Hand-held machine tool having suction hose

A technology of hand-held machine tools and hoses, which is applied in the direction of manufacturing tools, metal processing machine parts, machine tools suitable for grinding workpiece planes, etc., and can solve the problems of difficult and uncomfortable positioning of processing heads or grinding heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

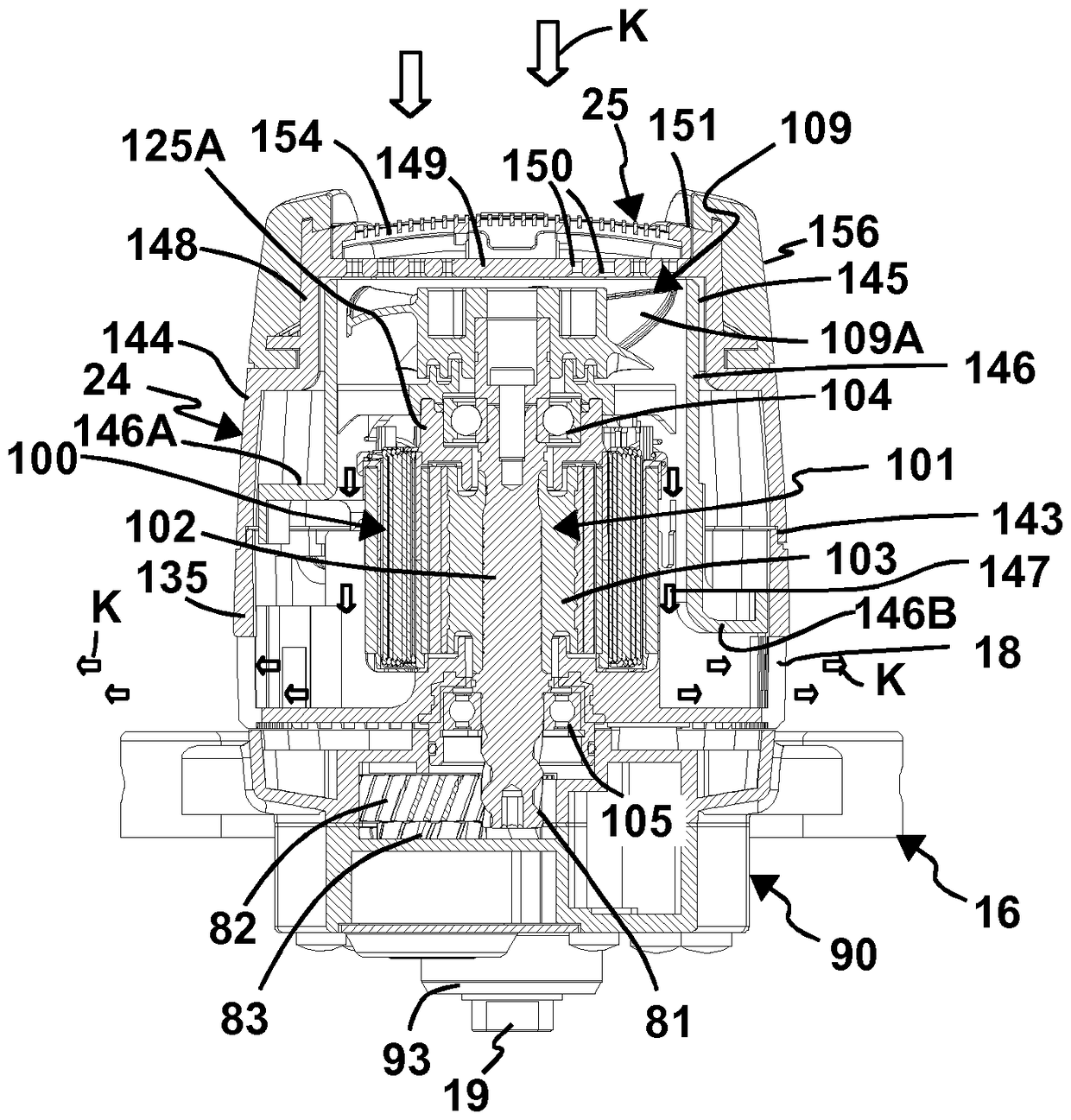

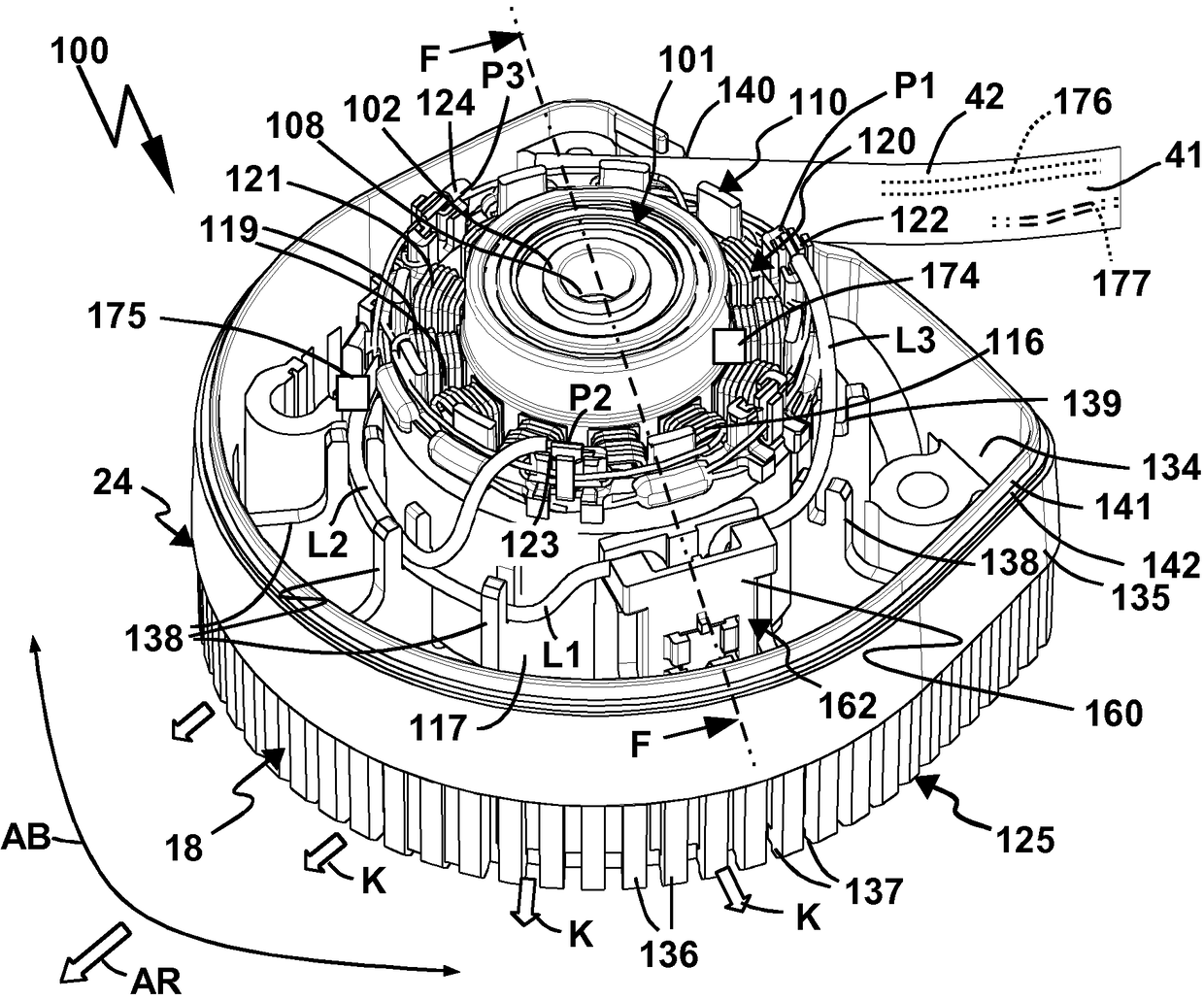

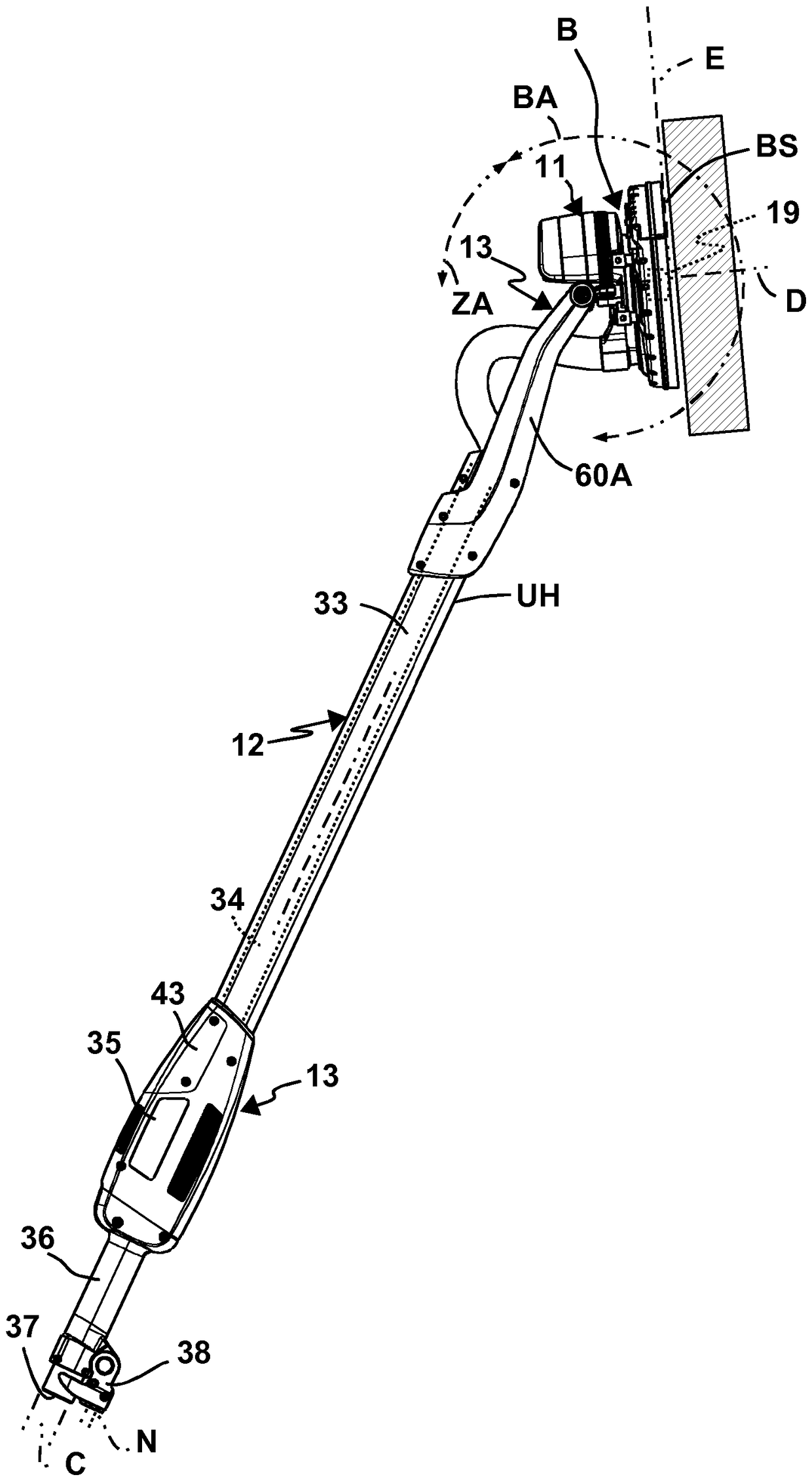

[0113] The exemplary embodiment relates to a hand-held power tool 10 in the form of a grinding machine, wherein, with respect to some aspects of the following description, however, other embodiments of the hand-held power tool are also possible, such as milling machines, polishing machines or the like thing. Furthermore, in the case of this embodiment an elongated handle element is shown, which can be shorter or longer altogether. The hand-held power tool according to the figures is advantageous for ceiling or wall machining. The hand-held power tool 10 according to the figures can also be referred to as a top grinder and / or a wall grinder. Aspects of the following embodiments do not necessarily only relate to grinding, polishing or milling machines, but can also be applied in the context of other hand-held power tools.

[0114] The hand-held power tool 10 has a machining head 11 , which is articulated on a handle element 12 by means of an articulation assembly 13 (albeit im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com