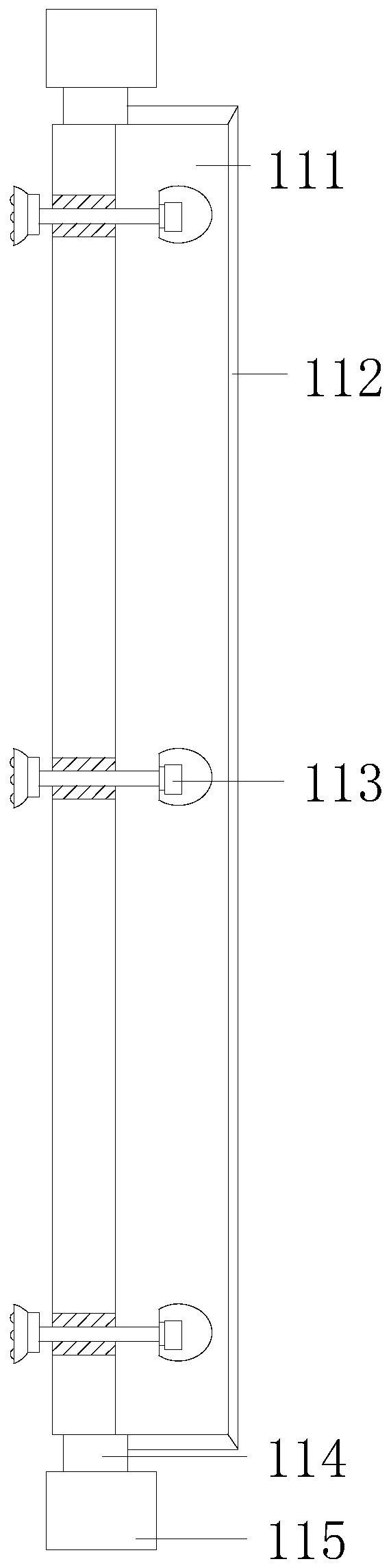

[0028] Such as Figure 1-Figure 9 As shown, the present invention provides an electrical cabinet with segmented self-locking and fixed circuit units. , the shell of the sub-panel frame body 1 is welded and fixed on the rear end of the protective outer box 2, the heat dissipation ceiling 3 covers the upper end of the heat dissipation hole on the top of the protective outer box 2, and the left side fan plate of the cabinet door 4 is connected with the lock The head 5 is fixed and fixed on the front end of the protective outer box 2, the indicator light 6 is fixed on the top of the cabinet door 4 and embedded in the light grooves on both sides of the front end of the protective outer box 2, and the inside of the sub-board frame 1 is The structure includes: a one-way ring column 11, a circuit base plate 12, an anti-fall eccentric wheel 13, a stabilizer 14, and a corner protection device 15. The one-way ring column 11 is closely attached to the front end of the circuit base plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com